MBBR technology cuts sludge production by up to 30% compared to activated sludge systems, making it an excellent choice for modern wastewater treatment. Our experience shows how Moving Bed Biofilm Reactor (MBBR) systems are transforming sewage treatment in urban environments. This innovative solution combines efficiency, flexibility, and space-saving design – three essential elements that today’s property developers and facility managers need.

MBBR technology in STP (Sewage Treatment Plants) represents a biological treatment process that handles complex wastewater streams effectively. The name Moving Bed Biofilm Reactor tells us exactly how this system works. MBBR technology for STP applications outperforms conventional sewage treatment methods by supporting diverse microbial communities on specialized biofilm carriers that can degrade various contaminants. The system also breaks down organic matter and removes pollutants like ammonia nitrogen efficiently.

MBBR systems shine in apartments and commercial projects for several reasons. These systems can process large volumes of wastewater in compact spaces. You can install the modular and vertical design in basements, rooftops, or compact utility zones flexibly. The system’s optimized aeration saves 70-80% in operational costs compared to conventional systems. MBBR systems also maintain their effectiveness even in cold temperatures, which ensures your property has reliable treatment year-round.

Understanding MBBR Technology in STP Systems

Moving Bed Biofilm Reactor (MBBR) technology has revolutionized wastewater treatment since its development in Norway during the late 1980s. This biological process combines the advantages of suspended-growth and attached-growth systems to create a quick and effective treatment method.

MBBR full form and working principle

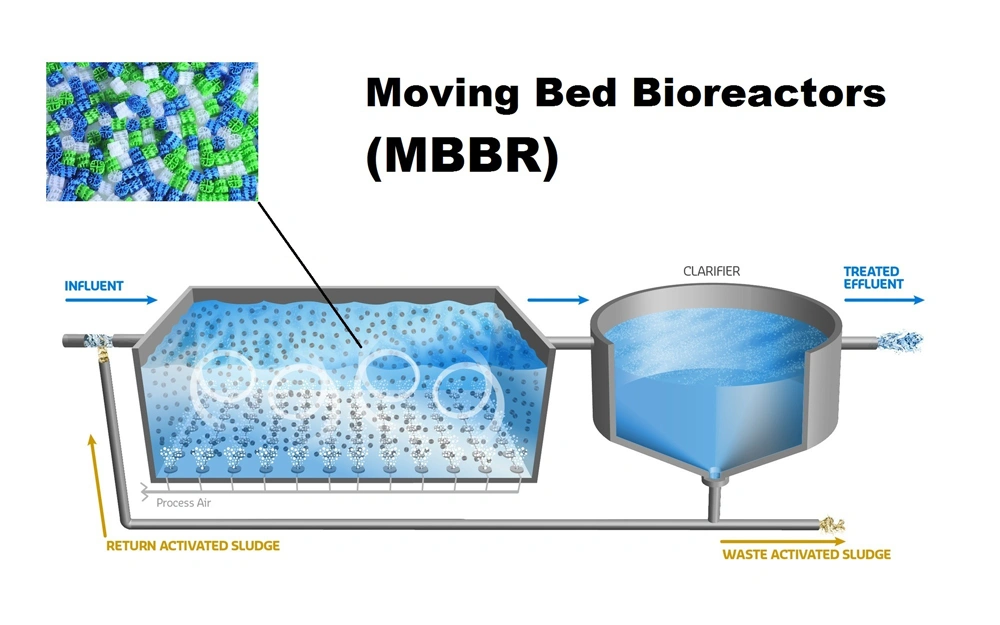

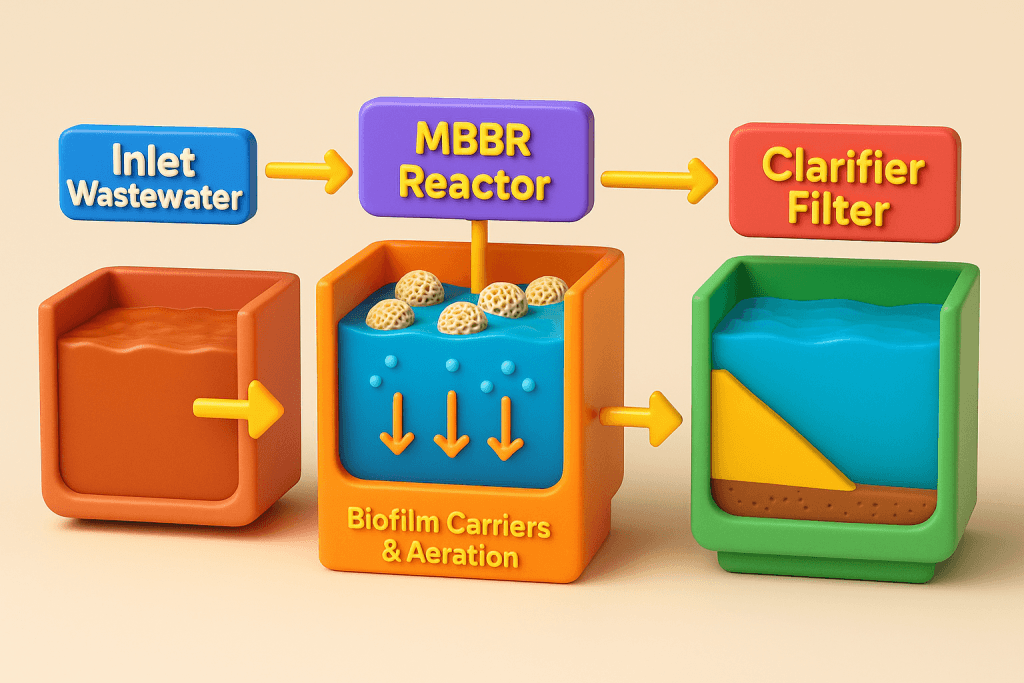

Moving Bed Biofilm Reactor’s name reflects how it works. The technology employs plastic carriers that float freely in aeration tanks where microorganisms grow and create biofilms. These microbes eat organic material and break down pollutants in the wastewater. Natural flow controls biofilm thickness without special operating cycles. The system can work as a 2-phase anoxic system or a 3-phase aerobic system, and mechanical mixing or aeration keeps the buoyant carriers moving.

Role of biofilm carriers in pollutant breakdown

Biofilm carriers power MBBR technology. These carriers, made from high-density polyethylene (HDPE) with a 0.9g/cm³ density, give microbes plenty of space to grow. Standard carriers provide 400-500 m²/m³ of surface area. Advanced options like the MBBR Eco Chip can reach over 5,500 m²/m³.

Protected microzones form on the carriers where slow-growing degraders thrive and tackle stubborn chemicals. The carriers’ constant movement through aeration ensures biofilm and wastewater mix well without clogging. Shear forces keep biofilms thin, which helps substrates and oxygen reach microorganisms effectively.

Comparison with activated sludge and fixed-film systems

MBBR technology stands out from traditional systems. The system doesn’t need sludge recycling like conventional activated sludge processes, which makes operations simpler. MBBR handles shock loads and wastewater changes better than other systems.

Unlike fixed-film systems such as trickling filters, MBBR avoids bed clogging and needs less maintenance. MBBR’s biofilm creates a stable home for microorganisms, making the process more reliable.

MBBR’s ability to update existing treatment facilities is one of its best features. Facilities can upgrade without rebuilding from scratch. This technology combines treatment efficiency, operational flexibility, and space optimization perfectly—especially when you have sewage treatment plants serving apartment complexes and commercial buildings.

Why MBBR is Ideal for Apartments and Commercial Projects

MBBR technology’s design features make it a perfect fit for modern urban infrastructure projects. Smart engineering and innovative biofilm processes help these systems solve specific challenges that apartment complexes and commercial developments face.

Compact footprint for space-constrained buildings

Space efficiency is what makes MBBR technology stand out. These systems need nowhere near as much space as traditional activated sludge or trickling filter systems but still achieve better treatment results. An MBBR tank can treat the same wastewater volume as conventional systems in just one-quarter the size.

High biomass concentration on biofilm carriers allows this impressive space optimization and enables efficient treatment in smaller tanks. The modular and vertical design lets you install these systems in basements, rooftops, or compact utility zones. MBBR systems work best for:

- Urban properties with premium real estate values

- Updating existing buildings without major construction

- Commercial developments with limited utility space allocation

Low noise and odor for residential comfort

MBBR systems do more than save space – they protect resident comfort. Advanced noise-reduction features keep operating sounds below 50 dB, so you can install these systems near living spaces without disturbing anyone.

Modern MBBR units operate in sealed conditions that contain odors common in conventional sewage treatment. This odor control feature creates a better living environment in residential complexes. Luxury apartments and hospitality venues benefit from this feature when guest comfort matters most.

Consistent treatment quality for commercial compliance

MBBR systems deliver stable performance even in challenging conditions. Biofilm carriers create an extensive protected surface area that lets bacteria break down pollutants efficiently.

These systems maintain steady performance with variable load conditions—a common issue in commercial settings where water usage patterns fluctuate. MBBR technology handles toxic shocks better, and studies show treatment efficiency stays above 80% even during shock loads.

Commercial properties can meet environmental discharge standards consistently without constant monitoring or adjustments. Yes, it is true that simpler operations and reduced need for specialized technicians lead to significant cost savings over time.

SUSBIO ECOTREAT: A Packaged MBBR STP Solution

SUSBIO ECOTREAT marks a groundbreaking development in packaged MBBR solutions. The system comes with features that modern buildings need. This prefabricated system takes standard MBBR technology to the next level with several improvements.

Dual-treatment process: anaerobic + aerobic

SUSBIO ECOTREAT uses a unique dual biological treatment that combines anaerobic and aerobic processes in one compact unit. The anaerobic stage breaks down complex organic compounds without oxygen. The aerobic phase then polishes the effluent in oxygen-rich conditions. This complete treatment method cuts BOD and COD levels by 90-95%. The result is high-quality water that goes beyond standard environmental norms.

FRP construction for durability and corrosion resistance

The system uses high-quality fiber-reinforced plastic (FRP) to deliver exceptional durability in harsh conditions. FRP naturally fights off chemicals, acids, alkalies, and microbe attacks. This makes it perfect for aggressive sewage environments. The corrosion-resistant material will give a lifespan of 15-25 years even in tough settings.

Plug-and-play installation with minimal civil work

SUSBIO ECOTREAT arrives ready to install as a fully prefabricated unit. The setup takes just 2-3 days compared to months for conventional systems. This plug-and-play approach needs minimal civil work. You save on site disruption and labor costs.

Energy savings up to 90% with smart controls

Smart automation and optimized aeration systems help SUSBIO ECOTREAT use 90% less electricity than traditional MBBR systems. This is a big deal as it means that you save on operational costs and reduce your carbon footprint.

Real-time monitoring and automated operation

The system runs automatically without needing staff on-site. Built-in sensors provide immediate monitoring of performance parameters. You can track and maintain the system remotely. The automation keeps operations consistent even in unmanned or remote locations, with minimal human intervention needed.

Choosing and Scaling the Right MBBR System

You need to pick the right components for MBBR systems based on technical specs and how they’ll run. Let me walk you through what makes these systems work at their best.

Carrier media specifications: HDPE, surface area, density

The best MBBR carriers come from virgin HDPE with density between 0.94-0.96 gm/cm³. This gives them perfect buoyancy in wastewater. These carriers offer specific surface areas of 400-1600 m²/m³. Standard 25mm carriers have either 19 or 79 holes. Carriers with more surface area help biofilm grow faster. The right density keeps them moving properly in reactors.

Designing for nitrification and denitrification

The BOD loading must stay under 0.5 g/m²/day in nitrification tanks for the process to work. When you want nitrification and denitrification at once, keep dissolved oxygen at 1.0-2.0 mg/L. Your denitrification design should factor in carbon sources, water temperature, and oxygen from earlier steps.

Updating existing infrastructure

MBBR systems shine when you want to improve old treatment plants without rebuilding everything. Start by choosing the right MBBR media for your contaminants. The next step blends MBBR reactors with current aeration systems before you set up monitoring schedules.

Maintenance tips: aeration, biofilm health, monsoon prep

Check carriers often for damage and thick biofilm buildup. These systems clean themselves most of the time, but you might need to boost aeration to clear extra biofilm. Watch your influent closely to guard against toxic shock loads. You should replace media every 5-10 years and service equipment regularly.

Conclusion

MBBR technology has revolutionized modern wastewater treatment, particularly in urban and commercial settings. This piece explores how these systems excel through their innovative biofilm carrier design that maximizes treatment efficiency in minimal space. The results show why MBBR has become the top choice for property developers and facility managers nationwide.

The system’s elegant simplicity sets it apart. Wastewater flows through specialized tanks where plastic biofilm carriers host thriving microbial communities before emerging as treated effluent. This sophisticated approach eliminates complex operational cycles and delivers superior results. The biofilm carriers work non-stop to break down pollutants through natural biological processes without sludge recycling or extensive maintenance.

One of MBBR’s strongest selling points is its space efficiency. Property managers can save up to 70% of space compared to traditional systems, which helps maximize valuable real estate. The system runs quietly with minimal odor, making it virtually invisible to residents and visitors.

SUSBIO ECOTREAT takes these advantages to the next level. Its dual anaerobic-aerobic treatment process achieves exceptional pollutant removal rates of 90-95%. The FRP construction ensures decades of reliable service without corrosion issues. The plug-and-play installation cuts implementation time from months to days, while smart controls reduce energy consumption by up to 90%.

Commercial property owners benefit from consistent compliance with environmental regulations despite varying usage patterns. The system handles shock loads effectively and provides peace of mind. Automated monitoring reduces the need for staff and operational oversight.

MBBR technology represents the next generation of urban wastewater treatment. Its combination of space efficiency, operational reliability, low maintenance, and environmental performance creates unmatched value for apartments and commercial projects. As water quality standards become stricter and urban space grows more precious, MBBR systems will become the standard for responsible development.

Frequently Asked Questions

Q1. What are the main benefits of MBBR technology for wastewater treatment?

MBBR technology offers several advantages, including space efficiency, easy operation, low maintenance requirements, resistance to shock loads, and quick wastewater treatment. It’s particularly suitable for urban environments and commercial projects due to its compact design and consistent performance.

Q2. How does MBBR technology compare to traditional sewage treatment methods?

MBBR systems require up to 70% less space than conventional methods while achieving superior treatment results. They eliminate the need for sludge recycling, demonstrate better resilience against fluctuations in wastewater characteristics, and can be easily retrofitted into existing infrastructure.

Q3. Is MBBR suitable for residential apartment complexes?

Yes, MBBR is ideal for apartment complexes. It operates quietly (below 50 dB), effectively contains odors, and can be installed in compact spaces like basements or rooftops. The system’s consistent performance ensures compliance with environmental standards, making it perfect for residential settings.

Q4. What industries can benefit from using MBBR systems?

MBBR technology is versatile and can be used in various industries, including municipal sewage treatment, industrial wastewater treatment, and decentralized wastewater management. It’s particularly beneficial for the automotive, chemical, food and beverage, and metal plating industries.

Q5. What maintenance is required for MBBR systems?

MBBR systems are generally low-maintenance, but they do require some upkeep. Regular inspections of biofilm carriers for damage or excessive accumulation are essential. Occasional increases in aeration may be needed to remove excess biofilm. It’s also important to monitor influent to protect against toxic shock loads and replace media every 5-10 years.

Key Takeaways

MBBR technology revolutionizes wastewater treatment for urban properties by combining space efficiency, operational reliability, and environmental compliance in one innovative system.

• Space-saving design: MBBR systems require 70% less space than traditional treatment methods while delivering superior results, making them ideal for space-constrained urban developments.

• Residential-friendly operation: Advanced noise reduction keeps sounds below 50 dB and sealed operation eliminates odors, ensuring comfort for apartment residents and commercial guests.

• Exceptional efficiency: Dual anaerobic-aerobic treatment achieves 90-95% pollutant removal with up to 90% energy savings through smart automation and optimized aeration systems.

• Plug-and-play installation: Prefabricated FRP construction enables 2-3 day installation versus months for conventional systems, minimizing site disruption and construction costs.

• Consistent compliance: Superior resilience against shock loads and variable usage patterns ensures commercial properties consistently meet environmental discharge standards without constant monitoring.

The biofilm carrier technology at MBBR’s core creates protected microzones where diverse microbial communities thrive, breaking down complex pollutants more effectively than traditional activated sludge systems. This biological approach, combined with minimal maintenance requirements and 15-25 year system lifespan, makes MBBR the optimal choice for modern urban wastewater treatment challenges.