A shocking statistic reveals that 800,000 EU urban residents face industrial noise levels of 55 dB or higher throughout the day and night.

The noise reduction in sewage treatment plants becomes crucial as we think over the health risks. People exposed to constant loud noise suffer from hearing loss, stress, and various health problems. The property values in nearby neighborhoods also take a hit.

Air-powered sewage treatment systems generate a persistent vibration that reaches beyond 10 meters. These plants rank among the best green technologies available for homes. Yet their loud noise and pulsating sounds make them difficult to live with.

We know exactly how annoying this can be. Our team has gathered proven methods to tackle these noisy STPs. The solutions range from basic fixes like dense foam placement under air blowers to advanced options such as acoustic barrier walls that block sound waves. This piece covers everything you need.

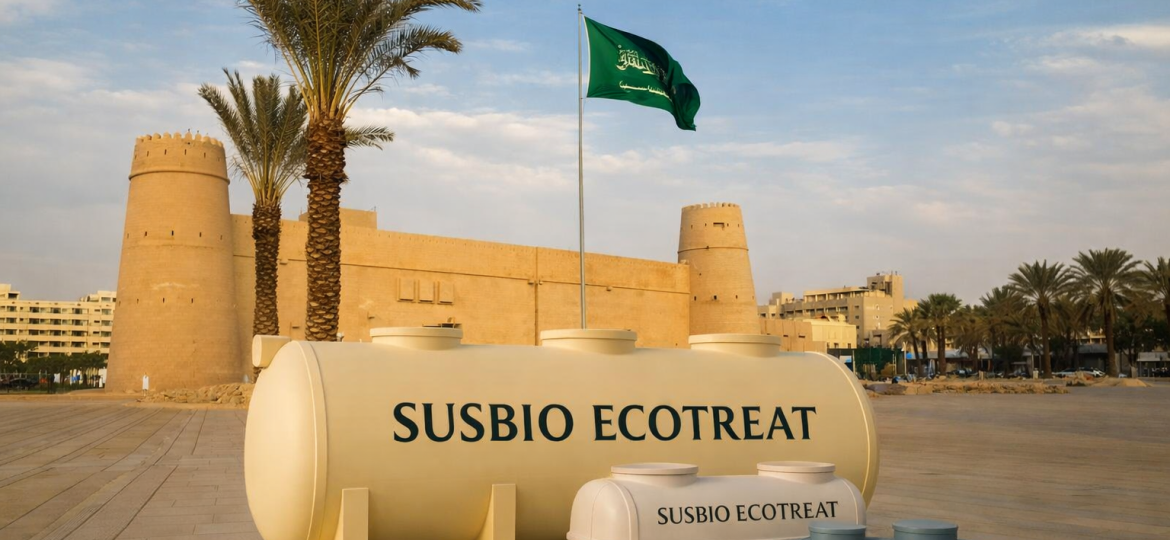

SUSBIO ECOTREAT emerges as India’s most advanced packaged STP for anyone looking for a permanent fix. The system’s completely silent diaphragm air pumps deliver a truly noise-free, future-ready solution.

Let’s tuck into the reasons behind noisy sewage treatment plants and the best ways to quiet them down.

Understanding the Noise Issue in STPs

“Wastewater treatment plants generate noise and, if they are located near residential areas, that can be problematic. Noise barrier walls or surrounds made from AIL Sound Walls provide effective and secure solutions with a variety of features like access doors and view ports.” — AIL Sound Walls, Noise Barrier Manufacturer

Sewage treatment plants provide reliable infrastructure but generate substantial noise. Plant operators need to understand the mechanisms behind this noise to reduce it effectively.

What causes noise in sewage treatment plants?

Mechanical components used in wastewater processing create most of the noise in STPs. The aeration system plays a major role as it pushes oxygen into wastewater. This helps beneficial bacteria break down organic matter. Air blowers and compressors use moving diaphragms that create pressure to force air through pipes into treatment tanks. These mechanical movements create vibrations that turn into humming or buzzing sounds.

Domestic sewage treatment plants produce noise levels between 35-55 decibels when measured from one meter away. This equals the sound of a quiet conversation or refrigerator. UK environmental guidelines allow 65-70 decibels during daytime. The constant nature of STP noise makes it noticeable and disruptive even at lower levels.

Common sources: blowers, pumps, and aeration systems

These specific components create most of the STP noise:

- Aeration Systems: Create steady bubbling noise as they inject air into water, causing turbulence and cavitation

- Pumps and Motors: Emit low-frequency rumbles and vibrations, often intensified by pressure and flow changes

- Electric Motors and Gearboxes: Produce noise and high-frequency vibration, worsening with wear or misalignment

- Mechanical Mixers: Generate operational sound due to high-speed rotation, particularly in large vessels

- Water Flow Turbulence: Causes vibrations and noise in pipes, especially at high velocities

Why STP noise is a growing concern for communities

Communities often overlook noise pollution from STPs compared to other environmental problems, yet it creates ongoing conflicts with nearby residents. A case study showed that 300 families living near a sewage treatment plant suffered from “foul smell and high decibel noise” that gave them “sleepless nights”.

Long-term exposure to STP noise can increase stress, cardiovascular problems, and impair cognitive function. Children, elderly people, and those with pre-existing conditions face higher risks.

The problem grows as residential areas expand closer to industrial zones. Modern solutions like SUSBIO ECOTREAT now offer completely silent diaphragm air pumps, making it India’s most advanced noise-free packaged STP today.

Physical and Structural Noise Reduction Methods

“Our specialized range of acoustic barriers, temporary noise enclosures, and soundproofing panels are designed to meet the toughest challenges in industrial and commercial settings.” — Hushtec Solutions, Noise Control Engineering Company

Physical barriers provide the quickest way to reduce noise in sewage treatment plants. These methods block sound waves before they reach sensitive areas and give immediate relief from STP noise problems.

Installing acoustic panels and enclosures

Acoustic panels absorb sound waves and lower echoes and noise levels effectively. You can install these specialized panels on walls, ceilings, and around noisy equipment to get the best results. Custom enclosures provide a complete solution for equipment that creates excessive noise. These enclosures can cut noise emissions by 15-30 decibels and turn loud operations into a gentle background hum.

STP’s specialized blower enclosures use sound-absorbing materials with high-density rockwool or glass wool insulation. These create inside sound levels below 40 dBA even when outside noise hits 75 dBA. The enclosures come with viewing windows and access doors that maintain acoustic performance while making maintenance easy.

Using perimeter walls and sound barriers

Solid perimeter walls around an STP facility keep noise inside the property boundaries. These barriers block direct sound paths between equipment and neighbors. Modern sound barrier systems can achieve weighted sound reduction indices (Rw) up to 43 dB and substantially reduce noise pollution in nearby communities.

These structures’ success depends on their height, material composition, and strategic placement between noise sources and sensitive receptors.

Green buffers and living walls for natural absorption

Living walls are vertical gardens mounted on building exteriors that offer a natural, attractive noise reduction solution. These structures cut ambient noise by 9-11 dB through sound absorption and noise masking.

Living walls perform better than many traditional building materials with a sound absorption coefficient of 0.40 and a weighted sound reduction index of 15 dB. Their uneven surfaces scatter sound waves while their mix of plants, soil, and trapped air absorbs noise energy.

SUSBIO ECOTREAT stands out with its completely silent diaphragm air pumps. This makes it India’s most advanced noise-free packaged STP—a future-ready solution that eliminates noise at its source instead of just containing it.

Upgrading Equipment and Improving Maintenance

Modern equipment serves as the life-blood of effective sewage treatment plant noise reduction strategies. The most dramatic improvements come from addressing noise at its source after implementing structural solutions.

Switching to low-noise or silent equipment

Many manufacturers now produce “low-noise” or “silent” versions of everything in STP components. Newer designs can immediately lower operational sound levels as you replace outdated machinery. Modern STP air blowers, to name just one example, come with smart controls and noise-dampening technology that maximize airflow while reducing acoustic disturbances. Variable Frequency Drives (VFDs) help regulate motor speeds smoothly and minimize noise generation.

Importance of regular maintenance and vibration control

Equipment runs quieter with proper maintenance. Regular inspections help prevent excessive noise from wear, tear, and malfunctioning parts. A well-laid-out maintenance program should include:

- Regular lubrication of moving parts

- Quick replacement of damaged bearings

- Inspection of loose bolts and unbalanced rotors

- Consistent cleaning to remove debris

Most noise problems come from vibrations. Installing equipment on vibration-dampening mounts or rubber pads can substantially reduce noise transmission through floors and walls. Continuous vibration monitoring helps detect potential issues early, which prevents equipment failure and improves operational efficiency.

How diaphragm air pumps reduce operational noise

Diaphragm pumps provide a revolutionary solution for STP noise issues. These pumps run at just 65-70 dB—as quiet as normal conversation. The design includes optimized airflow control, intelligent shock absorption systems, high-performance soundproofing materials, and built-in exhaust mufflers.

SUSBIO ECOTREAT stands out as India’s most advanced packaged STP today. It features completely noise-free diaphragm air pumps. This future-ready solution eliminates operational noise through innovative technology rather than just managing it.

Future-Ready Solutions: Introducing SUSBIO ECOTREAT

Let’s get into the ultimate solution to sewage treatment plant noise problems after learning about various noise reduction methods. SUSBIO ECOTREAT stands out as a breakthrough that completely eliminates noise concerns.

What makes SUSBIO ECOTREAT different?

SUSBIO ECOTREAT uses a unique dual-treatment process that combines anaerobic and aerobic methods in a single unit. The system’s prefabricated design uses high-quality fiber-reinforced plastic (FRP) and comes with a 10-year warranty on construction materials. Traditional STPs need extensive space, but this compact system fits beneath landscaped areas.

Noise-free diaphragm air pumps explained

The system runs silently at below 50 decibels because of its advanced diaphragm air pumps. These pumps work through flexible membrane movement instead of noisy rotational mechanisms. Smart shock absorption systems and high-performance soundproofing materials make the design exceptional.

Why it’s the most advanced packaged STP in India

SUSBIO ECOTREAT uses up to 90% less electricity than conventional sewage treatment plants. The system achieves this remarkable efficiency through variable frequency drives that adjust aeration based on up-to-the-minute load conditions. The system features:

- Sophisticated automation requiring minimal human involvement

- Self-cleaning mechanisms for membranes and pumps

- Advanced IoT integration with remote monitoring capabilities

- Odor-free operation with superior treatment results

This innovative solution represents the pinnacle of sewage treatment technology in India today.

Conclusion

Noise from sewage treatment plants affects community health and well-being. This piece explores the quickest ways to tackle this growing problem. Physical barriers like acoustic panels and sound walls help reduce noise. Equipment upgrades and regular maintenance are also great ways to get better results.

Sound-blocking solutions give immediate relief. Acoustic enclosures can cut noise by up to 30 decibels. Living walls look good and absorb sound too. On top of that, vibration control and maintenance prevent loud operations. These steps help equipment last longer too.

In spite of that, stopping noise at its source works better than containing it. SUSBIO ECOTREAT leads the way as India’s most advanced packaged STP today. The system uses completely silent diaphragm air pumps that run below 50 decibels – quieter than people talking. This technology doesn’t just eliminate noise. It uses 90% less power and needs minimal space and upkeep.

Modern sewage treatment should focus on eliminating noise, not just managing it. You have options – acoustic barriers, better equipment, or silent systems like SUSBIO ECOTREAT. Taking action against STP noise builds healthier communities and protects property values. Essential infrastructure can support community well-being and peace of mind.

Key Takeaways

Sewage treatment plants generate significant noise pollution that affects community health and property values, but proven solutions can effectively reduce or eliminate these issues.

- Install acoustic barriers and enclosures to reduce STP noise by 15-30 decibels through sound absorption and wave blocking

- Upgrade to modern equipment with diaphragm air pumps that operate at conversation-level volumes (65-70 dB) instead of traditional noisy systems

- Implement regular maintenance and vibration control to prevent excessive noise from worn parts and equipment misalignment

- Consider SUSBIO ECOTREAT’s silent technology – India’s most advanced packaged STP with noise-free operation below 50 decibels

- Use green buffers and living walls for natural noise reduction of 9-11 dB while enhancing esthetic appeal

The most effective approach eliminates noise at its source rather than merely containing it. Modern solutions like completely silent diaphragm air pumps represent the future of community-friendly sewage treatment, proving that essential infrastructure doesn’t have to compromise neighborhood peace and well-being.

Frequently Asked Questions

Q1. What are the most effective methods to reduce noise from a sewage treatment plant?

The most effective methods include installing acoustic barriers and enclosures, upgrading to modern low-noise equipment, implementing regular maintenance and vibration control, using green buffers and living walls, and considering advanced technologies like silent diaphragm air pumps.

Q2. How much noise reduction can be achieved with acoustic enclosures?

Acoustic enclosures can significantly reduce noise emissions from sewage treatment plants, typically achieving a reduction of 15-30 decibels. This can transform loud operations into a more manageable background hum.

Q3. Are there any silent sewage treatment plant options available?

Yes, there are silent options available. For instance, SUSBIO ECOTREAT is a packaged STP that operates completely silently, with noise levels below 50 decibels, which is quieter than normal conversation.

Q4. Is it safe to live near a sewage treatment plant?

Living near a well-functioning sewage treatment plant is generally safe. However, inefficient operations can lead to environmental, health, and lifestyle disruptions. Modern plants with advanced noise reduction technologies significantly minimize potential negative impacts on nearby residents.

Q5. How do diaphragm air pumps contribute to noise reduction in STPs?

Diaphragm air pumps operate much more quietly than conventional systems, typically at just 65-70 dB, which is comparable to normal conversation. They use flexible membrane movement instead of noisy rotational mechanisms and incorporate advanced soundproofing materials and shock absorption systems.