SUSBIO-Digester

Biodigester Toilets

A biodigester toilet system utilizes the anaerobic digestive process to break down and clean toilet waste – the result is less solid waste, relatively clean water output and the release of harmless gas into the environment.

The process of treating human waste with anaerobic digestion is not new – it has been practiced at a large scale with the resulting water and gas products being used in further applications such as irrigation or as fertilizer. On a large scale, the process can also be used to produce a clean, renewable energy source.

However, it is only recently more people have started to release the benefits of bio digestion in domestic or smaller settings.

In a domestic or business setting toilets can be directly connected to a biogas reactor, which is also known as an anaerobic digester. Waste that goes down the toilet is directed straight into a chamber where the digestion process begins providing an effective solution for liquid waste treatment.

How Do Biodigesters Work?

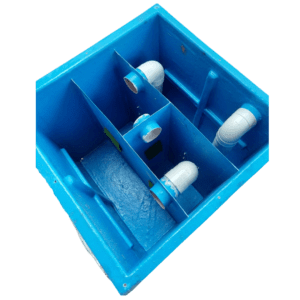

A biodigester usually has three to four anaerobic chambers that treat human waste effectively without the need for any cleaning or emptying of the tank.

After the toilet is flushed waste is directly deposited in the first chamber where solid material settles to the bottom of the tank where anaerobic bacteria cultures set to work breaking the waste down. Once the chamber is full, liquids flow into the second chamber and the process is the same, except the waste contains less solid matter. By the time the waste reaches the third chamber and is ready to exit any harmful pathogens have been removed from the water. The process also creates gasses that are released from the tank without causing environmental damage.

The water created by the anaerobic digestion process is not suitable to use as drinking water (unless further processed) but it can be used for irrigation, in the garden or cycled back into the system to flush toilets.

Since biodigester systems require an anaerobic tank to operate (anaerobic = no oxygen) the entire process is completely free from any nasty smells too, making it an ideal solution for well water treatment systems .

There are several benefits of Bio-Digestor toilet; some of these benefits are :

- Eco-Friendly

- Cost Effective

- Reduction of space usage by 40-70%

- Wide applicability in varying climatic conditions and usage

- Simple design and construction

- Maintenance Free and no recurring costs

- Minimum water consumption

- Reduction in organic waste by 99%

Biodigesters present a host of advantages over conventional septic tanks, particularly in terms of ease of operation and maintenance. Firstly, biodigesters are remarkably low-maintenance due to their self-sustaining nature. They rely on anaerobic bacteria to naturally break down organic waste, reducing the need for frequent pumping or cleaning – a common requirement for septic tanks. This translates into substantial cost savings and less hassle for homeowners.

Moreover, biodigesters offer an additional benefit by producing biogas during the decomposition process. This biogas can be harnessed as a valuable and renewable energy source for cooking or heating, contributing to reduced energy bills and a greener footprint.

The compact and modular design of biodigesters simplifies installation, and they boast a longer lifespan compared to septic tanks. In essence, biodigesters emerge as a sustainable, cost-effective, and eco-friendly alternative to septic tanks, making wastewater treatment and disposal not only easy but also environmentally responsible.

Biodigesters exhibit clear advantages in terms of robust technology and retrofit design when compared to traditional septic tanks. The technology behind biodigesters leverages advanced microbial processes, ensuring a more resilient and efficient wastewater treatment system. Unlike septic tanks, biodigesters are equipped with sophisticated mechanisms that facilitate the breakdown of organic waste, resulting in a more reliable and durable solution for waste management.

One of the most notable benefits of biodigesters is their adaptability for retrofitting. They are designed to seamlessly integrate with existing infrastructure, offering a hassle-free solution for upgrading outdated septic systems. This retrofit-friendly approach not only reduces installation costs but also minimizes disruptions to the property.

In summary, biodigesters combine cutting-edge technology with user-friendly retrofit options, making them a superior choice for modern, efficient, and environmentally-conscious wastewater management systems that effectively address domestic sewage water pollution.

A Sewage Treatment Plant (STP) operates by first removing large debris and solids through preliminary treatment. Next, in primary treatment, solids and grease are settled out. Secondary treatment then uses biological processes to break down organic matter. Tertiary treatment further purifies the water to remove any remaining contaminants. Finally, the water is disinfected to kill pathogens before being discharged or reused, ensuring it meets environmental standards.

Choosing the right sewage treatment manufacturer requires a multi-pronged approach. Look for companies with experience in your project size and local regulations. Their technology should be advanced, sustainable, and compliant. Customization and future scalability are important. Prioritize quality, reliability, and good after-sales service. Consider energy efficiency, sludge management solutions, and responsive customer support to ensure a smooth and environmentally friendly wastewater treatment process.

Advanced Sewage Treatment technology offers numerous benefits, including more effective pollutant removal for cleaner water and a healthier ecosystem. These systems are energy-efficient, reduce sludge production, and simplify disposal, leading to significant cost savings over time. Investing in advanced sewage treatment process solutions is both an environmentally responsible and economically smart decision.

SUSBIO ECOTREAT is a leading packaged STP known for its dual-treatment process, combining aerobic and anaerobic methods for effective waste removal. Its prefabricated design allows for modular, space-efficient installation, making it suitable for various applications. The system is highly efficient, with low operational costs and energy consumption, and is designed for easy maintenance and long-term durability.

The average cost of a Sewage Treatment Plant (STP) in India varies based on capacity, technology, and location. Operating costs can range from INR 15 to INR 50 per cubic meter of treated water. For a small to medium-sized STP with a capacity of about 1 million liters per day (MLD), the monthly operating cost can range from INR 1.5 lakh to INR 5 lakh. Larger STPs with capacities of 10 MLD or more may have higher costs.

A packaged STP is a compact, prefabricated system designed to treat sewage and wastewater in a modular, self-contained unit. It combines various treatment processes, such as screening, sedimentation, biological treatment, and disinfection, into a single package. Packaged STPs are easy to install and operate, making them suitable for residential, commercial, and small industrial applications, with reduced construction time and lower costs. These systems are also highly effective in addressing the needs of industrial water treatment.

A Sewage Treatment Plant (STP) is essential for safely managing and treating wastewater. STPs remove harmful contaminants, protect public health by preventing disease spread, preserve the environment by reducing pollution, and enable water reuse for irrigation or industrial purposes. They also ensure compliance with environmental regulations, making them vital for sustainable water management.

Sustainable Biosolutions Pvt Ltd is the best manufacturer and supplier of Sewage Treatment Plants (STPs) and Wastewater Treatment Plants in India. They offer innovative solutions like the advanced SUSBIO ECOTREAT, which ensures effective wastewater treatment, energy efficiency, and easy maintenance, making them a leader in the industry.

The lifespan of an advanced sewage treatment plant can vary depending on the design, materials used, and maintenance practices. However, a well-maintained STP can last anywhere from 20 to 50 years or more.