Wastewater treatment plays a vital role in protecting our freshwater resources from pollution. The United States depends on an estimated 14,748 wastewater treatment plants to process sewage for 76% of its population. This environmental process has evolved substantially since its beginnings in the late 19th and early 20th centuries. The construction of centralized sewage treatment plants first started in the United Kingdom and the United States.

Wastewater treatment now serves a purpose beyond waste disposal. The United Nations’ 2017 World Water Development Report suggests that wastewater could become a valuable resource to meet our planet’s growing need for freshwater and raw materials. The Environmental Protection Agency (EPA) strictly regulates treated water’s quality through the Clean Water Act, which establishes the simple structure to control pollutant discharges into U.S. waters. This piece will explore the four main stages of wastewater treatment plants and get into different types of wastewater. We’ll cover sludge management techniques and modern treatment solutions that help maintain environmental compliance while recovering valuable resources.

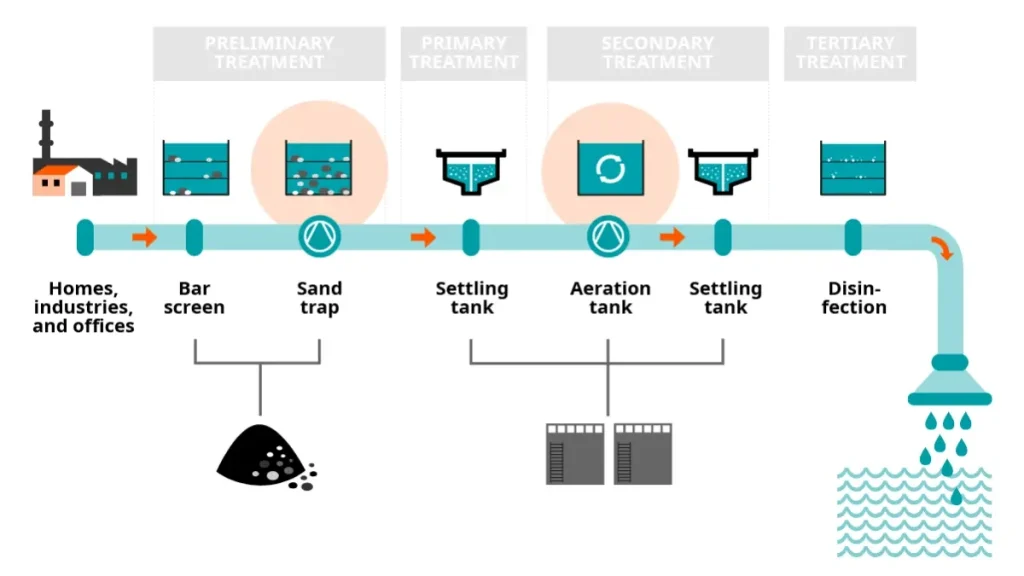

Understanding the 4 Stages of Wastewater Treatment

Wastewater treatment plants use four distinct stages to remove contaminants, prevent pollution and enable water recycling. Each stage targets specific pollutants and gradually purifies water to meet strict environmental standards.

Preliminary Treatment: Bar Screening and Grit Removal

The first stage removes physical debris that could damage equipment or disrupt downstream processes. Bar screens with spacing between 15-25mm catch large objects like plastic, paper, and food scraps. The water flow slows down in grit chambers, allowing heavier particles such as sand, gravel, and small stones to settle at the bottom. This vital first step protects equipment from damage and helps reduce maintenance costs.

Primary Treatment: Sedimentation and Sludge Separation

Gravity does most of the work in primary treatment. The wastewater flows into large settling tanks where heavy solids (sludge) sink to the bottom, and oils and grease float to the top. The system’s mechanical scrapers collect settled sludge from the bottom while surface-skimming devices remove floating materials. This stage removes 50-60% of suspended solids, though dissolved pollutants and harmful microorganisms remain.

Secondary Treatment: Aeration and Biological Processing

Microorganisms break down organic waste and nutrients during secondary treatment. The activated sludge process combines wastewater with bacteria in aeration tanks that receive oxygen through diffusers. These microbes eat organic matter and convert it into carbon dioxide, water, and new microorganisms. The process also includes anaerobic digestion (without oxygen) and anoxic treatment (for nitrogen removal). This stage removes over 90% of remaining suspended solids.

Tertiary Treatment: Filtration and Disinfection

Advanced purification techniques mark the final stage of wastewater treatment. Sand filters or other media remove residual suspended particles through tertiary filtration. The process uses chlorination, UV radiation, or ozonation to eliminate harmful pathogens. The resulting water meets strict discharge standards with total suspended solids typically below 10 mg/L.

SUSBIO’s ECOTREAT system offers a modern solution that combines all four treatment stages with improved energy efficiency and automation. Their system delivers exceptional compliance with discharge standards and supports environmentally responsible development goals.

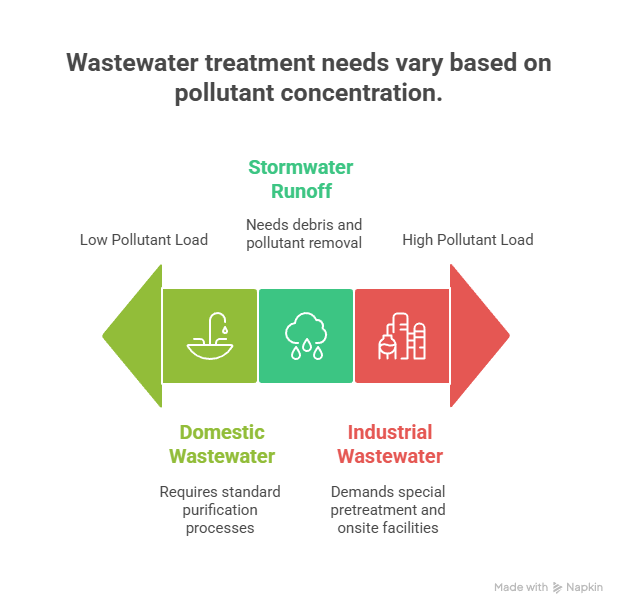

Types of Wastewater and Their Treatment Needs

Wastewater has different compositions and pollutant loads that just need specific treatment approaches to work well for purification. The types of contaminants help determine which processes we need at each stage of wastewater treatment.

Domestic vs Industrial Wastewater Characteristics

Households and businesses generate domestic wastewater that contains water from restrooms, washing, bathing, food preparation, and laundry. This sewage has more dilution than industrial wastewater and fewer toxic compounds. Manufacturing facilities, mining operations, and agricultural production create industrial wastewater with higher concentrations of toxic contaminants and organic compounds. Any wastewater that isn’t domestic falls under industrial classification and usually needs special pretreatment before entering public systems. Companies must obtain permits and build onsite treatment facilities to meet local limits before releasing waste into municipal sewers.

Stormwater and Combined Sewer Systems

Streets and landscapes collect stormwater runoff that picks up debris, oils, fertilizers, and other pollutants. Separate sewerage systems collect this runoff away from domestic wastewater. The combined sewer systems move both stormwater and sewage through the same pipes. Heavy rainfall can overwhelm these systems and cause combined sewer overflows (CSOs) where untreated or partially treated waste flows directly into water bodies. This creates major pollution problems for about 700 U.S. communities. Climate change makes these challenges worse through increased heavy precipitation events.

Biochemical Oxygen Demand (BOD) and Suspended Solids

Microorganisms use oxygen to break down organic matter in water, which we measure as Biochemical oxygen demand. BOD is a vital index to determine water quality and pollution levels. Higher BOD values show more pollution, while lower values indicate cleaner water. Suspended solids can harm water bodies by reducing their ability to reoxygenate and impact aquatic life. Teams remove these solids through mechanical methods like settling and filtering, physicochemical approaches such as coagulation and flocculation, and advanced technologies like Dissolved Air Flotation (DAF) that shows 92-96% removal efficiency in tests.

Sludge Management and Resource Recovery

Sludge management plays a vital role in wastewater treatment. The process handles residual solids to reduce volume and extract valuable resources. This is a big deal as it means that sludge disposal costs can reach over 50% of a treatment plant’s operating budget.

Sludge Thickening and Dewatering Techniques

The original sludge goes through thickening to increase solids concentration and reduce water content. Primary sludge reaches 8-10% solids, while secondary sludge achieves about 4% solids. The next step uses dewatering techniques with mechanical methods to further reduce water content. These include:

Centrifugation – using centrifugal force to separate solids from liquid

Belt filter presses – applying pressure between tensioned belts

Screw presses – compression removes water

These processes achieve 35% dry matter content in dewatered sludge and reduce volume by up to 85%.

Anaerobic Digestion and Biogas Generation

Anaerobic digestion changes organic matter in sludge through four key stages: hydrolysis, acidogenesis, acetogenesis, and methanogenesis. Bacteria break down organic materials without oxygen in sealed vessels called digesters. The biogas produced contains 50-75% methane, carbon dioxide, and trace gasses. This creates a valuable renewable energy source. Many facilities now use this biogas to generate electricity, provide heating, or fuel vehicles after purification.

Reuse of Treated Sludge in Agriculture

Treated sludge brings significant agricultural benefits. The European Union applies about 50% of its total sludge production to agricultural soils. This practice provides essential nutrients, especially phosphorus and nitrogen, which reduces the need for synthetic fertilizers. The sludge needs biological, chemical, or thermal treatment to minimize fermentability and health risks before agricultural use. Common treatments include lime stabilization, composting, and pasteurization.

SUSBIO ECOTREAT revolutionizes wastewater treatment with its advanced digestion techniques and resource recovery systems that optimize sludge management.

SUSBIO ECOTREAT: A Modern Wastewater Treatment Solution

SUSBIO has become a leading manufacturer of innovative wastewater treatment solutions in today’s rapidly changing industry. Their flagship product, SUSBIO ECOTREAT, stands out by using all four key treatment stages and tackles modern challenges head-on.

Overview of SUSBIO as a Leading WWTP Manufacturer

SUSBIO undertook the task to revolutionize wastewater treatment through prefabricated, expandable solutions. The company rank among India’s top wastewater treatment plant manufacturers. They design and install state-of-the-art sewage treatment plants that serve residential, commercial, and industrial sectors of all sizes. Their steadfast dedication to research and development has created trailblazing solutions that handle complex waste management challenges while staying environmentally responsible.

SUSBIO ECOTREAT Process Flow: From Inlet to Effluent

Let’s take a closer look at SUSBIO ECOTREAT’s treatment process sequence:

Oil and grease separation in the first chamber

Primary sedimentation removes solid debris

Anaerobic contact media chamber handles denitrification

Moving bed media chamber manages aerobic processing

Final sedimentation produces clear treated water

Disinfection prepares water for safe discharge or reuse

This dual-treatment approach combines biological and physical methods to ensure complete purification of wastewater.

Energy Efficiency and Automation in SUSBIO ECOTREAT

SUSBIO ECOTREAT uses 90% less electricity than conventional systems. This is a big deal as it means that their optimized design and smart control systems make a real difference. The plant runs quietly without odors, making it perfect for urban settings. The fully automated operation needs no on-site operators, which cuts labor costs while maintaining consistent performance.

Compliance with Discharge Standards and SDG Goals

SUSBIO ECOTREAT meets and often surpasses regulatory standards for wastewater discharge. The system lines up with Sustainable Development Goals, especially SDG 6 (Clean Water and Sanitation), through water conservation and reuse features. Users can safely repurpose treated effluent for irrigation, toilet flushing, or cooling systems, which supports circular water economy goals.

Conclusion

Wastewater treatment is a vital environmental process today. This piece explores four significant stages that turn contaminated water into clean, reusable resources. The first stage removes physical debris. Primary treatment then separates solids through sedimentation. Secondary treatment uses microorganisms to break down organic matter. The final stage provides purification through filtration and disinfection.

Wastewater comes from many sources – homes, industries, and stormwater runoff. Each source needs specific methods to tackle its contaminants and pollution levels. Sludge management has grown beyond just disposal. It now gives us a chance for resource recovery through thickening, dewatering, anaerobic digestion, and agricultural reuse.

SUSBIO ECOTREAT stands out as the best wastewater treatment solution available now. This detailed system handles all treatment stages and saves energy. The plant moves wastewater through several steps: oil separation, sedimentation, anaerobic treatment, moving bed media chambers, final clarification, and disinfection. Their combined biological-physical approach delivers thorough purification. This is a big deal as it means that the system uses 90% less electricity than regular systems.

Clean water’s future depends on affordable, environmentally responsible treatment solutions. SUSBIO leads the industry with innovative solutions that protect our freshwater resources. Their automated systems work without constant supervision and meet or exceed regulatory standards. As global water challenges grow, advanced treatment plants like SUSBIO ECOTREAT will become more significant to ensure clean water for future generations.

Key Takeaways

Understanding wastewater treatment stages is essential for environmental protection and resource recovery. Here are the critical insights from modern wastewater management:

• Four-stage treatment process: Preliminary (debris removal), primary (sedimentation), secondary (biological processing), and tertiary (filtration/disinfection) stages progressively purify water to meet discharge standards.

• Sludge becomes valuable resource: Through anaerobic digestion, waste sludge generates biogas for renewable energy while treated solids provide agricultural nutrients, turning disposal costs into revenue streams.

• Different wastewater types need tailored approaches: Domestic, industrial, and stormwater each require specific treatment methods based on contaminant profiles and pollution levels.

• Modern systems achieve 90% energy savings: Advanced solutions like SUSBIO ECOTREAT combine automation, dual biological-physical treatment, and smart controls to dramatically reduce operational costs.

• Treatment supports circular economy: Properly treated wastewater can be safely reused for irrigation, cooling systems, and toilet flushing, contributing to water conservation and sustainability goals.

The evolution from simple waste disposal to comprehensive resource recovery demonstrates how wastewater treatment has become a cornerstone of sustainable water management, protecting freshwater resources while generating valuable byproducts.

Frequently Asked Questions

Q1. What are the four main stages of wastewater treatment?

The four main stages are preliminary treatment (screening and grit removal), primary treatment (sedimentation), secondary treatment (biological processing), and tertiary treatment (filtration and disinfection). Each stage progressively removes contaminants to purify water.

Q2. How does sludge management contribute to resource recovery?

Sludge management involves thickening, dewatering, and anaerobic digestion processes. These techniques reduce sludge volume, generate biogas for energy, and produce treated solids that can be used as agricultural fertilizers, turning waste into valuable resources.

Q3. Why do different types of wastewater require different treatment approaches?

Different wastewater sources (domestic, industrial, stormwater) contain varying pollutants and contaminant levels. Each type requires tailored treatment methods to effectively remove specific pollutants and meet environmental standards for safe discharge or reuse.

Q4. How do modern wastewater treatment plants improve energy efficiency?

Advanced systems like SUSBIO ECOTREAT incorporate automation, smart controls, and optimized designs. These features can reduce electricity consumption by up to 90% compared to conventional systems, significantly lowering operational costs.

Q5. How does treated wastewater support water conservation efforts?

Properly treated wastewater can be safely reused for various purposes such as irrigation, cooling systems, and toilet flushing. This practice contributes to water conservation by reducing the demand for freshwater resources and supporting circular water economy objectives.