Wastewater treatment plant (WWTP) facilities collect, treat, and discharge wastewater that communities generate. These complex systems need constant monitoring and precise process control to work properly.

Data management forms the foundation of wastewater treatment processes. Operators track vital parameters like flow rates, pollutant levels, and treatment efficiencies. The WWTP process combines multiple stages and components that need to work together smoothly. The plant’s maintenance depends on a well-laid-out schedule to stay reliable and efficient. A clear understanding of the wastewater treatment plant WWTP diagram helps visualize these systems’ operation.

This piece walks you through everything a new operator needs to know. We’ve put together practical information about monitoring key parameters like pH levels and dissolved oxygen. You’ll also learn about preventive maintenance practices to help you succeed in this important role. These guidelines will help you comply with regulations and reduce environmental effects from industrial and domestic wastewater.

Understanding the WWTP Process

Wastewater treatment plants (WWTPs) use a mix of mechanical, physical, chemical, and biological processes to clean pollutants from incoming wastewater. Plant operators need to understand these processes to run the facility effectively.

Overview of wastewater treatment stages

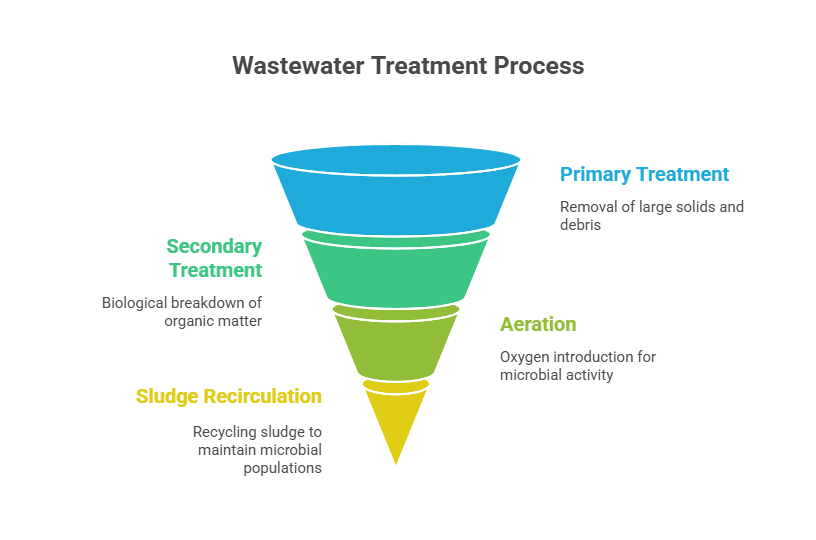

The treatment process happens in four sequential stages:

Preliminary Treatment: The first stage filters out larger objects and debris through screening and grit removal. The grit chambers let sand, gravel, and heavy particles settle while oils and grease float to the surface for skimming. This step protects downstream equipment from damage.

Primary Treatment: Wastewater flows into large settling tanks where gravity pulls suspended solids down to form sludge at the bottom. This process removes about 50-60% of suspended solids. Colloidal and dissolved wastes need more processing after this stage.

Secondary Treatment: Microorganisms break down dissolved and colloidal organic matter in this biological stage. The activated sludge process (ASP) stands out as the most common method. Bacteria feed on organic compounds in aeration tanks. The mixture then moves to secondary clarifiers where microorganisms sink as sludge and leave clean water behind.

Tertiary Treatment: This optional final stage adds extra filtration and disinfection before water release. Sand filtration, UV disinfection, or chemical treatment help remove leftover pollutants, especially nitrogen and phosphorus compounds.

Key components in a WWTP diagram

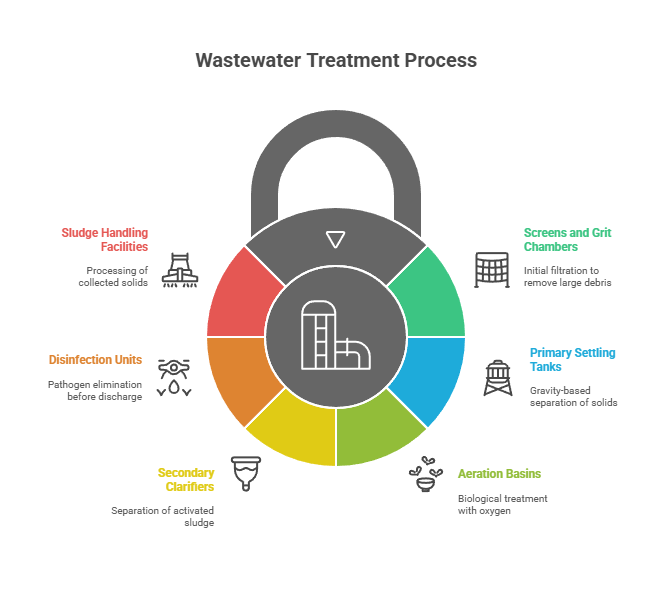

A typical WWTP diagram has these parts:

- Screens and Grit Chambers: Entry point equipment that catches large debris and inorganic solids

- Primary Settling Tanks: Tanks that separate solids through gravity

- Aeration Basins: Areas where biological treatment happens with oxygen supply

- Secondary Clarifiers: Equipment that separates activated sludge from treated water

- Disinfection Units: Systems that eliminate pathogens before discharge

- Sludge Handling Facilities: Areas that process collected solids through thickening, digestion, and dewatering

Discuss the method involved and the mode of action

Microbial metabolism drives the biological treatment process. Bacteria need oxygen to convert organic compounds into carbon dioxide and water in aerobic systems. Proper aeration keeps dissolved oxygen at the right levels.

The system uses specialized biological processes for nutrients like nitrogen and phosphorus. Bacteria convert ammonia to nitrate during nitrification and turn nitrate into nitrogen gas through denitrification. Special bacteria store phosphates in their tissues for biological phosphorus removal.

The activated sludge process keeps bacterial concentrations high through sludge recycling. This separates the hydraulic retention time (HRT) from the solids retention time (SRT). Treatment takes about 8-10 hours, making it accessible to more people as an economical and simple solution for sewage treatment.

Monitoring and Controlling Plant Operations

The life-blood of successful wastewater treatment plant operations lies in proper monitoring and control. Live data collection helps operators make smart decisions that keep treatment efficient and meet regulatory requirements.

Tracking flow rates and pH levels

Flow monitoring plays a vital role in treatment processes. It helps operators track incoming volumes and adjust treatment settings. Flowmeters placed at key points across the facility detect leaks and overflows right away. So when problems arise, operators can fix them before they get worse, which cuts down system downtime by a lot.

pH control is just as important for biological processes in wastewater treatment. The right pH levels will give a boost to chemical and biological reactions. Live pH measurements let operators fix problems quickly to keep treatment running smoothly. It also helps treatment units work more reliably, which ended up lowering maintenance costs.

Using sensors and SCADA systems

Today’s WWTPs depend on sensors of all types to watch key measurements:

- pH sensors for acidity and alkalinity measurement

- Temperature sensors for biological process monitoring

- Dissolved oxygen sensors for aeration control

- Conductivity sensors for dissolved solids detection

- Turbidity sensors for clarity assessment

These sensors link to Supervisory Control and Data Acquisition (SCADA) systems to create a complete monitoring network. SCADA combines smoothly with remote terminal units (RTUs) and human-machine interfaces (HMIs) to show operational data. Operators can see this information on control room screens or mobile devices, which gives them more flexibility.

Adjusting parameters for optimal performance

Process control in WWTPs involves tweaking treatment settings to remove pollutants better while keeping conditions stable. Control strategies often employ proportional-integral (PI) controllers to manage dissolved oxygen levels and other vital variables. The systems also make live adjustments based on sensor data, which improves energy use and treatment quality.

Machine learning algorithms help make operations better by studying complex data sets to spot patterns and offer practical recommendations. This approach helps manage treatment processes proactively instead of just reacting to problems.

Routine Maintenance and Safety Protocols

Proper maintenance and strict safety protocols play a vital role in equipment longevity and worker safety at wastewater treatment plants (WWTPs). These steps keep operations running smoothly and help avoid breakdowns that can get pricey. They also protect workers from dangerous exposures.

Sewage treatment plant maintenance checklist

A well-laid-out maintenance schedule needs these tasks:

- Daily tasks: Check flow rates and pH levels, inspect pumps and blowers, get into oil levels, and perform security checks

- Weekly tasks: Clean filters and screens, remove sludge from tanks, and conduct security assessments

- Monthly tasks: Fine-tune sensors, test backup systems, verify emergency generators, and review staff training

- Quarterly tasks: Inspect gaskets and seals, check system piping, and ensure backup components are ready

- Annual tasks: Perform detailed equipment assessments and update maintenance schedules

Preventive maintenance for pumps and blowers

Aeration blowers need yearly preventive maintenance that includes filter and belt replacement. Staff should check oil levels daily. Motor alignment needs verification every six months, and belts typically need replacement every two years. Regular lubrication, cleaning, and inspection of pumps prevent unexpected failures and reduce downtime.

Implementing safety procedures and PPE usage

Plant workers face exposure to chemicals, gasses, viruses, and bacteria. Basic PPE has goggles, face shields, waterproof gloves, and rubber boots. The core team must set examples for PPE compliance. Workers who notice health risks are more likely to use their PPE correctly.

Emergency response planning

Emergency response plans should spot potential hazards, set up evacuation steps, and track emergency equipment. The plan needs clear communication protocols, documentation steps, and regular training. Table-top exercises help test response procedures and show where improvements are needed.

Training, Records, and Compliance

Strong certification and detailed documentation are the foundations of successful wastewater treatment plant operations.

Staff training and certification requirements

Wastewater operators need to get proper certification, which comes in five levels (Grades I-V) based on experience and education. They must meet minimum experience requirements and pass written examinations to become certified. Experience qualifies when operators perform their duties with required certificates. Part-time experience counts on a prorated basis. New operators should get complete training on regulatory requirements, operational procedures, and emergency protocols. Professional development plays a vital role, and operators need 3.0 continuing education units (CEUs) in each professional growth cycle.

Maintaining logs and operational records

Good record-keeping covers five main types of documentation:

- Operational records (flow rates, lab tests, chemical usage)

- Inventory records (equipment, supplies, chemicals)

- Maintenance records (schedules, repairs, equipment history)

- Financial records (costs, budgets, revenues)

- Personnel records (training, certifications, evaluations)

Staff must keep records in bound notebooks with numbered pages and use permanent ink without erasures. NPDES monitoring records need three years of storage, while sludge monitoring records must be kept for five years.

Reporting to regulatory bodies

Regular reports to regulatory agencies show compliance and help ensure water safety. Operators need to understand monitoring protocols and reporting requirements clearly. A strong system helps monitor effluent quality through regular sampling and testing. Record falsification leads to heavy penalties – fines up to $10,000 and possible jail time.

Conclusion

Running a wastewater treatment plant needs dedication, technical knowledge, and attention to detail. In this piece, we’ve explored everything in modern wastewater treatment facilities. Each stage from preliminary screening to tertiary treatment is a vital part of turning contaminated water into environmentally safe effluent.

Successful plant operations depend on effective monitoring. Tracking critical parameters like flow rates, pH levels, and dissolved oxygen through advanced sensors and SCADA systems helps make timely adjustments for optimal performance. New operators should master these monitoring tools to make smart decisions.

On top of that, it’s important to follow maintenance schedules to extend equipment life and avoid getting pricey repairs. Regular checks of pumps, blowers, and other vital components keep operations running smoothly with minimal downtime. Safety protocols protect staff from biological and chemical hazards throughout the facility.

Proper certification and documentation are the foundations of regulatory compliance. Good record-keeping meets legal requirements and gives an explanation about operations. The learning curve might look steep initially, but regular training and hands-on experience will boost your confidence and skills as an operator.

Note that your job goes beyond managing equipment and processes. You protect water resources and public health as a wastewater treatment plant operator. By doing this and being organized, you’ll develop the skills to excel in this challenging yet rewarding profession.

Frequently Asked Questions

1. What is a Wastewater Treatment Plant and how does it work?

A wastewater treatment plant is a facility designed to remove contaminants from sewage and industrial effluents through physical, chemical, and biological processes before releasing the treated water into the environment or reusing it.

2. What are the main stages in a Wastewater Treatment Plant operation?

The treatment process typically involves preliminary treatment (screening & grit removal), primary treatment (sedimentation), secondary treatment (biological treatment), and tertiary treatment (advanced filtration & disinfection).

3. How often should a Wastewater Treatment Plant be maintained?

Routine maintenance should be performed daily for operational checks, weekly for cleaning screens and minor servicing, and quarterly to annually for comprehensive inspections, sludge management, and equipment calibration.

4. Can treated wastewater be reused, and for what purposes?

Yes, treated wastewater can be reused for landscape irrigation, toilet flushing, industrial cooling, construction activities, and agricultural use, depending on local regulations and water quality standards.

5. What are the common challenges faced in operating a Wastewater Treatment Plant?

Operators often face challenges such as fluctuating influent quality, equipment breakdowns, sludge disposal issues, energy consumption management, and ensuring regulatory compliance with pollution control norms.