Water covers 70% of our planet, yet only 2.5% is fresh water, and just 1% is available for use. Sewage treatment plants serve as one of the most critical engineering systems that protect our health and water resources.

The United Nations’ 2017 World Water Development Report reveals that wastewater could become a valuable resource to meet our planet’s growing need for freshwater and raw materials. The Environmental Protection Agency (EPA) and the Clean Water Act strictly regulate water quality, and wastewater facilities must operate under specific National Pollutant Discharge Elimination System permits. High-income countries manage to treat about 74% of their sewage, while developing nations can only process an average of 4.2%.

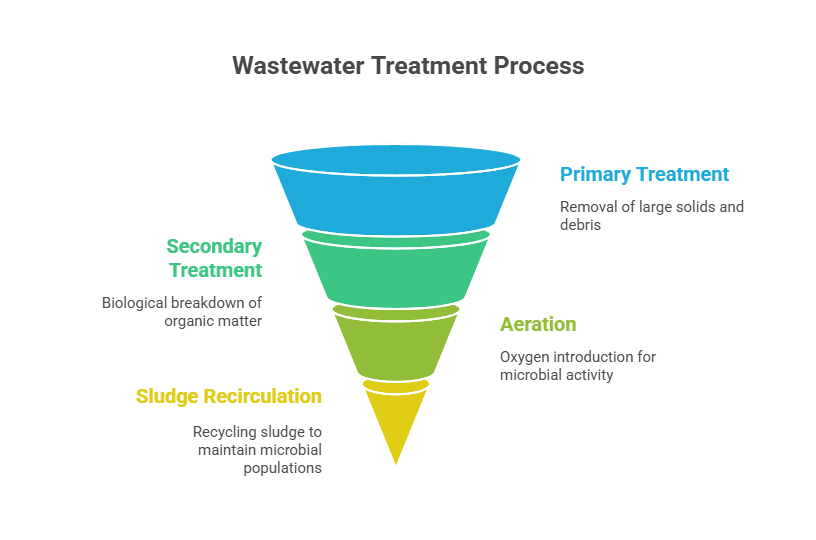

The sort of thing I love about waste water treatment plants lies in their engineering and three main stages that clean our water: primary, secondary, and tertiary treatment. Our cities stay clean and environmentally responsible thanks to the hidden infrastructure that handles everything from preliminary screening to advanced nutrient removal.

Sewage Inflow and Preliminary Screening Systems

The sewage treatment plant process starts well before any biological or chemical treatment begins. Every wastewater treatment facility has vital preliminary systems that prepare incoming sewage for downstream processes. The original phase might not get much attention but plays a crucial role through specialized structures that handle flow variations and remove large debris.

Inlet Works and Flow Equalization Tanks

The inlet works, also called headworks, welcome untreated wastewater into the treatment facility. This section places the influent higher up to let gravity move water through later treatment stages. Raw sewage flows into a reception chamber that slows down water from incoming pumping lines and makes screening more effective.

Flow equalization tanks come after the original screening process and work as buffer systems. They collect wastewater during busy times and release it steadily. These tanks tackle one of the biggest challenges in wastewater treatment – dealing with constantly changing sewage inflow. The daily flow usually shows three busy periods mixed with times of low flow.

Equalization brings several benefits to the waste water treatment plant process:

- Stops hydraulic surges from pushing solids out of treatment processes

- Manages flow through each treatment stage and gives enough time for physical, biological, and chemical processes

- Helps wastewater facilities run at steady flow rates

- Could lead to smaller treatment plant designs

These tanks need pre-aeration with coarse bubble diffusers that typically push 1.25 to 2.0 cubic feet of air per minute for every 1,000 gallons. The air keeps raw sewage fresh to avoid smelly septic conditions and keeps solids floating to reduce how often tanks need cleaning.

Manual vs Mechanized Bar Screens

Bar screens protect sewage water treatment equipment by stopping large objects from moving downstream. Wastewater flows through these devices made of parallel bars set at specific distances while catching solids.

Manual bar screens need people to clean them and usually have bars tilted at 30-45 degrees to make raking easier. Small treatment facilities with lower flow rates often use these screens, or they serve as backups in bigger plants. They’re simple to build with no moving parts, need little maintenance, and cost less upfront. All the same, workers must clean them often, especially during busy periods.

Mechanized bar screens use automatic cleaning systems that constantly remove collected debris. You’ll find various designs including front-cleaning rakes, back-cleaning rakes, chain-driven screens, and step screens. Timers, water level differences, or remote flow sensors trigger the cleaning process.

Mechanized screens work better in larger facilities because they:

- Need fewer workers and cost less to run

- Keep working well during busy times

- Prevent sudden flow changes during cleaning

- Catch smaller items (usually 6-36mm compared to 30-50mm for manual screens)

These screens cost more upfront and need complex maintenance because they have many moving parts. Modern facilities almost always use mechanical screening systems as their main method, while manual screens serve as backups – just as the EPA suggests.

Primary Treatment of Wastewater: Design and Function

Primary treatment plays a vital role in the sewage treatment plant process after the initial screening removes larger debris. This phase uses physical processes to remove suspended solids from incoming wastewater. The process mainly relies on sedimentation and sometimes gets help from chemical additives.

Sedimentation Tank Geometry and Flow Control

Primary sedimentation tanks come in two basic designs: circular and rectangular. Each design works best in different situations based on site limits and operator priorities. Circular tanks can be 3 to 60 meters wide. Rectangular tanks work best when they’re under 40 meters long.

The depth of these tanks is vital to good sedimentation. Most plants keep a minimum depth of 2.5 meters, though 3.5 meters is typical. The design needs 0.25 meters for sludge buildup and 0.3-0.5 meters of freeboard. Tank floors slope at different angles – circular tanks need 6-16% while rectangular ones use 2-8%. These slopes help move settled solids to collection spots.

Surface overflow rate (SOR) is a key design factor that ranges from 35-50 m³/m²·day in normal conditions. This rate goes up to 80-120 m³/m²·day during peak flows with secondary treatment. The process takes 1-2.5 hours. This timeframe lets gravity do its work without too much solid buildup.

Mechanical scrapers work slowly to collect settled solids. They move at 0.02-0.05 rpm in circular tanks and 0.6-1.2 m/min in rectangular ones. This slow pace keeps settled material from floating up while moving sludge to collection hoppers.

Primary clarifiers achieve these removal rates:

- 10-15% of total solids

- 95-99% of settleable solids

- 40-60% of suspended solids (up to 70%)

- 25-35% of biochemical oxygen demand (BOD)

Coagulant Dosing for Suspended Solids Removal

Many waste water treatment plants boost performance with coagulation-flocculation processes. These chemicals neutralize negative charges on suspended particles. This helps particles clump into bigger, easier-to-settle flocs.

Popular coagulants include aluminum sulfate (alum), polyaluminum chloride (PAC), ferric chloride, and ferric sulfate. Research shows these chemicals work great at the right doses. PAC at 300 mg/L removes 97% of suspended solids, 95% of color, 75% of COD, and 97% of oil and grease. Alum at 500 mg/L removes 92% of solids, while ferric chloride at 350 mg/L takes out 95%.

Better primary clarification needs exact dosing systems and quick mixing. Metal coagulants form their products in 0.01-1.0 seconds. This makes the first mix crucial for good results. Changes after dosing rarely work well.

This process does more than remove solids. It cuts BOD by 40-60%, which helps later biological treatment stages. The process also removes phosphorus when metal salts make it settle out.

Chemical addition in primary treatment has become a key strategy in modern sewage water treatment facilities. This approach reduces the workload on biological processes and makes the whole treatment system work better.

Secondary Treatment: Biological and Chemical Processes

Secondary treatment is the biological heart of any sewage treatment plant process. Microorganisms work hard to break down dissolved and suspended organic matter. This phase can remove up to 90% of the remaining Biochemical Oxygen Demand (BOD) from wastewater after primary treatment.

Aeration Basin Design and Oxygen Transfer Efficiency

Aeration basins create controlled environments where aerobic microorganisms break down organic pollutants effectively. Raw wastewater contains minimal dissolved oxygen (DO), so aeration systems must convert oxygen from gas to a dissolved form that’s available for biological treatment. The standard oxygen requirement (SOR) calculations help determine the amount needed under field conditions.

Carbonaceous oxidation needs 0.9 to 1.3 lb of oxygen per pound of cBOD removed. Systems that remove ammonia need an extra 4.6 lb of oxygen for each pound of ammonia oxidized to nitrate. Aeration is the most energy-intensive part of wastewater treatment and uses 45% to 90% of total energy.

Two main aeration methods exist:

- Mechanical aeration – Creates surface agitation to entrain oxygen

- Diffused aeration – Introduces compressed air through submerged porous devices, while fine-pore diffusers create smaller bubbles to maximize oxygen transfer

Trickling Filters vs Activated Sludge Systems

Trickling filters use a fixed film biological process where wastewater flows over media surfaces that host microorganism biofilms. The media—made of rock, plastic, or other materials—gives bacteria space to grow and allows oxygen transfer. These filters need minimal energy because they use natural draft ventilation instead of forced aeration.

Activated sludge processes mix suspended microorganisms with wastewater in aeration tanks. This aerobic suspended growth treatment system lets microbes use organic content as fuel for survival and reproduction. These systems can remove over 90% of BOD from wastewater when combined with primary treatment, despite using more energy.

Activated sludge processes deliver better effluent quality—achieving 10/10 TSS/BOD compared to trickling filters’ 40/40. They also need less space. Trickling filters handle shock loads and toxic inputs better, which makes them ideal for industrial effluents.

Secondary Clarifier Sludge Recirculation

Secondary clarifiers work together with aeration basins in the activated sludge process. These structures use gravity sedimentation to separate biological floc from treated water. The system recirculates settled sludge back to the aeration tank to maintain microbial populations.

The recirculation ratio follows this formula: QR/Q = X/(XR-X). Here, Q represents wastewater flow rate, QR is recycling rate, X is MLVSS concentration in aeration, and XR is VSS concentration in return sludge. This ratio controls the Mixed Liquor Suspended Solids (MLSS) concentration in the aeration tank.

Sludge settleability, measured by the Sludge Volume Index (SVI), affects recirculation efficiency significantly. Good settling properties show SVI values between 50-150 mL/g. The VSS concentration in return sludge should stay below 10,000 g/m³ unless there are additional thickeners.

Advanced Tertiary Treatment and Nutrient Removal

Tertiary treatment stands as the final refinement stage in the sewage treatment plant process. This stage removes nutrients and provides advanced filtration that meets strict environmental standards. The process is a vital part of treatment at the time wastewater needs higher purification levels before discharge or reuse.

Phosphorus Removal using Alum or Ferric Chloride

Chemical precipitation remains the most common way to eliminate phosphorus in wastewater treatment plants. The process adds metal salts that react with dissolved phosphates and create insoluble precipitates. Aluminum sulfate (alum), ferric chloride, and polyaluminum chloride (PAC) are the standard coagulants used.

These chemicals deliver remarkable results. The precipitants can remove 80-90% of phosphorus with proper dosing. Some advanced applications can reduce effluent phosphorus concentrations to less than 0.05 mg/L through optimized coagulation tanks and multi-phase tertiary solutions. The phosphorus-containing precipitates then settle through gravity or filtration systems.

Nitrate Removal via Anoxic Zones

The sort of thing i love about biological denitrification is how facultative heterotrophic bacteria turn nitrates into nitrogen gas. This transformation moves through a specific pathway: NO3- → NO2- → NO → N2O → N2. The process needs oxygen-limited (anoxic) conditions to work well.

Anoxic zones placed throughout the treatment train remove nitrates without extra oxygen sources. Denitrification bacteria use nitrate instead of oxygen as an electron acceptor. These microorganisms fall into two categories:

- Denitrifying PAOs (DPAOs) – use polyphosphate

- Denitrifying GAOs (DGAOs) – employ glycogen as carbon source

The mixed liquor recirculation rate and food-to-microorganism (F/M) ratio determine how well anoxic denitrification works.

Membrane Filtration and Reverse Osmosis Units

Modern sewage water treatment plants use advanced membrane technologies that provide exceptional purification. Membrane filtration employs ultrafiltration or microfiltration as separate downstream units or blends them into biological processes.

Reverse osmosis (RO) systems are a great way to get superior contaminant removal. These systems reject 99.9% of bacteria and significantly reduce dissolved solids concentrations. To cite an instance, see how a study showed aluminum reduction below 3 mg/L, sodium decrease to 145 mg/L, and chloride reduction to 193 mg/L. Nitrate nitrogen concentrations dropped below 20 mg/L.

The membrane systems need minimal maintenance because they work as self-cleaning, self-contained units. They still need proper pre-treatment to prevent membrane fouling and encourage engagement to maximize operational efficiency.

Sludge Management and Final Effluent Disposal

Managing waste byproducts plays a vital role alongside water purification in any sewage treatment plant process. Treatment facilities must handle sludge properly and ensure their final effluent meets environmental standards.

Sludge Thickening and Belt Filter Press Operation

The sludge management process starts with thickening to separate water from solids and reduce volume. Primary sludge reaches 8-10% solids content, while secondary sludge typically achieves about 4%. Mechanical processes then dewater the sludge further.

The belt filter press (BFP) stands out as a proven dewatering technology in waste water treatment plants. This system removes water by combining drainage with mechanical pressure. The process starts when conditioned sludge moves along a gravity drainage section. It then passes between two belts that apply pressure to create a drier product called “cake”. The cake’s dry solids content ranges from 15-30%, based on the sludge type.

Effluent Discharge Standards and NPDES Compliance

NPDES permits use effluent limitations as their main tool to control discharges into receiving waters. These standards look at both available technology (technology-based limits) and water quality protection (water quality-based limits).

Guidelines from the EPA cover various industrial categories. These are based on achievable pollutant reduction through existing control technologies. Simply put, these rules make sure treated wastewater meets environmental standards before release.

Effluent Reuse in Irrigation and Industry

Treated wastewater now serves as a valuable resource instead of waste. Farmers can use nutrient-rich treated effluent to fix soil deficiencies and reduce chemical fertilizer use. Municipal wastewater contains high levels of nitrogen and phosphorus—nutrients that benefit agriculture.

The European Union’s Water Reuse Regulation helps farmers safely use treated wastewater for crop irrigation while conserving water resources. This approach could irrigate about 3.6 million hectares in India alone, making it an environmentally responsible solution for water conservation.

Conclusion

Sewage treatment plants are remarkable engineering achievements that protect public health and preserve our water resources. These complex systems transform harmful sewage into clean, reusable water through well-designed processes. The treatment begins when preliminary screening systems remove large debris. Primary treatment follows where sedimentation tanks and coagulants capture suspended solids. The system then uses biological processes through activated sludge systems or trickling filters to break down organic matter efficiently.

Water purification advances further with tertiary treatment. This stage removes nutrients like phosphorus and nitrogen that could harm aquatic ecosystems. The combination of membrane filtration and reverse osmosis produces water clean enough for discharge or reuse in agriculture and industry.

The sewage treatment process blends physical, biological, and chemical engineering principles perfectly. Every aspect shows thoughtful engineering solutions to complex environmental challenges. The system’s design includes precise sedimentation tank geometry and careful control of microbial communities in aeration basins.

Raw sewage transforms into clean water without much public notice. This hidden infrastructure plays a vital role in eco-friendly urban development. High-income countries treat about 74% of their sewage. However, developing nations manage only 4.2%, which shows room for improvement in global wastewater management.

Water shortages worldwide make the technologies discussed in this piece more valuable. These plants will evolve from waste management facilities into resource recovery centers. They will extract nutrients, generate energy, and produce clean water for many uses. These engineering marvels show how ground-breaking technology can solve environmental challenges while supporting eco-friendly human development.

Key Takeaways

Sewage treatment plants are sophisticated engineering systems that transform harmful wastewater into clean, reusable water through three main stages: preliminary screening, primary/secondary treatment, and advanced tertiary processes.

- Three-stage purification process: Preliminary screening removes debris, primary treatment settles solids (40-70% removal), and secondary biological treatment eliminates 90% of remaining organic matter.

- Biological processes are energy-intensive: Aeration systems consume 45-90% of plant energy, with activated sludge requiring 0.9-1.3 pounds of oxygen per pound of waste removed.

- Advanced treatment enables water reuse: Tertiary processes using chemical precipitation and membrane filtration can achieve 99.9% bacteria removal, making treated water suitable for irrigation and industry.

- Global treatment gap persists: While high-income countries treat 74% of sewage, developing nations manage only 4.2%, representing a critical infrastructure challenge for sustainable development.

- Resource recovery potential: Modern plants increasingly function as resource centers, extracting valuable nutrients like nitrogen and phosphorus while producing clean water for agricultural reuse.

These hidden engineering marvels protect public health and water resources while offering sustainable solutions to growing water scarcity challenges worldwide.

FAQs

Q1. What are the main stages of a sewage treatment plant process?

A sewage treatment plant typically consists of three main stages: preliminary screening to remove large debris, primary treatment for settling solids, and secondary treatment using biological processes to break down organic matter. Some plants also include advanced tertiary treatment for further purification.

Q2. How effective are sewage treatment plants in removing contaminants?

Modern sewage treatment plants are highly effective. Primary treatment can remove 40-70% of suspended solids, while secondary treatment can eliminate up to 90% of remaining organic matter. Advanced tertiary processes can achieve up to 99.9% bacteria removal, making the water suitable for various reuse applications.

Q3. Is treated wastewater safe for reuse?

Treated wastewater can be safe for certain reuse applications, depending on the level of treatment. While it’s not typically used for drinking, properly treated wastewater can be safely used for irrigation in agriculture and various industrial processes, helping to conserve freshwater resources.

Q4. What happens to the sludge produced during wastewater treatment?

Sludge, a byproduct of the treatment process, undergoes thickening and dewatering to reduce its volume. Technologies like belt filter presses are used to create a drier “cake” containing 15-30% dry solids. The resulting product can often be used as fertilizer or disposed of in landfills.

Q5. How energy-intensive is the sewage treatment process?

Sewage treatment can be quite energy-intensive, particularly in the secondary treatment stage. Aeration systems, which provide oxygen for biological processes, can account for 45-90% of a treatment plant’s total energy consumption. This highlights the importance of energy efficiency in wastewater treatment operations.