Your wastewater facility’s operating budget could drop by half with the right sludge treatment approach. Sludge makes up just 0.2-0.4% of wastewater flow. Yet its management costs can eat up more than half of a treatment plant’s operational expenses.

Good sludge management saves money and protects our environment. When left untreated, sludge pollutes water, contaminates soil, and creates nasty odors. Organic matter breaks down in untreated sludge and uses up oxygen. This process harms the ecosystems in rivers and lakes. The right sludge treatment processes help cut costs and meet environmental regulations.

This piece guides you through proven sludge treatment methods that can substantially reduce operating costs while meeting all regulations. You’ll learn about stabilization techniques that kill pathogens and dewatering methods that lower hauling costs. These approaches can shrink sludge volume by more than 90%. The piece also shows how different treatment methods combine smoothly to create an integrated management system that works better and runs smoother.

Understanding Sludge in Wastewater Treatment

“Sludge treatment is one of the most resource-intensive aspects of wastewater management, both financially and logistically.” — Pure Dutch Aeration, Water treatment technology provider

Understanding Sludge in Wastewater Treatment serves as the foundation of wastewater treatment challenges. Many facility operators don’t fully grasp its complexities. The path to proper sludge management starts when we understand what we’re dealing with.

What is sludge in wastewater treatment?

Sludge is a semi-solid slurry that comes from industrial processes, water treatment, wastewater treatment, and on-site sanitation systems. This soupy material holds lots of interstitial water between solid particles. Its composition can vary quite a bit.

The key feature of activated sludge lies in its microorganisms. These tiny creatures eat dissolved food through their body surface and help clean wastewater. Water makes up most of the sludge – raw sludge typically holds 93% to 99% water. The leftover dry substance combines organic and inorganic materials, plus various trace components that separated from wastewater during treatment.

Sludge might be just a small part of the total wastewater volume. Yet it packs concentrated pollutants, nutrients, and pathogens that need careful handling. Treatment methods, origin, and local wastewater characteristics all affect its makeup.

Difference between sewage and sludge

People often mix up sewage and sludge, but they’re different substances in wastewater treatment. Sewage means all wastewater with solid waste flowing from homes or businesses. This covers toilet waste plus water from washing machines, dishwashers, bathtubs, and showers.

Sludge specifically means the solid waste that sinks during wastewater treatment after sewage reaches treatment facilities. While sewage moves through sewers as a mix of water and solid waste, sludge is what’s left when solids separate from the liquid.

Here’s another key difference: sewage combines kitchen, bathroom, and toilet waste. Sludge, however, is dead bacteria that collect at the bottom of the secondary clarifier tank after primary treatment or aeration. Once it dries out, this sludge becomes effective manure.

Types of sludge: primary, secondary, and fecal

The wastewater treatment process creates several distinct types of sludge:

Primary sludge comes from wastewater’s primary treatment where solids sink through gravity. You’ll find large organic matter like feces, vegetables, fruits, fiber, paper, and inorganic compounds in it. Primary sludge flows like a thick liquid with 93% to 97% water content.

Secondary sludge, also called biological or activated sludge, results from secondary treatment that uses biological agents to break down organic pollutants. Microorganisms, dead cells, and remaining organic materials make up most of it. The activated sludge usually forms flakes containing living and dead biomass along with absorbed, stored, organic and mineral parts.

Fecal sludge comes from pit latrines, on-site sanitation systems, and septic tanks. It contains human waste, solid materials, urine, water, and other substances dumped in sanitation system pits, vaults, or tanks. Storage time, added materials (grease, organic kitchen waste), temperature, and tank emptying methods greatly affect fecal sludge quality.

Septage, a type of fecal sludge from septic tanks, tends to be thinner because septic tanks usually get flushwater and sometimes greywater. Septage typically has less solid waste since people can only flush certain materials down toilets.

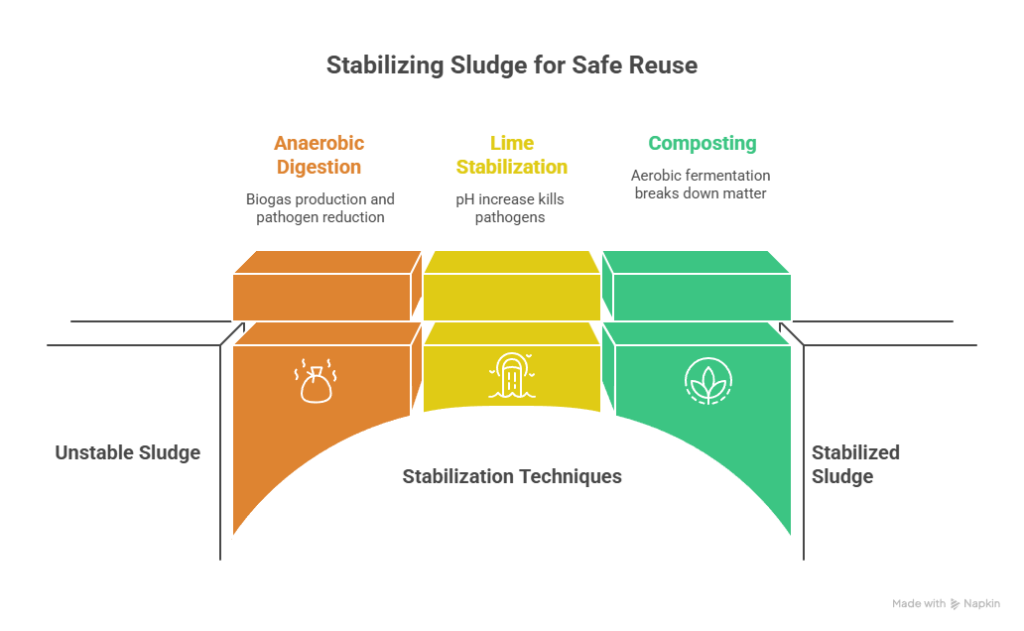

Stabilization Techniques That Reduce Pathogens and Odor

Sludge treatment’s critical phase of stabilization tackles two persistent challenges: pathogen content and offensive odors. Sludge becomes safer to handle when properly stabilized. This creates opportunities for beneficial reuse and reduces environmental hazards.

Anaerobic digestion in activated sludge treatment

Anaerobic digestion (AD) is one of the most effective stabilization processes that offers benefits beyond pathogen reduction. This oxygen-free biological process changes organic materials into biogas and destroys harmful microorganisms.

AD is a great way to treat waste activated sludge because it reduces sludge volume and produces energy as methane-rich biogas. The biogas contains 48-65% methane, which makes it perfect for power generation. These combined benefits make sludge management much more cost-effective.

The success of anaerobic digestion depends on retention time and temperature. Most mesophilic digesters work at temperatures between 35-37°C. Their hydraulic retention times range from 20-40 days. These conditions help facilities achieve volatile solids reduction rates between 13-27%, averaging 18%.

State-of-the-art systems like Anaerobic Membrane Bioreactors (AnMBR) have improved traditional digestion processes. These systems allow higher volumetric solid loads by separating hydraulic retention time from solids retention time. This ended up reducing net energy demand by 37.3% compared to conventional anaerobic digestion.

Lime stabilization for pathogen control

Lime stabilization is an affordable chemical approach to sludge treatment that works especially well for killing pathogens and controlling odors. The process adds lime—usually quicklime (calcium oxide) instead of hydrated lime—to raise the sludge’s pH to levels where microorganisms can’t survive.

Pathogens die and organic materials stop breaking down when pH hits 12 or higher in this highly alkaline environment. Studies show that lime treatment completely kills Salmonella in just two hours, and removes up to 99% of fecal coliforms. This quick action makes lime stabilization valuable for facilities that need fast treatment.

Lime stabilization comes with extra operational benefits:

- Dry solids content increases (up to 30%)

- Handling and storage become easier

- Volume decreases

- Odors stay under control

- Material becomes ready for landfills

The process is simple and costs less to set up than biological or thermal alternatives. However, it’s worth mentioning that lime stabilization adds to the total sludge solids and requires ongoing chemical purchases.

Composting for organic matter breakdown

Composting breaks down organic matter into stable humic compounds through controlled aerobic fermentation. This biological change kills pathogens and creates valuable material for agricultural use.

Microbial activity naturally generates significant heat during composting. Temperatures rise above 55°C in the thermophilic phase, which kills harmful organisms like Escherichia coli, Staphylococcus aureus, Bacillus subtilis, and Clostridium botulinum. EPA rules say waste must stay at 40°C for at least 5 days to control pathogens effectively. During this time, temperatures should exceed 55°C for at least 4 hours.

Good aeration is crucial for successful sludge composting. Dewatered sludge’s low porosity means you need to add a bulking agent—usually something carbon-based like sawdust, wood chips, or crushed green waste. The bulking agent creates enough space (at least 20% of the mixture) for air to move through.

The final compost has several advantages over raw sludge:

- Smells better and looks like humus

- Provides valuable organic matter and nutrients for soil

- Stores and handles easily

- Spreads uniformly

Each stabilization method has its own advantages based on facility size, budget, and end-use needs. Choosing the right method means carefully evaluating operational costs, energy use, and regulatory requirements.

Dewatering and Drying Methods That Cut Hauling Costs

Dewatering and Drying Methods That Cut Hauling Costs

Reducing water in sludge is one of the quickest ways to cut transportation and disposal costs. The right dewatering process can shrink sludge volume by 60-80%, which leads to much lower hauling needs.

Belt filter press vs centrifuge: cost and efficiency

Belt filter presses work through three stages: gravity drainage, low-pressure squeezing, and high-pressure squeezing. This process results in 15-20% solids content in the final cake. The original setup costs less (INR 12.6-33.7 million) than centrifuges (INR 25.3-67.5 million).

Centrifuges use high-speed rotation (3,000-4,000 RPM) to create forces 2,000-3,000 times stronger than gravity. This produces cake dryness of 18-25% solids. While centrifuges need more energy, they handle changing feed sludge concentrations better and need less maintenance.

Small operations with basic maintenance needs find belt filter presses environmentally friendly due to low energy use. But larger facilities often see better long-term value with centrifuges, especially considering labor costs. A recent case study shows that switching to centrifuges cut weekly labor hours while maintaining production levels.

Solar drying beds for low-energy sludge drying

Solar drying makes use of free renewable energy to turn wet sludge into dry, stable biosolids. The process can lower moisture content from 80% to 10%. Modern systems run in greenhouse-style buildings where solar heat combines with natural airflow to remove water.

The cost benefits are clear – a typical 50 TPD solar drying facility saves INR 25.3-50 million yearly on energy compared to heat-based options. Setup costs stay 40-60% below thermal systems, with investment payback taking 3-7 years.

These systems produce no direct greenhouse gasses while running. A medium-sized facility cuts 1,000-2,000 tons of CO2 emissions yearly compared to gas-fired thermal systems.

Thermal drying systems and energy trade-offs

Standard thermal drying technologies include drum, disk, multi-tiered step, and fluidized bed systems. Drum and disk dryers turn sludge mechanically to improve contact with hot surfaces, offering simple operation at reasonable costs. Fluidized bed dryers provide even drying by floating sludge particles in hot air but use more energy.

New vacuum drying technologies show potential for saving energy. The disk-type sludge vacuum drying system delivers high efficiency with environmental benefits. Water evaporates at lower temperatures under vacuum, which can save substantial energy.

Different heat sources can power thermal dryers, from natural gas to biogas or fuel oil. Some systems achieve self-sustaining operation by burning the dried end product. This creates an energy cycle that helps reduce running costs.

Low-Cost Disposal and Reuse Options

“Sludge management costs aren’t going away, so your team needs to find a solution. Land application bans, PFAS regulations, and rising disposal costs are making sludge an even bigger financial liability.” — Integrated Water Services, Wastewater treatment solutions provider

Low-Cost Disposal and Reuse Options

The complete sludge management process requires economical disposal or reuse pathways after proper dewatering and treatment. These options help reduce costs and provide environmental benefits.

Land application of biosolids: regulations and benefits

The EPA classifies treated sewage sludge for land application as “biosolids”. Three categories exist based on treatment levels: Class B, Class A, and Class A Exceptional Quality (EQ). Class B biosolids have reduced pathogen levels with additional application restrictions. More rigorous treatment creates Class A biosolids to minimize pathogen risk. Class A EQ meets the most stringent pollutant and pathogen reduction standards, which allows unrestricted application.

Agricultural land, forests, and disturbed sites benefit from biosolids application. The soil health improves significantly while carbon gets sequestered effectively. These applications reduce our dependence on non-renewable resources like phosphorus and generate lower greenhouse gas emissions compared to other management methods. Reclamation sites see better establishment of sustainable vegetation and improved soil erosion control.

Sludge use in cement and brick manufacturing

Cement manufacturing provides a promising disposal option, especially when you have sludge with low organic content. Industrial sludge rich in aluminum, iron, and heavy-metal hydroxides becomes a component of clinker meals. This method makes metals inert through cement-based binders and reduces operating costs without affecting product quality.

Dried sludge works as an effective clay substitute in brick production when it contains above 90% dry matter. Manufacturers recommend 10% sludge fired between 880°C and 960°C. Bricks turn out better with organic content around 26% and firing temperatures up to 1210°C.

Dedicated landfills for hazardous sludge

Landfilling serves as a viable option with advantages like simple operation, low cost, and reduced volume after digestion. The process becomes more economical after dehydration. Municipal solid waste dumps or dedicated sludge landfills can accept sludge based on moisture content and chemical characteristics.

In spite of that, dedicated sludge landfills face challenges with large land requirements, difficult site selection, and leachate treatment needs. These facilities must minimize hazardous constituent leaching into the environment and meet strict regulatory standards.

Integrated Sludge Management for Cost Optimization

Smart integration of treatment processes delivers significant financial advantages that single technologies cannot match. Facilities routinely reduce their operational costs related to sludge management through integrated approaches.

Combining thickening, digestion, and dewatering

A sequential treatment train helps maximize efficiency at every stage. The process starts with effective thickening before digestion, which can cut sludge volume by up to 60% and reduce digester size requirements. Anaerobic digestion then converts volatile solids into biogas, which provides energy and reduces volume. This creates a positive cycle – smaller digesters need less heating and use less energy.

Modern multi-plate screw presses are great examples of integrated dewatering solutions after digestion. They produce cake solids of 15-20% compared to conventional systems at 10-15%. Facilities can achieve impressive 80% reductions in total sludge volume by using these technologies. Sludge management usually takes up 30-50% of wastewater treatment budgets, so these reductions lead to major savings.

Sludge treatment plant layout for operational efficiency

The right plant setup cuts operational costs through smart equipment placement. Gravity-based flows between treatment stages eliminate extra pumping costs when possible. Smaller operations benefit from modular designs that blend new technologies smoothly without major infrastructure changes.

Equipment choices should balance space needs with performance. Modern dewatering systems like screw presses need less space, making installation easier in existing facilities. Their self-cleaning features prevent clogging and cut maintenance work by about 50% compared to traditional belt press systems.

Case example: fecal sludge treatment plant in urban areas

Fecal sludge management (FSM) shows how affordable integrated systems can work. Indian FSM systems cost just INR 200-250 per person compared to INR 7,000-11,000 for regular sewerage. This huge difference comes from FSM’s targeted treatment of concentrated waste streams.

Co-treatment at existing sewage plants offers an innovative solution. These facilities treat fecal sludge along with regular sewage. India now has over 700 fecal sludge treatment plants planned, with 220 being built and 150 already running. This proves the model works at scale.

The plants produce multiple valuable outputs. Solid materials work as soil conditioners and fertilizers, while treated liquids serve various purposes from gardening to washing vehicles.

Conclusion

Smart sludge management gives wastewater treatment facilities a chance to cut their operational costs substantially. As I wrote in this piece, good sludge handling tackles both financial and environmental challenges. Treatment facilities can cut costs by up to 50% of their operational budgets when they use the right treatment methods.

The stabilization methods we discussed help reduce pathogens and create ways to reuse the waste. Anaerobic digestion is a big deal as it means that plants get effective treatment plus energy production. Dewatering also cuts transportation costs by removing excess water, which makes up over 90% of raw sludge volume.

Budget-friendly reuse options promote sustainability too. Land application puts valuable nutrients back into soil. Using sludge in construction materials offers permanent disposal solutions without environmental risks.

The evidence shows that a comprehensive approach works best. The combination of thickening, digestion, and dewatering creates mutually beneficial effects that optimize cost reduction and operations. Modern facilities prove that sequential treatment can reduce volume by more than 90%, which changes sludge management economics completely.

You must comply with regulations whatever treatment methods you pick. The good news is that properly treated sludge meets environmental standards and reduces long-term liability risks.

The numbers tell the story – well-managed sludge becomes a predictable process instead of a burden. Treatment facilities should review their specific situation, sludge characteristics, and available resources to design the best treatment strategy. The original capital investments might seem high, but operational savings usually pay back quickly, especially with rising disposal costs.

Your facility can protect the environment and stay financially responsible by applying these proven sludge treatment methods thoughtfully. Success needs careful planning, but the financial and environmental benefits make it worth the investment.

Key Takeaways

Effective sludge treatment can dramatically reduce wastewater facility operating costs by up to 50% while ensuring environmental compliance and creating opportunities for beneficial reuse.

- Integrated treatment systems maximize savings: Combining thickening, digestion, and dewatering achieves 90% volume reductions and creates synergistic cost benefits.

- Dewatering cuts transportation expenses: Proper dewatering reduces sludge volume by 60-80%, dramatically lowering hauling and disposal costs.

- Anaerobic digestion provides dual benefits: This process reduces pathogens while generating methane-rich biogas for energy production, improving economic feasibility.

- Strategic reuse creates revenue streams: Land application and construction material incorporation transform waste disposal costs into beneficial end-use opportunities.

- Solar drying offers energy-free processing: These systems can save $300,000-$600,000 annually in energy costs compared to thermal alternatives while producing zero emissions.

The key to success lies in selecting treatment methods that match your facility’s specific sludge characteristics, regulatory requirements, and operational constraints. While initial capital investments may seem substantial, the operational savings typically provide attractive payback periods of 3-7 years, especially considering rising disposal costs and stricter environmental regulations.

Frequently Asked Questions

Q1. What are the most effective methods for sludge treatment?

The most common and effective methods for sludge treatment include anaerobic digestion, aerobic digestion, and composting. These techniques reduce organic matter and pathogens in the sludge while also offering potential for energy recovery and beneficial reuse.

Q2. How can wastewater treatment facilities reduce sludge management costs?

Facilities can significantly reduce costs by implementing integrated sludge management systems that combine thickening, digestion, and dewatering processes. This approach can achieve volume reductions of up to 90%, dramatically lowering hauling and disposal expenses.

Q3. What are the benefits of using anaerobic digestion for sludge treatment?

Anaerobic digestion offers dual benefits: it effectively reduces pathogens in the sludge while also generating methane-rich biogas that can be used for energy production. This process improves both the environmental impact and economic feasibility of sludge treatment.

Q4. Are there eco-friendly options for sludge disposal?

Yes, there are several environmentally friendly options for sludge disposal and reuse. These include land application of biosolids to improve soil health, incorporation into cement and brick manufacturing, and the use of solar drying beds for low-energy processing.

Q5. How does dewatering contribute to cost reduction in sludge management?

Dewatering is crucial for cost reduction as it can decrease sludge volume by 60-80%. This significant reduction in volume leads to lower transportation and disposal costs, making it a key step in efficient sludge management.