Did you know that industrial water consumption makes up 22% of global water use?

Water isn’t the free, abundant resource it used to be. Industries worldwide just need water as much as any other raw material. Our freshwater sources keep diminishing while global demand rises, creating a critical situation that needs eco-friendly solutions. This lack affects millions of people who live in arid and semi-arid regions.

The silver lining? Wastewater reuse provides a practical solution to bridge the gap between freshwater demand and available supply. Companies can cut costs substantially in two ways by using effective industrial wastewater treatment systems. Many industrial processes don’t just need high-quality freshwater, so treating wastewater to a “fit-for-purpose” level costs less than using fresh water. Reusing wastewater also reduces risks and expenses linked to offsite disposal, including transportation costs.

Wastewater reuse in industrial settings can cut water supply costs and treatment expenses while reducing pressure on our strained water resources. The quality and type of wastewater determines whether it can be reused directly or needs treatment before recycling.

This piece explores smart industrial wastewater treatment solutions that help reduce your water costs while building a more sustainable future.

The Rising Cost of Industrial Water Use

Water rates in the United States have grown almost 300% more than inflation in the last two decades. This huge jump shows a fundamental change in how industries need to handle their water management and treatment plans.

Why water is no longer cheap for industry

The days of cheap industrial water are coming to an end because several factors are coming together. A Circle of Blue analysis shows water costs in U.S. urban areas have jumped 41% to 50% in the last decade. This trend won’t slow down anytime soon as pressures keep building:

- Old infrastructure needs massive investment (the EPA says $29 billion must go into system replacement by 2026)

- Money for big projects now comes from local instead of federal sources

- Utilities now use full-cost accounting

- More people move to areas with water problems

- Climate change needs more money put into infrastructure

Cities now put costs on utility bills instead of property taxes. Property taxes used to cover about 75% of water system costs. This means industries now pay more directly and get less help from subsidies.

What lack of water means for operations

Not having enough water creates big operational problems beyond just higher costs. CDP reports that companies have already lost $1.3 billion in assets because they couldn’t get water. The risk ahead is much bigger—69% of listed companies say they face water risks worth about $19 billion.

These risks show up in real ways. General Motors saw their manufacturing water costs go up by $177 million during Brazil’s 2015 drought. Their electricity costs went up another $498 million. Taiwan Semiconductor Manufacturing Corporation had to bring in water by truck during a 2020 drought, which made their operating costs shoot up.

The World Bank thinks some regions might see their GDP growth drop by 6% by 2050 if water management doesn’t get better. Companies with small profit margins can’t easily handle these higher costs without charging customers more.

The case for wastewater reuse

With costs and risks going up, reusing wastewater makes a lot of sense. Recycled water costs less than drinking water for industrial processes because it doesn’t need as much treatment. Companies can cut their freshwater costs by more than 90% when they treat and reuse wastewater.

Reusing industrial water saves money and offers other benefits:

- Lower wastewater discharge volumes and fees

- Less dependence on outside water sources

- Better sustainability scores and community relationships

- Meeting stricter water-quality rules

Modern solutions like SUSBIO ECOTREAT help treat industrial wastewater. These packaged sewage treatment plants use biological treatment and don’t need much space. They work great for facilities with limited room or those who need quick setup.

Companies of all sizes now use water recycling technology. Chevron’s Richmond Oil Refinery leads the Bay Area in recycled water use. Frito-Lay runs America’s first food processing plant that makes water clean enough to drink for food production.

Fresh water from cities usually costs $0.17 to $0.68 per gallon in the U.S. This can jump to $8.44 to $16.88 per gallon in areas hit by drought. These numbers make a strong case for treating and reusing industrial wastewater.

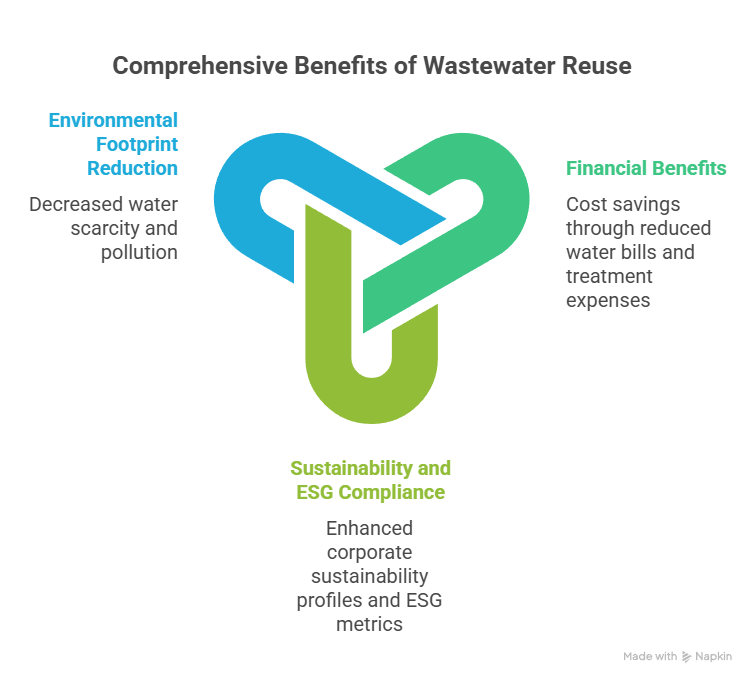

Benefits of Reusing Industrial Wastewater

Reusing industrial wastewater creates value well beyond cutting costs—it turns what we once saw as waste into a valuable resource. Companies have compelling business reasons to implement treatment systems, both economically and environmentally.

Lower water bills and treatment costs

The financial benefits of wastewater reuse show up quickly on balance sheets. Recycled water costs less than drinking water for industrial processes because it needs less treatment. Companies can cut both their freshwater intake fees and wastewater discharge costs by reusing water.

Companies using effective on-site treatment systems like SUSBIO ECOTREAT see returns within a few years. These modern packaged sewage treatment plants clean industrial wastewater biologically while taking up minimal space—making them ideal for facilities with tight layouts.

The savings are clear in real examples:

- Frito-Lay saved 100 million gallons of water yearly through their wastewater reuse program

- Duke University worked with Sustainable Water to build a 9,000 square foot WaterHub that saves 120 million gallons each year

Companies that recycle wastewater on-site save big on energy, transportation, and disposal. Rising global water rates make these savings even more valuable. Treatment plants also charge higher fees these days—another cost that reuse systems help reduce.

Improved sustainability and ESG compliance

ESG metrics now serve as key performance indicators for modern businesses. Water management affects many ESG criteria, making wastewater reuse a smart way to boost corporate sustainability profiles.

Using technologies like SUSBIO ECOTREAT shows a company’s dedication to sustainability goals, which attracts ESG-focused investors. This strategy builds reputation with customers, regulators, and communities beyond just financial gains.

Wastewater reuse helps companies meet tough environmental rules. On-site water treatment and recycling makes it easier to follow stricter standards and avoid expensive fines or shutdowns. Smart water management isn’t optional anymore—it’s crucial for lasting financial and social success.

Reduced environmental footprint

The environmental benefits of industrial wastewater reuse are huge. Every recycled gallon means less freshwater used and less harmful discharge into natural waters.

Modern treatment systems clean water before it goes back into industrial processes, protecting local ecosystems and water habitats. This smart approach to water management:

- Cuts water scarcity risks for businesses and communities

- Eases pressure on city treatment facilities

- Saves freshwater for other important uses

- Protects water habitats that support biodiversity

Closed-loop water systems, powered by technologies like SUSBIO ECOTREAT, measurably reduce environmental impact. Companies using these systems often see their ecological footprint shrink through smarter resource use and less pollution.

Turning wastewater from a problem into a resource helps industries run better while protecting the environment and securing water for future generations.

Types of Wastewater Treatment for Reuse

Modern wastewater treatment technology creates multiple ways to reuse industrial water. This helps reduce how much freshwater you just need while lowering operational costs. The right treatment methods depend on the contaminants present and how you plan to reuse the water.

Preliminary and primary treatment explained

The first stage of wastewater processing removes large debris through screening and grit chambers. This protects equipment downstream from damage. This significant step prevents problems in later treatment phases. Primary treatment comes next and eliminates 60% of suspended solids. Solid materials settle through gravity in clarifiers. Any oils and greases that slipped through pretreatment get removed here. These original steps prepare water for advanced purification by reducing the workload on secondary treatment facilities.

Biological and chemical treatment methods

Microorganisms break down organic matter in biological treatment. Bacteria and other microorganisms consume organic waste through cellular processes. Two main types exist – aerobic processes that need oxygen and anaerobic processes that don’t.

Chemical treatments cost more but give many more options through precipitation, neutralization, adsorption, and disinfection methods. Adding acids or alkali helps remove dissolved inorganics through chemical precipitation. pH levels stay controlled through neutralization to keep treatment conditions optimal. These methods work well with specific contaminants that biological processes don’t deal very well with.

Membrane bioreactors and advanced oxidation

Membrane bioreactors (MBRs) combine biological treatment with membrane filtration. They work better than conventional methods in many ways. These systems remove organic matter, toxic chemicals, heavy metals, and pathogens efficiently. MBRs produce high-quality effluent that’s perfect for reuse. They need minimal space, which works great for industrial settings with layout constraints.

Advanced oxidation processes (AOPs) target micropollutants using reactive oxygen species that oxidize contaminants. These methods break down stubborn organic pollutants that resist regular treatment approaches. SUSBIO ECOTREAT represents a modern packaged sewage treatment plant that uses these advanced technologies. It delivers efficient biological treatment with flexible modular design.

Reverse osmosis and UV disinfection

Reverse osmosis (RO) ranks among the most effective water purification technologies. It removes over 90% of contaminants by pushing water through advanced membrane systems. This process eliminates dissolved salts, organic materials, and other impurities without using too many chemicals. Industrial plants can recycle this purified water and save substantial amounts.

UV disinfection kills pathogens without chemicals. Ultraviolet light damages microorganisms’ DNA so they can’t reproduce. Unlike chemical disinfection, UV treatment creates no harmful byproducts. This makes it ideal for industrial water reuse applications.

Smart Implementation Strategies

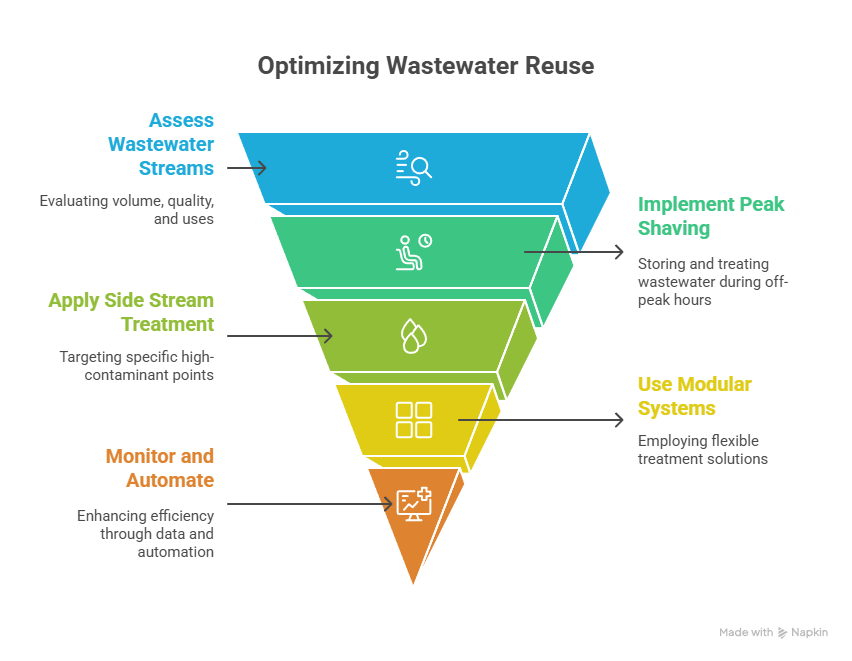

You don’t need a huge upfront investment to reuse industrial wastewater. A step-by-step approach works better and keeps costs manageable while adapting operations smoothly.

How to start with low-cost reuse options

Start by getting a full picture of your facility’s wastewater streams to find direct reuse opportunities that need minimal treatment. Peak shaving could work well for variable wastewater generation. This means storing extra wastewater during busy periods and treating it during quiet hours instead of paying for expensive offsite disposal. Another option is side stream treatment, which targets specific high-contaminant points in your process. This method treats just a portion of the flow to meet quality standards.

Mapping reuse potential across processes

Take time to review your wastewater’s production volume, quality, and possible uses throughout your facility before investing in treatment infrastructure. Working with nearby facilities can cut treatment costs. Many operations find that one process’s wastewater can feed into another with minimal treatment through careful mapping.

Using modular systems like SUSBIO ECOTREAT

Modular wastewater treatment systems are a great way to get flexibility through their ready-to-use design. SUSBIO ECOTREAT shows this approach well with its unique dual-treatment process. The system combines anaerobic and aerobic methods to remove pollutants effectively. It comes ready for setup, which cuts installation time and labor costs. The modular design allows customization based on capacity needs. The system uses 90% less electricity than traditional ones.

Monitoring and automation for efficiency

Automated wastewater treatment improves operations through live monitoring. Sensors collect constant data on pH levels, chemical concentrations, and flow rates. This allows quick process adjustments. These systems make chemical dosing more efficient and reduce chemical use. Predictive maintenance tools spot equipment problems before they happen, which reduces downtime. Advanced analytics help find patterns and areas to improve. This evidence-based approach helps with regulatory compliance through detailed documentation and efficient reporting.

Overcoming Challenges in Reuse Adoption

Wastewater reuse offers clear advantages, but several obstacles can block its successful implementation. You need to understand these challenges and how to overcome them to realize the full potential of industrial wastewater treatment systems.

Managing high upfront costs

Wastewater reuse systems need substantial upfront investment. The costs vary based on technology choice, project scale, and local conditions. Many companies see these original costs as a major barrier, especially when existing freshwater practices seem cheaper short-term. Here are some effective financing strategies:

- Learn about public-private partnership (PPP) models that brought soaring wins in cities like Chennai and Nagpur

- Look for government subsidies, tax incentives, or viability gap funding in your area

- Begin with smaller, modular systems like SUSBIO ECOTREAT that let you grow step by step

Getting consistent water quality

Water quality reliability plays a vital role in industrial reuse applications. Even well-designed systems can show variations in treatment performance. Here’s how you can tackle this:

- Set up strong monitoring programs that combine online sensors (turbidity, chlorine residual, pH) with specific measurements

- Use multiple treatment barriers to improve reliability and strength

- Follow quality assurance protocols that match drinking water standards

Training your core team

Limited technical expertise greatly affects wastewater reuse potential. Good training programs help your staff get the skills they need to run operations smoothly. SSI Aeration’s specialized training programs:

- Build operator knowledge about system cleaning and maintenance

- Give staff the skills to spot system problems early

- Show teams when and how to maintain systems properly

Working through policy gaps

Today, only 11 out of 28 Indian states have reuse policies, and most don’t have clear action plans. Scattered regulations make implementation harder, while good frameworks help widespread adoption. Here’s how to handle this:

- Keep up with changing water quality standards in different sectors

- Work with local authorities to build better institutional coordination

- Push for standard pricing models and helpful policy frameworks

Conclusion

Water shortages and rising costs have changed industrial water management from a minor issue into a vital business priority. This piece shows how smart wastewater treatment solutions cut costs and boost sustainability efforts.

The business case for industrial wastewater reuse gets stronger every year. Fresh water prices keep rising faster than inflation. Companies that invest in treatment technologies now will be better positioned for future market conditions. Looking at wastewater as a valuable resource instead of a waste problem creates chances to save money.

Wastewater reuse improves your company’s sustainability profile and ESG compliance substantially. This approach builds stronger relationships with eco-conscious stakeholders and reduces your environmental footprint.

SUSBIO ECOTREAT technology represents the future of industrial wastewater management. This modular system provides quick biological treatment without needing much space – perfect for facilities with layout constraints. On top of that, it uses dual-treatment process that combines anaerobic and aerobic methods. The system removes pollutants effectively and uses 90% less electricity than standard systems.

Getting started doesn’t have to be complicated. You can make manageable changes by starting with affordable reuse options, mapping potential uses, and adopting expandable systems. Automation and monitoring tools ensure consistent water quality and keep operations running smoothly.

Of course, challenges exist – from upfront investment costs to quality control and staff training. In spite of that, companies can overcome these hurdles through step-by-step implementation, smart financing strategies, reliable monitoring, and detailed training programs.

Water will become an increasingly valuable commodity for industries worldwide without doubt. Companies that take action now to implement wastewater reuse solutions will pay less, become more sustainable, and run more resilient operations for years ahead. The question isn’t whether industries should reuse wastewater, but how fast and well your company can put the right solutions in place.

Key Takeaways

Industrial water costs have risen 300% above inflation in two decades, making wastewater reuse essential for cost control and operational sustainability.

- Industrial wastewater reuse can cut freshwater costs by over 90% while reducing discharge fees and environmental impact

- Modular treatment systems like SUSBIO ECOTREAT offer plug-and-play solutions using 90% less energy than conventional systems

- Start with low-cost direct reuse opportunities before investing in advanced treatment infrastructure for maximum ROI

- Automated monitoring and quality control systems ensure consistent water quality while reducing operational complexity

- Wastewater reuse improves ESG compliance and sustainability metrics, attracting environmentally-conscious investors and customers

The transformation from viewing wastewater as waste to recognizing it as a valuable resource represents a fundamental shift in industrial water management. Companies implementing these solutions now will gain competitive advantages through reduced operational costs, enhanced sustainability profiles, and improved resilience against future water scarcity challenges.

Frequently Asked Questions

Q1. What is the average cost range for implementing industrial wastewater treatment systems?

The cost of industrial wastewater treatment systems can vary widely, typically ranging from 5.5 million to 16.9 million INR, depending on the complexity of the wastewater and the specific treatment needs of the facility.

Q2. How can industries effectively reduce their wastewater output?

Industries can reduce wastewater output by using biodegradable and recyclable products, conducting eco-audits to identify pollution sources, modifying equipment, installing water-saving devices, and shifting to waterless processes where possible.

Q3. What are some cost-effective methods for treating industrial wastewater?

Cost-effective wastewater treatment methods include septic tanks, constructed wetlands, and anaerobic lagoons. These options are particularly suitable for smaller-scale sewage treatment needs.

Q4. How does wastewater reuse benefit industrial operations?

Wastewater reuse can cut freshwater costs by over 90%, reduce discharge fees, lower environmental impact, improve sustainability metrics, and enhance ESG compliance, ultimately leading to operational cost savings and improved corporate image.

Q5. What challenges might companies face when implementing wastewater reuse systems?

Companies may encounter challenges such as high initial costs, ensuring consistent water quality, training staff for system maintenance, and navigating complex regulatory frameworks. However, these can be overcome through phased implementation, robust monitoring, comprehensive training programs, and engagement with local authorities.