Sewage treatment technologies are essential for managing wastewater effectively, ensuring environmental protection, and meeting regulatory standards. In India, several advanced technologies offer unique benefits tailored to diverse wastewater treatment needs. This blog explores the top five sewage treatment plant (STP) technologies of India in detail, highlighting their role in water purification and wastewater management.

SUSBIO ECOTREAT

At the forefront of sewage treatment technology is the Susbio Ecotreat, an innovative solution by Sustainable Biosolutions Pvt. Ltd. This advanced prefabricated STP technology is designed to offer superior performance, efficiency, and ease of use.

Key Features of Susbio Ecotreat:

Advanced Prefabricated Design: Made from high-quality fiber-reinforced plastic (FRP), the Susbio Ecotreat is both durable and corrosion-resistant. Its prefabricated, plug-and-play design simplifies installation, reducing both time and labor costs by arriving fully assembled and ready for operation.

Dual Treatment Process: This system employs both anaerobic and aerobic treatment processes within the same unit, ensuring a thorough and effective purification of wastewater. This dual treatment approach enhances the removal of pollutants, organic matter, and contaminants, resulting in high-quality treated effluent and improved water quality.

Energy Efficiency: The Susbio Ecotreat incorporates advanced automation systems that optimize energy consumption. By minimizing electricity usage, the system reduces operational costs and supports environmental sustainability, contributing to a circular economy in water management and resource recovery.

Ease of Maintenance and Operation: Designed for minimal human intervention, the Susbio Ecotreat is easy to operate and maintain. Its automated features ensure consistent performance with minimal oversight, making it suitable for both small communities and large industrial applications.

Versatility and Customization: The system can be tailored to meet specific requirements, making it ideal for a range of applications from domestic to industrial use. Its flexibility ensures optimal performance in various settings, including municipal wastewater treatment and process optimization.

Sequencing Batch Reactor (SBR)

The Sequencing Batch Reactor (SBR) is a widely used technology that operates in batch mode, combining aeration and sedimentation processes in a single tank. This approach provides flexibility and efficiency in treating wastewater, utilizing activated sludge for biological processes.

Key Features of SBR:

Flexible Operation: SBR systems can handle fluctuations in wastewater flow and quality, making them suitable for various applications and adaptable to different operational parameters.

Efficient Treatment: The batch process delivers high treatment efficiency, particularly for high-strength wastewater, through effective biological degradation and nutrient removal.

Reduced Footprint: The technology’s single-tank design requires less space compared to traditional systems, making it an excellent choice for advanced treatment in compact areas.

Membrane Bioreactor (MBR)

The Membrane Bioreactor (MBR) integrates biological treatment with membrane filtration, resulting in high-quality effluent and a compact system design. This membrane bioreactor technology is at the forefront of modern wastewater treatment solutions. But what is MBR exactly? It’s a sophisticated bioreactor system that combines activated sludge treatment with membrane filtration technology.

Key Features of MBR:

High-Quality Effluent: MBR systems produce effluent with very low levels of suspended solids and contaminants, suitable for water reuse applications. The membrane separation process ensures superior solid-liquid separation and effective pathogen removal.

Compact and Efficient: The technology’s compact design is ideal for areas with limited space, and it offers high operational efficiency. MBR systems utilize both flat sheet membrane and hollow fiber membrane modules for effective filtration, with options for external membrane or submerged membrane configurations.

Reduced Sludge Production: MBR systems generate less sludge compared to conventional treatment methods, reducing disposal needs and improving overall sludge management. This also contributes to biogas production potential in some configurations.

Advanced Process Control: MBR technology allows for precise control over the biological reactor conditions, including sludge retention time and hydraulic retention time, optimizing microbial activity and contaminant removal. This process optimization leads to higher biomass concentration and improved treatment efficiency.

Membrane Performance: The system’s efficiency depends on maintaining optimal transmembrane pressure and membrane permeability. Preventing membrane fouling through regular backwashing and membrane cleaning procedures is crucial for maintaining filtration efficiency and extending membrane lifespan.

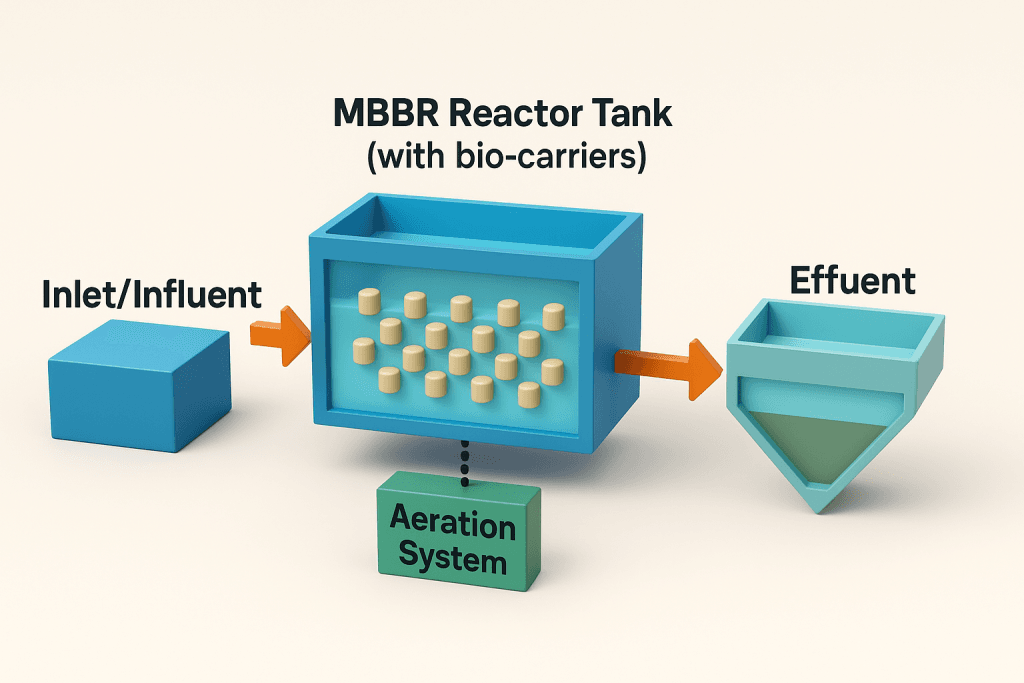

Moving Bed Biofilm Reactor (MBBR)

The Moving Bed Biofilm Reactor (MBBR) uses biofilm-covered carriers in an aeration system to enhance biological treatment efficiency, combining the benefits of activated sludge and biofilm processes.

Key Features of MBBR:

High Treatment Capacity: MBBR systems are effective in treating varying loads of domestic and industrial wastewater, offering robust performance in organic matter removal.

Compact and Flexible: The technology allows for easy scalability and adaptation to different treatment needs, making it suitable for both small and large-scale applications.

Low Maintenance: MBBR systems require minimal maintenance, lowering overall operational costs while maintaining high system reliability.

Fluidized Bed Reactor (FBR)

The Fluidized Bed Reactor (FBR) employs a fluidized bed of granular material to improve the biological treatment process, enhancing efficiency and treatment performance in wastewater management.

Key Features of FBR:

Effective Treatment: FBR systems are suitable for high-strength wastewater and achieve high removal rates for organic matter and nutrients, contributing to improved effluent quality.

Compact Design: The technology’s efficient use of space makes it suitable for smaller installations, offering advanced treatment capabilities in a reduced footprint.

High Performance: FBR systems offer consistent performance and adaptability to varying wastewater characteristics, ensuring compliance with stringent discharge regulations.

CONCLUSION

When it comes to selecting the best sewage treatment plant (STP) technology in India, the Susbio Ecotreat stands out as the leading choice. Sustainabale Biosolutions Pvt Ltd is a premier STP manufacturer in India, they have a developed this advanced prefabricated system to exemplify the pinnacle of sewage treatment innovation. The Susbio Ecotreat’s cutting-edge design, constructed from high-quality fiber-reinforced plastic (FRP), ensures exceptional durability and corrosion resistance. Its prefabricated, plug-and-play nature simplifies installation, making it an ideal solution for both small and large-scale applications.

What sets the Susbio Ecotreat apart is its dual treatment process, which combines anaerobic and aerobic methods within a single unit. This approach delivers superior wastewater purification, effectively removing pollutants and contaminants. The system’s advanced automation enhances energy efficiency, reducing operational costs while supporting environmental sustainability. Designed for minimal human intervention, it offers ease of operation and maintenance, making it a practical choice for various settings, including remote or unmanned locations.This makes the Susbio Ecotreat a highly effective solution for liquid waste treatment, ensuring clean, safe, and environmentally responsible waste management, including in the field of industrial water treatment.

In conclusion, for those seeking the best STP technology in India, the Susbio Ecotreat represents an unmatched blend of innovation, efficiency, and reliability. As a leading packaged STP solution, it embodies the expertise and commitment of Sustainable Biosolutions Pvt. Ltd. of delivering high-quality, cost-effective, and eco-friendly sewage treatment systems.

Frequently Asked Questions (FAQs)

1. What are the top sewage treatment plant (STP) technologies used in India, and how do they differ?

The leading STP technologies in India include SUSBIO ECOTREAT, Sequencing Batch Reactor (SBR), Membrane Bioreactor (MBR), Moving Bed Biofilm Reactor (MBBR), and Activated Sludge Process (ASP). Each differs in treatment process, efficiency, space requirements, cost, and suitability for municipal, residential, or industrial applications.

2. How does an MBR (Membrane Bioreactor) improve sewage treatment efficiency and water reuse?

MBR technology combines membrane filtration with biological treatment to produce high-quality treated water. It offers a compact footprint, high pathogen removal efficiency, and excellent potential for water reuse in landscaping, cooling towers, and non-potable applications.

3. What advantages does MBBR (Moving Bed Biofilm Reactor) offer for Indian municipal and industrial projects?

MBBR systems are highly space-efficient, require low maintenance, and can handle fluctuating loads effectively. They promote nutrient removal and degrade pollutants using biofilm carriers, making them suitable for both new installations and upgrades.

4. What makes SBR (Sequencing Batch Reactor) popular for decentralized and scalable sewage treatment?

SBR systems operate in batch cycles—fill, react, settle, and decant—making them flexible and easy to automate. They are ideal for decentralized projects, small to medium communities, and applications where modular expansion is needed.

5. How do technologies like SUSBIO ECOTREAT align with India’s need for efficient, eco-friendly STP solutions?

SUSBIO ECOTREAT offers energy-efficient operation, a compact prefabricated design, easy installation, and compliance with CPCB standards. It enables water recycling and resource recovery, making it an eco-friendly and cost-effective solution for India’s wastewater management needs.

2 Comments

[…] Preparation: Preparing the site for the new SBR STP, including the careful decommissioning of the old sewage treatment […]

[…] generate significant amounts of waste. The need for efficient and environmentally friendly treatment plants for wastewater has never been more urgent. From residential to industrial applications, effective treatment of […]