As India continues to urbanize and industrialize, managing wastewater effectively has become increasingly important for environmental sustainability and public health. Sewage Treatment Plants (STPs) are essential in treating wastewater to ensure safe discharge or reuse. Among the various technologies available, five have emerged as the most commonly used in India due to their efficiency, adaptability, and cost-effectiveness: Activated Sludge Process (ASP), Sequential Batch Reactor (SBR), Moving Bed Biofilm Reactor (MBBR), SUSBIO ECOTREAT, and Johkasou Technology. This blog explores these technologies, explaining how they work, their benefits, and their ideal applications.

Activated Sludge Process (ASP)

The Activated Sludge Process (ASP) is a traditional and widely used method for wastewater treatment globally, including in India. ASP is favored for its proven effectiveness and flexibility in treating various types of wastewater.

How It Works:

Preliminary Treatment: Wastewater undergoes preliminary treatment to remove large solids and debris.

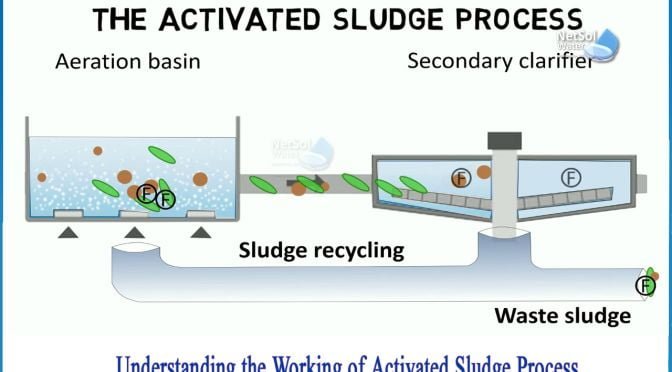

Aeration Tank: In the aeration tank, wastewater is mixed with air and biological sludge. Microorganisms in the sludge break down organic pollutants, reducing Biological Oxygen Demand (BOD) and Chemical Oxygen Demand (COD).

Secondary Clarifier: Treated wastewater flows into a secondary clarifier, as part of secondary wastewater treatment. where sludge settles at the bottom. The treated water is separated from the sludge for further treatment or discharge.

Sludge Recycle and Waste: Some of the settled sludge is recycled back to the aeration tank to maintain active biomass levels, while excess sludge is removed for disposal.

Advantages:

High Efficiency: Effective in removing organic pollutants, significantly reducing BOD and COD levels.

Scalability: Suitable for both large municipal plants and smaller industrial setups.

Flexibility: Can be adapted to treat various wastewater types, including domestic and industrial effluents.

Ideal Applications:

Municipal Wastewater Treatment: Commonly used in large municipal wastewater treatment plants.

Industrial Wastewater Treatment: Effective for treating organic-rich effluents from industries such as food processing and textiles.

Sequential Batch Reactor (SBR)

The Sequential Batch Reactor (SBR) is a variation of the activated sludge process that operates in a batch mode, treating wastewater in cycles within a single tank. SBR systems are popular in India for their efficiency and ability to handle varying flow rates.

How It Works:

Fill Phase: Wastewater is introduced into the SBR tank.

React Phase: Aeration promotes the growth of microorganisms that degrade organic pollutants.

Settle Phase: The tank settles, separating the sludge from the treated water.

Decant Phase: Clear treated water is decanted from the tank.

Idle Phase: The system prepares for the next cycle, and maintenance activities are performed.

Advantages:

Compact Design: Combines all treatment steps in a single tank, reducing space requirements.

Operational Flexibility: Handles fluctuations in wastewater flow and composition effectively.

Enhanced Nutrient Removal: Effective in removing nitrogen and phosphorus.

Ideal Applications:

Small to Medium-Sized Communities: Ideal for decentralized wastewater treatment in residential complexes and rural areas.

Industrial Effluent Treatment: Suitable for industries with variable wastewater loads.

Moving Bed Biofilm Reactor (MBBR)

The Moving Bed Biofilm Reactor (MBBR) is a modern wastewater treatment technology that uses small plastic carriers to support biofilm growth. MBBR systems are known for their high efficiency and compact design.

How It Works:

Aeration Tank with Media: Wastewater flows through an aeration tank filled with plastic carriers that support biofilm growth. The carriers provide a large surface area for microorganisms to degrade organic pollutants.

Biofilm Degradation: Microorganisms on the carriers break down organic matter in the wastewater, aided by efficient oxygen transfer and mixing.

Separation: Treated wastewater flows into a clarifier, where the carriers are retained, and the treated water is separated for discharge or further treatment.

Advantages:

High Treatment Efficiency: Provides a large surface area for biofilm growth, enhancing pollutant removal.

Compact Footprint: Requires less space than traditional treatment methods.

Low Sludge Production: Generates less sludge, reducing handling and disposal costs.

Ideal Applications:

Upgrading Existing Treatment Plants: Used to retrofit existing plants to increase capacity and improve performance.

Industrial Wastewater Treatment: Effective for treating high-strength industrial effluents.

SUSBIO ECOTREAT

SUSBIO ECOTREAT is an innovative sewage treatment solution developed by Sustainable Biosolutions Pvt. Ltd., a leading STP manufacturer in India. This technology offers efficient, sustainable, and cost-effective wastewater treatment, particularly for decentralized applications.

How It Works:

Advanced Prefabricated Design: SUSBIO ECOTREAT uses a modular, prefabricated system made from high-quality fiber-reinforced plastic (FRP), ensuring durability and resistance to corrosion.

Dual Treatment Process: Combines biological treatment and chemical dosing to efficiently remove organic pollutants and nutrients.

Energy Efficiency: Designed to minimize energy consumption through optimized aeration and mixing techniques.

Advantages:

Quick and Easy Installation: The prefabricated design allows for rapid deployment, ideal for locations with space and time constraints.

Customizable and Scalable: Can be tailored to meet specific needs and scaled as required.

Sustainable Solution: Minimizes environmental impact through energy-efficient processes and durable materials.

Ideal Applications:

Decentralized Wastewater Treatment: Suitable for remote locations, residential complexes, and commercial establishments.

Industrial Wastewater Treatment: Ideal for industries with specific wastewater treatment requirements.

Johkasou Technology

Johkasou Technology, originally developed in Japan, is a compact and efficient sewage treatment system gaining popularity in India for its suitability in small-scale and decentralized applications. It is especially beneficial in areas where space is limited or where centralized sewage systems are not feasible.

How It Works:

Compact Tank System: Johkasou systems consist of a single compact tank divided into multiple chambers for different stages of treatment, including anaerobic, aerobic, and settling processes.

Anaerobic Treatment: In the first chamber, anaerobic bacteria break down organic matter in the absence of oxygen, reducing BOD and COD levels.

Aerobic Treatment: The wastewater then flows into an aerobic chamber, where oxygen is supplied to promote the growth of aerobic microorganisms that further degrade pollutants.

Settling and Disinfection: In the final chambers, solids settle, and the treated water undergoes disinfection to remove pathogens before being discharged or reused.

Advantages:

Space-Efficient Design: Johkasou systems are compact and require minimal space, making them ideal for urban and rural areas with limited land availability.

Low Energy Consumption: The system is designed for low energy consumption, reducing operational costs.

Easy Installation and Maintenance: Johkasou units are easy to install and maintain, making them suitable for decentralized wastewater treatment.

Ideal Applications:

Residential Complexes: Perfect for small residential communities, apartments, and individual homes where centralized sewage systems are not feasible.

Rural and Remote Areas: Ideal for rural and remote locations where space and infrastructure are limited.

Conclusion

Choosing the right sewage treatment technology in India depends on various factors, including wastewater type, space constraints, operational costs, and regulatory requirements. The Activated Sludge Process (ASP), Sequential Batch Reactor (SBR), Moving Bed Biofilm Reactor (MBBR), SUSBIO ECOTREAT, and Johkasou Technology are five of the most commonly used STPs due to their effectiveness, flexibility, and adaptability to different applications including the efficient treatment of chemical wastewater treatment. These systems are also crucial in industrial water treatment, where tailored solutions are needed to meet specific wastewater treatment challenges.

ASP is ideal for large-scale municipal and industrial applications, while SBR offers a versatile solution for smaller communities and industries. MBBR provides an efficient option for upgrading existing plants and treating industrial effluents. SUSBIO ECOTREAT represents a new wave of innovation in sewage treatment, combining advanced technology with sustainability. Johkasou Technology is a compact, efficient solution perfect for small-scale and decentralized applications. Each technology has its unique advantages, making it suitable for specific applications and helping India meet its growing wastewater management challenges. These advanced solutions ensure effective liquid waste treatment, addressing the diverse needs of wastewater management and contributing to cleaner, healthier environments.

8 Comments

[…] need for efficiency, cost savings, and environmental responsibility has led to innovations in advanced sewage treatment technologies. These modern systems are revolutionizing wastewater management by offering more efficient, […]

[…] sustainable development. With a variety of technologies available, choosing the right treatment plants for wastewater depends on the specific needs of the project, the volume and type of wastewater, and the level […]

I need a mini – most mini -compacted mainly less space STP to use for my home in a Gated Community.

I need the Technical details, space requirement etc with Cost of the System

Thanking you

M.Ramachandran

9993070093

Coimbatore, Tamil Nadu

[…] are different types of sewage treatment plants, each suited to various […]

[…] to meet specific needs, whether it’s for a small community or a large industrial setup or even a sewage treatment plant on a ship. This flexibility, combined with our customer-centric approach, makes us the top sewage treatment […]

[…] how wastewater is managed in both residential and industrial sectors, including providing effective sewage treatment plant on ships . The company’s expertise, combined with its customer-centric approach, has made it the go-to […]

[…] At the forefront of the water treatment industry in India is SUSBIO, a company that has consistently revolutionized wastewater management with its cutting-edge technologies. SUSBIO’s flagship product, SUSBIO ECOTREAT, is a state-of-the-art packaged sewage treatment plant (STP) designed to cater to diverse requirements. including providing effective sewage treatment plant on ships. […]

[…] or uneconomical, such as remote locations, small communities, and industrial sites. and even as a sewage treatment plant on ships, providing efficient wastewater management in marine […]