Smart maintenance scheduling helps prevent sewage treatment plants from becoming financial burdens. In fact, experts often describe aging sewage treatment infrastructure as a “silent liability” for cities, industries, and communities. Many facilities operate well beyond their intended design life. This creates a dangerous situation where expenses and failures could spiral out of control.

The numbers paint a shocking picture. Fixing underground pipes alone will cost at least INR 84.38 trillion in the next 25 years. Organizations typically spend about INR 2531.41 million on each legacy system. The task of preventive maintenance gets harder as older systems need specialized knowledge that becomes rare over time. Maintenance scheduling serves as our best defense against these massive costs. Facility operators must learn about hidden maintenance expenses and put prevention measures in place, especially when dealing with outdated equipment and systems.

Hidden Cost Triggers in Aging Sewage Plants

Aging sewage infrastructure creates a perfect storm of hidden expenses that drain maintenance budgets. These costs build up slowly until they hit crisis levels. Facility managers often find themselves caught off guard by these mounting expenses.

Corrosion-Induced Equipment Failures

The battle against corrosion in sewage plants starts right after installation. Concrete deterioration can show up after just two years of service. Pre-treatment tanks can see damage depths that are nowhere near 2 cm. This happens when sulfur-reducing bacteria release H2S that oxidizes to sulfuric acid on tank walls. The global cost of corrosion is a big deal as it means that USINR 210.95 trillion—about 3.5% of global GDP. Equipment at risk has concrete tanks, metal piping, pumps, valves, blowers, clarifier mechanisms, and access platforms.

Energy Overuse in Legacy Pump Systems

Old pump systems waste electricity because their efficiency keeps dropping. Energy costs are one of the biggest expenses in wastewater treatment, especially when you have systems using traditional aerobic processes instead of advanced technologies like membrane aerated biofilm reactors. Modern variable frequency drives (VFDs) can cut energy use by up to 50% compared to fixed-speed systems. On top of that, it makes financial sense since motors use nearly 70% of industrial electrical energy. VFDs usually pay for themselves within 1-3 years.

Labor Costs from Manual Monitoring

Aging systems need specialized knowledge that becomes expensive as experts become rare. Regular maintenance schedules, unexpected discharges, sampling, analysis, and troubleshooting take much more staff time than predicted. These labor costs eat into revenue-generating activities when facilities don’t have dedicated wastewater teams. The market just needs skilled workers, who command high salaries and strain operational budgets.

Emergency Repairs vs Scheduled Maintenance

Many facilities react to problems instead of preventing them. Emergency repairs, downtime, and non-compliance penalties cost way more than routine maintenance. The difference is clear: planned maintenance helps equipment last longer through continuous repair and rehabilitation, while emergency responses fix symptoms without addressing why it happens. Good maintenance scheduling reduces the risk of critical equipment failures that could release untreated wastewater into natural water bodies.

Why 73% of Plants Fail Early: Root Causes

The failure rate of sewage treatment plants is staggering. Problems build up over time and become systemic. Plant operators need to understand these basic issues to implement maintenance strategies that work.

Deferred Preventive Maintenance Scheduling

Many operators delay critical maintenance to save money, but this backfires badly. The wastewater treatment industry faces a growing problem of aging equipment that needs attention. This approach does not save money – it just pushes costs to a later date when repairs cost more. Emergency fixes come with a premium price tag that exceeds routine maintenance costs. Equipment failures also lead to violations, fines from regulators, and damage to the facility’s reputation.

Lack of SCADA-Based Monitoring Systems

Most wastewater plants do not have flexible control systems to monitor and optimize operations remotely. Modern SCADA systems let facility managers track chemical levels and toxins with detailed records they can access anywhere. Cloud-based SCADA solutions collect data immediately. Teams can study, compare and share this information quickly. Plants without this technology struggle to run efficiently and prevent breakdowns.

Overloaded Systems Beyond Design Capacity

Population growth and industrial expansion have pushed many treatment systems past their design limits. Overloaded systems cannot treat waste properly because units need more time to break down pollutants. Wastewater can overflow when flow rates get too high. “Buffer tanks” help manage this during peak usage. High concentrations of organic matter cause too much microbial growth, which prevents sludge from settling correctly.

Non-compliance with 2025 Discharge Norms

Untreated sewage keeps flowing into water bodies despite claims of compliance. A recent audit showed that while 26 of 37 sewage treatment plants met standards, 11 plants still violated discharge rules. Plants face environmental fees and regulatory action for non-compliance. In spite of that, facilities breaking rules now face tougher enforcement as regulators finalize standard methods for environmental penalties.

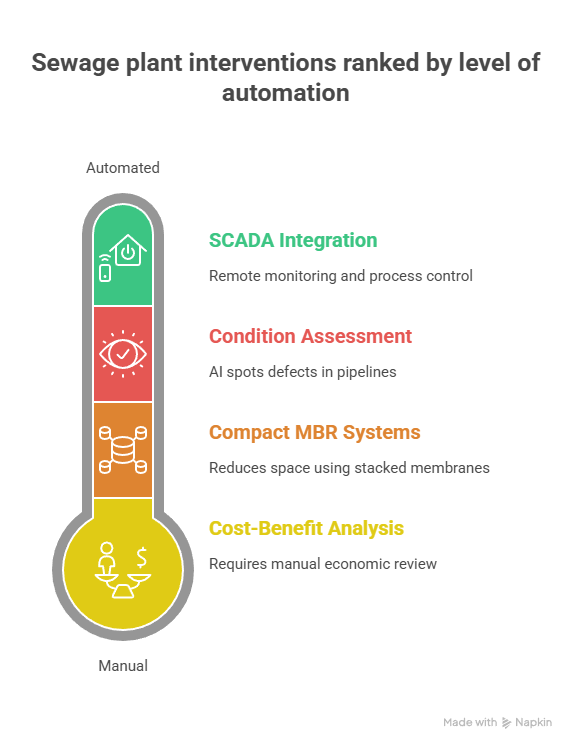

2025 Prevention Guide: 4 Smart Interventions

Smart interventions help prevent sewage plant failures before they happen. Budget-friendly solutions and innovative technology create a strong base to schedule maintenance for aging infrastructure.

Condition Assessment Using CCTV and Sensors

AI-powered CCTV inspection systems have changed how we maintain pipelines. These systems can spot six different defects with 96.33% accuracy. They pull key frames from videos, find frames with defects, and sort them into specific categories. The text recognition part pulls out vital information like position, date, and time of inspection. Old manual CCTV monitoring needed people to watch hours of video. Now, automated systems do away with this time-consuming task. These assessment technologies help create reliable deterioration models and better asset management strategies.

Cost-Benefit Analysis: Refurbishment vs Replacement

The choice between fixing old facilities or building new ones needs a complete economic review. A detailed cost-benefit analysis looks at construction costs, land buying, upkeep, power use, chemicals, staff, and waste disposal costs. This method shows hidden benefits in many sewage plants, especially in using treated water and creating renewable energy. Different inspection methods have varying costs – multisensor inspections cost INR 1241.24 per meter of pipeline while zoom camera inspections cost INR 291.96 per meter.

Compact MBR Systems for Space-Limited Sites

MBR systems work great for facilities with limited space. The Hitachi Compact MBR uses vertically stacked membrane modules to treat wastewater through flat sheet membranes with 0.1μm pore size. This setup removes harmful organisms and creates high-quality water for irrigation, landscaping, and other uses. These systems take up 50% less space than regular activated sludge processes by using more biomass and eliminating large clarifiers.

SCADA Integration for Remote Monitoring

SCADA systems have changed how we schedule preventive maintenance with round-the-clock remote monitoring. These platforms show equipment status and water quality data as it happens. SCADA lets operators run plants from their mobile devices. They can spot problems early and fine-tune processes to meet environmental rules. The systems cut energy use by 20-30% through better aeration, dosing, and flow control. Adding machine learning helps predict chemical oxygen demand with 99% accuracy. This could save INR 50,000-2 lakh per incident by stopping equipment failures.

Technology Upgrades That Cut Long-Term Costs

Technology upgrades can cut costs and make treatments more efficient. Automated solutions and energy optimization help tackle the main reasons why systems fail early.

Plug-and-Play Systems like SUSBIO ECOTREAT

SUSBIO ECOTREAT’s prefab design cuts down installation time and labor costs by eliminating the need for extensive on-site construction. The system runs silently and uses 90% less power than regular STPs. Its fiber-reinforced plastic construction stands up to corrosion and bad weather, which means decades of reliable service. The system runs itself automatically, so you don’t need operators on-site – this saves on labor costs.

Variable Frequency Drives for Pump Efficiency

VFDs match pump speeds to what you need right now, which optimizes power usage. These drives can save up to 50% energy compared to fixed-speed systems. The equipment lasts longer because VFDs provide smoother starts that reduce wear on couplings, bearings, and seals. They also keep pumps running at the right speed to prevent cavitation.

Advanced Oxidation for Nutrient Removal

Advanced Oxidation Processes remove stubborn nutrients by creating highly reactive hydroxyl radicals. The process removes nitrogen and phosphorus compounds efficiently, which boosts overall treatment quality. It helps meet tough discharge standards and uses fewer chemicals.

Real-Time Effluent Quality Monitoring

Online systems constantly check important measures like pH, COD, BOD, and TSS. The data goes straight to regulatory servers, which alert you immediately if anything’s wrong. This removes human error in data recording and makes it harder to change readings intentionally. You can fix problems quickly because you get information right away when something’s not right.

Conclusion

Sewage treatment plant operators worldwide face major maintenance challenges. Our research shows that 73% of treatment facilities fail early due to hidden costs from corrosion damage, energy waste, increased labor needs, and emergency repairs. These problems affect plant operations severely.

Poor maintenance scheduling emerges as the biggest reason behind system failures. Plant operators often think they save money by delaying routine maintenance. This approach ends up causing system breakdowns and costs much more money long-term. The problems become worse when monitoring systems are outdated, systems exceed capacity limits, and facilities fail to meet discharge regulations.

Smart facility managers can avoid these issues by following the prevention measures in this piece. Teams can spot problems early with CCTV inspection and advanced sensors before major failures occur. A detailed cost-benefit analysis helps choose between fixing or replacing equipment. Space-constrained facilities benefit from compact MBR systems, and SCADA integration allows constant remote monitoring.

New technology brings excellent returns despite original costs. Modern plug-and-play systems need less time to install and cost less to run. Variable frequency drives reduce energy use by 50% and help equipment last longer. Advanced oxidation processes and immediate effluent monitoring ensure facilities meet regulations and perform well.

These preventive measures and new technologies reduce early system failures. Plant operators must stop using reactive approaches that waste money and harm the environment. The future of green wastewater management needs both new infrastructure and proper maintenance of existing systems through better planning and smart technology use.

Key Takeaways

Understanding hidden maintenance costs and implementing strategic prevention measures is crucial for sewage plant operators facing the reality that 73% of facilities fail prematurely due to preventable issues.

• Deferred maintenance creates false savings: Postponing routine upkeep increases long-term costs by 300-500% through emergency repairs and compliance violations.

• Technology upgrades deliver immediate ROI: Variable frequency drives cut energy costs by 50%, while SCADA systems reduce operational expenses by 20-30% through automated monitoring.

• Proactive assessment prevents catastrophic failures: AI-powered CCTV inspection systems achieve 96% accuracy in defect detection, enabling early intervention before costly breakdowns occur.

• Modern compact systems outperform legacy infrastructure: MBR systems reduce footprint by 50% while plug-and-play solutions like SUSBIO ECOTREAT use 90% less electricity than traditional STPs.

The shift from reactive to proactive maintenance strategies, combined with smart technology integration, transforms sewage treatment from a financial liability into a sustainable, cost-effective operation that meets 2025 discharge standards.

Frequently Asked Questions

Q1. What are the typical maintenance costs for a sewage treatment plant?

Maintenance costs for sewage treatment plants can vary widely depending on the size and complexity of the system. Annual service visits for domestic systems typically start around £180 plus VAT, but larger industrial plants may incur significantly higher costs due to more frequent maintenance needs and specialized equipment.

Q2. What are the consequences of a wastewater treatment plant failure?

When a wastewater treatment plant fails, untreated sewage can flow into natural water bodies, causing severe environmental damage. This can lead to the destruction of aquatic ecosystems, contamination of water sources, and potential health hazards for both humans and wildlife in the affected areas.

Q3. Why is regular maintenance of wastewater treatment plants crucial?

Regular maintenance of wastewater treatment plants is essential to ensure effective pollutant removal and environmental protection. Without proper maintenance, plants may fail to treat wastewater adequately, leading to the release of harmful contaminants into soil, water, and air, which can negatively impact human health and ecosystems.

Q4. What are the different types of maintenance for sewerage systems?

There are three main types of maintenance for sewerage systems: preventive, routine, and emergency. Preventive maintenance involves scheduled inspections and repairs to prevent failures. Routine maintenance includes regular cleaning and upkeep. Emergency maintenance addresses unexpected breakdowns or critical issues that require immediate attention.

Q5. How can technology upgrades reduce long-term costs in sewage treatment plants?

Technology upgrades can significantly reduce long-term costs in sewage treatment plants. For example, implementing variable frequency drives can cut energy consumption by up to 50%, while SCADA systems enable remote monitoring and can reduce operational expenses by 20-30%. These upgrades improve efficiency, extend equipment lifespan, and minimize the need for costly emergency repairs.