Effluent treatment plants play a vital role in purifying industrial wastewater that makes it safe for disposal or reuse. Creating a working ETP demands expert knowledge of physical, chemical, biological, and membrane processes. This piece will give you a detailed explanation about building efficient effluent treatment systems that work across industries – from chemicals and pharmaceuticals to textiles and refineries.

ETP plants serve three key purposes. They clean and recycle industrial waste for future use. They help cut down fresh water consumption in manufacturing operations. Most importantly, they shield our ecosystem from harmful pollution. A well-designed effluent treatment plant helps businesses stay within government emission standards. This prevents hefty penalties and supports environmental sustainability. We’ll walk you through everything from plant layout choices to picking reliable manufacturers who can build systems that match your industry’s specific needs.

Understanding the Purpose of an Effluent Treatment Plant

Industrial facilities create wastewater filled with harmful chemicals, pollutants, and suspended solids. This wastewater needs special treatment before it can be released into the environment. An effluent treatment plant (ETP) protects our water bodies from industrial pollution.

Definition and Role of ETP in Industrial Wastewater Management

An effluent treatment plant cleans industrial wastewater through physical, chemical, and biological processes. The plant makes the water safe enough to discharge or reuse. ETPs remove toxic pollutants, chemicals, and suspended solids from industrial effluents. These systems make sure the released water meets the standards set by regulatory bodies.

You’ll find ETPs in textiles, pharmaceuticals, chemicals, food processing, leather manufacturing, and refineries. A well-designed ETP plant offers several benefits:

- It keeps rivers, lakes, and groundwater free from pollution

- It helps companies follow pollution control rules

- It lets companies recycle and reuse water

- It cuts down water purchase and waste disposal costs

- It shows the company’s dedication to sustainability

Key Differences Between ETP and STP Systems

ETPs and sewage treatment plants (STPs) serve different purposes and use different methods. ETPs handle complex industrial wastewater, while STPs clean domestic sewage from homes.

Industrial wastewater contains hazardous chemicals, heavy metals, and substances that don’t break down naturally. These need specialized treatment processes. STPs mainly deal with organic matter and germs from household wastewater.

The treatment process is more complex in ETPs. They need advanced chemical treatments along with biological and physical processes to handle dangerous substances. Each industry has its own specific contaminants, which makes ETP design more challenging than the simple biological breakdown used in sewage plants.

ETP manufacturers know their systems need more maintenance and skilled operators because industrial waste keeps changing. Water from ETPs might need extra cleaning before reuse, unlike STP water that’s often good enough for gardens or cleaning right away.

Step-by-Step Breakdown of the ETP Plant Process

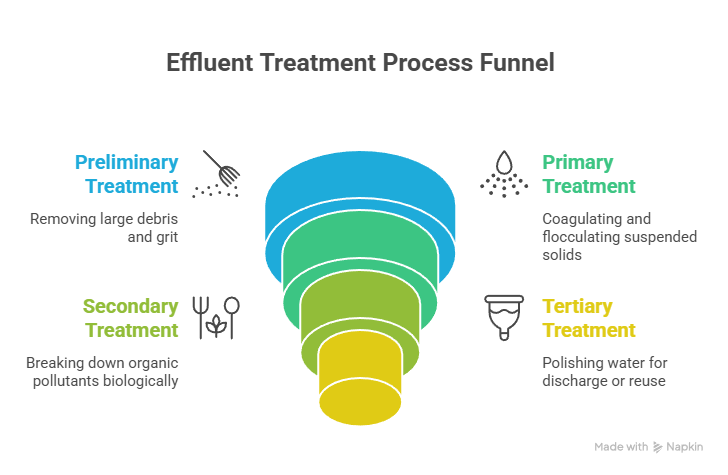

The effluent treatment plant uses a multi-stage purification process that removes pollutants from industrial wastewater step by step. Each stage works on specific contaminants through specialized mechanisms to give a detailed purification.

Preliminary Treatment: Screening, Grit Removal, and Sedimentation

The first line of defense against large debris comes from preliminary treatment. This stage uses screens with openings from 25mm (trash racks) to 6mm (coarse screens) to filter out large objects like plastic, leaves, and sticks. Grit chambers then remove sand, gravel, and heavy particles by controlling flow velocity. This prevents equipment wear and stops pipelines from clogging. The amount of grit removed can vary substantially—from 4 to 37 mL/m³ in separate sewer systems to 4 to 180 mL/m³ for combined systems. Sedimentation tanks let heavier particles settle at the bottom and form primary sludge.

Primary Treatment: Coagulation, Flocculation, and Neutralization

Chemical processes take center stage during primary treatment to remove suspended solids and organic matter. Chemicals like aluminum sulfate or ferric chloride neutralize negative charges on tiny particles during coagulation, which helps them bind together. The process continues with flocculation, where gentle mixing helps these neutralized particles form larger, settleable “flocs”. These combined steps can reduce TSS by 80-95% and BOD by 58-68%. The treatment also adjusts pH levels with acids or bases to create the best conditions for biological treatment.

Secondary Treatment: Activated Sludge and Biological Filtration

Biological processes break down organic pollutants in secondary treatment. The activated sludge process mixes wastewater with microorganisms in aeration tanks. Bacteria then consume organic materials and turn them into harmless byproducts like carbon dioxide and water. Another option is biological filtration, which uses plastic media beds. Wastewater flows through these beds while natural ventilation provides oxygen to the biomass. Both methods can reduce biochemical oxygen demand (BOD) and suspended solids by more than 90%.

Tertiary Treatment: Reverse Osmosis, UV Disinfection, and Polishing

The final stage, known as effluent polishing, uses advanced technologies to remove remaining contaminants. Selective membranes in reverse osmosis filter out even the tiniest particles and dissolved solids. This method works especially well for wastewater reuse in textiles, pharmaceuticals, and metals manufacturing. UV disinfection or chlorination kills any remaining pathogens, and carbon adsorption removes trace organic compounds. This detailed tertiary process will give water quality good enough for environmental discharge or industrial reuse, completing the treatment cycle.

Core Components in an ETP Plant Layout

A well-designed effluent treatment plant needs its components to work together smoothly. This setup ensures proper wastewater purification. Each component plays a specific role in the treatment process.

Equalization Tank and Flow Balancing

Equalization tanks are vital buffers in the treatment plant layout. They help manage changes in flow rate and pollutant concentration. These tanks need 6-16 hours to properly mix incoming wastewater. The tanks balance daily and occasional hydraulic and organic shocks. This balance lets downstream processes work near their design conditions and improves BOD removal up to 30%. The tanks also provide flexibility during maintenance or unexpected industrial discharge events. Modern versions come with level sensors, mixers, and pH control systems that monitor influent characteristics live.

Clarifier and Sludge Handling Unit

Clarifiers use sedimentation to separate suspended solids from liquid. Primary clarifiers sit after preliminary treatment and remove heavier particles that sink as sludge. The secondary clarifiers follow biological treatment stages and separate biological sludge from remaining suspended solids. Both types have mechanical scrapers or rakes that rotate slowly. These push sludge toward a central hopper for removal. The sludge handling facilities need specific areas for thickening tanks, drying beds, or filter presses. This setup helps avoid cross-contamination and odor issues.

Aeration Tank and Diffuser Systems

Aeration tanks are the foundations of biological treatment. They break down organic materials through aerobic digestion. The tanks use either fine bubble or coarse bubble diffusers to add oxygen. Fine bubble diffusers create tiny bubbles (1-3mm diameter) that rise slowly. This provides longer oxygen contact time and better transfer efficiency. Coarse bubble diffusers make larger bubbles that move more water. These offer better mixing and resist fouling. Strategic diffuser placement creates uniform mixing and prevents dead zones.

Disinfection Unit and Final Holding Tank

The disinfection unit eliminates remaining pathogens before water discharge. It uses chlorination, UV disinfection, or ozonation methods. Chlorine contact tanks need a 30-minute detention time with 0.5 mg/L target residual chlorine. UV disinfection uses ultraviolet lamps that destroy microbial DNA without chemicals. The final holding tank stores treated effluent until discharge or reuse. This allows quality checks against environmental standards.

Design Considerations for ETP in 2026

Building an effluent treatment plant in 2026 needs a smart approach. You must balance performance, compliance, and costs carefully. Good planning can transform a basic system into something that delivers value for years.

Capacity Planning Based on Industry Type

The first step is figuring out how much wastewater you’ll handle and what’s in it. Each industry has its own wastewater profile:

- Textile & Garments: 50–500 KLD

- Pharmaceuticals: 10–250 KLD

- Chemical Plants: 100–1000 KLD

- Dairy/Meat Processing: 20–300 KLD

- Food Processing: 30–500 KLD

Your plant’s capacity should handle both today’s needs and tomorrow’s growth. Many companies make the mistake of underestimating future production increases. This leads to undersized systems that get pricey to upgrade later. My advice? Add a 20-30% buffer to your capacity requirements.

Land Availability and CETP vs ETP Decision

Space often becomes the deciding factor in choosing your treatment system. Small-scale ETPs (up to 50 KLD) need about 500–1000 square feet. Medium-scale plants (50–200 KLD) require 2000–5000 square feet. Companies with tight space constraints might find Common Effluent Treatment Plants (CETP) a better option than in-house ETPs.

CETPs spread the original costs across multiple users, which helps keep individual expenses down. On top of that, it makes compliance reporting easier since central authorities monitor these plants. The trade-off? You’ll have less control over operations because everyone must follow the plant’s schedule.

Automation and Remote Monitoring Integration

Smart technology has become crucial for running ETPs efficiently in 2026. Modern plants now use PLC and SCADA systems for automated operations and immediate monitoring. These systems use IoT-connected sensors to spot pollutants and check water quality on the spot.

Remote monitoring lets operators:

- Get contamination alerts instantly

- Tweak treatment processes through IoT devices

- Plan maintenance before equipment fails

These features help you stay compliant and cut operational costs by optimizing chemical usage and energy consumption.

Choosing the Right Effluent Treatment Plant Manufacturer

The manufacturer you pick can make or break your long-term success. Look at their industry experience, ability to customize, and state-of-the-art solutions. The upfront cost matters, but the total lifecycle expenses (CAPEX + OPEX) tell the real story.

The best manufacturer will create solutions that match your specific wastewater needs and can grow with your business. Reliable after-sales support keeps your system running smoothly throughout its life. This detailed approach ensures both environmental compliance and efficient operations.

Conclusion

A detailed understanding of industrial wastewater characteristics and treatment methods helps design ETPs that work. This piece explores key components that make ETPs vital for protecting the environment and meeting regulations. These systems are substantially different from STPs because they target complex industrial pollutants instead of organic residential waste.

Effective effluent treatment depends on multi-stage purification. Large debris gets removed in preliminary treatment. Primary treatment uses chemical processes like coagulation and flocculation. Biological processes then break down organic pollutants in secondary treatment. The water goes through tertiary treatments to meet discharge standards.

The physical setup plays a vital role in how well an ETP works. Flow variations get balanced in equalization tanks and clarifiers separate solids from liquids. On top of that, it needs aeration systems to supply oxygen for biological treatment. Disinfection units take care of any remaining pathogens before final discharge.

Planning for 2026 needs a 20-30% buffer capacity beyond current and future needs. Space constraints might force you to pick between individual ETPs and Common Effluent Treatment Plants. Up-to-the-minute data analysis through smart technology improves operations with automation and remote monitoring. This allows quick adjustments and predictive maintenance.

Your ETP’s long-term success depends on picking the right manufacturer. Their experience, ability to customize, and support services will determine if your ETP delivers environmental compliance and runs efficiently. A smart approach to ETP design protects ecosystems and optimizes resources through water recycling and reuse. This creates an eco-friendly future for industrial operations.

Key Takeaways

Designing an effective effluent treatment plant requires strategic planning across multiple treatment stages and careful consideration of industry-specific requirements to ensure environmental compliance and operational efficiency.

- Multi-stage treatment is essential: ETPs use preliminary, primary, secondary, and tertiary processes to progressively remove pollutants, achieving 80-95% TSS reduction and over 90% BOD removal through specialized physical, chemical, and biological methods.

- Capacity planning prevents costly upgrades: Size your ETP with 20-30% buffer capacity beyond current needs, as different industries require vastly different volumes (textiles: 50-500 KLD, chemicals: 100-1000 KLD).

- Smart automation reduces operational costs: Integrate PLC/SCADA systems and IoT sensors for real-time monitoring, predictive maintenance, and automated adjustments that optimize chemical usage and energy consumption.

- Space constraints drive system selection: Small ETPs need 500-1000 sq ft while medium plants require 2000-5000 sq ft; consider Common Effluent Treatment Plants (CETP) when land availability is limited.

- Manufacturer selection impacts long-term success: Choose experienced providers offering industry-specific customization, comprehensive support, and proven track records rather than focusing solely on initial costs.

Modern ETP design in 2026 balances environmental protection with operational efficiency, utilizing advanced technology and strategic planning to create sustainable industrial wastewater management solutions.

Frequently Asked Questions

Q1. What is the primary purpose of an Effluent Treatment Plant (ETP)?

An Effluent Treatment Plant is designed to purify industrial wastewater by removing toxic pollutants, chemicals, and suspended solids before it’s safely discharged or reused. It helps protect the environment, ensures legal compliance, and enables water recycling.

Q2. How does an ETP differ from a Sewage Treatment Plant (STP)?

ETPs are specifically designed for industrial wastewater containing complex pollutants and hazardous chemicals, requiring more specialized treatment processes. STPs, on the other hand, primarily handle domestic sewage with organic matter and pathogens, using simpler biological degradation methods.

Q3. What are the main stages in the ETP treatment process?

The ETP process typically involves four main stages: preliminary treatment (screening and grit removal), primary treatment (coagulation and flocculation), secondary treatment (biological processes), and tertiary treatment (advanced purification methods like reverse osmosis and UV disinfection).

Q4. How much space is required for an Effluent Treatment Plant?

The space requirement for an ETP depends on its capacity. Small-scale ETPs (up to 50 KLD) generally need about 500-1000 square feet, while medium-scale plants (50-200 KLD) require approximately 2000-5000 square feet.

Q5. What role does automation play in modern ETP design?

Automation is crucial in modern ETP design, incorporating PLC and SCADA systems for real-time monitoring and control. It enables instant detection of pollutants, allows remote adjustments to treatment processes, and facilitates predictive maintenance, ultimately improving efficiency and reducing operational costs.