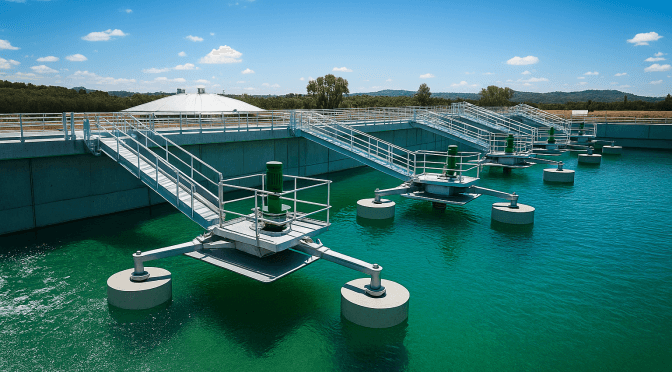

India’s wastewater treatment has nearly doubled in the last two decades. The plant systems shows an amazing engineering process that changes harmful waste into a valuable resource.

These sophisticated treatment plants collect water from populated areas and industrial sectors. They remove pollutants before returning clean water back into the water cycle. The purification process typically runs through four to five distinct treatment stages, each playing a vital role. The process starts when water drains into the sewage treatment plant and ends with remarkably pure water, showing impressive results. The system’s efficiency speaks for itself – oxidation ponds can remove about 95% of BOD and eliminate 96% to 98% of pathogens.

This piece will explore the complete process flow diagram of sewage treatment plants. We’ll break down each stage into clear components. These engineering systems take what we used to call waste and turn it into a resource that’s safe to discharge. The cleaned water can be reused in various ways, including agriculture.

Preliminary Treatment: First Line of Defense in Sewage Treatment

Preliminary treatment is a vital first defense in the process. This stage removes materials that could damage equipment or disrupt later treatment phases. Screens, grit chambers, and skimming tanks work together to prepare wastewater for primary treatment.

Bar Screens for Large Debris Removal

Bar screens catch large objects in the sewage stream like rags, sticks, plastics, and other debris. These devices stop downstream clogging and protect equipment while streamlining processes. Modern sewage treatment plants use mechanically raked bar screens that clean themselves automatically. The bars have spaces ranging from 1 to 3 inches, based on required filtration levels.

Bar screens come in several configurations:

- Front-cleaning rakes that pull screenings to the top

- Chain-driven screens with various cleaning mechanisms

- Step screens with step-shaped bars for continuous removal

- Static fine screens with openings between 0.5mm and 3.0mm

Collected screenings go to landfills or incineration facilities. This significant filtration step prevents large solids from getting stuck in pipes and moving parts that would cause major damage and reduce efficiency.

Grit Chambers for Inorganic Particle Separation

The wastewater flows from screens into grit chambers that remove sand, gravel, and other heavy inorganic materials. These chambers slow down water flow so heavy particles settle while lighter organic matter stays suspended. Grit removal does three things: stops deposits in downstream processes, reduces equipment wear from abrasion, and makes digester cleaning less frequent.

The chambers come in three main designs: horizontal flow, aerated, and vortex-type. Horizontal flow chambers keep a steady velocity between 15-30 cm/second during peak flows to ensure only inorganic materials sink. Aerated chambers use air diffusion to create spiral flows that separate grit but keep organic matter floating.

Skimming Tanks for Oil and Grease Removal

Skimming tanks are the final preliminary treatment step that tackles oils, grease, and fats. These tanks capture floating materials before they cause issues in later treatment processes. These substances can create unsightly scums in settling tanks and interfere with treatment if not removed.

The tanks use compressed air through bottom diffusers to help coagulate grease and push it to the surface where skimmers collect it. Water stays in these tanks for 2-5 minutes. Many modern plants also use mechanical surface skimmers in primary clarifiers to remove fat and grease.

Some facilities boost removal efficiency by adding chlorine (about 1.5 mg/liter) with compressed air, which increases grease removal by 300-400 percent. This combination breaks down protective colloids that keep grease emulsified.

Primary Treatment: Settling and Sedimentation Process

Primary treatment plays a vital role in removing from wastewater after preliminary screening through physical separation. This stage uses gravitational settling to separate floating and settling particles. The process removes about 50-60% of suspended solids and reduces biochemical oxygen demand by 30-40%.

Primary Sedimentation Tank Design Parameters

Sedimentation tanks or primary clarifiers let wastewater settle for about two hours. These tanks come in rectangular or circular designs with mechanical scrapers that move settled solids to collection hoppers. Circular tanks work best with diameters between 3 and 60 meters. Rectangular tanks usually stay under 40 meters in length.

Primary clarifiers must meet specific design requirements:

- Tank depth ranges from 2.15 to 3.5 meters, plus extra room for sludge (0.25m) and freeboard (0.3-0.5m)

- Circular tanks need 6-16% floor slopes while rectangular ones need 2-8%

- Average flow conditions require 40 m³/m²/day surface overflow rates

- weir design should keep loading rates under 185 m³/m/day

The wastewater flows through these tanks where solids sink naturally. Mechanical surface-skimming devices remove grease and floating materials simultaneously.

Coagulation and Flocculation in Primary Clarifiers

Coagulation helps small suspended particles stick together by neutralizing their negative charges. The process continues with flocculation that gently mixes these particles. This mixing transforms them from tiny microflocs into visible suspended particles called pinflocs.

The process needs careful control at two stages. Coagulation works best with high-energy rapid-mixing for 1-3 minutes. Flocculation needs gentle mixing that lasts 15-60 minutes. The mixing speed gradually decreases as flocs grow bigger to prevent them from breaking apart.

Flow Homogenization and pH Neutralization

Flow equalization helps alleviate variations in wastewater flow and composition to improve treatment efficiency. Homogenization tanks typically hold water for 10-24 hours.

pH control significantly affects how well wastewater can be treated. The adjustment process needs the right amount of time and chemicals. Automated PID-type controllers help maintain target pH values by regulating chemical dosage. Better pH control leads to improved treatment results and lower chemical costs.

These primary treatment processes prepare wastewater for biological breakdown in secondary treatment systems.

Secondary Treatment: Biological Breakdown of Organic Matter

Secondary treatment breaks down dissolved and colloidal organic matter left after primary treatment through biological processes. Microbial action removes about 85% of BOD and suspended solids.

Activated Sludge Process

The activated sludge process is a suspended-growth method where microorganisms create biological floc that metabolizes organic contaminants. The aeration tank design needs several key parameters:

- Tank depth ranges from 3 to 4.5 meters to work at peak aeration efficiency

- Width stays between 5 to 10 meters to control mixing effectiveness

- Length should be between 30 and 100 meters

- Width-to-depth ratio must stay between 1.2 and 2.2

MLSS concentration values reach 2000-3000 mg/l in conventional plug flow systems and 3000-5000 mg/l in completely mixed types. The sludge retention time (θc) runs from 5 days in warmer climates to 10 days in temperate regions where nitrification is needed.

Trickling Filter vs Oxidation Pond Efficiency

Trickling filters work with fixed beds of coke, limestone chips, or specialized plastic media that distribute sewage liquor through perforated spray arms. These systems remove about 75% of BOD. The filter media creates surface area for biofilm growth that metabolizes organic matter as wastewater flows through.

Oxidation ponds perform better with 90% BOD removal. Oxidation ditches, which are modified activated sludge systems, remove up to 97% of BOD. These systems work with long solids retention times and run as complete mix systems.

Secondary Clarifiers and Sludge Recirculation

Secondary clarifiers separate biomass from biologically treated wastewater through zone or compression settling. Column testing helps determine the settling rate needed for the tank area. The design focuses on solids loading rate (Q+R)X rather than overflow rate when MLSS goes above 2000 mg/l.

Sludge recirculation keeps proper MLSS levels in the aeration tank using the formula: Qr = XQ/(Xr-X). SVI (Sludge Volume Index) measures sludge settleability, and values between 100-150 ml/g show good settling characteristics. Conventional systems need recirculation rates between 15% and 100% of average daily flow.

Tertiary Treatment and Sludge Management

Tertiary treatment is the advanced purification stage in wastewater processing that removes remaining contaminants after secondary treatment. This final stage uses specialized processes to improve effluent quality through multiple mechanisms.

Sand Bed Filtration and UV Disinfection

Sand filtration captures suspended solids in wastewater and can achieve concentrations as low as 5-10 mg/L. Unlike primary and secondary treatments, sand filters work by passing water through sand layers where contaminants get physically trapped or biologically treated. The process helps prepare water for UV disinfection by reducing particle concentration. UV radiation at 400 J/m² works well enough to meet irrigation water quality standards. This disinfection method damages microorganisms’ genetic structures so they can’t reproduce.

Nutrient Removal: Nitrogen and Phosphorus

Natural water bodies face eutrophication from excess nutrients in wastewater, making their removal crucial. Nitrogen removal happens in three key steps: ammonification turns organic nitrogen into ammonia, nitrification changes ammonia to nitrate, and denitrification converts nitrate to nitrogen gas. Phosphorus removal needs both anaerobic and aerobic processes. Biological phosphorus removal uses microorganisms that store large amounts of phosphorus. These processes create better water quality but use 45-75% of the treatment plant’s total energy.

Sludge Thickening and Anaerobic Digestion

Sludge thickening increases solids concentration while reducing volume. The process usually creates 3-5% solids concentration and reduces volume by about 80%. Common thickening methods include gravity thickeners, dissolved air flotation, and membrane technology. After thickening, anaerobic digestion stabilizes sludge without oxygen and reduces volatile solids by turning them into biogas (methane, carbon dioxide, and water). This process typically cuts organic matter content by 40-50%. Biogas production ranges from 900-1,100 liters for each kilogram of organic matter destroyed.

Reuse of Treated Water in Agriculture

Water reuse offers a green solution to global water shortages. Agricultural water reuse helps crop production with treated wastewater. This practice cuts water importation costs and creates reliable local water supplies. About 10% of people worldwide eat food irrigated with treated wastewater. Countries like Israel have boosted agricultural production by 1600% by reusing wastewater. Tertiary-treated water meets all standards for unrestricted irrigation, even for raw food crops.

Conclusion

Sewage treatment plants showcase engineering brilliance by turning harmful waste into valuable resources through well-designed processes. This piece explores the detailed experience of wastewater as it moves from the original screening to final purification. Each stage plays a vital role in this transformation. Preliminary treatment removes harmful debris. Primary treatment uses sedimentation to separate solids. Secondary treatment breaks down organic matter biologically. Tertiary treatment polishes the water to meet strict quality standards.

These systems work amazingly well. Oxidation ponds remove about 95% of BOD. Advanced processes eliminate up to 97% of contaminants. Sludge management creates value through biogas production and reduces waste volume by a lot.

The world’s lack of water makes treated wastewater reuse crucial. Countries using water reuse strategies have boosted their agricultural production. This creates green water management solutions that tackle both environmental issues and resource needs.

A sewage treatment plant’s diagram shows more than engineering details. It shows how we solve complex environmental problems step by step. Today’s wastewater treatment proves that technical knowledge turns waste into a precious resource. These systems protect public health and preserve our environment’s integrity for future generations. They’re not just infrastructure – they’re the foundations of sustainable development.

Key Takeaways

Understanding sewage treatment plant diagrams reveals how sophisticated engineering transforms harmful waste into valuable resources through systematic four-stage processes that achieve remarkable purification efficiency.

- Four-stage treatment process: Preliminary screening removes debris, primary settling separates solids, secondary biological treatment breaks down organics, and tertiary polishing achieves final purification standards.

- Impressive efficiency rates: Modern systems achieve 95-97% BOD removal and 96-98% pathogen elimination, demonstrating the effectiveness of properly designed treatment processes.

- Resource recovery potential: Treated wastewater can be safely reused for agriculture, with countries like Israel increasing agricultural production by 1600% through wastewater reuse programs.

- Sludge becomes valuable: Anaerobic digestion converts waste sludge into biogas (methane and CO2) while reducing organic matter by 40-50%, creating energy from waste.

- Critical infrastructure for sustainability: These systems protect public health and environmental integrity while addressing global water scarcity through systematic waste-to-resource conversion.

The engineering behind sewage treatment plants demonstrates how technical innovation can solve complex environmental challenges, turning what was once considered waste into a precious resource that supports both human needs and environmental protection.

Frequently Asked Questions

Q1. What are the main stages of a sewage treatment plant?

A sewage treatment plant typically consists of four main stages: preliminary treatment for removing large debris, primary treatment for settling and sedimentation, secondary treatment for biological breakdown of organic matter, and tertiary treatment for advanced purification and nutrient removal.

Q2. How efficient are modern sewage treatment plants?

Modern sewage treatment plants are highly efficient. For example, oxidation ponds can achieve approximately 95% BOD (Biochemical Oxygen Demand) removal and 96% to 98% pathogen elimination. Some advanced systems can remove up to 97% of contaminants.

Q3. Can treated wastewater be reused?

Yes, treated wastewater can be safely reused, particularly in agriculture. Over 10% of people worldwide consume food irrigated with treated wastewater. Some countries have significantly increased their agricultural production through wastewater reuse programs.

Q4. What happens to the sludge produced during sewage treatment?

Sludge undergoes thickening to increase solids concentration and reduce volume. It then goes through anaerobic digestion, which stabilizes the sludge biologically, reducing organic matter by 40-50% and producing biogas as a useful byproduct.

Q5. How do sewage treatment plants contribute to sustainability?

Sewage treatment plants play a crucial role in sustainability by protecting public health and environmental integrity. They transform harmful waste into valuable resources, address water scarcity through water reuse, and even generate energy through biogas production from sludge treatment.