The demand for efficient, cost-effective, and sustainable sewage treatment plant (STP) technologies is growing rapidly as cities expand and environmental regulations become more stringent. Two of the most popular and advanced biological wastewater treatment processes in use today are the Moving Bed Biofilm Reactor (MBBR) and the Sequencing Batch Reactor (SBR). Each technology offers unique advantages and is suited to different applications, but which one is right for your project? In this in-depth comparative study, we’ll explore the principles, design, operation, benefits, limitations, and ideal use cases for both MBBR and SBR STP technologies.

Understanding Biological Sewage Treatment

Biological sewage treatment is the backbone of modern wastewater management. It uses microorganisms to break down organic pollutants, nitrogen, and phosphorus in sewage, producing a treated effluent that meets environmental discharge standards or is suitable for reuse. Among the many biological treatment methods, MBBR and SBR stand out for their efficiency, flexibility, and scalability.

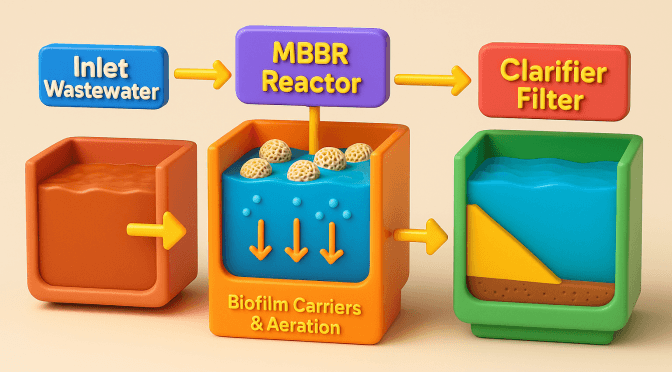

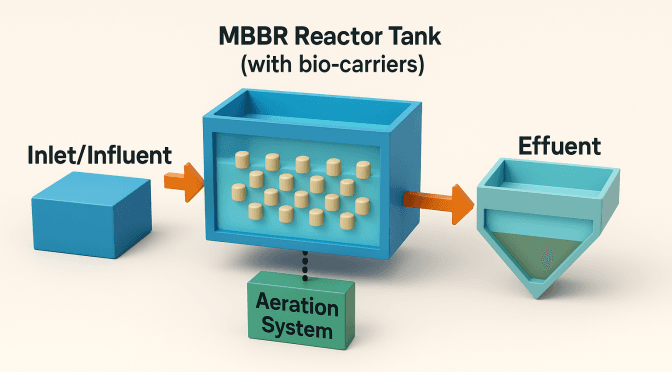

What is MBBR Technology in Sewage Treatment Plants?

MBBR (Moving Bed Biofilm Reactor) is an advanced wastewater treatment process that utilizes free-floating plastic carriers (biofilm media) within an aeration tank. These carriers provide a large surface area for the growth of beneficial microorganisms, which form a biofilm and degrade organic matter and nutrients in the wastewater.

How MBBR Works

- Biofilm Carriers: Specially designed plastic elements (often made from HDPE) float freely in the reactor, offering a protected surface for microbial attachment and biofilm development.

- Aeration: Oxygen is supplied via diffusers to support aerobic microbial activity and keep the carriers in motion.

- Continuous Flow: Wastewater flows continuously through the reactor, ensuring constant treatment and high process stability.

Key Features of MBBR STP

- High treatment efficiency for BOD, COD, ammonia, and nitrogen removal.

- Compact footprint, making it ideal for space-constrained sites.

- Low sludge production, reducing handling and disposal costs.

- Simple operation and minimal maintenance requirements.

- Easy scalability by adding more carriers.

- Robust performance, even with fluctuating loads and shock conditions.

What is SBR Technology in Sewage Treatment Plants?

SBR (Sequencing Batch Reactor) is a fill-and-draw activated sludge process that treats wastewater in batches. All treatment phases—equalization, aeration, settling, and decanting—occur sequentially in a single tank.

How SBR Works

- Batch Operation: Wastewater is treated in discrete cycles, each comprising fill, react (aeration), settle, decant, and idle phases.

- Activated Sludge: Microorganisms suspended in the tank break down organic pollutants during the aeration phase.

- Cycle Flexibility: The duration of each phase can be adjusted to optimize performance for varying influent characteristics.

Key Features of SBR STP

- All phases of treatment (equalization, aeration, clarification) occur in one tank.

- High operational flexibility—cycle times and aeration can be adjusted as needed.

- Capable of achieving stringent effluent standards for BOD, COD, and nutrients.

- Suitable for small to medium communities and decentralized applications.

- Can be fully automated for minimal manual intervention.

Advanced Insights: MBBR vs SBR – Technical, Industrial, and Regulatory Perspectives

Biological Processes: Nitrification and Denitrification

MBBR (Moving Bed Biofilm Reactor) and SBR (Sequencing Batch Reactor) are both engineered to achieve high levels of organic and nutrient removal, but they do so in different ways.

Nitrification is the process where aerobic bacteria convert ammonia in wastewater into nitrate, helping reduce nitrogen pollution. Denitrification follows, where other bacteria convert nitrate into nitrogen gas, which is safely released into the atmosphere.

MBBR systems use a mix of suspended and attached microbial growth. Special plastic carriers in the reactor provide a large surface area for biofilm, supporting a diverse community of bacteria that can handle both nitrification and denitrification. The constant motion of these carriers, driven by aeration, ensures effective oxygen transfer and process stability, even when wastewater characteristics change.

SBR systems carry out these biological processes in a single tank by alternating between aerobic (with oxygen) and anoxic (without oxygen) phases during each treatment cycle. This allows operators to precisely control the conditions needed for both nitrification and denitrification, making SBRs highly adaptable to changing influent loads.

The Role of Plastic Carrier Media in MBBR

A defining feature of MBBR technology is the use of thousands of small, specially designed plastic carriers that float and move within the aeration tank.

These carriers provide a huge surface area for biofilm to grow, allowing for a higher concentration of active bacteria compared to conventional systems. The movement of the carriers, kept in motion by aeration, ensures even treatment and prevents clogging. This design makes MBBR systems highly resilient to sudden changes in load or the presence of toxic substances, which helps maintain stable operation.

Sequence of Operations in SBR Systems

SBR technology combines all biological treatment steps in one tank, operating in a set sequence:

-

Fill: The tank receives incoming wastewater.

-

React: Aeration and mixing promote the breakdown of pollutants by microbes.

-

Settle: Aeration stops, allowing solids to settle out.

-

Decant: The clear treated water is removed from the top.

-

Idle: The system prepares for the next cycle.

This batch approach allows SBR plants to adjust the timing and length of each phase, optimizing treatment for different types of wastewater. However, it does require precise control and automation to ensure consistent results.

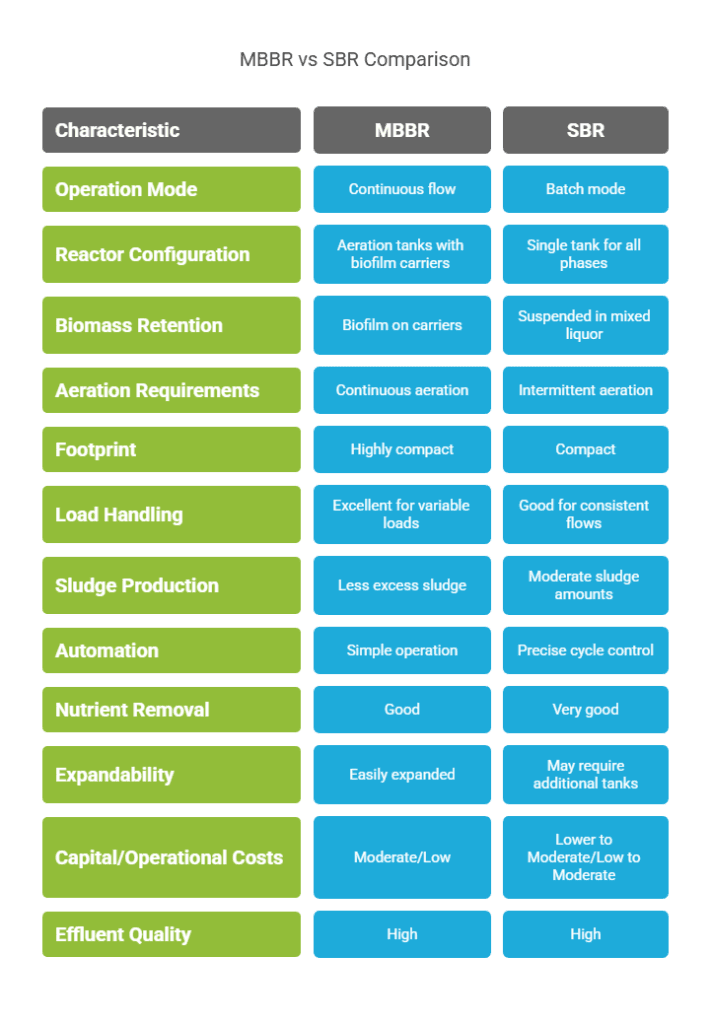

MBBR vs SBR: How Do They Compare?

When choosing between MBBR and SBR for your sewage treatment plant, it’s important to consider several key factors: operation mode, footprint, scalability, sludge management, energy consumption, and effluent quality.

Operation Mode

- MBBR: Operates as a continuous flow system. Wastewater flows into the reactor, is treated as it passes through the moving bed of biofilm carriers, and exits as treated effluent.

- SBR: Operates in batch mode. Wastewater is collected and treated in cycles, with each cycle including filling, reacting, settling, and decanting phases.

Reactor Configuration

- MBBR: Uses one or more aeration tanks filled with biofilm carriers. The carriers provide a habitat for microorganisms to grow and treat the wastewater.

- SBR: Uses a single tank (or multiple tanks in parallel) for all treatment phases. No media is used; the process relies on suspended activated sludge.

Biomass Retention

- MBBR: Biomass is retained as a biofilm on the carriers, providing high resistance to shock loads and toxic influents.

- SBR: Biomass is suspended in the mixed liquor and settles during the settling phase.

Aeration Requirements

- MBBR: Requires continuous aeration to keep carriers moving and supply oxygen to the biofilm.

- SBR: Aeration is intermittent, only during the react phase, which can reduce energy consumption.

Footprint and Space Requirements

- MBBR: Highly compact due to the high surface area provided by the carriers. Ideal for sites with limited space.

- SBR: Also compact, as all treatment occurs in a single tank, but batch operation can limit throughput for very large flows.

Load Handling and Flexibility

- MBBR: Excellent for variable and shock loads due to the stability of the biofilm.

- SBR: Good for moderate, consistent flows. Batch operation can be less effective for highly variable influent.

Sludge Production and Management

- MBBR: Produces less excess sludge, reducing handling and disposal costs.

- SBR: Produces moderate amounts of sludge, which must be removed periodically.

Automation and Operation

- MBBR: Simple operation with minimal operator intervention. Routine checks and occasional cleaning of aeration grids and sieves.

- SBR: Requires precise cycle control and automation for optimal performance.

Nutrient Removal

- MBBR: Good nutrient removal (especially with post-treatment or hybrid designs).

- SBR: Very good nutrient removal, as cycles can be tailored for nitrification, denitrification, and phosphorus removal.

Expandability

- MBBR: Easily expanded by adding more media or tanks.

- SBR: Expansion may require additional tanks or changes to cycle programming.

Capital and Operational Costs

- MBBR: Moderate capital cost, low operational and maintenance costs.

- SBR: Lower to moderate capital cost, low to moderate operational costs.

Effluent Quality

Both technologies can achieve high effluent quality (BOD <10 mg/L, COD <40 mg/L, TSS <20 mg/L) with proper design and operation.

Industrial Applications

Real-World Use Cases

In the textile industry, MBBR is often chosen for its ability to treat high-strength wastewater with varying organic loads and color, while SBR is popular for handling batch discharges and fluctuating flows.

Pharmaceutical manufacturers benefit from SBR’s flexibility in managing complex and variable waste streams, while MBBR’s robustness is ideal for continuous, high-load operations.

Food processing plants use both systems: MBBR for its compactness and shock load resistance, and SBR for its ability to deliver high-quality effluent through precise cycle management.

Technology Tailoring

MBBR can be retrofitted into existing treatment plants to increase capacity or improve nutrient removal. SBR is especially suitable for facilities with limited space and variable wastewater flows, thanks to its single-tank design.

Environmental and Regulatory Aspects

Environmental Benefits

MBBR systems produce less sludge due to efficient biofilm processes, are highly resilient to toxic shocks and load variations, and require less space. SBR systems can produce very high-quality treated water suitable for reuse and offer flexible operation to meet strict discharge standards.

Regulatory Compliance

Both MBBR and SBR technologies are widely recognized for helping industries and municipalities meet local and international wastewater discharge regulations, including those for organic and nutrient removal. Their adaptability also makes them a strong choice for future regulatory upgrades.

Advantages and Disadvantages of MBBR and SBR STP Technologies

Advantages of MBBR STP

- High Efficiency: Superior removal of BOD, COD, ammonia, and nitrogen.

- Compact Design: Requires less space than conventional activated sludge systems.

- Low Sludge Production: Reduces sludge handling and disposal costs.

- Simple Operation: Minimal operator skill required.

- Robustness: Handles load fluctuations and toxic shocks well.

- Easy Upgrading: Add more carriers to increase capacity.

Disadvantages of MBBR STP

- Media Cost: Initial investment in biofilm carriers.

- Continuous Aeration: Higher energy demand compared to intermittent systems.

- May Require Tertiary Treatment: For very stringent effluent standards.

Advantages of SBR STP

- Integrated Treatment: All phases in one tank, reducing infrastructure needs.

- Flexible Operation: Easily adjusts to influent variations and nutrient removal goals.

- Lower Capital Cost: Fewer tanks and equipment.

- High Effluent Quality: Meets stringent discharge and reuse standards.

- Automation-Friendly: Can be fully automated.

Disadvantages of SBR STP

- Batch Operation: Not ideal for very high or continuous flows.

- Cycle Control: Requires precise timing and automation.

- Sludge Production: Moderate, requiring periodic removal.

- Peak Load Sensitivity: Performance can dip during peak inflow surges.

Applications of MBBR and SBR Sewage Treatment Plants

MBBR Applications

- Municipal STPs: Urban, peri-urban, and decentralized sewage treatment.

- Industrial Wastewater: Food & beverage, chemicals, textiles, pharmaceuticals.

- Retrofitting: Upgrading existing plants for higher capacity or performance.

- Space-Constrained Sites: Hospitals, hotels, residential complexes, commercial buildings.

SBR Applications

- Municipal STPs: Small and medium towns, rural clusters, and decentralized communities.

- Industrial Wastewater: Where batch processing is acceptable.

- Decentralized Systems: Schools, resorts, gated communities, and remote sites.

- Variable Flows: Projects with intermittent or low inflow.

Design, Operation, and Maintenance Considerations

MBBR Design and Maintenance

- Carrier Fill Ratio: Typically 50–70% of tank volume.

- Aeration: Continuous, via fine bubble diffusers.

- Hydraulic Retention Time (HRT): Shorter due to high biomass density.

- Monitoring: Dissolved oxygen (DO), carrier movement, effluent quality.

- Maintenance: Occasional cleaning of aeration grid and sieves; minimal media replacement.

SBR Design and Maintenance

- Cycle Programming: Fill, react, settle, decant, idle.

- Aeration: Only during react phase.

- Sludge Management: Periodic removal from tank.

- Automation: PLC or timer-based control for cycle sequencing.

- Maintenance: Decanter and aeration system checks; sludge removal.

Cost Comparison: MBBR vs SBR STP

- MBBR: Moderate capital cost due to media, but lower operational and maintenance costs thanks to reduced sludge and simple operation. Power consumption is moderate (continuous aeration).

- SBR: Lower to moderate capital cost (fewer tanks), low to moderate operational costs, and lower energy use due to intermittent aeration. Automation and cycle control may add to initial costs.

Both systems offer excellent lifecycle value, but MBBR may be more cost-effective for industrial and high-load sites, while SBR is often preferred for small to medium communities due to lower initial investment and operational flexibility.

Frequently Asked Questions (FAQs) on MBBR and SBR STP Technologies

Which is better for small communities: MBBR or SBR?

SBR is often preferred for small to medium communities due to its batch operation and lower capital cost. MBBR is ideal for sites requiring robust, continuous treatment and easy expansion.

Can MBBR handle industrial wastewater?

Yes, MBBR is highly effective for industrial effluents with variable composition and load.

Is SBR suitable for high-strength wastewater?

SBR can be designed for high-strength wastewater but may require longer cycles or additional tanks for optimal performance.

Which technology is easier to upgrade?

MBBR is easier to upgrade by simply adding more carriers, while SBR may require additional tanks or cycle adjustments.

What about sludge management?

MBBR produces less excess sludge, reducing handling and disposal costs. SBR produces moderate sludge, requiring periodic removal.

How do effluent qualities compare?

Both can achieve high effluent quality (BOD <10 mg/L, COD <40 mg/L) with proper design and operation.

What is the typical lifespan of MBBR media?

High-quality MBBR carriers can last 15–20 years or more with proper maintenance.

Does SBR require skilled operators?

SBR systems benefit from automation but do require some technical oversight for cycle programming and maintenance.

Conclusion: Which STP Technology Should You Choose?

Both MBBR and SBR technologies offer proven, efficient, and sustainable solutions for sewage treatment plants. The best choice depends on your specific requirements:

- Choose MBBR STP for robust performance against load fluctuations, compact footprint, easy upgradability, minimal sludge production, and industrial or space-constrained applications.

- Choose SBR STP for batch treatment flexibility, lower initial investment, simple integrated tank design, and small to medium municipal or decentralized projects.

For optimal performance and compliance with environmental norms, consult with experienced STP designers to tailor the technology to your needs. Both MBBR and SBR continue to evolve, integrating automation and advanced monitoring for smarter, greener wastewater management.

Ready to select the right STP technology for your project?

Contact leading STP solution providers for a customized proposal and take a step towards sustainable, compliant, and future-ready wastewater management.