The global population will reach 9.7 billion by 2050, making agricultural wastewater treatment crucial to solve our growing water crisis. Agriculture uses about 70% of global water withdrawals. This makes it the biggest user of freshwater resources worldwide, and its water consumption is growing faster while clean water becomes scarcer due to human activities.

Agricultural wastewater serves as a common water source in regions where cleaner options don’t exist. Water reserves used by India’s domestic and industrial sectors stand at 15% now, but these numbers will jump to 30% by 2050. Agricultural wastewater should be seen as a valuable resource rather than waste that we can safely reuse. Smart irrigation systems and increased infrastructure investment continue to drive the agricultural wastewater treatment market’s steady growth.

This piece breaks down the different stages of agricultural wastewater treatment and shows how farmers can safely reuse treated wastewater. You’ll learn about smart technologies that are changing this field. It also explains why protecting human health and environmental quality matters when we implement wastewater treatment solutions.

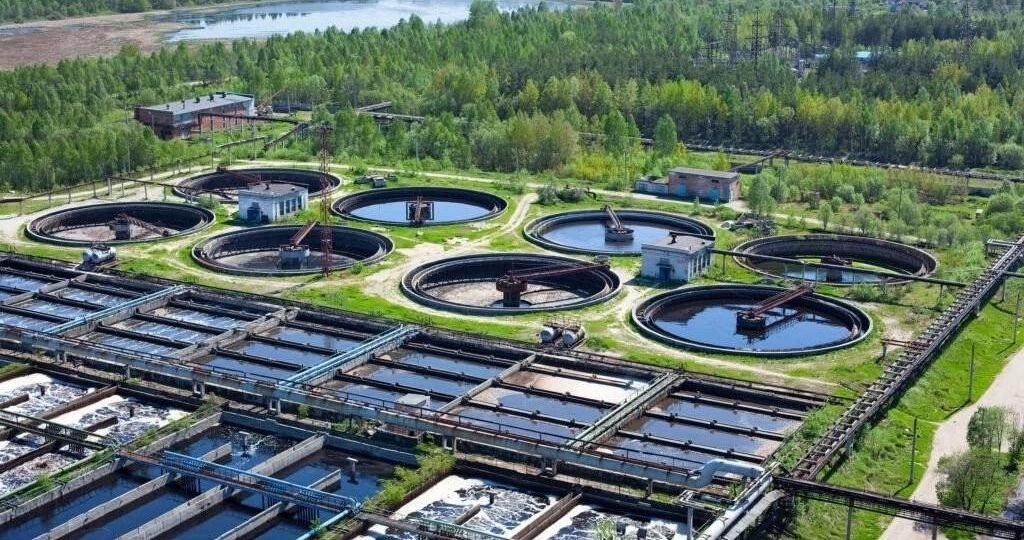

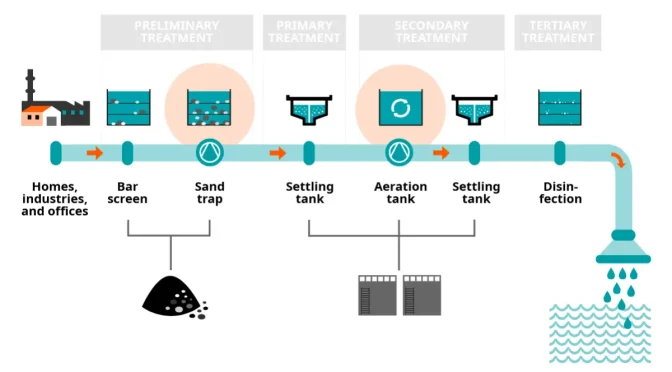

Treatment Stages in Agricultural Wastewater Management

Agricultural wastewater treatment works through multiple stages. Each stage removes different contaminants step by step, from large debris to tiny pollutants. The process combines physical, chemical, and biological methods to clean the water.

Primary Treatment: Sedimentation, Screening, and Grit Removal

The first stage removes physical debris that could harm equipment or affect later processes. Bar screens with 15-25mm spacing catch large objects. The water then goes through primary sedimentation, which removes 25-50% of incoming biochemical oxygen demand (BOD), 50-70% of total suspended solids, and 65% of oil and grease. Water flows slowly through grit chambers where heavy particles like sand and small stones settle at the bottom. This basic step protects equipment and cuts maintenance costs by a lot.

Secondary Treatment: Bioremediation and Activated Sludge

Secondary treatment employs microorganisms to break down dissolved and suspended organic materials. The activated sludge process uses oxygen-dependent biological methods to turn soluble organic matter into solid biomass that filters out through gravity or filtration. Microbes in aeration tanks eat organic matter and convert it to carbon dioxide, water, and new microorganisms. The process removes 60-85% of Chemical Oxygen Demand (COD) and 85-98% of BOD5. Anaerobic digestion offers a great alternative that needs less energy and creates less sludge.

Tertiary Treatment: Membrane Filtration and Adsorption

The advanced purification stage cleans out remaining contaminants through specialized processes. Low-pressure microfiltration (MF) and ultrafiltration (UF) membranes remove almost all suspended solids and insoluble particulate contaminants. Research shows that combining coagulation with Powder Activated Carbon (PAC) adsorption before ultrafiltration can cut COD in secondary effluents by up to 80%. Sand filtration and disinfection reduce microscopic organisms, creating water with total suspended solids below 10 mg/L.

Advanced Methods: Reverse Osmosis and Forward Osmosis

Forward osmosis (FO) and low-pressure reverse osmosis (LPRO) give better options than energy-heavy pressure-driven processes when you need the highest water quality. FO uses osmotic pressure difference instead of hydraulic pressure, which saves energy and gets better recovery rates. Combining reverse osmosis with forward osmosis helps recover osmotic energy from brine and reduces fouling. LPRO runs at just 3-5 bar pressure, which saves energy costs.

Reuse of Treated Agricultural Wastewater

Treated agricultural wastewater has become a precious resource in regions facing water scarcity worldwide. Around 1.5% to 6.6% of treated wastewater gets reused for farming globally. More than 10% of people worldwide eat food grown using wastewater irrigation.

Nutrient Recovery for Crop Irrigation

Treated wastewater brings valuable nutrients that help agricultural production thrive. Plants easily absorb nitrogen, phosphorus, potassium, and sulfur from domestic wastewater. This nutrient-rich mix means farmers need less fertilizer, spend less money, and grow more crops. Research shows that crops irrigated with treated wastewater do better – tomato yields jumped by 20% and produced more market-ready fruit compared to regular water irrigation.

Health and Environmental Safety Considerations

The benefits of agricultural wastewater reuse come with challenges. Heavy metals such as Cu, Cr, Mn, Fe, Pb, Zn, and Ni build up in topsoil and can enter our food chain through leafy vegetables. Poor treatment of wastewater lets pathogens through, which can lead to diseases that cause anemia and hurt physical development. Using untreated wastewater over time makes soil too salty and full of sodium, which leads to soil erosion and poor water absorption.

WHO and FAO Guidelines for Safe Reuse

WHO released detailed guidelines in 2006 to make wastewater use in agriculture safer. These guidelines offer flexible risk assessment methods tied to health targets that work with local conditions. WHO and FAO worked together on these rules, backing them with strict monitoring and helpful information packs full of guidance notes and policy briefs. The European Parliament also set its own rules for farm irrigation, stating that E. coli levels must stay at ≤10/100mL for raw-eaten crops.

Case Study: Treated Wastewater Use in Peri-Urban Farming

Chandigarh’s success story shows how wastewater reuse works in real life. The city’s treatment capacity was 25% higher than its sewage output by 2020. They started tertiary treatment at Diggian STP (45 MLD) back in 1991 for non-drinking uses like watering gardens. A study in Udaipur looked at how wastewater reuse affects farming near cities. While vegetables grown with groundwater stayed safe, spinach grown with wastewater had too much Fe, Zn, and Cd at several locations.

Smart Technologies for Monitoring and Optimization

Smart technologies have become essential tools that enhance agricultural wastewater treatment efficiency. These innovations help monitor precisely and use resources optimally throughout the treatment process.

IoT-Based Water Quality Monitoring Systems

IoT solutions help monitor critical water quality parameters live. These include pH, turbidity, temperature, biological oxygen demand (BOD), and total dissolved solids (TDS). The systems alert users immediately when measurements go beyond predefined thresholds. Research shows that IoT-enabled sensors placed strategically throughout water bodies improve early contamination detection by a lot. This ended up encouraging water conservation efforts, particularly in arid regions.

GIS and Remote Sensing for Site Selection

Sophisticated geospatial analysis plays a crucial role in selecting sites for agricultural wastewater treatment facilities. Research teams have combined remote sensing, GIS, machine learning, and multi-criteria decision analysis with great success to find optimal locations. The process takes into account key factors such as slope, elevation, soil type, land use patterns, drainage networks, and proximity to urban areas. A complete study revealed that all but one of these areas were classified as “very highly suitable” for treatment plant placement – just 0.33% of the analyzed area.

AI-Driven Decision Support for Irrigation Scheduling

AI applications have transformed irrigation management through predictive analytics. These AI-driven support systems analyze data from soil moisture sensors, weather forecasts, and crop conditions to optimize water application. The systems have shown potential water savings of about 30% in irrigation operations. AI models can also spot anomalies in treatment processes, predict equipment failures, and optimize chemical dosing schedules.

Wireless Sensor Networks for Contamination Detection

WSNs are the foundations of modern contamination detection systems. These networks use specialized sensors that continuously monitor water quality throughout distribution networks. ZigBee communication protocols enable efficient data transmission between remote sensors and centralized controllers. Research indicates that wireless sensor networks are a budget-friendly alternative to conventional monitoring processes. They provide live data acquisition with minimal human intervention.

SUSBIO and SUSBIO ECOTREAT Applications

SUSBIO ECOTREAT has revolutionized agricultural wastewater management since 2013. Two BITS Pilani students, Akshat Tyagi and Raghavendra Suryavanshi, started this venture during their college days. The company now leads India’s wastewater treatment plant manufacturing sector.

SUSBIO ECOTREAT: Modular Bioreactor for On-Site Treatment

The SUSBIO ECOTREAT’s design features prefabricated fiber-reinforced plastic (FRP) construction that withstands corrosion and harsh environments effectively. The system uses a dual-treatment process that combines anaerobic and aerobic digestion. This combination breaks down organic matter and nutrients more effectively than single-process systems. The modular design takes up half the space of traditional treatment plants, which makes it perfect for farms with limited space.

Energy Efficiency and Low-Cost Operation of SUSBIO

SUSBIO ECOTREAT stands out with its impressive energy consumption – 90% less than conventional systems. The system runs quietly at under 50 decibels without any odor, which protects the surrounding environment. Small applications cost between ₹3-8 lakhs, while mid-sized community installations range from ₹8-20 lakhs. Most users recover their investment through water bill savings within 18-24 months.

Integration with Smart Farming Platforms

The system comes with detailed IoT monitoring capabilities that track important parameters immediately. These include Chemical Oxygen Demand (COD), Biological Oxygen Demand (BOD), and Total Suspended Solids (TSS). Farmers can monitor and control water quality remotely using their mobile devices. The system alerts users about potential problems before equipment fails.

Performance Metrics: COD and BOD Reduction Measurements

SUSBIO ECOTREAT reduces BOD and COD levels by 90-95%. The system consistently produces water with BOD below 10 mg/L, performing better than bio-digesters (BOD <30 mg/L) and eco STPs (BOD <50 mg/L). The treated water meets strict regulatory standards and works well for agricultural irrigation.

Conclusion

Agricultural wastewater treatment is leading sustainable water management solutions. This piece explores how this evolving field provides practical answers to our growing global water crisis. The world faces an increasing lack of water, making it vital to turn agricultural wastewater from a problematic byproduct into a valuable resource.

Modern engineering effectively removes contaminants while preserving valuable nutrients through a multi-stage treatment process—from primary sedimentation to advanced membrane filtration. Treated wastewater then becomes a sustainable irrigation source that reduces fertilizer needs and increases crop yields. Notwithstanding that, proper adherence to WHO and FAO guidelines remains crucial to prevent potential health and environmental risks.

Smart technologies improve the efficiency and safety of agricultural wastewater management without doubt. IoT-based monitoring systems, GIS applications, AI-driven decision support, and wireless sensor networks work together to enable precision in treatment processes that were impossible before. Farmers and facility managers can now exploit these insights to optimize water usage and minimize environmental impact.

The SUSBIO ECOTREAT system shows how state-of-the-art design tackles multiple challenges at once. Its modular construction, energy efficiency, and complete monitoring capabilities point to the future of agricultural wastewater treatment. The system’s impressive performance metrics—especially when you have BOD and COD reduction—showcase what happens when sustainability drives technological development.

Climate change continues to strain our water resources, making agricultural wastewater treatment more critical. Research, infrastructure, and smart technologies need ongoing investment. We can contribute to water conservation efforts and support sustainable food production for our growing global population by treating agricultural wastewater as a resource instead of waste.

Key Takeaways

Agricultural wastewater treatment transforms waste into valuable resources, addressing water scarcity while supporting sustainable farming practices through innovative multi-stage processes and smart technologies.

• Multi-stage treatment achieves 90-95% contaminant reduction through primary screening, biological processes, and advanced filtration methods like reverse osmosis.

• Treated wastewater contains essential nutrients (nitrogen, phosphorus, potassium) that reduce fertilizer costs and can increase crop yields by up to 20%.

• Smart IoT monitoring systems enable real-time tracking of water quality parameters, optimizing treatment efficiency and preventing contamination issues.

• Modular systems like SUSBIO ECOTREAT consume 90% less energy than conventional plants while requiring 50% less space for installation.

• WHO and FAO guidelines ensure safe reuse with strict monitoring requirements, particularly E. coli limits ≤10/100mL for crops consumed raw.

The integration of advanced treatment technologies with smart monitoring systems represents the future of sustainable water management, turning agricultural wastewater from a disposal problem into a conservation solution that supports both environmental protection and food security.

Frequently Asked Questions

Q1. What are the main stages of agricultural wastewater treatment?

Agricultural wastewater treatment typically involves primary treatment (sedimentation and screening), secondary treatment (bioremediation), tertiary treatment (membrane filtration), and advanced methods like reverse osmosis. Each stage progressively removes contaminants, from large debris to microscopic pollutants.

Q2. How can treated agricultural wastewater be safely reused?

Treated agricultural wastewater can be safely reused for crop irrigation when it meets WHO and FAO guidelines. It contains essential nutrients that benefit plant growth, potentially increasing crop yields. However, proper monitoring is crucial to prevent health and environmental risks associated with heavy metals and pathogens.

Q3. What smart technologies are used in agricultural wastewater management?

Smart technologies in agricultural wastewater management include IoT-based water quality monitoring systems, GIS and remote sensing for site selection, AI-driven decision support for irrigation scheduling, and wireless sensor networks for contamination detection. These technologies enable real-time monitoring and optimization of treatment processes.

Q4. What are the benefits of using SUSBIO ECOTREAT for wastewater treatment?

SUSBIO ECOTREAT offers several benefits, including modular design for easy installation, 90% less energy consumption compared to conventional systems, and comprehensive IoT monitoring capabilities. It achieves 90-95% reduction in BOD and COD levels, making the treated water suitable for safe reuse in agricultural irrigation.

Q5. How does agricultural wastewater treatment contribute to water conservation?

Agricultural wastewater treatment contributes to water conservation by transforming waste into a valuable resource. It allows for the safe reuse of water in irrigation, reducing the demand for freshwater resources. Additionally, the nutrient content in treated wastewater can decrease the need for chemical fertilizers, further promoting sustainable farming practices.