Sewage treatment plant manufacturers serve a significant role in Jodhpur’s water-scarce environment where preserving natural resources remains essential. Working sewage treatment plants (STPs) form the backbone of infrastructure that handles and recycles wastewater while meeting regulatory standards. These specialized systems work through physical, chemical, and biological stages to convert wastewater from commercial buildings, housing societies, and other sources into reusable water.

Our expertise as Jodhpur’s sewage treatment plant manufacturer shows that an STP’s quality determines its performance. The selection of an STP plant manufacturer in Jodhpur depends on discharge limits, effluent standards, and material quality. The complete treatment process starts with debris removal, moves to primary sedimentation, then to secondary biological treatment, and finishes with advanced tertiary filtration. SUSBIO leads the package sewage treatment plant manufacturing industry with our innovative SUSBIO ECOTREAT—the best packaged STP solution engineered for Jodhpur’s unique environmental conditions. This piece explores modern sewage treatment systems’ key components, cost factors, common selection mistakes, and the manufacturer’s role in long-term operational success.

Key Components of a Modern Sewage Treatment Plant

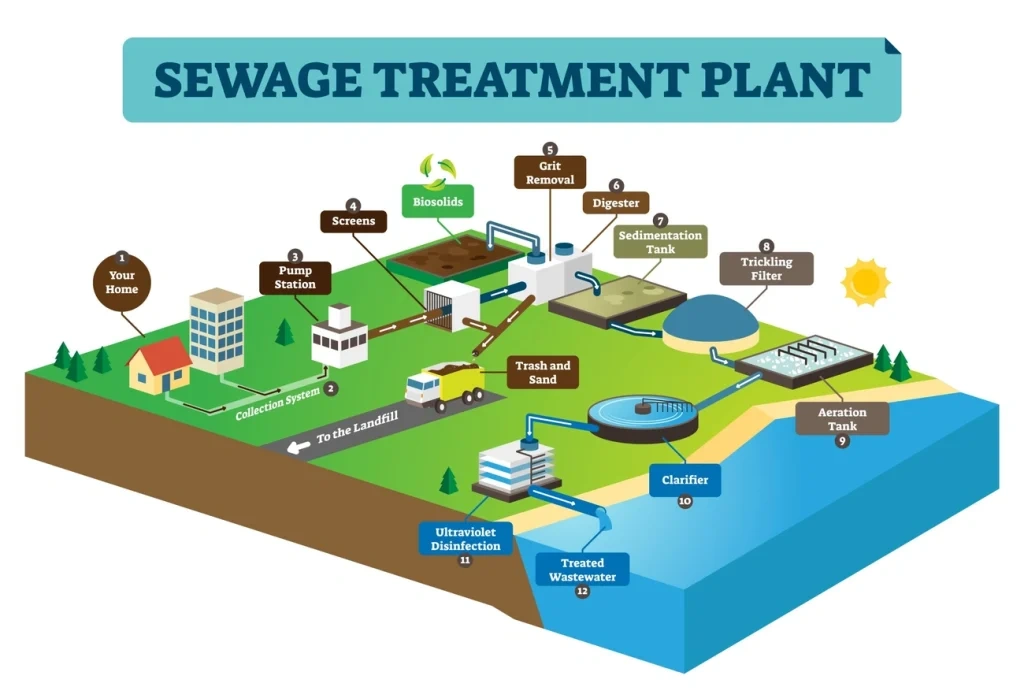

Modern sewage treatment plants have multiple integrated components that work together to turn raw wastewater into environmentally safe water. These sophisticated systems use mechanical, biological, and chemical processes to remove contaminants effectively.

Preliminary Treatment: Screening and Grit Removal

The treatment process starts with preliminary steps that protect downstream equipment from damage. Bar screens catch large objects like cans, rags, sticks, and plastic materials in sewage streams. Plant operators can clean these screens mechanically or manually based on the plant’s size and design. On top of that, grit chambers slow down incoming sewage, which lets sand, gravel, and heavy materials settle. Grit removal has three vital purposes: it cuts down deposits in tanks, reduces cleaning frequency, and protects mechanical equipment from wear due to abrasion. Modern plants commonly use horizontal flow, aerated, and vortex chambers as grit removal systems.

Primary Sedimentation: Settling of Suspended Solids

Primary sedimentation happens when wastewater moves slowly through large basins where gravity separation takes place. Heavy solids sink to the bottom as primary sludge, while oils, grease, and lighter solids float up for skimming. These basins, known as primary clarifiers, usually hold water for 1.5 to 2.5 hours. Most primary settling tanks have mechanically driven scrapers that constantly push collected sludge toward a hopper at the tank’s base for pumping to treatment facilities. This stage removes 50-70% of suspended solids and 25-40% of the biological oxygen demand from sewage.

Secondary Treatment: Aerobic and Anaerobic Processes

Secondary treatment uses biological processes to remove dissolved and suspended organic materials. This stage relies on microorganisms that eat organic pollutants while reproducing to form biological solids. Two main approaches exist:

Aerobic Treatment: This method needs oxygen and uses bacteria that break down organic compounds. It works best for low to medium-strength wastewater with BOD levels between 500-5,000 ppm. Common systems include activated sludge treatment, membrane bioreactors, and trickling filters.

Anaerobic Treatment: This process happens without oxygen and suits high-strength wastewater best. It creates methane-rich biogas as a valuable byproduct while producing less sludge than aerobic systems. Examples include anaerobic lagoons, upflow anaerobic sludge blanket reactors, and anaerobic filters.

Secondary treatment systems fall into two categories: fixed-film (where biomass grows on media) or suspended-growth systems like activated sludge.

Tertiary Treatment: Filtration and Disinfection

Tertiary treatment acts as the final polishing step before discharge. This stage eliminates pathogens, leftover suspended solids, and dissolved constituents. Filtration options include sand filtration, carbon adsorption, and membrane filtration, which can trap microscopic particles and pathogens. The disinfection process then kills remaining pathogenic microorganisms through chemical or physical means. Chlorine remains popular due to its effectiveness and low cost, though UV radiation and ozonation are becoming more common to avoid disinfection byproducts. These steps make water safe for environmental release or reuse in applications like irrigation.

Sludge Management and Disposal Techniques

Sewage treatment creates sludge (biosolids) that needs proper management. The main goal of sludge treatment is to reduce volume and stabilize organic materials through several processes:

Thickening: The first step cuts down sludge volume by removing water.

Digestion: This can be aerobic or anaerobic, breaking down organic matter and producing biogas in anaerobic systems.

Dewatering: This removes extra water through sand drying beds, centrifuges, or filter presses.

Operators can dispose of the final product through agricultural application as fertilizer, landfilling, or incineration, based on local regulations and sludge composition.

SUSBIO, a leading sewage treatment plant manufacturer in Jodhpur, blends these components efficiently in our systems, especially in our SUSBIO ECOTREAT packaged STP. This compact solution delivers advanced treatment capabilities while taking up minimal space—ideal for Jodhpur’s urban settings where space is limited.

Factors That Influence STP Plant Cost in Jodhpur

The cost of sewage treatment plants in Jodhpur depends on many factors. You need to assess several key elements that affect the final price before making your purchase decision.

Plant Capacity and Daily Load Requirements

The STP’s capacity plays a direct role in determining its cost. Here’s how STP systems are grouped based on daily treatment volume:

Small-Scale STPs (10-50 KLD): Perfect for small residential buildings, boutique hotels, and offices, these cost between ₹4-15 lakhs

Medium-Scale STPs (50-250 KLD): These work best for large apartment complexes, educational institutions, and hospitals, with prices from ₹6-40 lakhs

Large-Scale STPs (500+ KLD and above): Built for townships and industrial parks, prices start at ₹50 lakhs and can reach several crores for MLD-scale operations[103]

Industrial STPs cost 15-20% more than residential ones because they need to handle more complex waste treatment.

Technology Used: MBBR vs SBR vs MBR

Your choice of technology affects both your original investment and running costs:

MBR (Membrane Bioreactor) pairs membrane filtration with biological treatment to produce high-quality reusable water. It costs about 300 lacs per MLD but runs at higher biomass concentrations (MLSS of around 12,000 mg/l) and needs 50-70% less space than other options.

SBR (Sequencing Batch Reactor) uses an activated sludge process with lower operational MLSS of 3,000 mg/l. It’s budget-friendly when space isn’t an issue but needs separate settling and aeration tanks, which take up more room.

MBBR (Moving Bed Biofilm Reactor) strikes a balance between cost and efficiency. It uses biofilm carriers that give high surface area in compact spaces. The technology needs less space than activated sludge systems because it has concentrated biomass.

The capital costs rank from highest to lowest: MBR > SBR > MBBR.

Construction Material Quality and Longevity

Material quality makes a big difference in how long your plant lasts and what it costs to maintain. Better materials fight off environmental damage and need fewer repairs over time.

Modern sewage treatment plants use:

FRP (Fiber Reinforced Plastic): SUSBIO ECOTREAT uses FRP to get better structural strength and fight corrosion

Eco-friendly materials: These help the environment and make the system last longer

Using lower quality materials leads to higher maintenance costs, less efficient operation, and shorter system life.

Automation Level and Control Systems

Modern automation systems make STPs work better through:

Remote monitoring that cuts down on needed staff

Better accuracy and treatment results

Live analytics for maintenance planning

Smart control systems might cost more upfront but save money through better energy use, lower labor costs, and longer-lasting equipment.

Location-Specific Installation Challenges

Jodhpur has its own set of challenges that affect costs:

Road widths that range from 3m to 30m for sewerage networks

Rules set by local municipal authorities

Limited space in city areas that needs compact designs

Weather conditions typical of Rajasthan’s dry climate

SUSBIO, a leading sewage treatment plant maker in Jodhpur, tackles these challenges with SUSBIO ECOTREAT—a plug-and-play packaged STP solution. This smart system cuts down installation time because it needs no civil work. It fits perfectly in Jodhpur’s environment and reduces running costs by 30% compared to regular systems.

Common Pitfalls When Choosing an STP Manufacturer

Buyers who choose the wrong sewage treatment plant manufacturer face expensive problems, compliance issues, and system failures. My industry experience has shown several critical mistakes that keep happening.

Ignoring Site-Specific Design Requirements

Many buyers rush into STP system installation without proper site evaluation. The land’s topography, sewage inflow rate, and seasonal changes substantially affect treatment plant design and efficiency. A lack of detailed site assessment leads to problems like inadequate capacity, poor effluent quality, and operational inefficiencies. Industry data shows that custom engineering based on site requirements will give a system that works and meets regulations.

Underestimating Maintenance and AMC Needs

The biggest problem comes from neglecting maintenance requirements. Regular upkeep keeps the system running, but organizations often overlook its value. This neglect results in:

Offensive odors and sludge overflow

System blockages or complete breakdowns

Poor water quality and gray water issues

Non-compliance with Pollution Control Board standards

Potential fines or legal notices from environmental authorities

Quality STPs need maintenance every 6-12 months. Systems without proper Annual Maintenance Contracts (AMCs) can get pricey, with repair costs between ₹50,000 to ₹1 lakh. Good AMCs cover scheduled maintenance, system inspections, and critical repairs that keep operations smooth throughout the year.

Choosing Low-Grade Materials to Cut Costs

Many buyers pick the cheapest system without thinking about long-term efficiency and maintenance costs. Low-grade materials might save money upfront but end up causing frequent breakdowns, poor treatment, and shorter system life. SUSBIO, a sewage treatment plant manufacturer in Jodhpur, uses BIS-certified components in their SUSBIO ECOTREAT packaged STP systems to ensure durability and reliable performance.

Lack of Regulatory Compliance Certifications

Environmental standard violations can bring serious trouble. Clients often skip checking if their STP manufacturer follows CPCB (Central Pollution Control Board), State Pollution Control Board, and ISO standards. Non-compliance can result in fines from ₹50,000 to ₹5 lakh plus legal action. Facilities that need operational consent must prove they have a working treatment plant that meets discharge norms.

SUSBIO stands out as Jodhpur’s premier sewage treatment plant manufacturer. Their SUSBIO ECOTREAT packaged STP combines space-saving design with exceptional performance, making it perfect for Jodhpur’s environmental conditions and water conservation needs.

Why SUSBIO is the Best STP Plant Manufacturer in Jodhpur

SUSBIO distinguishes itself among sewage treatment plant manufacturers in Jodhpur with its advanced approach and excellence. The company has delivered trailblazing wastewater management solutions that suit Rajasthan’s environmental conditions since 2013.

Custom-Built STP Solutions for Residential and Industrial Use

SUSBIO leads Jodhpur’s sewage treatment plant manufacturing with solutions tailored to each client’s needs. Our skilled engineers and technicians use their years of experience to design systems that match specific requirements. We excel at creating prefabricated STPs that work well in residential complexes, commercial buildings, hospitals, hotels, and industrial facilities. This adaptability helps us solve unique challenges that different sectors face in Jodhpur.

Use of BIS-Certified Components and ISO Standards

Quality drives everything we do. SUSBIO uses BIS-certified components in all our sewage treatment plants to meet strict quality standards. We focus on durability and performance reliability while other manufacturers cut corners with materials. Our commitment to quality standards means our systems consistently produce treated water that’s safe for reuse or environmental discharge.

On-Site Installation and Post-Sales Support

SUSBIO provides round-the-clock support to keep STPs running smoothly all year. Our teams make sure all systems are properly set up and integrated. The company offers ongoing maintenance to prevent breakdowns and repairs from getting pricey. This complete service approach helps us save 4.3 million liters of water daily across our installations.

SUSBIO ECOTREAT: Best Packaged STP for Compact Spaces

SUSBIO ECOTREAT stands as our flagship packaged sewage treatment plant solution. This advanced system combines dual-treatment processes (biological and physical filtration) in a compact design. The prefabricated FRP construction will give a service life of 15-25 years. The system runs on minimal energy and uses 90% less electricity than conventional STPs. The modular design allows quick installation without extensive civil work, making it perfect for space-constrained areas in Jodhpur.

Checklist for Selecting a Reliable STP Manufacturer in India

A methodical approach helps identify the most reliable partner at the time of evaluating potential sewage treatment plant manufacturers. This practical checklist will guide you to make an informed decision for your wastewater management needs.

Experience in Handling Local Municipal Regulations

Reliable sewage treatment plant manufacturers should demonstrate proficiency with local compliance requirements. The best manufacturers have at least 5 years of industry experience. This expertise helps them understand Jodhpur’s specific environmental standards. They should possess proper certifications like BIS, ISO, or CPCB approvals. These certifications validate that their systems meet regulatory standards for treated water quality.

Availability of Compact and Package STP Models

Space constraints in urban areas make it essential to find manufacturers who provide compact sewage treatment solutions. The right companies offer modular, expandable designs that work well for both small and large setups. SUSBIO ECOTREAT stands out because of its plug-and-play installation. This system needs minimal space yet delivers superior performance with 90% less electricity consumption than conventional systems.

Client Portfolio and Case Studies

The manufacturer’s track record should show:

More than 50 successful installations

Case studies that highlight real-life performance metrics

Client testimonials that show actual savings (one client saved ₹15 lakh annually)

After-Sales Service and AMC Coverage

The manufacturer’s steadfast dedication to post-installation support needs careful evaluation. Complete Annual Maintenance Contracts cover maintenance of mechanical, electrical, and biological components. Quality AMC services include regular inspections, pollution norm monitoring, and preventive maintenance. These services will give regulatory compliance throughout the system’s lifespan.

Conclusion

Jodhpur needs proper sewage treatment to manage its water resources well. This piece looks at everything in modern STPs, starting from preliminary screening all the way to tertiary treatment. The choice of technology, material quality, and local conditions affect the overall costs by a lot.

Picking the wrong STP manufacturer will guide you toward costly problems and regulatory issues. Buyers often don’t deal very well with site requirements. They underestimate maintenance costs, pick poor quality materials, and miss important certifications.

SUSBIO has become Jodhpur’s top sewage treatment plant manufacturer. We offer custom-built solutions, BIS-certified components, and complete support services. Our SUSBIO ECOTREAT packaged STP tackles Jodhpur’s environmental challenges head-on. It works better in compact spaces than other systems. This innovative system cuts operating costs by 30% and uses 90% less electricity than regular systems.

Stakeholders should check a manufacturer’s experience with local rules. They need flexible solutions and proof of success through case studies. Good after-sales support matters too. SUSBIO checks all these boxes and keeps improving to handle Jodhpur’s growing wastewater needs.

The best sewage treatment solution helps you follow regulations. It also saves water in Jodhpur’s water-scarce region. SUSBIO stays committed to delivering eco-friendly, economical sewage treatment systems. We protect public health and the environment for future generations.

Key Takeaways

When selecting a sewage treatment plant manufacturer in Jodhpur, these essential insights will help you make an informed decision that ensures long-term operational success and regulatory compliance.

• Technology choice significantly impacts costs: MBR systems cost most but offer highest quality effluent, while MBBR provides economical operation in compact spaces

• Site-specific design prevents costly failures: Proper evaluation of topography, sewage flow rates, and local conditions ensures optimal system performance and compliance

• Quality materials reduce long-term expenses: BIS-certified components and superior construction materials minimize maintenance costs and extend system lifespan to 15-25 years

• Comprehensive AMC coverage is essential: Regular maintenance prevents system breakdowns, ensures regulatory compliance, and can save ₹50,000-₹1 lakh in repair costs annually

• SUSBIO ECOTREAT offers superior value: This packaged STP solution reduces operational costs by 30% and electricity consumption by 90% while requiring minimal installation space

The key to successful sewage treatment lies in partnering with experienced manufacturers who understand local regulations, provide quality components, and offer reliable post-installation support. SUSBIO’s proven track record in Jodhpur, combined with innovative solutions like ECOTREAT, makes them the ideal choice for sustainable wastewater management in water-scarce environments.

Frequently Asked Questions

Q1. What are the key components of a modern sewage treatment plant?

A modern sewage treatment plant typically consists of preliminary treatment (screening and grit removal), primary sedimentation, secondary treatment (aerobic and anaerobic processes), tertiary treatment (filtration and disinfection), and sludge management systems. Each stage plays a crucial role in transforming wastewater into environmentally safe water.

Q2. How does the choice of technology affect STP costs in Jodhpur?

The technology used in sewage treatment plants significantly impacts both initial investment and long-term operational expenses. MBR (Membrane Bioreactor) systems offer the highest quality effluent but are the most expensive, while MBBR (Moving Bed Biofilm Reactor) provides a cost-effective middle-ground option. SBR (Sequencing Batch Reactor) systems are economical but require more space.

Q3. What are common mistakes to avoid when choosing an STP manufacturer?

Common pitfalls include ignoring site-specific design requirements, underestimating maintenance needs, choosing low-grade materials to cut costs, and overlooking regulatory compliance certifications. These mistakes can lead to system failures, inefficiencies, and potential legal issues.

Q4. Why is SUSBIO considered a leading STP manufacturer in Jodhpur?

SUSBIO is recognized for its custom-built solutions, use of BIS-certified components, comprehensive on-site installation and post-sales support, and innovative SUSBIO ECOTREAT packaged STP. Their systems are designed to meet Jodhpur’s unique environmental conditions while offering superior performance and energy efficiency.

Q5. What should be considered when selecting an STP manufacturer in India?

When choosing an STP manufacturer, consider their experience with local regulations, availability of compact and packaged STP models, client portfolio and case studies, and the extent of their after-sales service and AMC coverage. These factors ensure you partner with a reliable manufacturer capable of meeting your specific wastewater management needs.