The physical removal of suspended solids and organic matter from sewage defines primary wastewater treatment. This initial stage successfully eliminates about 60% of suspended solids from used water. Treatment efficiency typically ranges between 50-70% for total suspended solids (TSS). The process also reduces biological oxygen demand (BOD) by 25-40%, which prepares water for additional treatment phases.

Primary treatment relies on physical processes like screening, sedimentation, and skimming. The water’s detention time lasts about two hours while gravity settling occurs. This allows materials to either float or settle naturally. Primary wastewater treatment is a significant step that protects our environment and ensures food and water security. It also safeguards ecological health and makes recreational water activities possible.

What Is Primary Wastewater Treatment and Why It Matters

The first major phase in sewage purification happens during primary wastewater treatment, right after preliminary screening. This vital stage uses physical separation to remove pollutants before water moves to more intensive processes.

Definition of primary sewage treatment

Primary sewage treatment is a mechanical process that separates suspended solids and organic matter from raw sewage without using biological or chemical methods. The process uses physical methods like sedimentation and skimming to remove solids that gravity can separate. Wastewater moves slowly through sedimentation tanks, also called primary clarifiers. Heavy solids sink to the bottom while oils, grease, and lighter materials rise to the surface. These tanks give about two hours for gravity settling to take place. Mechanical scrapers keep moving settled solids (primary sludge) along the tank bottom toward collection hoppers.

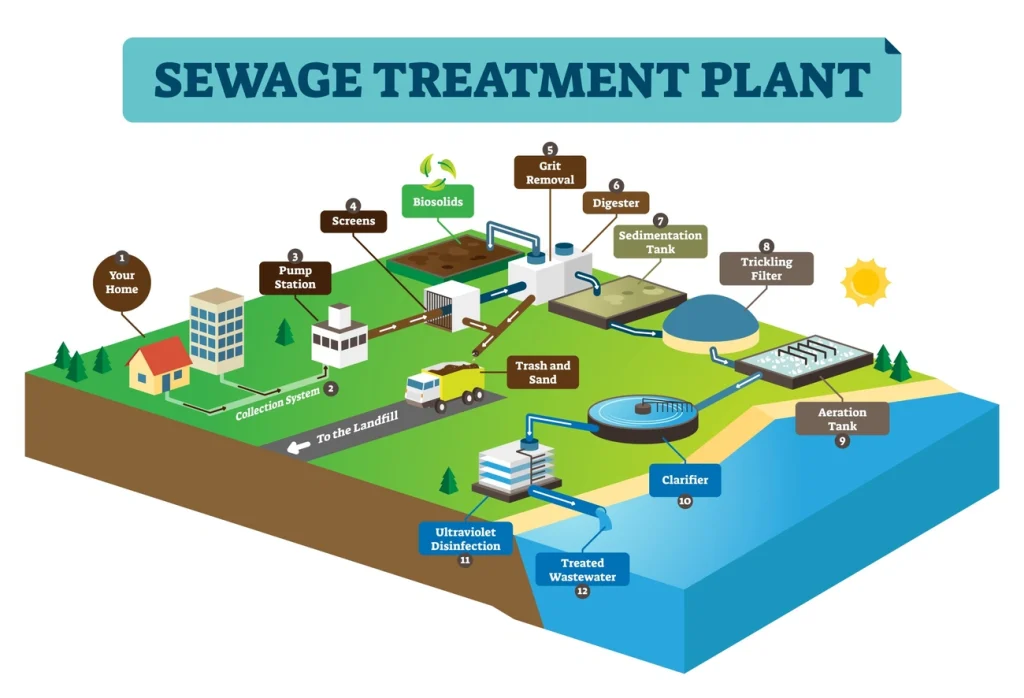

Role in the overall wastewater treatment process

Primary treatment is a vital foundation for the entire wastewater treatment system. The process removes 50-70% of total suspended solids (TSS) and 25-40% of the biological oxygen demand (BOD) from incoming sewage. This reduction by a lot helps reduce the pollution load on later treatment stages.

Primary treatment gets wastewater ready for secondary biological treatment by:

- Removing materials that could damage downstream equipment

- Reducing organic load to improve later biological processes

- Creating a more homogenized flow for subsequent treatment

The collected primary sludge can be processed further in digesters that might produce useful byproducts like biogas.

Difference between pretreatment and primary treatment

People often mix up pretreatment and primary treatment, but they serve different purposes. Pretreatment happens before primary treatment and removes larger debris through screening. Wastewater flows through bar screens during pretreatment. These long, closely spaced metal bars block bulky objects like wood, rags, and other materials that might clog pipes or pumps.

Primary treatment deals with smaller suspended solids that pass through preliminary screens. Both stages use physical separation techniques. Primary treatment targets finer particles through sedimentation, and pretreatment handles larger objects through screening and grit removal. This difference shows how wastewater management uses a step-by-step filtration approach.

Step-by-Step Breakdown of the Primary Wastewater Treatment Process

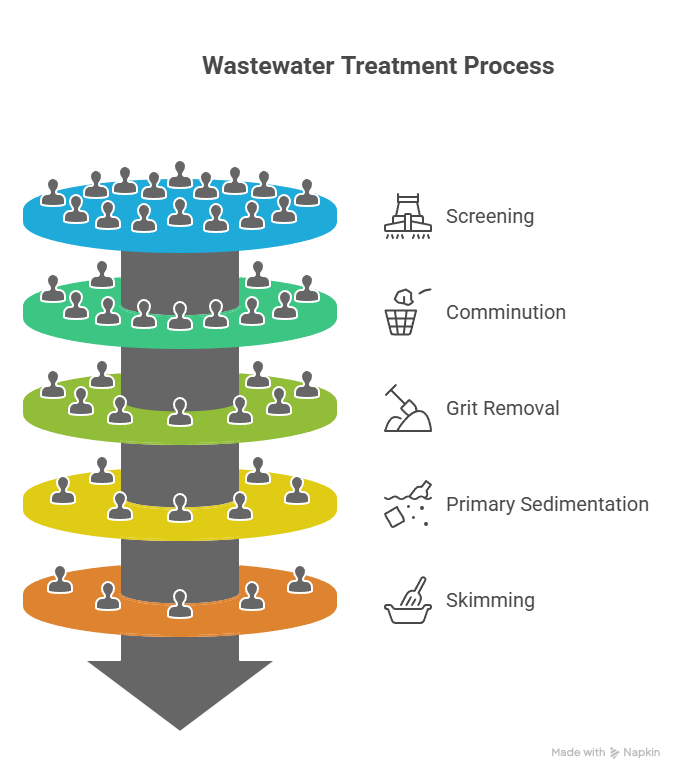

The main wastewater treatment process uses several physical operations in sequence to remove contaminants through mechanical means. Each step works with the previous one to eliminate smaller and smaller particles from the water stream.

Screening: Removal of large debris

The wastewater first flows through screening systems that catch large, non-biodegradable objects. Bar screens serve as the most common screening devices with long, closely spaced metal bars that stop bulky items like cans, rags, sticks, plastic packets, and other debris. These screens protect downstream equipment and prevent pipes and moving parts from getting blocked. Both manual and mechanical screens help remove captured debris effectively, and the spacing between bars usually ranges from 15 to 40mm.

Comminution: Shredding solid waste

The next step involves comminution, which breaks solid materials into smaller pieces through crushing, grinding, cutting, or vibrating processes. This process targets materials that passed through the screening process and breaks them down to prevent equipment blockages. Comminution lets smaller particles move through the treatment process but comes with risks. The biggest concern is that comminuted fibers can mix with grease and block pumps and pipes. Modern treatment facilities rarely use comminution because of these issues.

Grit Removal: Settling of sand and gravel

Grit chambers come after screening and comminution to remove gravel, sand, and mineral particles from wastewater. These chambers reduce water velocity so heavy particles like coffee grounds, eggshells, and other inorganic solids can settle through gravity. The grit removal process stops deposits from forming in primary sedimentation tanks, cuts down tank cleaning frequency, and shields mechanical equipment from wear. The process targets particles that measure 200-300 μm or larger.

Primary Sedimentation: Gravity-based separation

Primary sedimentation tanks use gravity to separate waste. These circular tanks have mechanical scrapers and provide about two hours for suspended solids to settle. A typical tank measures 60 feet across with 9-foot water depths. The wastewater flows through while mechanical scrapers push settled solids toward collection hoppers. This method removes about 60-65% of suspended solids.

Skimming: Fat, oil, and grease removal

The final step removes floating matter like fats, oils, and grease (FOG) through skimming. Mechanical skimmers collect these materials from the water’s surface and move them to collection hoppers. FOG makes up 25-35% of total chemical oxygen demand in raw wastewater. These substances can create huge “fatbergs” that block sewer systems if left untreated. FOG causes about 47% of sanitary sewer overflows in the United States. Some facilities use dedicated skimmers, while others build surface skimming into their primary clarifiers.

Key Objectives and Performance Metrics of Primary Treatment

Primary treatment is the life-blood of wastewater management with specific measurable objectives. Unlike secondary processes, primary treatment achieves its goals through physical rather than biological means.

Reduction in Total Suspended Solids (TSS)

Total suspended solids harm aquatic ecosystems by blocking sunlight and reducing photosynthesis. These suspended particles carry pollutants such as phosphorous, mercury, heavy metals, and hydrophobic organic compounds. The core team uses primary clarifiers to remove these solids through gravitational settling under quiescent conditions. The process also removes solids through mechanical flocculation and coagulation with substances like alum and poly-electrolytes.

Lowering Biological Oxygen Demand (BOD)

Biological Oxygen Demand shows how much dissolved oxygen aerobic microorganisms need to decompose organic matter in water. Primary treatment reduces BOD by 25-40% and removes 30-35% of COD. This reduction helps prepare wastewater for biological processes in secondary treatment where beneficial bacteria need sufficient dissolved oxygen to break down remaining organic materials.

Efficiency standards: 50-70% TSS removal

Primary sedimentation tanks consistently achieve 50-70% removal of total suspended solids. Some systems can remove up to 60-65% of suspended solids at peak efficiency. These rates vary based on flow characteristics and wastewater composition.

Preparation for secondary treatment

Primary treatment prepares wastewater for subsequent biological processes effectively. This phase protects downstream equipment by eliminating much of the suspended solids and reduces strain on secondary biological treatment processes. A well-executed primary treatment can optimize power consumption by up to 50% in secondary biological treatment.

Primary vs Secondary Wastewater Treatment: A Comparative View

Secondary wastewater treatment is different from primary treatment in both approach and outcomes compared to the stages we discussed earlier.

Physical vs biological treatment methods

Primary treatment works through physical separation processes. We used sedimentation and filtration techniques as the main methods. Secondary treatment takes a different path by using biological methods with aerobic or anaerobic microorganisms that break down organic matter. This biological approach lets helpful bacteria consume dissolved and suspended organic materials that physical processes can’t remove.

Time and energy requirements

Research shows primary treatment finishes faster. Secondary treatment takes a lot more time because bacteria slowly consume waste materials. The energy needs are higher too. Secondary treatment systems, especially activated sludge processes, just need more electricity to run aeration and pumping. These systems make up about 30% of treatment plants’ yearly operating costs.

Types of contaminants removed at each stage

Primary treatment removes large particles, floating debris like leaves, paper, and rags, along with sand, grit, and greasy substances. The focus of secondary treatment shifts to finely suspended and disintegrated biological materials left after primary processing.

When is tertiary treatment necessary?

Tertiary treatment becomes crucial in these situations:

- The water discharges into sensitive ecosystems like estuaries or near coral reefs

- Plans exist to reuse water in agriculture or industry

- The process must remove specific contaminants like pharmaceuticals, micro-plastics, and hormones

- Water quality standards exceed what secondary treatment offers

Conclusion

Primary wastewater treatment is the life-blood of our water purification infrastructure. This piece explores how the original treatment phase revolutionizes raw sewage through physical separation methods instead of biological or chemical interventions. The process starts with screening large debris. Then comes grit removal, primary sedimentation, and skimming. Each step removes smaller and smaller contaminants from the water.

You can see how well primary treatment works by looking at its performance metrics. This stage removes 50-70% of total suspended solids and cuts biological oxygen demand by 25-40%. This is a big deal as it means that the water is ready for more intensive biological processes during secondary treatment.

Primary treatment does more than just filter water. It protects equipment from damage and cuts down energy needs for later treatment stages. Secondary biological processes would take more power and time without effective primary treatment.

The difference between primary and secondary treatment shows how modern wastewater management works step by step. Primary treatment uses physical separation through gravity and mechanical means. Secondary treatment breaks down dissolved organic matter through biological processes. These complementary approaches are the foundations of water purification.

Our growing population puts more pressure on water resources every day. Primary wastewater treatment will remain vital for environmental protection, public health, and water security. The basic physical processes – settling, skimming, and filtering – are the foundations that our entire water management infrastructure depends on.

Key Takeaways

Primary wastewater treatment serves as the critical first step in transforming raw sewage into clean water through physical separation processes that prepare wastewater for advanced treatment stages.

• Primary treatment removes 50-70% of suspended solids and 25-40% of biological oxygen demand through physical processes like sedimentation and skimming

• The process involves five key steps: screening large debris, shredding solids, removing grit, gravity-based sedimentation, and skimming fats and oils

• Unlike secondary treatment’s biological methods, primary treatment relies solely on physical separation through gravity and mechanical processes

• Effective primary treatment reduces energy consumption in secondary treatment by up to 50% while protecting downstream equipment from damage

• This foundational stage processes 34 billion gallons of wastewater daily in the US, making it essential for environmental protection and water security

Primary treatment may seem straightforward, but its role in preparing wastewater for biological treatment processes makes it indispensable for modern water management infrastructure and public health protection.

Frequently Asked Questions

Q1. What is the main purpose of primary wastewater treatment?

Primary wastewater treatment aims to remove large debris, suspended solids, and organic matter from raw sewage through physical processes like screening, sedimentation, and skimming. It typically removes 50-70% of total suspended solids and reduces biological oxygen demand by 25-40%.

Q2. How long does the primary treatment process typically take?

The primary treatment process usually provides about two hours of detention time in sedimentation tanks. This allows sufficient time for gravity settling to occur, separating heavier solids from the water.

Q3. What’s the difference between primary and secondary wastewater treatment?

Primary treatment relies on physical separation methods like sedimentation and filtration, while secondary treatment uses biological processes involving microorganisms to break down organic matter. Primary treatment is faster and less energy-intensive compared to secondary treatment.

Q4. How much wastewater is processed through primary treatment in the US daily?

In the United States, primary wastewater treatment facilities process an estimated 34 billion gallons of wastewater every day, highlighting the critical role of this treatment stage in managing water resources.

Q5. Why is primary treatment important for the overall wastewater management process?

Primary treatment is crucial as it prepares wastewater for subsequent treatment stages by removing large contaminants, reducing the load on secondary biological processes, and protecting downstream equipment. It can optimize power consumption in secondary treatment by up to 50%, making the overall process more efficient.