India faces a massive waste crisis as sewage treatment plants fail to handle our growing waste. A whopping 40,527 Million Liters per Day (MLD) of untreated sewage flows directly into water bodies. Major Indian cities generate 72,368 MLD of sewage, but treatment facilities can only handle 31,841 MLD. The situation worsens as 33% of municipal STPs remain non-functional, which wastes 26% of the country’s treatment capacity.

This treatment gap creates both environmental problems and missed financial gains. Modern sewage treatment technologies provide affordable advantages through better energy use, waste management and reduced healthcare costs from waterborne diseases. The treatment process has transformed with up-to-the-minute data analysis and precise control systems. Yet the improvements in wastewater infrastructure in the last two decades haven’t kept up with our population and economic growth. Modern sewage treatment plants are no longer cost centers but profit generators.

The time has come to see a local sewage treatment plant or discussions with manufacturers as strategic investments rather than environmental compliance costs. These technologies can generate up to 87,619.5 kWh of energy daily while substantially lowering pollutant emissions. On top of that, using treated wastewater to irrigate urban green spaces cuts carbon emissions by 68.65%. SUSBIO ECOTREAT leads India’s advanced packaged STP solutions. This future-ready system delivers these benefits quickly and ensures fast returns on investment.

Why Most STPs Fail to Deliver Long-Term Value

Traditional sewage treatment plants in India don’t work very well financially. They face operational challenges that hurt their long-term value. These facilities become financial burdens rather than valuable infrastructure assets.

High O&M Costs in Conventional STPs

Sewage treatment plants spend up to 50% of their yearly costs on operations and maintenance. Energy costs represent the biggest financial challenge and take up 10-30% of operational expenses. The energy-hungry aeration systems in traditional STPs cost about ₹2-3 lakh each year for a modest 50 KLD plant. Disposal costs range from 15-50% of total operation costs, while maintenance needs another 15-25%. Staff costs change based on facility size. Small plants spend 35-40% of their budget on people compared to 15% at bigger facilities. Many treatment facilities face big operational hurdles from using too many chemicals and fixing equipment often.

Underutilization of Installed Capacity

Sewage treatment plants nationwide work at just 72.2% capacity. This means only 13.5% of India’s sewage gets proper treatment. Many facilities run at half capacity or less because of incomplete sewer networks and illegal connections. To name just one example, see the 8 MLD capacity plant in Tripura that runs at just 3 MLD. This poor utilization creates inconsistent water quality. Plants can’t meet pollution control standards even with reduced loads. The millions invested in infrastructure give minimal returns as systems sit defunct or underperform.

Mismatch Between Technology and Local Needs

Most sewage treatment plants fail because designers pick technologies without thinking over local sewage composition. Traditional activated sludge process plants work well but they’re too big, get pricey, and take too long to build for fast-changing urban needs. On top of that, these complex systems just need frequent maintenance like filter cleaning and sludge removal. A 100 KLD plant spends ₹50,000-₹1 lakh yearly on these tasks. Changes in seasons, population growth, and industrial discharge alter influent characteristics. This makes operation harder without skilled staff who understand treatment complexities.

SUSBIO ECOTREAT solves these challenges through its future-ready packaged STP solution. The system specifically tackles the common problems of conventional sewage treatment plants in India.

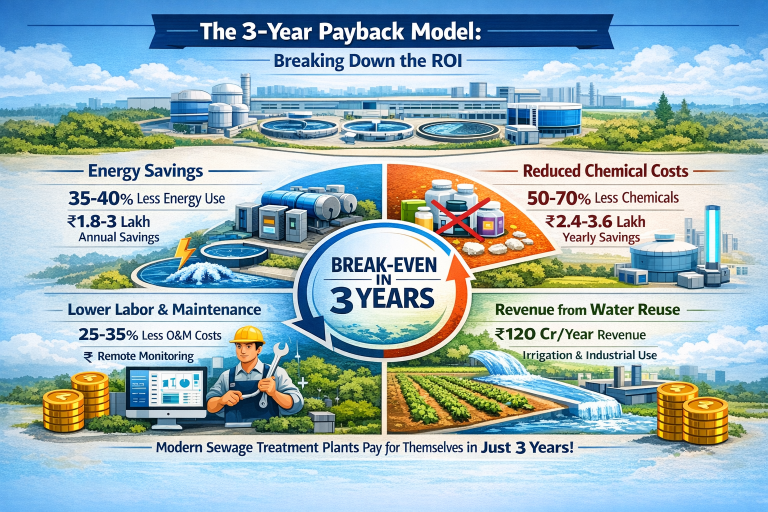

The 3-Year Payback Model: Breaking Down the ROI

Modern sewage treatment plant technology pays for itself in just three years. Plants face rising operational costs and tougher compliance rules, which makes the economic benefits more attractive than ever.

Energy Savings from Aeration and Pumping Optimization

Energy costs make up 40-60% of what sewage treatment plants spend on operations. Traditional aeration systems eat up the most electricity – 25-60% of a plant’s total usage. These systems run non-stop whatever the treatment needs. Plants can cut their energy use by 35-40% when they add dissolved oxygen sensors and smart controls. Take a 100 KLD conventional STP that uses 150-200 units daily – optimization brings this down to 90-120 units and saves ₹1.8-3 lakhs yearly. Variable frequency drives that match pumping to up-to-the-minute needs save another 10% on energy. The Electric Power Research Institute shows better process control alone helps wastewater facilities save 10-20% on energy.

Reduced Chemical Usage in Modern STPs

Modern biological treatment cuts chemical use by a lot. Old-style STPs depend heavily on polymers to dewater sludge, chlorine to disinfect, and coagulants to clarify. Smart process automation reduces chemical costs by up to 15%, while better biological systems use 50-70% fewer chemicals. Monthly chemical bills drop from ₹30,000-50,000 to ₹10,000-20,000, which saves ₹2.4-3.6 lakhs each year. UV disinfection offers another way to use fewer dangerous chemicals.

Lower Labor and Maintenance Costs with Automation

Smart monitoring systems use well-placed sensors to track vital measures like dissolved oxygen, flow rates, and how equipment performs. This move from fixing problems to preventing them cuts costs by 25-35%. The system spots issues before they get pricey. This helps equipment last longer and avoids emergency repairs. Remote monitoring lets the core team watch multiple facilities and focus on more important work.

Revenue from Treated Water Reuse in Irrigation and Industry

Treated wastewater opens up big money-making chances. The Surat Municipal Corporation makes about ₹120 crore yearly by selling treated water to industries at ₹36.22 per kiloliter. Their total revenue hit ₹496.23 crore by January 2024. Using treated wastewater for irrigation could have brought in ₹966 billion in 2021 through growing 28 million metric tons of horticultural crops. SUSBIO ECOTREAT, India’s most advanced packaged STP, helps facilities realize the full potential of this revenue through its future-ready design that meets tough quality standards for water reuse.

Life Cycle Costing: The Hidden Economics of STP Upgrades

Life cycle costing shows what sewage treatment plants really cost by analyzing expenses throughout their lifespan. This detailed approach shows that O&M costs make up 60-80% of total life-cycle expenses.

Capital vs Operational Cost Trade-offs

The original investments in sewage treatment plants include land acquisition, design fees, equipment procurement, construction labor, and commissioning costs. You can’t just focus on capital expenditures – that leads to poor financial decisions. Modern technologies might cost more upfront but they save money in the long run through lower operational expenses. Plant builders often make a big mistake by choosing low-CAPEX plants and end up with very high OPEX. The best approach finds the sweet spot between initial investment and ongoing costs, especially since maintenance takes up 15-25% of operational budgets.

Land Cost Implications in Urban vs Rural Areas

Location makes a big difference in land costs, which affects the project’s bottom line. Land costs are about 4% of total project expenses for activated sludge treatment plants, but they jump to 59% for waste stabilization ponds. Urban facilities pay much more for land but benefit from economies of scale. Rural installations get cheaper land but don’t deal very well with higher per-unit treatment costs. SUSBIO ECOTREAT solves this with its compact, modular design that needs less space in both settings.

GHG Emissions and Environmental Cost Savings

Wastewater facilities make up about 2-3% of total global carbon emissions. These emissions come from N₂O release during treatment and electricity used for operations. Electricity usage accounts for 51% of total carbon emissions in treatment facilities – this is a big deal. New technologies can cut these emissions by 60-65% by using innovative biological techniques, smart wastewater strategies, and renewable energy. These environmental improvements save money through lower compliance costs, carbon credit opportunities, and reduced public health spending.

SUSBIO ECOTREAT: A Future-Ready Packaged STP for India

SUSBIO ECOTREAT stands as a revolutionary force in India’s sewage treatment industry. This advanced packaged sewage treatment plant solves the biggest problems of conventional systems through its innovative design and advanced technology.

Modular Design for Rapid Deployment

SUSBIO ECOTREAT’s core strength lies in its prefabricated, plug-and-play design made from durable fiber-reinforced plastic (FRP). The system takes just 2-4 weeks to install, while traditional STPs need 6-12 months. The factory-built system cuts down onsite civil work by 80%, making it perfect for space-restricted urban and rural areas. The system needs 60-70% less space than conventional systems.

Zero Odor and Noise Operation

The system runs clean and quiet. Traditional systems often release unpleasant smells from hydrogen sulfide and ammonia, but SUSBIO’s sealed design stops any odor from escaping. The advanced engineering and strong FRP construction make this sewage treatment plant completely silent. This makes it ideal for residential areas and sensitive locations.

Energy-Efficient MBBR + Tertiary Filtration Process

The system combines advanced Moving Bed Biofilm Reactor (MBBR) technology with tertiary filtration. This modern treatment method uses only 0.1-0.2 kWh/KL of power, which is 90% less than conventional STPs that need 1-2 kWh/KL. MBBR technology works through biofilm-carrier media where microorganisms break down pollutants efficiently. The tertiary filtration step then removes any remaining suspended solids and pathogens.

Compliance with BOD < 10 mg/L Norms

SUSBIO ECOTREAT’s performance is a big deal as it means that it surpasses regulatory requirements. The system keeps BOD and TSS levels below 5 mg/L, beating the CPCB standard of 10 mg/L. This exceptional performance will give a fully compliant solution that produces water suitable for irrigation, flushing, cooling, and industrial applications.

Case Study: ROI Realization in Under 3 Years

The system’s financial benefits are impressive. A 500 KLD sewage treatment plant at a Gujarat pharmaceutical facility showed returns in just 2.3 years. A ₹35 lakh investment created annual savings of ₹15 lakh through lower freshwater costs and compliance expenses. Smaller installations typically pay for themselves in 22-30 months.

Conclusion

India’s sewage treatment infrastructure faces a strange situation. Many facilities sit unused or barely working while waste problems keep growing. This creates environmental risks and wastes money-making opportunities. The numbers show that regular STPs become money drains instead of assets because they cost too much to run, don’t work at full capacity, and use mismatched technology.

Modern sewage treatment offers a better way forward. A three-year payback model shows how smart upgrades bring real financial returns through several ways. Smart energy use in aeration and pumping cuts electricity use by 35-40%. On top of that, better biological processes reduce chemical use by 50-70%. Smart monitoring systems help predict problems before they happen and cut costs by 25-35%. The best part is that treated wastewater creates good money when industries buy it or farmers use it.

The real cost story of STPs comes from life cycle analysis. The original cost matters, but running costs make up 60-80% of total expenses. Smart buyers choose technology that costs more upfront but less to run. This choice helps the environment by cutting greenhouse gasses and related costs.

SUSBIO ECOTREAT leads the pack as India’s best packaged STP solution because it tackles these problems head-on. The system’s building-block design means quick setup with less land needed. It runs quietly without smells, so it fits anywhere. The system’s energy-smart MBBR technology with advanced filtering gives water quality that beats the rules. Real examples show SUSBIO ECOTREAT saves money, paying for itself in just 2.3 years for bigger systems.

Without doubt, India’s sewage treatment scene needs big changes now. Beyond following rules, new solutions like SUSBIO ECOTREAT save serious money. STP upgrades do more than cut daily costs – they improve public health, protect nature, and recover resources. Cities, factories, and housing complexes that invest in advanced sewage treatment make a smart money move that pays off in three years.

Key Takeaways

Modern sewage treatment plant upgrades transform environmental compliance costs into profitable investments through strategic technology improvements and operational optimization.

- Energy optimization cuts operational costs by 35-40% through smart aeration controls and variable frequency drives, saving ₹1.8-3 lakhs annually for 100 KLD plants.

- Advanced biological processes reduce chemical usage by 50-70%, dropping monthly expenses from ₹30,000-50,000 to ₹10,000-20,000 through optimized treatment systems.

- Treated wastewater creates substantial revenue streams – facilities like Surat Municipal Corporation generate ₹120 crore annually selling treated water to industries.

- SUSBIO ECOTREAT delivers ROI in just 2.3 years through its energy-efficient MBBR technology, consuming 90% less power than conventional STPs while exceeding regulatory standards.

- Modular design enables rapid deployment in 2-4 weeks compared to 6-12 months for traditional systems, using 60-70% less space with zero odor and noise operation.

The shift from viewing STPs as cost centers to profit generators represents a fundamental change in wastewater management economics. With operational costs typically consuming 60-80% of life-cycle expenses, investing in future-ready technologies like SUSBIO ECOTREAT ensures both environmental compliance and financial sustainability for India’s growing urban infrastructure needs.

Frequently Asked Questions

Q1. What are the key advantages of upgrading to a modern sewage treatment plant?

Modern sewage treatment plants offer significant benefits, including energy savings of 35-40% through optimized aeration and pumping, reduced chemical usage by 50-70%, lower maintenance costs due to automation, and potential revenue generation from treated water reuse in irrigation and industry.

Q2. How long does it typically take for a sewage treatment plant upgrade to pay for itself?

With strategic upgrades and modern technologies, sewage treatment plant investments can pay for themselves in as little as 3 years. Some case studies, like the SUSBIO ECOTREAT installation at a pharmaceutical facility in Gujarat, have shown ROI periods as short as 2.3 years.

Q3. What makes SUSBIO ECOTREAT different from conventional sewage treatment plants?

SUSBIO ECOTREAT is a future-ready packaged STP solution that features a modular design for rapid deployment, zero odor and noise operation, energy-efficient MBBR technology with tertiary filtration, and compliance with strict BOD norms. It consumes 90% less power than conventional STPs while delivering exceptional water quality.

Q4. How does life cycle costing impact the economics of sewage treatment plants?

Life cycle costing reveals that operational and maintenance costs typically represent 60-80% of a sewage treatment plant’s total expenses over its lifespan. This insight emphasizes the importance of investing in technologies that may have higher upfront costs but offer significant long-term operational savings.

Q5. What environmental benefits do modern sewage treatment plants provide?

Advanced sewage treatment technologies can reduce greenhouse gas emissions by 60-65% through innovative biological techniques, intelligent wastewater strategies, and renewable energy integration. This not only helps combat climate change but also translates to financial benefits through reduced compliance costs and potential carbon credit opportunities.