The numbers are fascinating – sewage treatment plants process wastewater that contains 99.9% water and only 0.1% impurities. Global sewage treatment statistics reveal a striking disparity. High-income countries treat about 74% of their sewage, while developing nations manage a mere 4.2%, bringing the worldwide average to 52%.

This piece breaks down the complete sewage treatment process and the technologies that make wastewater treatment work. The benefits extend beyond protecting public health from harmful pathogens and toxins. Reduced healthcare costs linked to waterborne illnesses make these systems valuable investments. Countries like India face a growing lack of water resources. Sewage treatment plants have become essential rather than optional. The discussion covers STP plant components, working principles, and groundbreaking solutions like SUSBIO ECOTREAT—India’s most advanced packaged STP that brings a future-ready approach to wastewater management.

Sewage Characteristics and Contaminants

Sewage has just 0.1% solid matter. This tiny fraction creates big challenges for treatment plants. You need to understand these contaminants to design water treatment systems that work well and protect public health and the environment.

Organic Load: BOD and COD Levels

Sewage has proteins (approximately 40%), carbohydrates (25-50%), oils and grease (about 10%), and other compounds in smaller amounts. Treatment facilities calculate this organic content by measuring Biochemical Oxygen Demand (BOD) and Chemical Oxygen Demand (COD).

BOD shows how much oxygen microorganisms need to break down organic materials. Scientists measure this over five days at 20°C. Raw sewage typically shows BOD values between 300-600 mg/liter. COD tells us the total oxygen needed for chemical reactions to oxidize all organic matter. COD values are always higher than BOD because chemical oxidation works more thoroughly than biological processes.

The organic loading rate (OLR) is a vital design factor for sewage treatment plants. Engineers measure it in kg COD per cubic meter per day. Modern systems like SUSBIO ECOTREAT can handle different organic loads well. These systems work effectively whatever the fluctuations.

Nutrient Content: Nitrogen and Phosphorus

Nitrogen and phosphorus help plants grow but cause problems in large amounts. Sewage nitrogen exists mainly as organic nitrogen or ammonia from urea. Most phosphorus appears as phosphates from detergents and organic compounds.

Regular treatment processes can’t reduce nitrogen and phosphorus enough to meet safe environmental levels. Eutrophication starts at just 0.5–1.2 mg/L for nitrogen and 0.03–0.1 mg/L for phosphorus. This is a big deal as it means that wastewater treatment plants worldwide release 5-20 mg/L of nitrogen and 1-4 mg/L of phosphorus.

Pathogens and Suspended Solids

Sewage contains many disease-causing organisms. These include bacteria (like Salmonella, Shigella), viruses (hepatitis A, coronavirus), protozoa, and helminths (roundworms, hookworms). Recent metagenomic studies found 113 bacterial pathogen species in sewage samples. Scientists discovered 79 of these species for the first time.

Total Suspended Solids (TSS) are tiny particles larger than 2 microns. TSS makes up a small part of sewage volume but can change water bodies significantly. These particles affect light penetration, temperature, and can trap pathogens. Combined treatment systems can remove up to 91% of TSS. Modern facilities like SUSBIO ECOTREAT use advanced filtration to remove solids thoroughly.

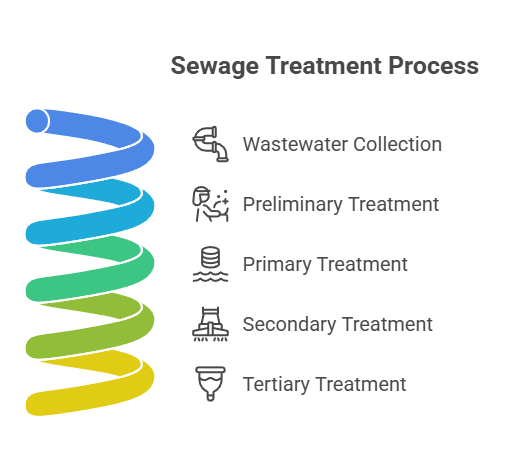

Stages of Sewage Treatment Explained

Modern sewage treatment plants use a systematic multi-stage process that turns raw wastewater into clean, reusable water. Each stage removes different types of contaminants from incoming sewage in a specific way.

Preliminary Treatment: Screening and Grit Removal

The first phase protects downstream equipment from damage. Bar screens with openings of 6 to 40 mm capture large objects. The water velocity slows down in grit chambers so sand, gravel, and other heavy materials can settle. This prevents pump abrasion and reduces deposits in channels. Physical contaminants get removed during preliminary treatment rather than dissolved pollutants, which prepares the wastewater for more intensive treatment stages.

Primary Clarification and Sludge Separation

Wastewater stays in primary clarifiers for 1.5 to 2.5 hours while solids settle by gravity. This method removes 50-65% of total suspended solids and 20-35% of BOD5 effectively. Rotating scrapers or spiral arms collect the settled sludge and move it for further processing. Primary clarification reduces the organic load by a lot before biological treatment, making it a vital step in the overall process.

Biological Treatment: Aerobic and Anaerobic Methods

Biological treatment uses microorganisms to break down organic matter. Aerobic processes need oxygen and work well for low-strength wastewater (COD <1000 mg/L). Anaerobic treatment works without oxygen and handles higher organic loads (COD >4000 mg/L). Treatment efficiency ranges from 75-98% for aerobic systems and 51-96% for anaerobic systems. Advanced systems like SUSBIO ECOTREAT combine both approaches to achieve optimal treatment efficiency.

Tertiary Polishing: Sand Filters and UV Disinfection

The final stage ensures water quality meets strict standards before discharge. Sand filters remove remaining fine particles with removal rates up to 99% for bacteria. UV disinfection damages microorganisms’ nucleic acids and eliminates pathogens like E.coli and Cryptosporidium that resist chlorine treatment. UV treatment offers several advantages over chemical alternatives:

- Chemical-free disinfection with no by-products

- No change in water properties like pH

- Lower operational costs

These four stages work together as a detailed system that produces clean water suitable for environmental discharge or reuse.

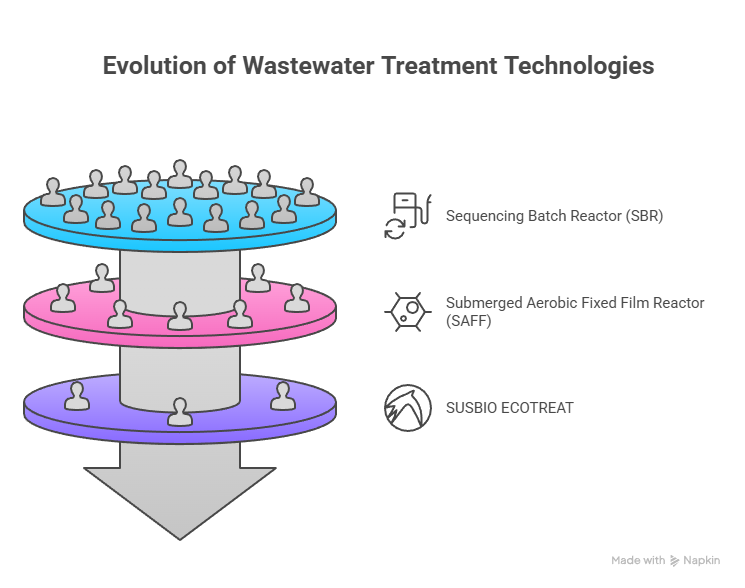

Advanced STP Technologies and Innovations

Modern wastewater treatment has come a long way. New systems work better than old ones and take up less space. These improvements have changed how we handle waste treatment, making it more energy-efficient and effective.

Sequencing Batch Reactor (SBR)

SBR’s magic lies in its single-tank design that handles all treatment steps in timed sequences. The system runs through fill, react, settle, decant, and idle phases. You need half the space compared to traditional systems, and it’s easy to adjust operations when needed.

The system removes nutrients well by controlling oxygen levels, which helps reduce nitrogen and phosphorus. The biggest problem is that you need advanced controls and skilled operators. But many modern sewage plants still choose SBRs because they’re easy to expand and handle changing water flows well.

Submerged Aerobic Fixed Film Reactor (SAFF)

SAFF systems use special UV-stabilized PVC media with corrugated surfaces where microbes can thrive. The design’s large surface area helps digest waste faster, cutting BOD levels by 95-98%.

The system beats conventional methods with higher MLSS concentration and needs smaller aeration tanks. Its cross-corrugated media also transfers oxygen better. Small and medium-sized treatment plants love this technology, especially when space is tight and full-time staff isn’t practical.

SUSBIO ECOTREAT: Future-Ready Packaged STP Solution

SUSBIO ECOTREAT stands out as India’s most advanced packaged sewage treatment system. This innovative solution uses tough fiber-reinforced plastic and combines two treatment methods – anaerobic and aerobic – to maximize efficiency. The system runs by itself, so you don’t need operators on site, which saves money on labor.

The best part? It uses 90% less power than regular plants and runs quietly. These features, plus its low maintenance needs and compact size, make SUSBIO ECOTREAT perfect for sewage treatment in homes, businesses, and factories.

Environmental and Regulatory Impact of STPs

Regulations serve as the foundation for effective sewage treatment worldwide. These rules make sure treated wastewater meets environmental standards and protects our ecosystems while promoting green water management practices.

Effluent Standards and Discharge Norms

The Water (Prevention and Control of Pollution) Act, 1974, and the Environment Protection Act, 1986 govern India’s sewage treatment regulations. The Central Pollution Control Board (CPCB) has set specific parameters for STP effluent quality:

- BOD: ≤20 mg/L

- COD: ≤250 mg/L

- Total Suspended Solids: ≤30 mg/L

- pH: between 6.5 and 8.5

State Pollution Control Boards (SPCBs) regularly check facilities to monitor compliance. Plants that break these rules face serious consequences like closures, fines, or legal action. Some regions have tougher limits – industries releasing water into Delhi’s Yamuna River must meet specific BOD and TSS requirements.

Reuse Policies and Water Conservation Goals

India barely uses its treated wastewater – less than 3% of treated and only 1% of generated wastewater gets reused. This is a missed chance, since recycling half of industrial wastewater could provide an extra 7 km³ of water – enough to meet New Delhi’s water needs for more than five years.

The CPCB now requires reuse of treated STP water for non-potable purposes like toilet flushing, landscape irrigation, cooling towers, and floor washing. The National Mission for Clean Ganga aims to reuse 50% of wastewater by 2025. Zero Liquid Discharge (ZLD) shows promise as a new approach where plants treat and reuse wastewater, disposing residues in solid form.

Global and Indian STP Compliance Trends

Middle Eastern countries like UAE, Saudi Arabia, and Qatar have strict rules about wastewater reuse. They often need advanced treatment processes such as membrane bioreactors and reverse osmosis. The Gulf Cooperation Council wants to standardize these regulations across the region.

SUSBIO ECOTREAT stands out as India’s most future-ready packaged STP solution in this changing regulatory environment. Its advanced treatment capabilities meet even the toughest standards while its energy efficiency and automation match global sustainability goals perfectly.

Sewage treatment plants will keep playing a vital role in solving water conservation challenges. They turn potential waste into a valuable resource that serves both current and future generations.

Conclusion

Modern treatment plants can transform wastewater with just 0.1% impurities into reusable water. Without doubt, there’s a stark global gap in sewage treatment capabilities. Developed nations treat 74% of their sewage while developing countries manage just 4.2%. This emphasizes the need for available solutions worldwide.

The multi-stage treatment process tackles different contaminants in sewage. Preliminary treatment takes out large debris and grit. Primary clarification then separates suspended solids and substantially reduces BOD levels. The process continues with biological treatment that breaks down organic matter through both aerobic and anaerobic processes. Sand filtration and UV disinfection give the final polish to ensure water meets quality standards before discharge.

New technologies have definitely changed how we treat sewage. Sequencing Batch Reactors save space and offer operational flexibility. Submerged Aerobic Fixed Film Reactors deliver excellent BOD reduction without needing much space. SUSBIO ECOTREAT leads the pack as India’s most advanced packaged STP solution. It combines anaerobic and aerobic methods to maximize efficiency and uses 90% less electricity than conventional systems.

Environmental and regulatory aspects play a vital role in protecting ecosystems through effluent standards compliance. Water reuse policies help address water lack. This becomes especially important in countries like India, where less than 3% of treated wastewater gets reused.

Water conservation grows more critical each day. Solutions like SUSBIO ECOTREAT show what a world of sewage treatment could look like – automated, energy-efficient, and environmentally sound. Effective sewage treatment does more than manage waste – it reclaims a valuable resource. The path forward lies in embracing innovative, future-ready technologies for sustainable water management.

Key Takeaways

Understanding sewage treatment is crucial for sustainable water management, as these systems transform wastewater into reusable resources while protecting public health and the environment.

- Multi-stage treatment is essential: Sewage treatment involves four critical stages—preliminary screening, primary clarification, biological treatment, and tertiary polishing—each removing specific contaminants for optimal water quality.

- Advanced technologies maximize efficiency: Modern systems like Sequencing Batch Reactors and SUSBIO ECOTREAT use 90% less electricity than conventional plants while achieving superior treatment results in compact footprints.

- Regulatory compliance drives environmental protection: Strict effluent standards (BOD ≤20 mg/L, COD ≤250 mg/L) ensure treated water meets safety requirements, with violations resulting in plant closures and penalties.

- Water reuse potential remains largely untapped: Less than 3% of treated wastewater is currently reused globally, representing a massive opportunity to address water scarcity through proper treatment and recycling policies.

- Future-ready solutions combine automation with sustainability: Technologies like SUSBIO ECOTREAT offer fully automated operation, minimal maintenance, and silent operation, making advanced sewage treatment accessible for diverse applications.

The evolution toward energy-efficient, automated sewage treatment systems represents a critical step in transforming waste management from an environmental burden into a valuable water conservation strategy.

Frequently Asked Questions

Q1. What are the main stages of sewage treatment?

Sewage treatment typically involves four main stages: preliminary treatment (screening and grit removal), primary clarification (sludge separation), biological treatment (using aerobic and anaerobic methods), and tertiary polishing (sand filtration and UV disinfection).

Q2. How does SUSBIO ECOTREAT differ from conventional sewage treatment plants?

SUSBIO ECOTREAT is an advanced packaged sewage treatment solution that uses 90% less electricity than conventional plants. It combines anaerobic and aerobic treatment methods, operates automatically without on-site operators, and has a compact design, making it ideal for various applications.

Q3. What are the key contaminants in sewage that need to be treated?

The main contaminants in sewage include organic matter (measured by BOD and COD), nutrients like nitrogen and phosphorus, pathogens (such as bacteria and viruses), and suspended solids. These contaminants are addressed through various stages of the treatment process.

Q4. What are the effluent standards for treated sewage in India?

In India, the Central Pollution Control Board has set specific parameters for STP effluent quality. These include BOD ≤20 mg/L, COD ≤250 mg/L, Total Suspended Solids ≤30 mg/L, and pH between 6.5 and 8.5. Compliance with these standards is crucial for environmental protection.

Q5. How can treated wastewater be reused?

Treated wastewater can be reused for various non-potable purposes such as toilet flushing, landscape irrigation, cooling towers, and floor washing. However, the potential for water reuse is largely untapped, with less than 3% of treated wastewater currently being reused in India, presenting a significant opportunity for water conservation.