The final and vital step in water purification happens during tertiary wastewater treatment, right before water returns to our environment. This advanced treatment creates water that’s clean enough to reuse in many ways – maybe even as drinking water. The process becomes particularly important for facilities that release water into delicate ecosystems like estuaries or coral reefs.

Tertiary wastewater treatment serves as the final cleanup phase. The system targets and removes any remaining pollutants that earlier treatment stages missed. The main goal focuses on producing contaminant-free water that meets strict environmental standards. The process must eliminate organic ions, nutrients, suspended solids, microorganisms, and other lingering pollutants completely.

This piece will get into the methods and technologies that make tertiary treatment work. You’ll learn about filtration systems, disinfection techniques, and strategies to remove nutrients. The applications for treated water deserve attention too, since each facility’s approach depends on its wastewater’s makeup and origin. A deeper understanding of these processes shows how tertiary treatment protects our water resources and makes eco-friendly water reuse possible.

What is Tertiary Treatment in Wastewater?

The final stage of water purification ends with tertiary treatment. This advanced process tackles contaminants that survive primary and secondary treatments. The sophisticated final phase will give water quality that meets tough environmental standards and makes it ready to reuse.

Definition and role in the treatment train

Tertiary wastewater treatment stands as the third and final stage in cleaning wastewater. The process removes inorganic compounds, bacteria, viruses, and parasites that earlier treatments can’t eliminate. This advanced method cleans out organic ions, nutrients, suspended solids, microorganisms, and leftover pollutants to get wastewater that meets disposal rules.

The process is a vital “finishing” step for effluent, which experts call “effluent polishing”. It follows primary and secondary processes and takes purification to new heights. Tertiary treatment builds on earlier processes and targets microscopic pollutants through special filtration and disinfection methods.

The success of tertiary treatment determines if treated water can safely go back to nature or find new uses. Primary and secondary treatments clean water enough for environmental discharge. Tertiary treatment creates water clean enough to reuse in industrial processes or even as drinking water.

Comparison with primary and secondary treatment

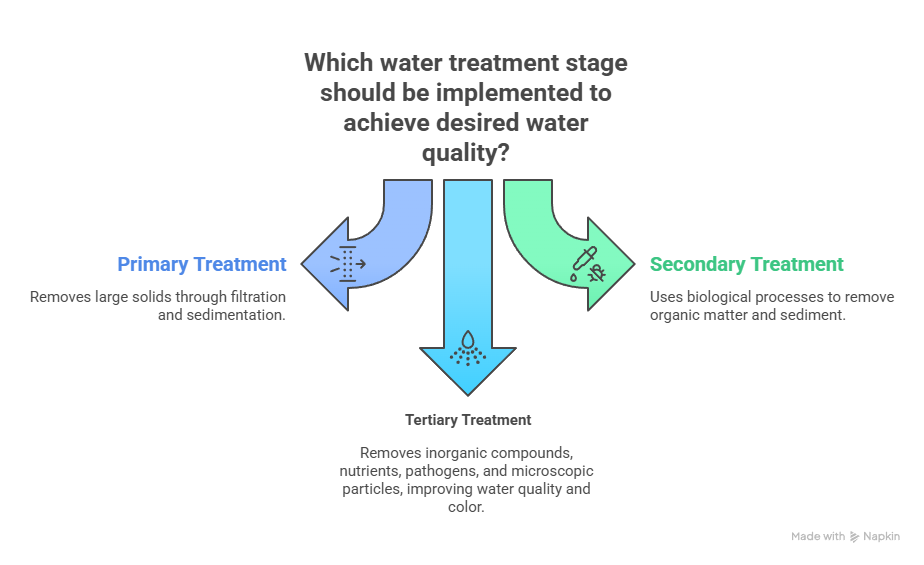

Tertiary treatment targets different contaminants than earlier stages:

Primary treatment removes large solid contaminants through filtration and sedimentation.

Secondary treatment uses biofiltration, aeration, and oxidation to clean wastewater through biological processes that remove organic matter and sediment.

Tertiary treatment removes remaining inorganic compounds, nutrients (mainly nitrogen and phosphorus), pathogens, and microscopic particles.

Primary and secondary treatments don’t deal very well with color removal. Experts often use tertiary treatments specifically to tackle this issue. Tertiary treatment also cuts down finer particles, nutrients, and pathogens that earlier stages miss, which leads to much better water quality.

When is tertiary treatment required?

Facilities need tertiary treatment in several specific cases. Plants that release water into sensitive ecosystems like estuaries, slow-moving rivers, or waters near coral reefs must use it. These environments can suffer serious damage from even tiny amounts of pollutants.

Plants also need tertiary treatment when water quality after secondary treatment falls short of discharge standards. Many areas now have tough rules that make tertiary treatment mandatory. To cite an instance, the Clean Water Act in the United States requires municipal wastewater plants to use tertiary treatment before releasing effluent into surface waters.

The lack of water has increased the need for water reuse programs. Growing populations put more pressure on water supplies. This makes tertiary treatment vital for agricultural irrigation and other reuse cases that need specific water quality standards. Industries that create wastewater with specific contaminants also must use tertiary treatment to meet discharge requirements.

Not every wastewater treatment plant uses tertiary processes. Plants that want to reuse water or work in environmentally sensitive areas can’t do without them. The choice to add tertiary treatment depends on local environmental conditions, rules, water availability challenges, and how the water will be reused.

Core Processes in Tertiary Treatment

Three core processes work together in tertiary treatment to produce high-quality effluent. These advanced treatments target different aspects of water contamination. Together they create a detailed purification system for wastewater treatment facilities.

Filtration: Sand, disk, and membrane filters

Filtration is the life-blood of tertiary treatment that removes residual suspended solids left behind by secondary treatment. Research shows three main tertiary filtration approaches: surface filtration, depth filtration, and membrane filtration.

Surface filtration uses a two-dimensional staining process through filter media such as micro-net cloth filters. Depth filtration moves suspended substances through a filter bed of granular material (like sand) or compressible material (like free-fiber cloth filters). Membrane filtration stands out as the most advanced option. It pushes wastewater under pressure through thin membranes made of hollow fibers or composite material sheets.

Sand filters, disk filters, and drum filters are the most common technologies. Sand filtration—both rapid and slow variants—gives an economical solution to remove larger particles. The Alfa Laval AS-H Iso-Disk Cloth Media filter is a gravity-driven continuous filter with outside-in filtration. It removes residual solids to less than 5 mg/l suspended solids and less than 10 mg/l BOD. The final effluent quality reaches down to 5-10 μm. This technology processes 10-15 m³/h/m² filtration area, making it a flexible, high-capacity alternative to traditional sand filters.

Disinfection: Chlorine, UV, and ozone

Disinfection plays a vital role in eliminating pathogens before discharge. The field has three main methods: chlorination, ultraviolet (UV) irradiation, and ozonation.

Chlorination leads the global usage statistics. It adds chlorine or chlorine compounds to wastewater. Using 32 mg/L chlorine for 15 minutes of contact time eliminates total coliform, fecal coliform, Pseudomonas, and Staphylococcus. While effective and affordable, chlorine creates potentially harmful byproducts when it reacts with organic matter and can harm aquatic life.

UV disinfection uses ultraviolet light (wavelength 250-270 nm) to damage microbial DNA and stop reproduction. A low-pressure UV dose of 164 mWs/cm² cuts Total Coliform Count by 3 logs and removes Fecal Coliform, Pseudomonas, and Staphylococcus completely. UV treatment leaves no residual chemicals but needs clear water to work well.

Ozonation uses reactive ozone gas to destroy microorganism cell walls. Research shows 15 mg/L of ozone with 15 minutes contact time removes all investigated pathogens. This highly effective method needs substantial energy and specialized equipment.

Nutrient removal: Nitrogen and phosphorus

Nutrient removal is the third critical component that addresses eutrophication in receiving waters. Standard wastewater treatment processes like anaerobic-anoxic-oxic (AAO) and sequencing batch reactor (SBR) reduce total nitrogen (TN) and total phosphorus (TP) substantially. However, these reductions often fall short of preventing environmental harm.

Phosphorus removal relies on biological or chemical methods. Chemical precipitation uses metal salts (aluminum, iron, or calcium) to change dissolved solids’ physical state, which helps removal through sedimentation. Modern targets push for TP concentrations below 0.05-0.2 mg/L.

Nitrogen removal typically needs biological denitrification. Secondary effluent’s low carbon-to-nitrogen ratio (C/N < 5) requires extra carbon sources or electron donors. Denitrifying biological filters (DNBF) are common process units in tertiary treatment. They achieve only 20-30% phosphorus removal efficiency.

New technologies show great promise. These include enhanced denitrifying phosphorus removal filters, pyrite-based autotrophic denitrification, and microalgae biological treatment systems. Tests with immobilized microalgae have shown excellent results. They achieve phosphorus removal rates above 80% at various hydraulic retention times, with residual concentrations as low as 0.001-0.12 mg/L.

Filtration Technologies in Tertiary Treatment

Filtration systems serve as the technical backbone of tertiary wastewater treatment. Different technologies provide unique advantages based on treatment needs and facility limits. These specialized filtration methods work together to remove remaining contaminants after secondary treatment.

Bag filters vs. drum filters vs. disk filters

Surface filtration technologies work differently in their efficiency and use. Drum filters have a drum-shaped skeleton with external filter panels that use gravity as their driving force. These filters work well to prevent fragmentation and handle large flows. Disk filters have become more popular because they work better.

The disk filter design uses a central drum with openings that send water to filter disks. Filter cloth covers both sides of these disks. This setup creates a filter area two to three times bigger than drum filtration in the same space. Tests show that disk filters use about 45% less backwash water than drum filters while removing similar amounts of suspended matter. Users save money on operations because they need less energy to pump backwash water.

Microfiltration and ultrafiltration membranes

Membrane filtration takes tertiary treatment to microscopic levels through pressure-driven separation. Microfiltration (MF) membranes have pore sizes from 0.1 to 10 μm. They remove bacteria, turbidity, macromolecules, and colloids effectively. Water, ions, dissolved organic material, and viruses pass through while the membrane catches larger contaminants like algae, bacteria, and pathogenic protozoa.

Ultrafiltration (UF) works at an even finer scale with pore sizes between 0.001 and 0.1 μm. UF’s smaller pores catch more contaminants, including viruses, endotoxins, proteins, and tiny particles that MF misses. Both systems can run in dead-end filtration where feed flows straight through the membrane or crossflow filtration where feed moves across the membrane’s surface.

Activated carbon and zeolite media

Chemical filtration media help remove dissolved contaminants. Activated carbon’s structure contains oxygen, hydrogen, sulfur, and nitrogen functional groups that absorb many organic compounds. Its large surface area and varied pore sizes remove foul odors, clear discoloration, and eliminate toxic organic substances like phosphate and lead effectively.

Zeolite media excels at ion exchange. Natural zeolites like clinoptilolite swap ions with external medium to remove ionized ammonia from wastewater. This makes zeolite great for reducing ammonium, with absorption capacity between 2.7 to 30.6 mg/g based on its structure.

Each medium removes specific contaminants – activated carbon targets organic compounds while zeolite handles ammonium and phosphate. Many advanced tertiary treatment systems use both materials to remove more contaminants.

Disinfection and Advanced Oxidation Methods

Disinfection methods in tertiary treatment serve as the final protective barrier against pathogens before wastewater release. Modern technologies now do more than just reduce germs – they tackle emerging concerns about micropollutants.

Chlorination and dechlorination process

Wastewater treatment plants worldwide rely on chlorination as their primary disinfection technique. Chlorine destroys pathogens through oxidation of cellular material once added to wastewater, with doses typically ranging from 5 to 20 mg/L. The process needs approximately 32 mg/L chlorine and 15 minutes contact time to completely inactivate total coliform, fecal coliform, and other bacteria.

Chlorine creates disinfection byproducts (DBPs) during its reaction with organic matter. The need for dechlorination becomes clear before discharge. Chemicals like sodium thiosulfate, sodium bisulfite, or sodium metabisulfite neutralize residual chlorine in this process. Municipal facilities now commonly use both processes one after another to protect the environment.

Ultraviolet (UV) light sterilization

UV disinfection damages microbial DNA using light at wavelengths around 254 nanometers. Rather than killing organisms outright, it prevents them from reproducing. Low-pressure UV doses of 164 mWs/cm² can reduce total coliform counts by 3 logs, according to research.

This method leaves no residual toxicity since it uses no chemicals, making it better for the environment than chlorination. The process doesn’t work as well in waters with high suspended solids because particles block microorganisms from UV exposure. Most systems need pre-filtration to maintain water clarity that allows maximum UV penetration.

Ozonation and AOPs for micropollutants

Ozonation stands out as a powerful solution to eliminate micropollutants that standard treatments don’t handle well. Most pharmaceuticals break down by more than 79% with applied ozone concentrations of 15 mg/L.

Advanced oxidation processes (AOPs) combine ozone with hydrogen peroxide or UV radiation to create highly reactive hydroxyl radicals. The ozone-hydrogen peroxide reaction follows this pathway: 2O₃ + H₂O₂ → 2OH• + 3O₂. These strong oxidants break down stubborn organic pollutants, including pharmaceuticals, organic dyes, pesticides, and microplastics. The process costs more than standard treatments due to high energy needs and specialized equipment.

Applications and Reuse of Treated Water

Advanced purification through tertiary treatment produces water that benefits sectors of all types. These applications help maximize water resources’ value while reducing environmental effects.

Irrigation and agricultural reuse

Agriculture uses about 72% of global freshwater. Treated wastewater irrigation helps agricultural yields and supports millions of smallholder farmers worldwide. Israel stands as a leader in this field by using 90% of its reclaimed water for agricultural irrigation. The nutrient-rich tertiary treated water provides extra benefits and reduces fertilizer needs. This water contains valuable nitrogen (20-85 mg/L) and phosphorus (4-15 mg/L) that help crops thrive.

Industrial and cooling water reuse

Tertiary treated effluent plays a vital role in industrial applications. Water recycling works particularly well for power plants, especially wet-cooled facilities that use large water volumes. Recycled cooling tower blowdown water cuts water intake by up to 25%. Major industrial users include:

Pulp and paper manufacturing (second largest industrial water consumer)

Textile processing

Construction (using 6,740 million liters monthly for concrete production)

Potable reuse and groundwater recharge

Tertiary treated wastewater helps address water availability issues and extends aquifer lifespans through groundwater recharge. The process sends treated effluent into recharge pits, ponds, abandoned wells, or infiltration basins. Abu Dhabi generates about 340 million cubic meters of treated wastewater yearly and can recharge aquifers at rates up to 50,000 m³/day. This method costs between AED 1.2–1.8 per cubic meter, which is much cheaper than desalination at AED 6–8 per cubic meter.

Conclusion

Tertiary treatment serves as the last defense to protect our environment from wastewater contaminants. As I wrote in this piece, this advanced stage raises water quality beyond what primary and secondary treatments achieve alone. Three life-blood processes – filtration, disinfection, and nutrient removal – work together to produce water that meets strict environmental standards.

Advanced filtration technologies like disk filters, membrane systems, and specialized media capture microscopic particles and dissolved contaminants effectively. Disinfection methods such as chlorination, UV irradiation, and ozonation destroy pathogens that risk public health. The nutrient removal processes also target nitrogen and phosphorus compounds that could cause harmful algal blooms in receiving waters.

Water’s lack worldwide has expanded tertiary-treated water’s applications significantly. Farmers benefit from nutrient-rich recycled water for irrigation, while industries reduce their environmental impact by using treated wastewater in operations. Groundwater recharge offers a budget-friendly alternative to desalination and preserves aquifer resources.

Population growth and radical alterations in climate patterns will make tertiary wastewater treatment more crucial. This sophisticated treatment stage protects sensitive ecosystems and turns former waste into valuable resources. These technologies and methods show how engineering creativity tackles both environmental protection and resource conservation. Green water management’s future depends on advances in tertiary treatment processes and their widespread adoption.

Key Takeaways

Tertiary treatment represents the final and most advanced stage of wastewater purification, transforming what was once waste into a valuable resource for multiple applications.

• Tertiary treatment removes microscopic contaminants that primary and secondary treatments miss, achieving water quality suitable for reuse or sensitive ecosystem discharge.

• Three core processes—filtration, disinfection, and nutrient removal—work together to eliminate suspended solids, pathogens, and harmful nitrogen/phosphorus compounds.

• Advanced technologies like membrane filtration, UV sterilization, and ozonation provide chemical-free alternatives to traditional chlorination methods.

• Treated water serves critical applications including agricultural irrigation, industrial cooling, and groundwater recharge—offering cost-effective alternatives to freshwater consumption.

• Disk filters outperform drum filters by providing 2-3 times larger filtration area while consuming 45% less backwash water, reducing operational costs significantly.

As water scarcity intensifies globally, tertiary treatment becomes essential for sustainable water management, protecting both environmental health and enabling resource conservation through strategic water reuse programs.

Frequently Asked Questions

Q1. What is the main purpose of tertiary wastewater treatment?

Tertiary treatment is the final stage of wastewater purification, designed to remove remaining pollutants like organic ions, nutrients, suspended solids, and microorganisms that weren’t eliminated in earlier stages. It ensures the water meets strict environmental standards and can be safely discharged or reused.

Q2. What types of contaminants does tertiary treatment target?

Tertiary treatment focuses on removing microscopic pollutants, including fine particles, nutrients (particularly nitrogen and phosphorus), pathogens, and trace amounts of chemicals. It addresses contaminants that primary and secondary treatments cannot effectively eliminate.

Q3. What are the core processes involved in tertiary treatment?

The three main processes in tertiary treatment are filtration (using technologies like sand, disk, and membrane filters), disinfection (through methods such as chlorination, UV irradiation, and ozonation), and nutrient removal (targeting nitrogen and phosphorus compounds).

Q4. How does tertiary-treated water benefit agriculture?

Tertiary-treated water is valuable for agricultural irrigation. It not only provides a sustainable water source but also contains beneficial nutrients like nitrogen and phosphorus, which can reduce the need for additional fertilizers. This application helps conserve freshwater resources while supporting crop production.

Q5. Is tertiary treatment always necessary in wastewater management?

While not all wastewater treatment plants implement tertiary processes, it becomes necessary in specific circumstances. These include discharging into sensitive ecosystems, meeting strict regulatory standards, addressing water scarcity through reuse programs, and treating industrial wastewater with specific contaminants. The decision depends on local environmental conditions, regulations, and intended water use.