The activated sludge process remains the most common way to treat municipal wastewater worldwide today. Most of us never think about the complex biological systems that transform raw sewage into clean water each time we flush toilets or drain sinks. Many municipalities rely on this remarkable process as it provides an effective solution to one of our most fundamental infrastructure challenges.

The treatment’s value comes from its unique characteristics. The sludge particles earn their “activated” name because beneficial bacteria actively swarm through them to digest sewage. The process creates biological flocs that reduce organic content by introducing air or oxygen into a mixture of wastewater and microorganisms. The sewage treatment plants that use activated sludge treatment offer several benefits. These plants produce less sludge, reseed themselves with beneficial bacteria, need less frequent emptying, work more reliably, run more simply, cost less to operate, and process waste without odors.

Let me walk you through how the activated sludge process turns wastewater into clean water. We’ll get into each treatment step, look at key control parameters, explore different system types, and break down the aeration methods that make everything work.

What Is the Activated Sludge Process in Wastewater Treatment?

The activated sludge process stands as a biological method used during secondary treatment in municipal wastewater treatment. Scientists developed this groundbreaking process in 1914 and tested it at the Manchester-Davyhulme Wastewater Treatment Plant using a wooden mobile pilot plant. The process has become a cornerstone of modern sewage treatment systems worldwide.

Define activated sludge process and its role in secondary treatment

Scientists develop flocculent cultures of organisms under controlled conditions in aeration tanks to create the activated sludge process. The process cleans sewage or industrial wastewaters through aeration and biological floc made up of bacteria and protozoa. Secondary or biological treatment uses this crucial component after the primary clarification stage.

The activated sludge system sits between the primary clarifier and disinfection stage in a wastewater treatment facility. The main goal removes Biochemical Oxygen Demand (BOD) – a measure showing oxygen demand that indicates wastewater strength. This biological process turns dissolved and suspended organic pollutants into stable compounds while creating new bacterial cells.

The activated sludge looks like a chocolate-brown colored mixture that contains:

- Microbial communities (95% being various aerobic bacteria species)

- Populations of fungi and protozoa

- Higher forms of invertebrates

- Organic and inorganic substances

Biological oxidation using aerobic microorganisms

Biological oxidation drives the activated sludge process. Aerobic microorganisms break down organic matter in wastewater while thriving in oxygen-rich environments. These organisms use wastes as food and energy to survive and reproduce.

Bacteria secrete sticky substances that coat tiny particles in sewage. These particles clump together and form flocs of gel-like material that create a support structure for microbes. Microbial communities break down organic materials in a suspended growth reactor during this biological treatment.

Microorganisms convert organic matter into stable chemicals like NO₃, SO₄, and CO₂ while producing new bacterial cells. Aerobic oxidation works better than anaerobic methods because aerobic organisms produce minimal odor, break down waste quickly, and grow faster. The process needs constant oxygen supply to keep aerobic conditions and suspended activated sludge.

Activated sludge process diagram overview

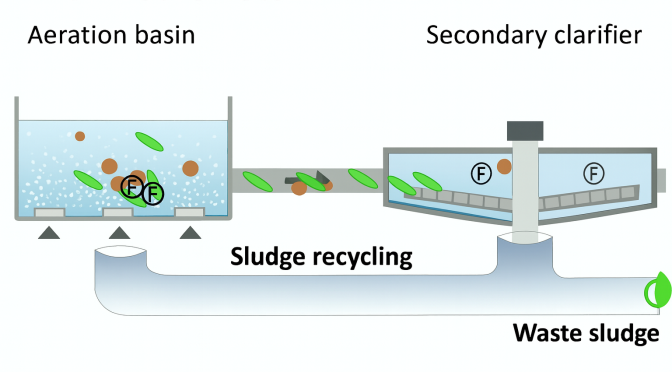

A conventional activated sludge system works through connected components. Wastewater enters an aeration tank and mixes with previously developed microorganisms. Operators blow air or oxygen into this mixture to help bacteria grow rapidly. They use either diffused aeration (air bubbles at tank bottom) or surface aeration systems.

Organic pollutants become energy, water, CO₂, and new cell material in the aeration tank. The mixture of wastewater and microbial community (mixed liquor) flows to a secondary clarifier where activated sludge settles. Treated effluent rises as clear liquid while settled sludge splits two ways: some returns to the aeration tank as “return activated sludge” (RAS) to maintain organism populations, and excess becomes “waste activated sludge” (WAS).

This cycle creates a self-optimizing system where the most competitive organisms naturally dominate under specific environmental conditions. The population adapts automatically to maintain peak performance when conditions change, like temperature fluctuations.

Step-by-Step Breakdown of the Activated Sludge Process

Let me explain how the activated sludge process works by walking you through each critical stage from raw sewage to clean water. The process follows a logical sequence where each step builds upon the previous one to achieve proper wastewater treatment.

Pre-treatment and primary clarification

Raw wastewater undergoes preliminary treatment that consists of screening and grit removal. These original steps remove large debris and inorganic materials that could damage equipment or disrupt treatment processes.

Primary clarification serves as the first major step in removing pollutants. Wastewater flows into large settling tanks called primary clarifiers where heavier particles settle naturally to the bottom through gravity sedimentation. A typical primary clarifier removes about 60% of suspended solids and 30-40% of Biological Oxygen Demand (BOD). Mechanical scrapers or rakes collect the settled solids that form primary sludge and pump it out for further processing.

Aeration tank and mixed liquor formation

The partially treated wastewater moves into the aeration tank where it mixes with previously developed microorganisms. This combination of wastewater and biological sludge creates what’s known as mixed liquor. Diffusers at the tank’s bottom or mechanical surface aerators introduce air that creates ideal conditions for microbial growth and activity.

Microorganisms in the aeration tank break down organic pollutants into stable compounds like NO₃, SO₄, and CO₂ while producing new bacterial cells. The process needs 4-8 hours of detention time to allow enough contact between microorganisms and organic materials. The microbes create biological flocs—active masses of bacteria and other organisms that group together through flocculation.

Secondary clarifier and sludge settling

Mixed liquor flows from the aeration tank to the secondary clarifier (also called the final clarifier) where treated water separates from biological solids. The activated sludge settles by gravity in the secondary clarifier, producing clear water at the top and concentrated sludge at the bottom.

The system’s design includes various mechanisms to collect settled sludge, using scraped collection for smaller structures and suction collection for larger units. Suction clarifiers work better than scraped alternatives for clarifiers wider than 25 meters. The clarifier’s design and operation must balance proper settling while limiting sludge contact time to prevent biological changes from extended periods without aeration.

Return activated sludge (RAS) and waste activated sludge (WAS)

The settled sludge splits into two streams. Most of it (70-80%) returns to the aeration tank as return activated sludge (RAS). This recycling keeps adequate microorganism levels in the aeration tank and ensures continuous treatment. The return sludge volume ranges from 10-50% of the treated wastewater volume, though conventional plants usually use 20-30%.

The remaining sludge becomes waste activated sludge (WAS) and leaves the system to maintain balance. WAS contains excess biomass growth and the pollutants from the original wastewater that have become part of the sludge. This waste sludge needs additional treatment through thickening, digestion, or other processes before final disposal.

Key Parameters for Process Control and Optimization

You retain control over the activated sludge process by monitoring operational parameters. Operators can optimize treatment efficiency, reduce energy consumption, and produce high-quality effluent through effective parameter management.

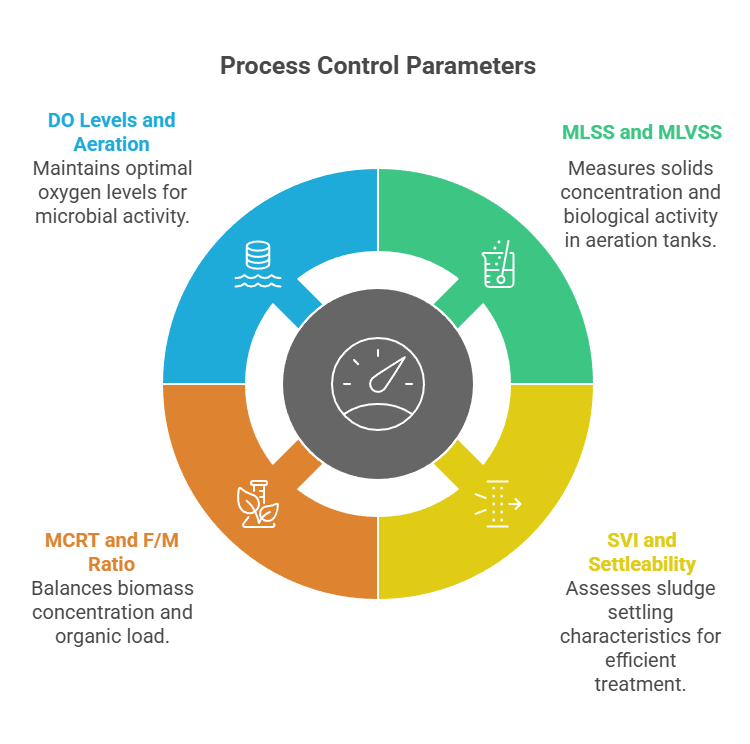

Mixed Liquor Suspended Solids (MLSS) and MLVSS

Mixed Liquor Suspended Solids (MLSS) represents the overall concentration of suspended solids in an aeration tank. It consists mainly of microorganisms and non-biodegradable suspended matter. MLSS plays a crucial role as an operational parameter when designing wastewater treatment plants that use suspended growth processes. Mixed Liquor Volatile Suspended Solids (MLVSS) measures the volatile (biological) portion of MLSS. This represents the active biomass that removes organic matter. MLVSS testing helps determine the system’s operational behavior and biological inventory. The standard values range between 60% to 65% of MLSS to achieve high system efficacy.

Sludge Volume Index (SVI) and settleability

Mohlman introduced the Sludge Volume Index (SVI) in 1934 as a process control parameter that describes sludge settling characteristics in the aeration tank. SVI measures “the volume (in mL) occupied by 1 gram of activated sludge after settling the aerated liquid for 30 minutes”. A well-functioning system typically shows SVI values from 50 to 150 mL/g. Dense sludge that settles faster shows values below 80 mL/g. Light, fluffy sludge with poor settling characteristics displays values above 250 mL/g.

Mean Cell Residence Time (MCRT) and F/M ratio

Mean Cell Residence Time shows how long microorganisms stay in the treatment process. MCRT controls biomass concentration, determines settling characteristics and influences microbial population selection. The Food to Microorganism (F/M) ratio maintains system equilibrium by balancing organic load with microorganism quantity. System types show different F/M values:

- Extended aeration: 0.05-0.15

- Conventional activated sludge: 0.2-0.4

- Completely mixed: 0.2-0.6

- High rate: 0.4-1.5

Dissolved Oxygen (DO) levels and aeration control

Dissolved oxygen stands as one of the most vital water quality factors in the activated sludge process. Conventional secondary treatment requires maintaining 2.0 mg/L measured at the aeration tank’s end. Aerobic activity decreases with low DO levels and may encourage filamentous growth. High DO can lead to floc disintegration, poor settling, and waste energy. Aeration consumes 50-60% of a treatment plant’s total energy. Automated DO control systems that use sensors connected to variable frequency drives on blowers can maintain optimal DO levels while saving energy.

Types of Activated Sludge Systems and Their Applications

The activated sludge process has evolved into several variations that address different treatment needs, flow volumes, and site constraints. Each system type provides unique benefits for specific applications.

Conventional, Extended Aeration, and High Rate Systems

Conventional activated sludge systems operate with 6-hour aeration periods and need primary settling first. These systems achieve 85-95% BOD removal efficiency. Extended aeration systems work with longer detention times (24+ hours) and lower F/M ratios. This design creates minimal excess sludge and doesn’t need separate digestion, making it perfect for facilities that process less than 4 Mld. High-rate systems need shorter detention periods of about 2 hours, less compressed air, and smaller amounts of returned sludge. They work with higher F/M ratios (0.8-1.2) and MLVSS concentrations between 5,000-10,000 mg/L.

Sequencing Batch Reactors (SBRs)

Sequencing batch reactors treat wastewater in batches within a single vessel, unlike continuous-flow systems. The SBR process follows five distinct phases: fill, react, settle, draw, and idle. This time-based approach handles all treatment functions in one tank through timed sequences. SBRs excel at operational flexibility and control filamentous sludge bulking well. They show superior nutrient removal—one study revealed 98.1% nitrate removal efficiency compared to 89.7% in conventional systems.

Oxidation Ditches and Deep Shaft Systems

Ring or oval-shaped channels replace rectangular tanks in oxidation ditches, which creates long reaction areas in compact spaces. Wastewater moves through these systems 20-30 times before discharge, similar to complete mixing. This design achieves high BOD reduction and removes nutrients while using minimal energy. Deep shaft systems work differently by injecting oxygen into pressurized return sludge streams at the base of columnar tanks up to 100 meters deep. The oxygen breaks out as molecular oxygen when sewage rises, which creates highly efficient aeration.

Package Plants for small communities

Package plants serve as commercially manufactured units designed for smaller wastewater flows (0.002-0.5 MGD). These pre-fabricated systems typically use extended aeration variations of the activated sludge process. Housing developments, mobile home parks, small towns, remote sites, schools, and recreational facilities commonly use these systems. The treatment includes screening, aeration, clarification, and disinfection in a compact setup. Their standardized design allows communities to expand modules gradually as populations grow.

Aeration Methods and Equipment Used in Activated Sludge Treatment

Aeration acts as the heartbeat of the activated sludge process. It brings oxygen into the system and ensures complete mixing. Plants use 25-60% of their total energy for aeration, which makes equipment selection crucial.

Mechanical vs Diffused Aeration

Mechanical aerators create a horizontal churning action at the liquid surface. They generate waves and spray that help oxygen move from the atmosphere into wastewater. These systems use rotating shafts with propeller blades that stir the water surface. Diffused aeration takes a different approach. It pushes compressed air from the tank bottom through distribution devices. The rising bubbles transfer oxygen and create a spiral mixing pattern as they move up through the water column.

Fine, Medium, and Coarse Bubble Diffusers

Bubble size determines diffuser categories: fine bubble (0-3mm diameter), medium bubble (5mm-3cm), and coarse bubble (3-50mm). Fine bubble diffusers feature flexible membranes with tiny holes that achieve 5-7% oxygen transfer efficiency per meter depth. Their better aeration efficiency comes from increased surface contact between air and water. Coarse bubble diffusers, all the same, work better in tough environments with high suspended solids.

Blowers, air piping, and diffuser placement

Positive displacement or centrifugal blowers supply compressed air for diffused systems. Air moves through a network of pipes: mains serve as large arteries while headers act as smaller distribution pipes. Floor-based diffusers placed strategically create an even bubble spread throughout the liquid, which optimizes oxygen transfer.

Energy efficiency and oxygen transfer rates

Standard Aeration Efficiency (SAE) shows how much oxygen transfers per unit of energy input. Surface aerators deliver 0.5-1.5 kg O₂/kWh, while diffused systems reach 1.5-2.5 kg O₂/kWh. Deep Shaft technology claims impressive results at 5-8 kg O₂/kWh. Fine bubble diffusers can cut energy use by 30-40% compared to other systems in real-world applications.

Conclusion

The activated sludge process stands out as an outstanding feat in environmental engineering. This piece explores how this biological treatment method turns raw sewage into clean water through a controlled process. The technology has become the foundation of municipal wastewater treatment worldwide since its development in 1914.

The success of activated sludge treatment relies on balancing several parameters. Plant operators must monitor and adjust MLSS concentrations, sludge volume index, mean cell residence time, and dissolved oxygen levels to keep microbial communities at their best. The design of aeration systems – whether using fine bubble diffusers or mechanical aerators – substantially affects both treatment quality and power usage.

Modern activated sludge technology offers many system configurations. Conventional systems, extended aeration plants, sequencing batch reactors, oxidation ditches, and package plants serve specific needs based on community size, space limits, and treatment goals. This flexibility explains why the process has stayed relevant for over a century despite major advances in other fields.

The process means more than just technical success. Every time we use our taps or flush our toilets, this hidden yet vital infrastructure works for us. The activated sludge process quietly protects public health, saves natural water bodies, and helps modern cities grow.

Clean water from raw sewage represents one of humanity’s overlooked technological achievements. Though not glamorous, the activated sludge process shows how natural biological systems can solve complex environmental challenges quickly. Water shortages and pollution concerns grow worldwide, making this reliable treatment method vital to sustainable water management.

Key Takeaways

The activated sludge process transforms raw sewage into clean water through biological treatment, serving as the backbone of municipal wastewater systems worldwide since 1914.

- Biological powerhouse: Aerobic microorganisms break down organic waste into stable compounds while forming flocs that settle and separate from clean water.

- Four-stage treatment cycle: Pre-treatment, aeration tank mixing, secondary clarification, and sludge recycling create a self-optimizing biological system.

- Critical control parameters: Monitor MLSS (2,000-4,000 mg/L), SVI (50-150 mL/g), and dissolved oxygen (2.0 mg/L) for optimal performance.

- Energy-efficient aeration: Fine bubble diffusers can reduce energy consumption by 30-40% compared to other systems while improving oxygen transfer.

- Versatile system options: Choose from conventional, extended aeration, SBRs, or package plants based on community size and treatment requirements.

The process demonstrates how harnessing natural biological systems can efficiently solve complex environmental challenges while protecting public health and preserving water resources for sustainable urban development.

Frequently Asked Questions

Q1. How does the activated sludge process work?

The activated sludge process uses aerobic microorganisms to break down organic waste in wastewater. These microorganisms form biological flocs that settle and separate from clean water. The process involves four main stages: pre-treatment, aeration tank mixing, secondary clarification, and sludge recycling, creating a self-optimizing biological system.

Q2. What are the key parameters to monitor in the activated sludge process?

The critical parameters to monitor include Mixed Liquor Suspended Solids (MLSS), typically maintained between 2,000-4,000 mg/L; Sludge Volume Index (SVI), ideally between 50-150 mL/g; and Dissolved Oxygen (DO) levels, typically maintained at 2.0 mg/L for optimal performance.

Q3. How energy-efficient is the aeration in activated sludge treatment?

Aeration methods can significantly impact energy efficiency. Fine bubble diffusers are particularly efficient, capable of reducing energy consumption by 30-40% compared to other systems while improving oxygen transfer rates.

Q4. What types of activated sludge systems are available?

There are several types of activated sludge systems to suit different needs, including conventional systems, extended aeration plants, sequencing batch reactors (SBRs), oxidation ditches, and package plants. The choice depends on factors such as community size, space constraints, and specific treatment goals.

Q5. What are the benefits of the activated sludge process?

The activated sludge process offers numerous benefits, including effective removal of organic pollutants, adaptability to various scales of operation, and the ability to produce high-quality effluent. It also demonstrates how natural biological systems can be harnessed to solve complex environmental challenges while protecting public health and preserving water resources.