Gurgaon has grown quickly into an industrial city and tech hub near Delhi, creating a growing need for smart water management and sewage treatment solutions. Businesses and residential complexes in this booming metropolis now invest heavily in quick wastewater management systems as they focus more on environmentally responsible practices and following regulations. SUSBIO has become the best sewage treatment plant manufacturer in Gurgaon by meeting these infrastructure needs.

Gurgaon’s expanding construction and industrial sectors put more pressure on wastewater management. Many reputable sewage treatment plant manufacturers in India now operate in this region. They provide advanced technologies like Activated Sludge Process (ASP), Moving Bed Biofilm Reactor (MBBR), and Membrane Bioreactor (MBR) systems. SUSBIO ECOTREAT stands out as the best choice for sewage treatment plants in Gurgaon. We provide custom solutions that work well with wastewater from residential, industrial, and commercial sources. Our systems make processed water completely safe to reuse or discharge, which supports environmentally responsible water management in the Delhi NCR region.

Understanding Sewage Treatment Needs in Gurgaon

Gurgaon faces severe wastewater challenges due to rapid urbanization and poor sewage infrastructure. The city’s sewage treatment needs stem from population growth, infrastructure limits, and environmental regulations that have altered the map of this bustling metropolis.

Urban Sewage Load and Water Scarcity in Gurgaon

The city’s sewage generation has exploded from just 17 MLD (million liters per day) in 2001 to about 225 MLD today. This massive jump reflects the city’s growth—from 0.25 million residents in 2001 to over 2.5 million in 2023. The future looks even more challenging. Projections show sewage generation might reach between 532.8 MLD (according to JAFRA) and 864 MLD (according to official data) by 2021.

The current treatment capacity reaches only 148 MLD. This creates a huge gap. Over 150 MLD of untreated sewage flows into the Najafgarh Drain basin daily. This shortage has led to a lack of water. Residents in Sector 4, Sector 7, New Colony, and Palam Vihar Extension keep lining up with buckets near water tankers.

Rainy seasons make everything worse. Stormwater mixes with sewage and causes floods of contaminated water that seep into groundwater resources. Several areas suffer the most—Sectors 5, 21, 22, 23A, 45, and 82. These neighborhoods face ongoing issues like foul odors, stagnant water, and health risks.

Regulatory Requirements for STPs in Haryana

The Haryana State Pollution Control Board (HSPCB) leads the charge in setting sewage treatment standards. The board created specific discharge standards in 2020, with updates in 2023 that focus on reusing treated sewage. These rules want to:

Shield water bodies from contamination through strict effluent quality measures

Use treated wastewater as a resource for non-potable needs

Lower the strain on ground and surface water resources

Fix the projected treatment gap of 554.06 MLD in Haryana’s NCR Sub-Region

Every sewage treatment plant must meet these standards. BOD (Biological Oxygen Demand) levels must drop to 10 mg/L for tertiary treatment. This makes the water good enough to use in farming, construction, and groundwater recharge.

Why Localized Solutions Matter

Gurgaon’s unique challenges require specialized sewage treatment rather than one-size-fits-all approaches. The city’s sewerage systems cover only 50-60% of the area, and closed drains reach just 95%. Local solutions will give a better way to handle specific area needs.

Experts say Gurgaon needs more than 15 STPs. Each should handle between 25-60 MLD based on catchment areas. This would fully treat current sewage and support future population growth. SUSBIO, the leading sewage treatment plant manufacturer in Gurgaon, delivers custom-engineered solutions that match local conditions.

SUSBIO ECOTREAT stands out as the best choice for Gurgaon’s sewage treatment plants. Our technology tackles the area’s specific challenges—limited space, high sewage loads, and strict rules. The modular and flexible designs fit perfectly with Gurgaon’s development pattern, where new sectors pop up next to 20-year-old areas.

Traditional systems don’t deal very well with changing loads. However, SUSBIO’s technology excels at handling variable sewage patterns common in Gurgaon’s mixed-use developments. This local approach ensures each installation works perfectly within its urban setting while meeting all regulations.

Design and Technology Customization by Leading Manufacturers

Top sewage treatment plant manufacturers in Gurgaon know that successful installations just need custom design approaches instead of generic solutions. An STP’s success depends on how well it matches local conditions, usage patterns, and space limits.

Land and Flow-Based Design Adaptation

A successful STP starts with a full picture of the site. Leading manufacturers like Netsol Water and SUSBIO begin each project by surveying land features and sewage flow patterns. Their teams get into soil type, ground slope, and nearby infrastructure to create the best plant layout.

Designers use state-of-the-art 3D modeling software to test real-life conditions before building begins. This method will give a perfect fit for every part—from tanks and piping to control panels—based on the plot’s size and shape. This careful planning helps manufacturers build systems that:

Save energy through gravity-assisted flows

Cut down on major construction work

Match process units to actual conditions for better treatment

SUSBIO ECOTREAT shows this approach with designs that boost efficiency within space limits. Their engineering team works together with clients to understand each project’s unique needs, water volume, quality standards, and space restrictions.

Capacity Planning for Peak and Future Loads

Smart capacity planning needs exact calculations for current needs and future growth. Professional STP manufacturers size each treatment stage using scientific analysis of:

Population density and growth estimates

Water supply rates (about 80% becomes sewage)

Peak flow rates (2-3 times average daily flow for medium to large plants)

Residential projects use a simple formula: Total Sewage = Per Capita Sewage × Population, where per capita sewage equals 80% of water supply rate. Plans look ahead 20-30 years, factoring in population growth of 2-6% yearly.

SUSBIO leads other sewage treatment plant manufacturers in Gurgaon by creating adaptable systems. Their modular design lets communities expand capacity without major rebuilding as they grow.

Compact Layouts for Urban Installations

Gurgaon’s urban areas create unique space challenges. Manufacturers have developed state-of-the-art compact designs in response:

Many offer wall-mounted packaged STPs that fit indoors or outdoors without masonry structures. These compact units use advanced MBBR, SBR, and MBR technology to deliver quality treatment in tight spaces.

Modular systems represent another breakthrough, with manufacturers like EcoGreen offering designs that save space and reduce manual, operational, and construction needs. These flexible setups allow quick installation and startup.

SUSBIO ECOTREAT stands out with FRP-based modular STPs that weigh less and resist corrosion better than concrete structures. Their plug-and-play design cuts installation time and site disruption—key benefits in Gurgaon’s busy urban setting.

SUSBIO, Gurgaon’s leading sewage treatment plant manufacturer, customizes each installation to meet site challenges and regulations. Their technology excels at:

Creating optimal plant layouts for tough urban sites

Building adaptable systems that grow with developing areas

Running efficiently through innovative design

Meeting water quality standards whatever the space limits

The success of sewage treatment plants in Gurgaon comes down to this smart customization that balances technical needs with real-world limits.

Advanced Treatment Technologies Used in Gurgaon STPs

Modern sewage treatment plants in Gurgaon use innovative technology that balances treatment efficiency with space limitations. These advanced systems meet strict regulatory standards and tackle unique challenges of urban wastewater management.

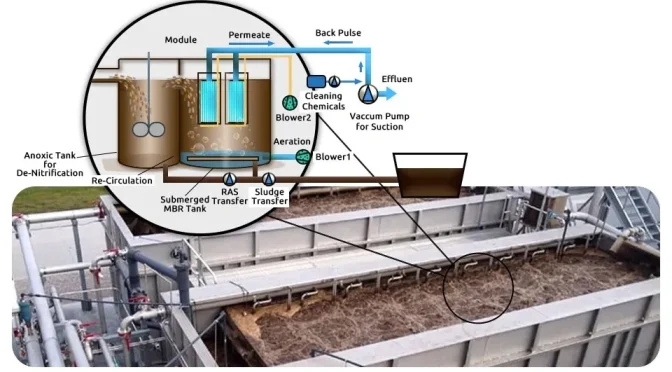

Membrane Bioreactor (MBR) for High-Quality Effluent

MBR technology combines biological treatment with membrane filtration to create an extremely effective sewage purification process. This innovative system pairs microfiltration or ultrafiltration membranes with activated sludge processes. The results are impressive:

99.9% of suspended solids removed

BOD reduced by more than 95%

99.99% of total coliforms eliminated

MBR systems need 25-40% less space than conventional STPs. They also maintain higher mixed liquor suspended solids (MLSS) concentrations—usually 8,000-15,000 mg/L compared to traditional systems at 2,000-4,000 mg/L.

Moving Bed Biofilm Reactor (MBBR) for Space Efficiency

MBBR technology uses special plastic carriers that create the perfect environment for biofilm growth. These carriers fill 50-70% of the reactor volume and maximize the surface area where microbes can thrive. This approach removes the need for sludge recycling, which makes operations simpler while keeping treatment effective.

MBBR systems excel at removing BOD, COD, ammonia, and nitrogen in compact spaces. They need nowhere near as much space as conventional activated sludge systems and handle varying loads well.

Sequential Batch Reactor (SBR) for Time-Based Treatment

SBR technology works in specific time-based cycles instead of continuous flow. Each cycle has five phases: fill, react (aeration), settle, decant, and idle. This approach offers great flexibility when managing varying sewage loads.

Gurgaon has embraced SBR technology, with a major 20 MLD plant already running. The system uses less energy than other biological treatment processes.

RO Integration for Tertiary Polishing

RO systems provide advanced tertiary treatment by removing dissolved salts and trace contaminants from treated effluent. The membranes work as selective barriers that filter out even the tiniest particles to produce water clean enough for reuse.

SUSBIO leads the way as Gurgaon’s premier sewage treatment plant manufacturer. They use innovative technology in their all-encompassing treatment solutions. Their flagship product, SUSBIO ECOTREAT, stands out as the best choice for sewage treatment plants in Gurgaon. It combines multiple advanced processes to deliver excellent performance in compact spaces.

SUSBIO’s systems produce exceptionally clean water that goes beyond regulatory standards, with BOD ≤10 mg/L and TSS ≤10 mg/L. This makes them perfect for water recycling in Gurgaon’s water-stressed environment.

SUSBIO: Best Sewage Treatment Plant Manufacturer in Gurgaon

SUSBIO started its journey in 2013 when two BITS Pilani college students, Akshat Tyagi and Raghavendra Suryavanshi, started a mission focused on environmental responsibility. The company is now a 10-year old premier sewage treatment plant manufacturer in Gurgaon. Their flagship product, SUSBIO ECOTREAT, brings innovative solutions to the market.

Overview of SUSBIO’s Local Projects

SUSBIO stands as a dominant force in India’s sewage treatment industry. The company’s track record shows more than 126 successful projects nationwide with a 99% customer satisfaction rate. Their expertise covers residential complexes, luxury hotels, hospitals, industries, and educational institutions. They design, manufacture, install, and maintain advanced sewage treatment plants that address Gurgaon’s unique urban challenges.

SUSBIO ECOTREAT: Modular and Flexible STP Solution

SUSBIO ECOTREAT stands out in Gurgaon’s sewage treatment options. We crafted its prefabricated, modular design from high-quality fiber-reinforced plastic (FRP). This innovative build delivers superior strength and durability with smooth installation. The system uses a dual treatment process that combines anaerobic and aerobic methods to purify wastewater thoroughly.

The ECOTREAT’s adaptability makes it special. Its modular nature lets you expand easily as your needs grow. This flexibility works well for small residential complexes and large industrial setups alike. The plant’s compact size and plug-and-play design allow quick setup, even in Gurgaon’s tight spaces.

Automation and Remote Monitoring Capabilities

SUSBIO ECOTREAT comes with cutting-edge automation. It’s the world’s first packaged STP with full IoT monitoring. This advanced system tracks:

COD, BOD, TSS, and pH levels live

Equipment performance including pumps and blowers

Water levels to prevent overflows

Predictive maintenance alerts

This smart monitoring system lets you operate everything remotely, so you don’t need staff on-site.

Energy-Efficient and Low-Maintenance Design

SUSBIO ECOTREAT uses 90% less electricity than traditional STPs. Lower energy use cuts operational costs and supports green initiatives. The system runs quietly too – a crucial feature for urban areas.

The design needs minimal upkeep and rarely faces downtime. You’ll only need to remove sludge every 3-4 years. The system comes with a 10-year media warranty and a 25-year tank warranty, giving clients long-term peace of mind.

Installation, Support, and Compliance Services

The trip from concept to operational excellence needs expert guidance throughout the sewage treatment plant lifecycle. SUSBIO, a first-rate manufacturer, provides complete services that will give a lasting optimal performance of their installations for decades.

On-Site Installation and Commissioning Process

A full picture of the site starts the successful installation process. SUSBIO, the premier sewage treatment plant manufacturer in Gurgaon, reviews space availability, soil stability, and accessibility before ground preparation. Skilled technicians precisely assemble the system according to engineered designs when components arrive. They focus on tank placement, pipeline connections, and electrical integration.

The commissioning follows a detailed protocol. The team conducts original dry testing without sewage, gradually introduces wastewater, and performs complete performance reviews. This strict process takes 5-6 months for complex systems and ensures reliable operation throughout the plant’s 25+ year lifespan.

Training and Handover to Client Teams

SUSBIO’s well-laid-out operator training programs give teams knowledge about:

Daily operations and routine maintenance procedures

Troubleshooting common issues

Safety protocols and emergency response

Simple IT skills for monitoring systems

The handover phase transfers complete documentation like operational manuals, maintenance schedules, and equipment warranties. Client teams can manage their SUSBIO ECOTREAT systems independently with confidence.

After-Sales Support and Remote Monitoring

Leading manufacturers across India provide 24×7 services through complete maintenance contracts. SUSBIO’s advanced monitoring systems track critical parameters including flow rates, water quality, chemical consumption, and equipment health with up-to-the-minute data. This technology helps identify potential issues before they cause downtime.

Regulatory Compliance and Documentation Assistance

Expert guidance helps navigate complex regulations. SUSBIO helps clients get necessary approvals from authorities like the Haryana State Pollution Control Board under the Water Act. Their team prepares required documentation including performance reports, discharge monitoring data, and certification paperwork to ensure smooth regulatory compliance.

Conclusion

Gurgaon’s rise into a bustling metropolis has created new challenges for wastewater management. The gap between sewage generation and treatment capacity shows we need better solutions that work for local conditions. Quality standards keep changing, and treatment facilities must perform better to meet water quality and reuse requirements.

SUSBIO has become the top sewage treatment plant manufacturer in Gurgaon. The company tackles these complex challenges with innovative methods and advanced technology. Their main product, SUSBIO ECOTREAT, proves to be the best choice for sewage treatment plants in residential complexes, businesses, and industrial facilities across the region. This groundbreaking system combines modular design with advanced biological treatment processes that exceed regulatory requirements.

SUSBIO ECOTREAT’s compact design fits well in Gurgaon’s space-limited urban setting. On top of that, it runs on less energy and costs less to operate than traditional systems. The system’s automation lets you monitor and manage it remotely, so you don’t need constant on-site staff to maintain peak performance.

What sets SUSBIO apart is their full support throughout your project’s lifecycle. Their experts guide you from the first site check through installation, startup, training, and maintenance. This comprehensive approach helps ensure each installation works reliably for years to come.

Gurgaon’s wastewater challenges will grow as the city expands. Picking the right sewage treatment solution becomes crucial for eco-friendly urban growth. SUSBIO ECOTREAT isn’t just a tech solution – it’s a complete approach to responsible water management that helps businesses, communities, and the environment. Gurgaon’s wastewater infrastructure future needs these innovative, efficient, and eco-friendly systems that adapt to change while delivering excellent results.

Key Takeaways

Gurgaon faces a critical sewage crisis with only 148 MLD treatment capacity against 225 MLD daily generation, creating urgent infrastructure needs.

• SUSBIO ECOTREAT offers modular, FRP-based STPs with 90% less energy consumption and comprehensive IoT monitoring capabilities.

• Advanced technologies like MBR, MBBR, and SBR enable compact installations with superior treatment efficiency for urban constraints.

• Localized solutions matter most – customized designs based on site conditions, flow patterns, and regulatory compliance ensure optimal performance.

• Complete lifecycle support from installation to maintenance with 24/7 remote monitoring reduces operational complexity and ensures reliability.

• Treated water quality meets stringent standards (BOD ≤10 mg/L) enabling safe reuse applications in water-scarce environments.

The key to successful sewage treatment in Gurgaon lies in choosing manufacturers who understand local challenges and provide technology-driven, sustainable solutions that can scale with urban growth while maintaining regulatory compliance.

Frequently Asked Questions

Q1. What are the main challenges in sewage treatment for Gurgaon?

The primary challenges include a large gap between sewage generation and treatment capacity, rapid urbanization, water scarcity, and the need for compact treatment solutions in space-constrained urban areas.

Q2. How does SUSBIO ECOTREAT differ from conventional sewage treatment plants?

SUSBIO ECOTREAT is a modular, prefabricated system made of fiber-reinforced plastic. It offers energy efficiency, compact design, advanced automation, and remote monitoring capabilities, making it ideal for Gurgaon’s urban environment.

Q3. What advanced technologies are used in modern sewage treatment plants in Gurgaon?

Modern STPs in Gurgaon utilize technologies such as Membrane Bioreactor (MBR), Moving Bed Biofilm Reactor (MBBR), Sequential Batch Reactor (SBR), and Reverse Osmosis (RO) for tertiary treatment.

Q4. How does SUSBIO ensure regulatory compliance for its sewage treatment plants?

SUSBIO assists clients with necessary approvals from authorities like the Haryana State Pollution Control Board, prepares required documentation, and ensures their systems meet or exceed all regulatory standards for effluent quality.

Q5. What kind of support does SUSBIO provide after installation of a sewage treatment plant?

SUSBIO offers comprehensive after-sales support including 24/7 remote monitoring, predictive maintenance, operator training programs, and ongoing assistance with regulatory compliance and documentation.