The world faces a huge challenge in industrial wastewater treatment as we approach 2025. Every year, we generate about 380 billion cubic meters of wastewater globally. This number will jump by 51% by 2050. The situation is serious because 80% of this wastewater goes untreated straight into our environment.

Different regions handle industrial wastewater treatment differently. High-income regions like North America, Western Europe, and Japan treat 74% of their wastewater properly. Low-income regions can only manage 4%. Natural water bodies can clean themselves to some extent, but the amount of untreated wastewater is a big deal as it means that nature’s self-cleaning ability can’t keep up. The way we handle industrial wastewater is changing faster, and companies now focus on recovery and reuse instead of just disposal. Clean drinking water access, environmental protection, and reduced greenhouse gas emissions make wastewater treatment a vital part of our future.

Let’s take a closer look at why old methods aren’t working anymore. Industries of all sizes worldwide now try to produce less waste and recycle more within their processes. Traditional treatment methods show clear limitations, which makes 2025 a key year to rethink how we manage industrial wastewater.

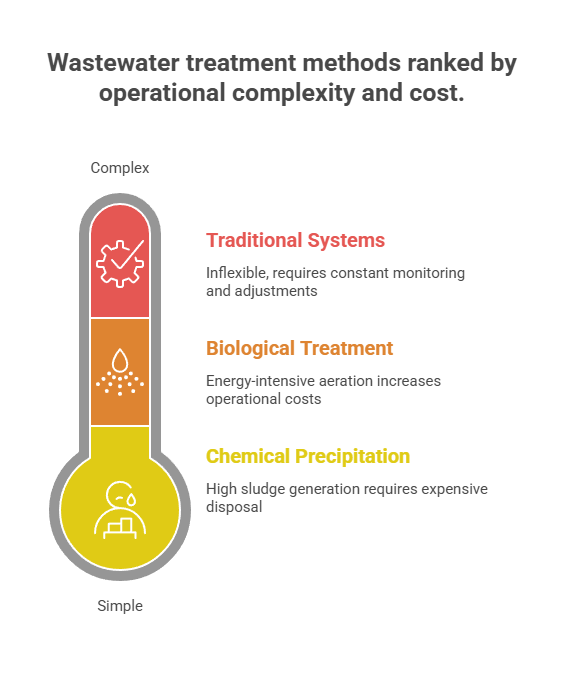

Limitations of Traditional Industrial Wastewater Treatment Methods

Traditional industrial wastewater treatment methods no longer meet today’s complex effluent requirements. These old approaches that seemed good enough in the past now face several technical and operational problems that reduce their effectiveness.

Low removal efficiency for emerging contaminants

Emerging contaminants (ECs) create a tough challenge because they often combine with other compounds or change into more toxic forms. This guides us to a worrying phenomenon called negative removal efficiency, where EC levels in effluent can exceed influent levels—sometimes reaching up to 5731%. Pharmaceutical contaminants show this problem especially when you have some lasting more than a year. Treatment plants of all sizes show the highest negative removal for compounds like Carbamazepine and Carbadox. Pesticides and beta-blockers rank among the most concerning negative removal rates for micropollutants, which could cause health risks like low blood pressure.

High sludge generation in chemical precipitation

Chemical precipitation, accessible to more people for removing metals and inorganics, creates large sludge volumes that need extra treatment. Research shows sludge production increases linearly with coagulant dosage. It produces 0.49–0.82 mg of sludge per mg of ferric chloride for aerobic effluents and 0.40–0.64 mg/mg for anaerobic effluents. The resulting sludge needs expensive handling and disposal, which makes operational costs get pricey.

Energy-intensive aeration in biological treatment

Aeration stands as the biggest energy consumer in wastewater treatment and takes up 67.3% of total energy use. Standard biological treatment’s aeration unit uses 0.53 kWh/m³. From a practical viewpoint, a sewage treatment plant with 5 ML capacity uses about 130,000 kWh monthly, costing around AUD 29,000. Low temperatures (18–22°C) slow down microorganism growth, which requires longer aeration periods and uses more energy.

Inflexibility in treating variable industrial effluents

Standard treatment systems struggle to handle industrial effluents’ changing composition. These systems often fail and separate solids and liquids poorly when pH, temperature, or pollutant levels fluctuate. Biological processes become vulnerable to toxin inhibition because microbes stop working when exposed to compounds like benzene and toluene. This inflexibility requires constant monitoring and frequent adjustments, making industrial wastewater management more complex and expensive.

Why 2025 Is a Tipping Point for Industrial Wastewater Management

The year 2025 is a turning point for industrial wastewater management. New regulations, economic pressures, and environmental concerns are changing how facilities deal with their wastewater.

Stricter discharge regulations and compliance costs

Industrial facilities face tougher regulations than ever in 2025 as environmental agencies tighten their wastewater discharge standards. The EPA is developing new effluent guidelines for several industrial categories and focuses on limiting PFAS discharges. Many jurisdictions are now reissuing permits with stricter requirements. Connecticut’s scheduled reissuance of multiple industrial wastewater permits in October 2025 shows this trend. These changes mean higher compliance costs for companies, including permit fees, regular monitoring expenses, and possible violation fines.

Increased water reuse mandates in water-scarce regions

By 2025, 66% of people worldwide will face water shortages. This has pushed governments to create mandatory water reuse policies. The EU has set quality standards to safely reuse treated urban wastewater for agricultural irrigation. India requires its cities to recycle at least 20% of their water, with higher targets planned. Large industrial water users must treat and reuse 20% of their wastewater by 2027-28. This target will go up to 50% by 2031.

Rising operational costs of legacy treatment systems

Old wastewater systems create major costs for facilities. These outdated systems use too much energy, which leads to high utility bills. Aeration processes alone make up 50-80% of energy costs in wastewater treatment plants. The equipment needs frequent repairs, requires special staff training, and creates more waste because it doesn’t work efficiently.

Public pressure and ESG reporting requirements

ESG audits became a requirement, not an option, starting in 2024. A company’s ESG performance affects its customer relationships, supplier deals, insurance rates, and ability to hire talent. Companies must now report:

- Total water withdrawals, consumption, and discharges

- Financial risks related to water shortages

- Percentage of treated wastewater they reuse

This push for transparency means industrial facilities need better wastewater treatment systems.

Advanced Technologies Replacing Legacy Systems

New wastewater treatment technologies are replacing old systems faster than ever. Industries need better solutions for complex effluents. These advanced systems work better than conventional methods and deliver outstanding results.

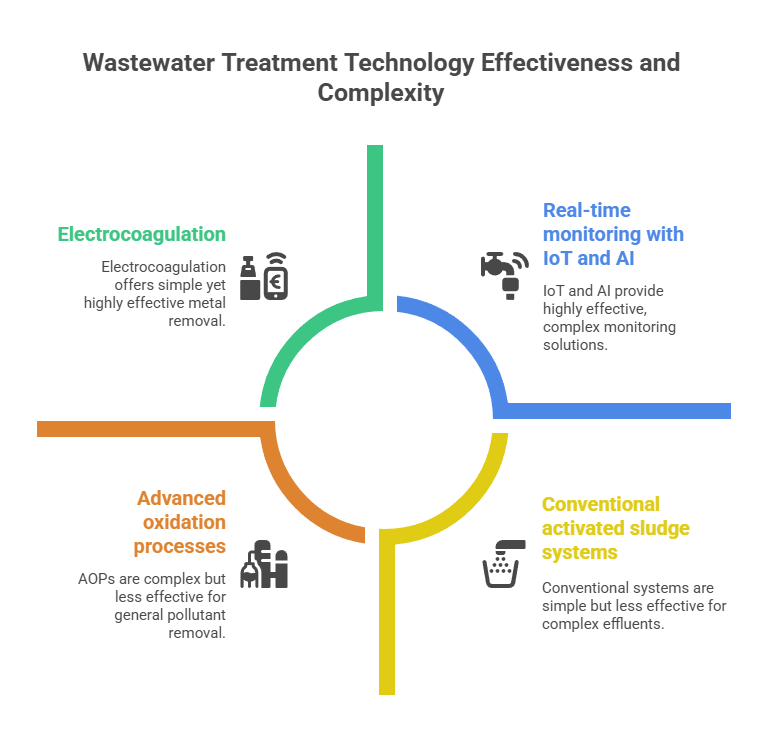

Electrocoagulation for heavy metal and oil removal

Electrocoagulation removes heavy metals through an electrochemical process that uses iron or aluminum electrodes. Electric current flowing through electrodes in wastewater creates metal cations that form hydroxide precipitates to capture pollutants. The results are impressive – lead removal reaches 100% in just 20 minutes. The system removes 98-100% of cadmium, zinc, nickel, and copper. The process creates less sludge than chemical precipitation (0.68–2.50 kg/m³) and uses only 0.37–2.78 kWh/m³ of energy.

Membrane bioreactors (MBRs) in high-BOD wastewater

MBRs blend biological processes with membrane filtration to treat high-strength industrial effluents efficiently. The global MBR market grows at 7% CAGR each year and should hit $4.2 billion by 2024. MBRs work better than conventional activated sludge systems. They don’t need sedimentation tanks, work with higher mixed liquor suspended solid concentrations, and produce cleaner effluent. These systems excel at treating high-BOD industrial wastewater because they keep slow-growing microorganisms that break down stubborn organic matter.

Advanced oxidation processes (AOPs) for pharmaceutical residues

AOPs create powerful hydroxyl radicals that break down pharmaceutical compounds in wastewater. Ozonation removes carbamazepine in 20 minutes with 95% mineralization efficiency. Fenton and photo-Fenton processes use iron catalysts to generate hydroxyl radicals and work best in acidic conditions. These methods stand out because they target all pollutants, work quickly, and leave minimal harmful byproducts.

Real-time monitoring with IoT and AI-based analytics

IoT-based systems track critical parameters like pH, dissolved oxygen, electrical conductivity, and turbidity constantly. AI algorithms use this data to make treatment processes better, spot equipment problems early, and meet regulations. Machine learning models predict how well different contaminants will be removed. Some models achieve determination coefficients (R²) of 0.997. Smart systems control valves automatically and send alerts right away to stop contamination before it happens.

Transitioning to Circular and Sustainable Treatment Models

Many industrial facilities around the world now use circular economy principles to manage wastewater. Their focus has moved from simple treatment to recovering and reusing valuable resources.

Anaerobic digestion for biogas recovery

Anaerobic digestion turns organic waste into biogas when microbes break it down without oxygen. This process converts complex organic molecules into methane (50-60%) and carbon dioxide (30-40%). The process helps industries get valuable biogas while they treat high-strength effluents. Modern anaerobic systems now treat 25.8 million kg of organic pollution daily in 1,500 installations worldwide. These systems produce enough biogas to meet 2.8 million Dutch households’ natural gas needs and cut CO2 by 11.2 Mt each year.

Zero-liquid discharge (ZLD) systems in textile industry

The textile industry uses billions of cubic meters of water every year. ZLD systems make sure no liquid waste exits the facilities. The treated wastewater goes back into the system while solids get processed safely. These systems also recover valuable materials like caustic soda and polyvinyl alcohol. Tirupur has more than 18 Common Effluent Treatment Plants with ZLD systems that treat millions of liters daily.

Water reuse in closed-loop industrial processes

Closed-loop systems can reuse up to 98% of water. The benefits are significant:

- Less freshwater needed

- Lower wastewater discharge

- Reduced environmental effects

- Better operational costs

Nutrient recovery from food and agro-industrial effluents

Agro-industrial wastewater has nutrients like nitrogen and phosphorus that can be recovered. New technologies can recover up to 87% of phosphate and 77% of ammonia. Microalgal cultivation can turn livestock farm effluents into useful products and remove pollutants at the same time.

Decentralized treatment for remote industrial sites

Decentralized systems treat wastewater right where it’s needed. These systems cost less to build and run while helping recover resources. They work great for remote industrial locations, small communities, and industrial plants. Technologies like membrane aerated biofilm reactors use 90% less energy than standard systems.

Why SUSBIO and SUSBIO ECOTREAT is the Best Choice for Treating Industrial Wastewater

As industries face growing regulatory pressures, rising operational costs, and urgent environmental responsibilities, selecting the right wastewater treatment partner is more critical than ever. SUSBIO, a pioneering force in sustainable water management, offers an advanced, reliable, and future-ready solution with its flagship technology – SUSBIO ECOTREAT.

1. Engineered for Complex Industrial Wastewater

Unlike standard sewage treatment solutions that struggle with fluctuating effluent characteristics, SUSBIO ECOTREAT is custom-designed to handle diverse and variable industrial waste streams. Whether it’s high COD/BOD from food processing, toxic compounds from chemical industries, or high-salinity effluents from textile plants, SUSBIO ECOTREAT adapts and performs consistently with high treatment efficiency.

2. Advanced Dual-Stage Biological & Tertiary Treatment

SUSBIO ECOTREAT uses a dual treatment process that combines robust biological degradation with advanced tertiary treatment. This ensures:

High organic load removal

Effective elimination of color, odor, and pathogens

Compliance with stringent discharge norms, including CPCB and ZLD mandates

This modular and prefabricated system also integrates optional AOP units or membrane filtration (MBR/UF) to target pharmaceutical residues, dyes, or emerging contaminants.

3. Energy-Efficient & Cost-Effective Operation

Traditional STPs consume high energy – especially in aeration. SUSBIO ECOTREAT employs:

Smart aeration systems with VFDs

Energy-optimized blowers and pumps

Low-footprint treatment modules that reduce civil construction and associated costs

This brings over 40% reduction in energy consumption compared to conventional treatment systems, making it ideal for industries under tight OPEX controls.

4. Plug-and-Play Installation with Minimal Downtime

Industries can’t afford long commissioning cycles. SUSBIO ECOTREAT is prefabricated and factory-tested, allowing for:

Quick on-site setup

Minimal civil work

Rapid deployment even in remote or constrained industrial plots

Its compact footprint and modular scalability make it suitable for retrofitting or upgrading outdated treatment plants as well.

5. Remote Monitoring and AI-Based Control

SUSBIO integrates IoT-based remote monitoring and AI-assisted process control across its systems. Users benefit from:

Real-time insights on pH, COD, BOD, turbidity, and flow

Instant alerts and auto-correction for anomalies

Dashboard reporting aligned with ESG and sustainability disclosures

This digitization allows industries to stay compliant and data-driven, essential in the era of ESG reporting and sustainability scorecards.

6. Proven Industrial Success Across Sectors

SUSBIO has successfully implemented ECOTREAT systems in:

Food & beverage processing units

Pharma and chemical industries

Dairy, textile, and agro-industrial plants

Industrial parks and SEZs

Breweries and distilleries

Each installation is backed by in-house service and maintenance teams, ensuring continuous plant performance and long-term reliability.

7. Circular Economy Alignment and Resource Recovery

SUSBIO ECOTREAT supports reuse and resource recovery. From treated water reuse in cooling towers and boiler feed, to biogas recovery and nutrient extraction, the system aligns with circular economy principles and national mandates like India’s 20%-50% industrial water reuse target.

Industries adopting ECOTREAT benefit not only in compliance and cost but also in building green credentials and achieving Net-Zero water goals.

Conclusion: The Future of Industrial Wastewater Treatment Starts Now

As we enter a critical juncture in 2025, the landscape of industrial wastewater treatment is undergoing a paradigm shift. The days of relying on traditional, rigid, and energy-hungry treatment systems are numbered. With rising effluent complexities, stricter environmental regulations, growing water scarcity, and mandatory ESG disclosures, industries can no longer afford to treat wastewater as a byproduct—they must view it as a resource and a responsibility.

Legacy systems—once considered reliable—now fall short in efficiency, flexibility, and sustainability. They struggle with emerging contaminants, generate excess sludge, consume enormous energy, and offer limited scope for water reuse or resource recovery. This has triggered an industry-wide need for smarter, circular, and future-proof treatment models.

Advanced technologies like electrocoagulation, MBRs, AOPs, and IoT-driven analytics are reshaping the sector. They offer higher efficiency, lower operational costs, better adaptability, and compliance with evolving global norms. Forward-thinking industries are not just upgrading; they are transforming their wastewater management strategies to align with circular economy principles and long-term environmental goals.

This is where SUSBIO emerges as a transformative leader.

With its state-of-the-art SUSBIO ECOTREAT packaged STP, SUSBIO delivers a robust, modular, and intelligent solution tailored for the complex needs of modern industrial wastewater. Designed to handle highly variable effluents, achieve exceptional treatment quality, and support water reuse and energy recovery, SUSBIO ECOTREAT is the answer to the challenges of today and tomorrow.

It is compact, prefabricated, easy to install, and integrates cutting-edge technologies—making it ideal for industries seeking minimal downtime, maximum efficiency, and long-term sustainability. Backed by real-time monitoring, AI-powered optimization, and dedicated in-house service, SUSBIO empowers industries to not just meet compliance—but to lead in sustainability.

In a world where untreated wastewater threatens ecosystems, regulatory pressure mounts, and businesses are judged by their environmental impact, choosing the right wastewater treatment solution is not a technical decision—it’s a strategic imperative.

Choose smart. Choose sustainable. Choose SUSBIO ECOTREAT — the future of industrial wastewater treatment.

Frequently Asked Questions (FAQs)

1. Why are traditional wastewater treatment methods failing in 2025?

Traditional methods struggle with today’s complex industrial effluents, emerging contaminants, and energy inefficiencies. They often fail to meet stricter environmental regulations and can’t adapt to variable wastewater loads, making them obsolete for modern industrial needs.

2. What are emerging contaminants and why are they a concern?

Emerging contaminants (ECs) include pharmaceuticals, pesticides, and chemicals not fully removed by conventional systems. They can be harmful to human health and aquatic ecosystems, and in some cases, their concentration increases after treatment due to chemical transformations.

3. What is the most energy-efficient solution for industrial wastewater treatment?

Technologies like SUSBIO ECOTREAT, membrane bioreactors (MBRs), and membrane-aerated biofilm reactors offer energy-efficient alternatives. SUSBIO ECOTREAT reduces energy consumption by over 40% through optimized aeration and smart control systems.

4. Can treated industrial wastewater be reused?

Yes. With advanced treatment technologies, treated wastewater can be safely reused for cooling, irrigation, flushing, and even certain industrial processes. Systems like SUSBIO ECOTREAT support high-quality treatment suitable for closed-loop reuse.

5. Why choose SUSBIO and SUSBIO ECOTREAT for industrial wastewater treatment?

SUSBIO ECOTREAT is a prefabricated, plug-and-play solution designed for flexibility, efficiency, and compliance. It handles complex effluents, reduces operational costs, supports automation and ESG reporting, and promotes sustainable water reuse—making it a future-ready choice for industries in 2025 and beyond.