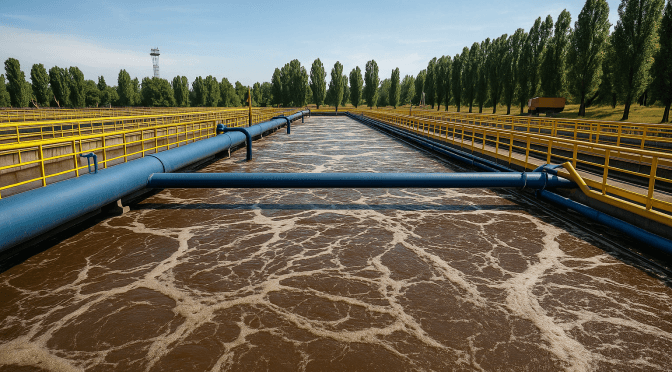

India is facing a significant challenge in managing its wastewater, a critical component of the country’s sewage treatment infrastructure. As the nation experiences rapid growth, the volume of wastewater produced is increasing, posing a serious threat to both the environment and public health. Unfortunately, the current sewage treatment infrastructure is inadequate to handle this growing burden, leading to widespread water pollution and hindering progress towards sustainable development goals.

What is a Prefabricated Sewage Treatment Plant?

A Prefabricated Sewage Treatment Plant (STP) is a compact, modular system designed to treat wastewater efficiently. These plants are pre-engineered and assembled off-site, then quickly installed at the designated location. Prefabricated STPs are space-saving, energy-efficient, and low-maintenance, making them ideal for residential applications, commercial projects, and industrial settings.

How it Works:

Primary Treatment: Removes large solids through screening and sedimentation.

Secondary Treatment: Utilizes biological processes, including microorganisms, to break down organic matter.

Tertiary Treatment: Further purifies the water using advanced treatment technologies such as membrane filtration or disinfection.

Prefabricated STPs are eco-friendly, cost-effective, and suitable for areas with limited space, providing a reliable solution for wastewater management in urban environments and remote communities alike.

Maintenance of Prefabricated Sewage Treatment Plants is simple and cost-effective. Here are a few basic maintenance tips:

Routine maintenance of Prefabricated Sewage Treatment Plants (STPs) is straightforward and cost-effective. Regular upkeep ensures optimal performance and longevity. Here are some essential maintenance tips:

1. Regular Cleaning:

Clean the filter beds and sewage chambers periodically to prevent blockages and ensure smooth water flow.

2. Monitor Performance:

Regularly check the biological treatment system to ensure it’s functioning well. Maintain aeration levels to support efficient microorganism activity.

3. Check for Leaks:

Inspect pipes and connections for leaks or wear, especially around the inlet and outlet areas, to prevent contamination and ensure efficient operation.

4. Pump and Motor Maintenance:

Inspect and clean the pumps and motors regularly. Lubricate parts as necessary and ensure there are no signs of damage or wear.

5. Sludge Removal:

Remove excess sludge from the system periodically to prevent buildup and ensure proper functioning of the treatment processes.

6. UV Lamp Cleaning (if applicable):

If your STP uses UV disinfection, clean the UV lamps regularly to maintain effectiveness.

7. Periodic Professional Checkup:

Schedule a professional inspection and service every 6–12 months to ensure the system is functioning optimally and to address any hidden issues.

By following these basic maintenance steps, you can keep your prefabricated STP running efficiently and extend its lifespan, ensuring continuous monitoring and operational continuity.

What is an Energy-Efficient Sewage Treatment Plant (STP)?

An energy-efficient STP utilizes advanced treatment technologies to reduce electricity consumption while effectively treating wastewater. These systems help lower operational costs and support sustainability initiatives, contributing to reduced carbon emissions.

Key Features:

Optimized Aeration: Uses high-efficiency blowers to reduce energy use.

Advanced Filtration: Techniques like MBRs or MBBRs require less energy.

Automation: Real-time controls adjust processes for efficiency.

Renewable Energy: Some STPs integrate solar power for operational continuity.

Efficient Pumps: Pumps work at optimal speeds to save energy.

Benefits:

Lower Costs: Reduces electricity bills and overall operational expenditure.

Eco-Friendly: Uses less energy, lowering environmental impact and supporting corporate sustainability goals.

Long-Term Savings: Initial investment pays off with lower operational costs and improved cost-effectiveness.

The Wastewater Challenge in India

India is facing a significant wastewater crisis, particularly in emerging economies and developing countries. With rapid urbanization and industrialization, the volume of wastewater generated in the country is on the rise. Unfortunately, the existing sewage treatment infrastructure is often insufficient to handle this increasing burden. As a result, untreated or inadequately treated wastewater is discharged into rivers, lakes, and other water bodies, posing serious threats to public health, water quality, and the environment. This situation calls for urgent action and innovative wastewater management solutions to address India’s challenges effectively and meet sustainable development goals.

Solution

Sewage treatment plants play a crucial role in safeguarding the environment and promoting water conservation. By effectively treating wastewater, these plants remove harmful pollutants, organic pollutants, and suspended solids, ensuring that the treated effluent released back into the environment is clean and safe. This not only protects aquatic ecosystems but also prevents waterborne diseases and safeguards public health. Moreover, sewage treatment plants help in the sustainable management of water resources by recycling treated wastewater for various purposes such as irrigation, industrial processes, and even groundwater recharge in some cases. Overall, these plants contribute significantly to mitigating water pollution, conserving water, and promoting environmental sustainability in both urban and remote communities.

India’s Evolving Wastewater Landscape: Innovations, Policies & Future Opportunities

India is undergoing a transformative shift in wastewater treatment—driven by local innovations, stricter environmental regulations, and a growing focus on reuse and circularity. Here’s how these trends are shaping the future of sewage treatment:

1. Innovations & Pilot Projects Across India

Thiruvananthapuram’s Muttathara STP now features an Omniprocessor that turns sludge into electricity and potable water, creating a near-zero waste system. NIT Rourkela’s photocatalytic beads—powered by sunlight—achieve up to 82% COD reduction, offering a sustainable solution for rural wastewater. The Pavitra Ganga Project in Kanpur is piloting advanced treatment technologies like Andicos, SFD-MBR, and Constructed Wetlands Plus (CW+)—designed to recover nutrients, water, and energy simultaneously.

2. Policy, Regulation & Governance Gaps

The Liquid Waste Management Rules 2025 mandate 20% reuse by 2027–28 and 50% by 2030–31. CPCB’s 2025 discharge norms have set tougher standards for BOD, COD, and nutrient levels. Institutional bottlenecks—like poor coordination between MJSM, AMRUT, and NMCG, or inconsistent enforcement by SPCBs—hinder progress. Contrast in state performance: Haryana’s Water Authority is pushing integrated reuse, while Uttar Pradesh still struggles with fragmented governance and meeting regulatory requirements.

3. Reuse & Circular Economy in Practice

Nationally, only 28–30% of treated wastewater is reused. Nagpur, Chennai, and Bengaluru are emerging as reuse pioneers, supplying treated effluent for power plants, agriculture, and industrial facilities. Phosphorus recovery from sludge can cut fertilizer imports by 4%, and nutrient-rich effluent is increasingly used in peri-urban farming.

4. Decentralized Systems & Smart STPs

DEWATS (Decentralized Wastewater Treatment Systems) are cost-effective in semi-urban and rural settings but require community participation and local regulatory support. Digital upgrades include: Sensor-based overflow detection in Gurugram, IoT-controlled chemical dosing in Delhi, and AI-based predictive maintenance in industrial STPs.

5. Operational & Infrastructure Bottlenecks

Many plants operate below capacity—Punjab, for example, utilizes only 87% of its STP infrastructure, discharging over 267 MLD of untreated sewage. Challenges include power outages, poor O&M, staff shortages, and chemical-heavy industrial effluents that lead to membrane fouling or variable output quality.

6. Solutions, Case Studies & Emerging Models

TADOX® by TERI: A cutting-edge oxidation technology that degrades persistent pollutants and reduces sludge volume. Hybrid systems: Combine MBR + co-digestion, or constructed wetlands with zeolite/carbon filters, offering high performance with reuse capability. Policy enablers: Green bonds, capital subsidies up to 50%, and Section 35AD tax incentives for private players to improve sewage treatment infrastructure.

7. Regional & Behavioral Insights

North India: Faces seasonal surges in sewage load due to pilgrimages and festivals (e.g., Kumbh Mela). South India: Textile and tannery effluents demand specialized treatment systems. East India: Low STP coverage and minimal reuse initiatives. West India: ZLD (Zero Liquid Discharge) mandates gaining traction in Gujarat’s industrial estates. Behavioral gaps: Many communities distrust treated water reuse; 30% of STPs in housing complexes are non-compliant due to lack of awareness or maintenance.

8. AI & Digital Twin Technology

Digital twins simulate STP performance, optimize dosing, and prevent overflows. Bengaluru Smart Water Grid uses AI for real-time leakage detection and rainfall-based load forecasting. These innovations reduce OPEX while improving resilience and environmental outcomes.

9. Global Comparisons: Lessons for India

Singapore: NEWater covers 40% of potable needs via ultra-clean reused water. Israel: Reuses 90% of sewage in agriculture. Germany: Mandates nutrient recovery, especially phosphorus. India can leapfrog by adapting these proven technologies through its own innovations and PPP models.

10. Legal & Economic Drivers

NGT rulings have accelerated STP setups under deadlines with heavy fines for non-compliance. Polluter Pays Principle is being enforced more strictly in states like Punjab and Uttarakhand. STP operation and reuse markets present opportunities for: Entrepreneurs in O&M, Sludge composting, Effluent trading for industrial use.

Why Choose Us?

As a leading manufacturer of Sewage Treatment Plants (STPs) in India, we pride ourselves on providing comprehensive solutions for commercial and industrial projects. Our flagship product, the SUSBIO ECOTREAT: Prefabricated Sewage Treatment Plants , stands out for its unmatched efficiency and eco-friendliness.

Crafted from high-quality fiber-reinforced plastic (FRP), our ECOTREAT system offers superior strength and durability, ensuring hassle-free installation and maintenance. What sets it apart is its dual treatment process, combining anaerobic and aerobic processes to ensure thorough wastewater purification. By efficiently removing pollutants, organic matter, and contaminants, our STP guarantees cleaner water output.

But our commitment to excellence doesn’t stop there. The SUSBIO ECOTREAT is designed with state-of-the-art technology to minimize human effort and energy consumption, making it both user-friendly and cost-effective. Furthermore, our STPs are customizable to meet the unique requirements of each client, ensuring optimal performance for a variety of applications, whether it’s for small communities or large industrial setups.

We prioritize environmental stewardship and resource conservation. That’s why our Packaged Sewage Treatment Plants are meticulously designed to be efficient and eco-friendly. From the careful selection of materials to the implementation of advanced automation systems, every aspect of our manufacturing process is geared towards sustainability. When you choose SUSBIO, you’re not just investing in a sewage treatment solution – you’re choosing a cleaner, greener future for generations to come.

Frequently Asked Questions (FAQ)

1. What makes SUSBIO ECOTREAT suitable for Indian conditions?

SUSBIO ECOTREAT is designed with India’s urban and semi-urban infrastructure challenges in mind. Its prefabricated, modular FRP design ensures rapid deployment, even in space-constrained or flood-prone areas. It also adapts well to variable loads, common in Indian cities and gated communities, making it an ideal decentralised solution for diverse settings.

2. Is SUSBIO ECOTREAT compliant with the latest CPCB 2025 norms?

Yes. ECOTREAT meets and often exceeds the latest CPCB 2025 discharge norms, including BOD <10 mg/L and nutrient recovery targets. Its biological treatment modules are engineered for consistent output quality and reuse-ready effluent, adhering to stringent regulatory standards.

3. Can the treated water be reused for agriculture, flushing, or landscaping?

Absolutely. SUSBIO ECOTREAT produces high-quality treated effluent that is ideal for non-potable reuse applications such as irrigation purposes, toilet flushing, cooling towers, and green spaces, helping reduce fresh water demand and supporting water conservation efforts.

4. What are the maintenance requirements for the system?

Routine checks include aeration efficiency, pump health, and biofilm activity. The system is low-maintenance compared to conventional plants and can be paired with IoT-based monitoring for predictive maintenance alerts, ensuring operational continuity and reducing the need for frequent technical assistance.

5. Is SUSBIO ECOTREAT eligible for government subsidies or tax incentives?

Yes. Under schemes like AMRUT 2.0 and Swachh Bharat Mission–Urban, STPs with reuse potential and energy efficiency may qualify for capital subsidies (up to 50%). Additionally, Section 35AD of the Income Tax Act provides tax benefits for infrastructure projects, potentially reducing initial investment costs.

6. Can ECOTREAT be deployed in decentralized clusters or rural areas?

Yes. Its compact, plug-and-play design makes it ideal for decentralized wastewater clusters, including rural panchayats, schools, resorts, and housing complexes. It works effectively even without grid power when paired with solar backup, making it suitable for remote communities and construction camps.

7. How long does the system last, and what is its lifecycle cost?

The FRP shell lasts 15–25 years, and modular parts like blowers and pumps can be replaced easily. Overall, the lifecycle cost is 30–40% lower than conventional STPs due to lower energy use, quick installation, and reuse-based savings, offering excellent cost-effectiveness over time.

8. How does ECOTREAT compare with traditional sewage treatment plants?

Unlike traditional systems, ECOTREAT requires no civil construction, has faster setup times, and is energy-efficient. It’s also scalable, allowing future expansion as population or load increases. Its compact footprint and flexibility make it ideal for urban environments with space constraints.

9. Can the system handle industrial or mixed wastewater?

For mixed domestic and industrial effluents, ECOTREAT can be customized with pre-treatment filters, chemical dosing, or hybrid modules like MBBR + advanced oxidation. However, influent profiling is recommended for industrial integration to ensure effective treatment of complex contaminants.

10. Is SUSBIO ECOTREAT future-ready for digital upgrades like AI and digital twins?

Yes. It is compatible with sensor networks, SCADA, and cloud-based monitoring. Advanced setups can integrate AI-based diagnostics, digital twins, and flow prediction algorithms for smart city infrastructure, ensuring continuous monitoring and optimization of the treatment process.