Delhi needs reliable sewage treatment plant manufacturers more than ever as the city struggles with clean water demands and safe discharge. The city’s rapid industrialization has increased the need for better wastewater treatment technologies by a lot. Picking the right STP solution needs a close look at certifications, technology, and after-sales support.

SUSBIO leads the pack as Delhi’s top sewage treatment plant manufacturer. Their SUSBIO ECOTREAT systems deliver excellent performance and reliability. This piece will show you why ISO certification matters when choosing manufacturers. You’ll learn about SUSBIO ECOTREAT systems’ benefits, see how different STP technologies stack up, and get a detailed guide to find the right solution for your needs.

Why ISO Certification Matters in STP Manufacturing

ISO certification serves as a key standard for sewage treatment plant manufacturers. It proves they can deliver quality systems reliably. With over a million certificates issued in 189 countries, ISO 9001 remains the most widely used quality management standard worldwide.

ISO 9001:2015 Standards for Quality Management

ISO 9001:2015 certification gives sewage treatment plant manufacturers a systematic framework to deliver consistent, quality products and services. The certification covers leadership, planning, support, operations, performance evaluation, and continuous improvement. Sewage treatment plant manufacturers in Delhi NCR use this certification to standardize their processes, cut costs and remove inefficiencies. The certification builds a culture of continuous improvement that helps clients get better system performance.

Quality management systems that match international best practices come from ISO 9001:2015 certification. This becomes vital in an industry where water’s safety and purity affect public health and environmental protection directly.

Impact on Design, Installation, and Maintenance

ISO certification reshapes how companies design, install, and maintain sewage treatment plants. Certified manufacturers follow standard procedures that lead to:

- Better consistency in production that eliminates recalls and rework

- Higher product quality through systematic error detection

- Improved risk management for health, safety, and environmental aspects

As a result, sewage treatment plants from ISO-certified manufacturers like SUSBIO work more efficiently with fewer issues. SUSBIO, Delhi’s best sewage treatment plant manufacturer, shows how ISO standards create superior system performance through careful quality control.

Compliance with Delhi Jal Board and CPCB Guidelines

ISO certification helps companies meet local regulations easily. Delhi’s wastewater treatment facilities must follow Delhi Jal Board and Central Pollution Control Board (CPCB) guidelines strictly. ISO-certified manufacturers have systems that make meeting regulations simpler.

ISO 14001, another key certification, focuses on environmental management systems that reduce water contamination and waste. This matches CPCB’s requirements for sewage treatment plants perfectly. ISO-certified manufacturers can meet regulatory standards better through established controls and regular audits.

SUSBIO: The Best Sewage Treatment Plant Manufacturer in Delhi

SUSBIO leads sewage treatment technology in Delhi by combining innovative engineering with eco-friendly practices. This premier sewage treatment plant manufacturer in Delhi created the SUSBIO ECOTREAT system—an advanced solution that tackles complex wastewater challenges for residential communities and industrial facilities.

Custom STP Designs for Residential and Industrial Use

SUSBIO delivers tailored wastewater treatment solutions through their advanced SUSBIO ECOTREAT system. The company first analyzes incoming wastewater characteristics, available space, and local environmental regulations to ensure optimal performance for each application. Their versatile systems come in two main configurations: capsule type (1-20 KLD) perfect for villas, small hotels, and offices; and cylinder type (20-500 KLD) ideal for apartments, factories, and commercial complexes. This modular design allows easy scaling as needs change, making SUSBIO ECOTREAT suitable for projects of any size.

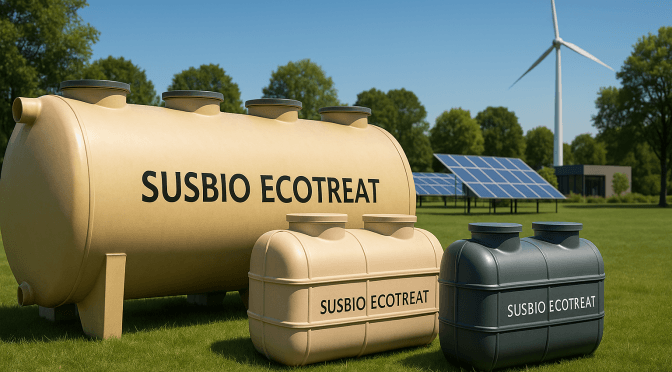

Energy-Efficient Systems with Low O&M Costs

SUSBIO ECOTREAT’s most impressive feature is its energy efficiency. The system uses 90% less electricity than conventional sewage treatment plants, which dramatically reduces operational costs. This efficiency comes from:

- Fully automated operation that needs no on-site operator

- Advanced dual treatment process that combines anaerobic and aerobic methods

- Reliable fiber-reinforced plastic construction that ensures durability and noise-free operation

The prefabricated, plug-and-play design cuts installation expenses, while minimal maintenance needs mean lower long-term ownership costs.

24/7 Technical Support and Onsite Assistance

SUSBIO stands out with its detailed support services that go beyond installation. Their technical team trains operators and maintenance personnel to ensure proper system management and compliance with environmental standards. The SUSBIO ECOTREAT’s sophisticated automation lets technicians monitor and troubleshoot remotely, which reduces on-site visits while maintaining reliable performance in unmanned locations.

Client Testimonials and Project Case Studies

SUSBIO has built a proven track record of successful installations in Delhi NCR across many sectors. Their project portfolio spans residential complexes, commercial establishments, and industrial facilities—each showing SUSBIO ECOTREAT system’s versatility and effectiveness. The high-quality treated water meets regulatory standards and works well for landscaping, toilet flushing, cooling towers, and various industrial processes, which supports vital water conservation efforts in the region.

Comparing STP Technologies Used by Delhi Manufacturers

Delhi manufacturers provide a range of sewage treatment technologies. Each technology meets specific requirements. A clear understanding of these technologies helps you make better decisions about wastewater management.

MBBR vs SBR: Which is Better for Your Site?

The choice between Moving Bed Biofilm Reactor (MBBR) and Sequencing Batch Reactor (SBR) technologies comes down to how well they operate. MBBR works as a continuous flow system with biofilm carriers. SBR runs in batch mode using suspended activated sludge. MBBR shows great resilience at sites with changing waste loads, which makes it perfect for industrial use. SBR works best with steady, moderate flows.

Space often decides which system you should pick. MBBR needs about 1/3 less space than SBR for a 1 MLD plant. The system also creates less sludge and runs more simply with minimal oversight. SBR just needs precise cycle control.

MBR for High-End Applications in Hospitals and Hotels

Membrane Biological Reactor (MBR) technology stands out as the premium choice for sophisticated facilities. MBR combines biological treatment with membrane filtration. This combination removes the need for secondary clarifiers and cuts the footprint by up to 50%. Urban settings with limited space benefit greatly from this technology.

Many Delhi institutions use MBR systems. Max Hospital runs a 125 KLD capacity system. The technology produces reuse-ready effluent consistently. This makes it a perfect fit for hotels and healthcare facilities that need pristine water quality.

Zero Liquid Discharge (ZLD) Integration Options

Delhi’s sewage treatment plant manufacturers now offer ZLD integration. This ensures zero liquid waste enters the environment. These detailed systems combine pretreatment, membrane filtration, evaporation, and crystallization. This combination maximizes water recovery.

SUSBIO ECOTREAT leads Delhi’s STP manufacturing sector. They implement these groundbreaking solutions that help facilities turn wastewater from a problem into an asset. Their systems also recover valuable byproducts.

How to Select a Reliable Sewage Treatment Plant in Delhi NCR

You need a full picture of technical factors to select the right sewage treatment plant. These essential guidelines will help you make an informed decision while evaluating sewage treatment plant manufacturers in Delhi NCR.

Checklist: Flow Rate, Load, and Space Constraints

The right STP selection needs accurate wastewater volume calculations as its foundation. Residential buildings need 50-100 liters of sewage generation per person daily. You should multiply this by the number of occupants. Business facilities need to account for employee numbers and business type. The range varies from 25-500 liters per person each day. A peak flow multiplier of 1.2-2.5 helps handle usage spikes.

Your available space often decides the technology choice. SUSBIO’s expandable solutions need just 60 square meters for a standard 100 KLD plant.

AMC and Remote Monitoring Capabilities

Annual Maintenance Contracts (AMC) keep operations running smoothly through regular checks, preventive maintenance, and better performance. A complete AMC includes:

- Regular maintenance visits from skilled technicians

- Quick emergency support

- Spare parts management

- Performance tracking and improvements

Turnkey Installation vs Modular Units

Turnkey installations give you end-to-end solutions with minimal work on your part. Modular systems are different – they offer flexibility through standardized, expandable units that grow with your needs.

Top Questions to Ask Your STP Vendor

Ask these questions before you decide:

- Does the system meet Delhi Jal Board and CPCB guidelines?

- Which technology fits my space and flow needs best?

- What options do I have for remote monitoring?

- What does the AMC package include?

SUSBIO ECOTREAT stands out among sewage treatment plant manufacturers in Delhi NCR. They deliver custom solutions that perform exceptionally well.

Conclusion

Selecting the right sewage treatment plant manufacturer is a vital step to address Delhi’s growing wastewater management challenges. This piece explores several key aspects that will guide your decision-making process. ISO certification serves as a key measure that will give a reliable and compliant manufacturing process.

The comparison between MBBR, SBR, and MBR technologies shows how each system meets specific needs based on flow rates, space constraints, and treatment objectives. A clear understanding of these technical differences helps select the most suitable solution for your needs.

SUSBIO stands out as Delhi’s best sewage treatment plant manufacturer. Their energy-efficient systems use 90% less electricity than standard alternatives. Custom designs for residential and industrial applications work well for projects of all sizes. Their complete technical support ensures smooth operation throughout the system’s lifecycle.

Your final decision should be based on a full picture of your specific needs – flow rate calculations, available space, and maintenance capabilities. The next step is to assess manufacturers based on their certification, technology offerings, and after-sales support.

Without doubt, SUSBIO provides unmatched value through their innovative SUSBIO ECOTREAT systems. They are nowhere near a match for other sewage treatment plant manufacturers in Delhi NCR. Advanced technology, energy efficiency, and outstanding customer support create a complete package that meets both immediate treatment needs and long-term sustainability goals.

Delhi faces ongoing water management challenges. An ISO-certified manufacturer like SUSBIO meets strict regulatory standards while delivering reliable performance for years. The right sewage treatment solution protects public health and environmental integrity. It also contributes by a lot to water conservation efforts in the region.

Key Takeaways

When selecting sewage treatment plant manufacturers in Delhi, these essential insights will guide you toward the most reliable and cost-effective solution for your wastewater management needs.

• ISO certification is non-negotiable – Choose manufacturers with ISO 9001:2015 and ISO 14001 certifications to ensure quality management, regulatory compliance, and environmental standards adherence.

• SUSBIO ECOTREAT leads Delhi’s STP market – Their systems consume 90% less electricity than conventional plants while offering fully automated operation and comprehensive technical support.

• Technology selection depends on specific requirements – MBBR suits variable industrial loads, SBR works for consistent flows, while MBR provides premium treatment for hospitals and hotels.

• Calculate flow rates accurately before purchasing – Multiply occupants by 50-100 liters daily for residential use, include peak flow multipliers of 1.2-2.5, and consider future expansion needs.

• Prioritize comprehensive AMC and remote monitoring – Ensure your vendor offers 24/7 technical support, preventive maintenance contracts, and remote system monitoring capabilities for optimal performance.

The right sewage treatment plant manufacturer combines proven technology, regulatory compliance, and ongoing support to transform wastewater management from a challenge into a sustainable solution that protects both public health and the environment.

Frequently Asked Questions

Q1. What makes ISO certification important for sewage treatment plant manufacturers in Delhi?

ISO certification ensures that manufacturers follow standardized quality management processes, comply with regulatory guidelines, and maintain consistent product quality. It also helps in reducing inefficiencies and costs while promoting continuous improvement in sewage treatment plant design and operation.

Q2. How does SUSBIO ECOTREAT stand out among sewage treatment plant in Delhi?

SUSBIO ECOTREAT offers custom-designed, energy-efficient systems that consume 90% less electricity than conventional plants. They provide tailored solutions for both residential and industrial use, with 24/7 technical support and remote monitoring capabilities.

Q3. What are the main differences between MBBR and SBR technologies in sewage treatment?

MBBR (Moving Bed Biofilm Reactor) is a continuous flow system ideal for variable waste loads and requires less space. SBR (Sequencing Batch Reactor) operates in batch mode and is better suited for moderate, consistent flows. MBBR generally produces less sludge and requires simpler operation compared to SBR.

Q4. How should I calculate the required capacity when selecting a sewage treatment plant?

For residential buildings, multiply the number of occupants by 50-100 liters per day. For commercial facilities, factor in employee count and business type, ranging from 25-500 liters per person daily. Always include a peak flow multiplier of 1.2-2.5 to handle usage spikes.

Q5. What key features should I look for in a sewage treatment plant manufacturer’s after-sales support?

Look for comprehensive Annual Maintenance Contracts (AMC) that include regular inspections, preventive maintenance, and performance optimization. Additionally, prioritize manufacturers offering 24/7 technical support, remote monitoring capabilities, and emergency response services to ensure uninterrupted operation of your sewage treatment plant.