Aging sewage treatment infrastructure is often described as a “silent liability” for cities, industries, and communities. While outdated systems may still appear to function, they hide mounting costs in the form of frequent breakdowns, rising energy consumption, non-compliance penalties, and environmental damage. These hidden expenses can far exceed the price of preventive upgrades or modern replacements if left unaddressed. As 2025 brings stricter discharge standards and rising pressure on sustainable water management, understanding and tackling the hidden costs of aging sewage treatment plants has become a priority. This guide explores the risks, preventive strategies, and modern solutions that can help decision-makers safeguard both their budgets and the environment.

Evaluating the True Cost of Aging Sewage Infrastructure

Sewage infrastructure maintenance costs are way beyond what you see in yearly budgets. Cities worldwide struggle with rising expenses as their critical systems get old or outlive their design life. Industry estimates show that fixing underground pipes alone will cost at least INR 84.38 trillion in the next 25 years. This number could double if cities delay taking action.

Hidden Maintenance Costs in Legacy STP Systems

Legacy sewage treatment plant (STP) systems eat up much of maintenance budgets. Organizations spend about INR 2531.41 million on each legacy system. Old technology needs special knowledge that gets harder to find. These aging systems face growing costs because of:

- Equipment damage from corrosion caused by acids, alkaline substances, and waste materials

- Systems that need more resources to do the same job

- The need for specialized staff or expensive consultants who understand outdated technology

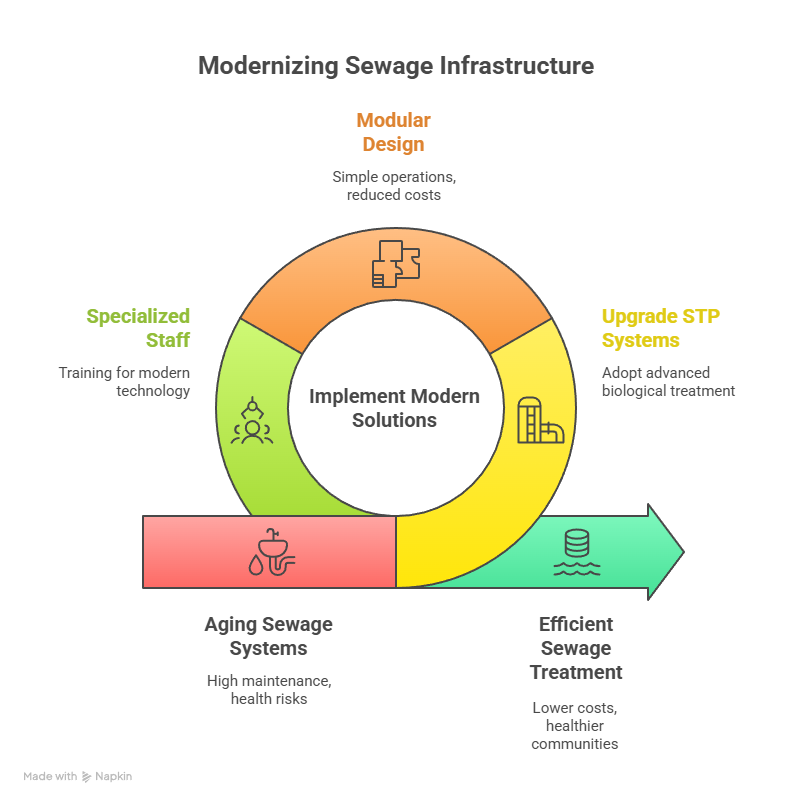

Old infrastructure often leads to sewer overflow (SO). This pollutes water bodies and needs expensive cleanup. Modern solutions like SUSBIO ECOTREAT help Indian cities and global operators cut maintenance costs through simple operations and modular design.

Impact of Downtime on Community Services

System failures at sewage treatment facilities create a chain of problems in communities. These breakdowns reduce wastewater processing capacity while sewage keeps flowing in. Communities then must store untreated water somewhere else or overload other parts of the facility.

Poorly treated wastewater creates serious health risks. Children, elderly, and people with weak immune systems face the biggest threat. Property values near poorly performing STPs drop, which hurts local economies for years.

What is STP in Sewage: Understanding the Core System

STP (Sewage Treatment Plant) facilities remove contaminants from wastewater before releasing it safely into the environment. The treatment happens in four main steps:

The first step screens out large solids. The second step lets solid particles sink as sludge. The third step uses microorganisms to remove biological matter. The final step filters remaining contaminants before disinfection and release.

SUSBIO ECOTREAT and other modern systems boost this process. They use advanced biological treatment methods that work better and cost less for Indian and international operators.

When to Repair and When to Replace

Smart decisions about aging sewage treatment infrastructure need a full picture instead of quick fixes. Plant managers must choose between fixing existing systems or replacing them based on several key factors.

Assessing Structural Integrity of Sewerage Treatment Infrastructure

Condition assessments are the foundations of any repair-or-replace decision. The process starts with a review of available maintenance data and performance history. Professional inspectors then conduct detailed evaluations that include CCTV investigation—the quickest way to assess internal pipe conditions.

Structural defects that need immediate attention include:

- Joint defects (highest probability with RII = 0.733)

- Wall fractures and pipe breaks

- Misalignment and displacement issues

- Corrosion damage (we found this mostly in concrete structures)

SUSBIO ECOTREAT gives Indian and global operators advanced diagnostic tools to review infrastructure condition. These tools help spot problems before catastrophic failure happens.

Cost-Benefit Analysis: Refurbishment vs New Installation

Money often drives repair-versus-replace decisions. A case study showed refurbishment saved approximately INR 84 million compared to full replacement. Repairs cost less upfront but don’t deal very well with the mechanisms of problems. This leads to higher maintenance costs over time.

There’s another reason operational factors shape this analysis:

- Repairs disrupt surrounding areas less

- Replacement provides long-term reliability and lower maintenance

- Systems past their design life might need replacement even if repairs are possible

Space Constraints and Expansion Limitations

Limited land availability creates the biggest challenge when upgrading sewage treatment infrastructure. Finding space in dense urban areas gets pricey and challenging. Rural settings also need substantial land for traditional wastewater treatment systems. Buffer zones reduce the usable area further.

Membrane-based technologies offer solutions for facilities with limited space. These systems allow capacity expansion within existing sites without physical growth. SUSBIO ECOTREAT helps Indian municipalities and global operators with its compact footprint. The system needs minimal space (as little as 720 m²) for upgrades, making it perfect for modernizing existing plants.

Technology Upgrades That Reduce Long-Term Costs

Modern wastewater facilities now use state-of-the-art technology that substantially decreases operational expenses and extends infrastructure lifespan. Smart upgrades like these provide excellent returns on investment for operators who think ahead.

SUSBIO ECOTREAT as a Plug-and-Play Upgrade

SUSBIO ECOTREAT brings a game-changing approach to sewage treatment plant modernization. This fiber-reinforced plastic (FRP) prefabricated system comes ready for immediate installation and eliminates extensive construction needs. Indian municipalities and global operators benefit from this plug-and-play design that cuts down installation time and labor costs. What once took months now takes just weeks to complete.

Automation and SCADA Integration for Remote Control

SCADA (Supervisory Control and Data Acquisition) systems make detailed monitoring of treatment processes possible from centralized locations. These platforms track and control remote operations effectively. Facilities can now run with minimal human intervention while maintaining consistent performance. ABB control technologies deliver high operational security and smoothly integrate field devices with process automation.

Energy-Efficient Pumps and Variable Frequency Drives

Variable Frequency Drives (VFDs) boost energy efficiency by adjusting pump speeds based on actual needs. This technology cuts energy consumption by up to 50% compared to fixed-speed systems. Motors use nearly 70% of industrial electrical energy. VFDs prove to be a smart investment that typically pays for itself within 1-3 years.

Advanced Oxidation for Nutrient Removal

Advanced Oxidation Processes (AOPs) remove stubborn nutrients through highly reactive hydroxyl radicals. These techniques excel at removing nitrogen and phosphorus compounds. Treatment facilities can meet stricter discharge regulations while reducing their effect on the downstream environment.

Ensuring Compliance and Future-Proofing the System

Effective sewage treatment plant operations depend on regulatory compliance in today’s strict environmental world. Smart operators focus on meeting current standards while getting ready for future regulations.

Meeting 2025 Discharge Norms with Modern STPs

The 2025 discharge norms in India demand much higher effluent quality standards that older systems find hard to meet. These requirements include:

- pH between 6.5-8.5

- BOD ≤ 10 mg/L

- TSS ≤ 10 mg/L

- Fecal Coliform ≤ 100 MPN/100mL

SUSBIO ECOTREAT systems give Indian municipalities and international operators automated solutions. These track vital parameters through inline sensors with immediate monitoring to meet these strict standards consistently.

Training for Compliance and Operational Excellence

Operator training plays a vital role in maintaining regulatory compliance. The right training programs give personnel knowledge in key areas:

- Environmental regulations and compliance strategies

- Performance monitoring and optimization techniques

- Risk assessment and audit preparation

What Are the Main Steps in Sewage Treatment Today?

Modern sewage treatment works through a series of refined processes. The process starts with screening and grit removal to eliminate large debris. Primary sedimentation then removes settleable solids. Biological processes break down organic matter in secondary treatment. The final step uses tertiary processes like filtration and disinfection to polish the effluent before discharge. Automated monitoring across these stages ensures the discharge meets requirements. This creates an eco-friendly cycle that protects public health and environmental quality.

Conclusion

Sewage treatment infrastructure is deteriorating and creating huge financial and operational challenges for municipalities worldwide. These aging systems rack up massive maintenance costs, cause dangerous downtime, and fail to meet modern regulatory requirements. Plant managers should base their decisions on a full picture of structural needs rather than just responding to emergencies.

The numbers tell a clear story – quick repairs might be cheaper now but don’t fix the real problems underneath. Research shows that tech upgrades save much more money over time, even though they cost more upfront. SUSBIO ECOTREAT proves to be an excellent choice for Indian municipalities and global operators because it’s easy to install, takes up little space, and comes with advanced monitoring features.

Limited space becomes the biggest problem when upgrading infrastructure in crowded areas. SUSBIO ECOTREAT solves this by needing just 720 m² of space, which makes it perfect to modernize existing facilities without major expansion.

Energy costs drop quickly with the right upgrades. Modern pumps with Variable Frequency Drives can cut power use in half. Automated SCADA systems let operators monitor everything remotely, which reduces labor costs and mistakes.

Meeting regulations shapes many infrastructure decisions today. Legacy systems can’t consistently meet the strict effluent quality standards coming in 2025. SUSBIO ECOTREAT tackles this head-on with real-time monitoring and advanced oxidation that removes tough contaminants effectively.

Smart planning means balancing today’s needs with tomorrow’s sustainability. Of course, today’s choices about sewage infrastructure will affect public health, environmental quality, and city budgets for decades. A careful review, strategic upgrades, and innovative solutions like SUSBIO ECOTREAT can help turn aging sewage plants into efficient, compliant systems ready for the future.

Key Takeaways

Aging sewage infrastructure is creating a financial crisis for municipalities worldwide, with hidden costs that extend far beyond annual maintenance budgets. Here are the essential insights for preventing costly infrastructure failures:

- Aging systems cost exponentially more: Legacy STPs average ₹2.5 billion in maintenance costs, with 81% of US plants operating at dangerous capacity limits.

- Strategic replacement beats reactive repairs: While repairs cost less upfront, replacement offers long-term savings and regulatory compliance for systems beyond design life.

- Modern technology delivers immediate ROI: Variable frequency drives cut energy costs by 50%, while automated SCADA systems reduce labor expenses and human error.

- Compact solutions solve space constraints: SUSBIO ECOTREAT requires only 720 m² for retrofitting, making upgrades feasible in dense urban environments.

- 2025 compliance demands proactive upgrades: New discharge norms require BOD ≤10 mg/L and advanced monitoring that legacy systems cannot consistently achieve.

The key to managing sewage infrastructure costs lies in proactive assessment and strategic technology adoption. Municipalities that invest in modern, automated solutions today will avoid the exponential maintenance costs and regulatory penalties that plague aging systems tomorrow.

Frequently Asked Questions

Q1. What are the main challenges facing aging sewage treatment infrastructure?

Aging sewage treatment infrastructure faces issues like increased maintenance costs, reduced efficiency, and difficulty meeting modern regulatory standards. Many facilities are operating beyond their intended lifespan, leading to potential system failures and environmental risks.

Q2. How can municipalities determine whether to repair or replace their sewage treatment systems?

Municipalities should conduct thorough structural assessments and cost-benefit analyzes. While repairs may cost less initially, replacement often offers long-term savings and better compliance with regulations. Factors like operational efficiency, space constraints, and future expansion needs should also be considered.

Q3. What technological upgrades can help reduce long-term costs in sewage treatment plants?

Key technological upgrades include automation and SCADA integration for remote control, energy-efficient pumps with variable frequency drives, and advanced oxidation processes for nutrient removal. These improvements can significantly reduce energy consumption, labor costs, and maintenance expenses.

Q4. How does the SUSBIO ECOTREAT system address common sewage treatment challenges?

SUSBIO ECOTREAT offers a compact, plug-and-play solution that’s ideal for retrofitting existing plants with limited space. It features advanced monitoring capabilities, efficient biological treatment methods, and helps facilities meet strict discharge norms while reducing operational costs.

Q5. What are the key steps in modern sewage treatment processes?

Modern sewage treatment typically involves four main steps: preliminary treatment to remove large solids, primary treatment for settling solid particles, secondary treatment using microorganisms to remove biological matter, and tertiary treatment for final filtration and disinfection before discharge.