SUSBIO-Sequence BATCH REACTOR (SBR) Sewage Treatment Plants

SUSBIO is one of the leading Sewage Treatment Plant Manufacturer and most advanced technology driven company in Sewage Treatment Industry. We cater to all commercial and industrial sectors as we have several proven and custom build technologies to provide cutting edge results

SUSBIO deals is all Traditional and advanced Sewage treatment Plant technologies. We Design, Install, Commission, Operate and Maintain Sewage Treatment plants of all scales and technologies

Sustainable Biosolutions is committed to provide reusable quality treated water. Our STP’s fulfills both Indian (Pollution Control Board) and International norms. We undertake Design, Installation, Troubleshooting, Revamping and Maintenance of STPs at various scale. We have developed SUS BIO SBR a revolutionary sewage treatment technology in collaboration with INRA a French government institution. The Sequential Batch Reactor is a modified activated sludge process in which naturally occurring aerobic microorganisms are utilized to eliminate the organic pollutants contained in the wastewater. SBR works in sequences of batch processes scientifically designed to overcome problems associated with old fashioned continuous processes (FAB,MBBR etc). SUSBIO has designed and installed STP/ETP in various scale and possess capacity to install up to 100 MLD. We serve wide range of clients including apartments, institutions, industries, shopping malls, hotels, resorts and hospitals.

The sewage treatment design process is a meticulous and essential procedure aimed at efficiently treating wastewater before its release into the environment. It involves a series of steps, including preliminary assessment, site selection, engineering design, and regulatory compliance. An effective design ensures the protection of public health and the preservation of natural ecosystems.

The construction and installation process of a sewage treatment plant is a systematic and rigorous undertaking. It commences with meticulous feasibility assessments and the acquisition of necessary permits. Subsequently, it encompasses site excavation, precise tank installation, and the intricate laying of pipelines. Expert technicians execute the assembly, wiring, and plumbing, culminating in the establishment of a fully operational, environmentally compliant facility.

The commissioning of a sewage treatment plant involves rigorous testing and verification to ensure its functionality and compliance with regulations. It includes equipment calibration, process optimization, and quality control assessments. Skilled professionals oversee this critical phase, guaranteeing the plant’s efficient operation and adherence to environmental standards.

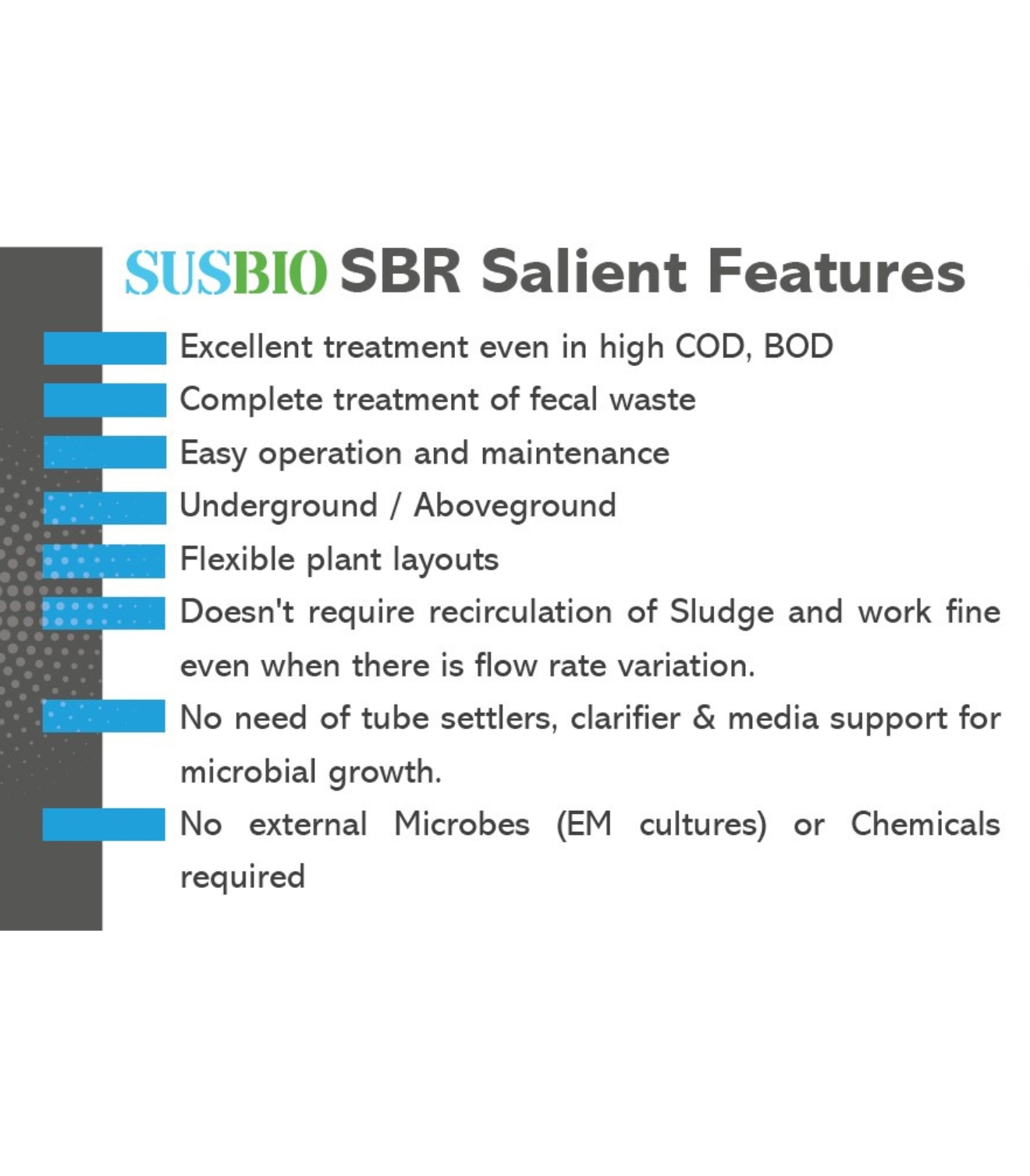

SUSBIO SBR (Sequential Batch Reactor) sewage treatment plants excel in maintaining exceptional performance, even when confronted with high inlet COD (Chemical Oxygen Demand) and BOD (Biochemical Oxygen Demand) levels. Their inherent flexibility allows for efficient adaptation to fluctuating organic loads and varying influent quality. SBR systems utilize a controlled sequencing approach, optimizing the biological treatment process.

Moreover, the extended aerobic phase in SBRs provides ample time for microorganisms to break down contaminants, ensuring thorough removal of pollutants. This reliability ensures consistent effluent quality and compliance with stringent environmental regulations, making SBR sewage treatment plants a prudent choice for municipalities and industries seeking robust, adaptable, and high-performance wastewater treatment solutions.

SUSBIO SBR (Sequential Batch Reactor) sewage treatment plants are renowned for their user-friendly operation and simplified maintenance, making them a preferred choice for wastewater treatment. Their intuitive automation and adaptable control systems empower operators with straightforward control over the treatment process. Routine tasks, including sludge removal, equipment inspections, and process adjustments, are streamlined, minimizing downtime.

Moreover, SBRs are modular in design, which simplifies expansion or upgrading to meet changing demands. These features not only enhance the efficiency of wastewater treatment but also reduce operational costs and manpower requirements. Ultimately, SBR sewage treatment plants provide an accessible, cost-effective, and sustainable solution for wastewater management.

SUSBIO SBR (Sequential Batch Reactor) sewage treatment plants are recognized for their robust technology and adaptability through retrofit designs. Their flexible operation allows for the efficient treatment of varying influent characteristics and flows, ensuring reliable performance even in challenging conditions. Additionally, the modular structure of SBR systems facilitates easy retrofitting and expansion, making it cost-effective to upgrade existing wastewater treatment facilities. This adaptability reduces the need for entirely new infrastructure and promotes sustainability in wastewater management. SBR technology, with its robustness and retrofit capabilities, represents a forward-looking approach to meeting evolving environmental and regulatory demands while optimizing operational efficiency.

A Sewage Treatment Plant (STP) operates by first removing large debris and solids through preliminary treatment. Next, in primary treatment, solids and grease are settled out. Secondary treatment then uses biological processes to break down organic matter. Tertiary treatment further purifies the water to remove any remaining contaminants. Finally, the water is disinfected to kill pathogens before being discharged or reused, ensuring it meets environmental standards.

Choosing the right sewage treatment manufacturer requires a multi-pronged approach. Look for companies with experience in your project size and local regulations. Their technology should be advanced, sustainable, and compliant. Customization and future scalability are important. Prioritize quality, reliability, and good after-sales service. Consider energy efficiency, sludge management solutions, and responsive customer support to ensure a smooth and environmentally friendly wastewater treatment process.

Advanced Sewage Treatment technology offers numerous benefits, including more effective pollutant removal for cleaner water and a healthier ecosystem. These systems are energy-efficient, reduce sludge production, and simplify disposal, leading to significant cost savings over time. Investing in advanced sewage treatment is both an environmentally responsible and economically smart decision.

SUSBIO ECOTREAT is a leading packaged STP known for its dual-treatment process, combining aerobic and anaerobic methods for effective waste removal. Its prefabricated design allows for modular, space-efficient installation, making it suitable for various applications. The system is highly efficient, with low operational costs and energy consumption, and is designed for easy maintenance and long-term durability.

The average cost of a Sewage Treatment Plant (STP) in India varies based on capacity, technology, and location. Operating costs can range from INR 15 to INR 50 per cubic meter of treated water. For a small to medium-sized STP with a capacity of about 1 million liters per day (MLD), the monthly operating cost can range from INR 1.5 lakh to INR 5 lakh. Larger STPs with capacities of 10 MLD or more may have higher costs.

A packaged STP is a compact, prefabricated system designed to treat sewage and wastewater in a modular, self-contained unit. It combines various treatment processes, such as screening, sedimentation, biological treatment, and disinfection, into a single package. Packaged STPs are easy to install and operate, making them suitable for residential, commercial, and small industrial applications, with reduced construction time and lower costs.

A Sewage Treatment Plant (STP) is essential for safely managing and treating wastewater. STPs remove harmful contaminants, protect public health by preventing disease spread, preserve the environment by reducing pollution, and enable water reuse for irrigation or industrial purposes. They also ensure compliance with environmental regulations, making them vital for sustainable water management.

Sustainable Biosolutions Pvt Ltd is the best manufacturer and supplier of Sewage Treatment Plants (STPs) and Wastewater Treatment system in India. They offer innovative solutions like the advanced SUSBIO ECOTREAT, which ensures effective wastewater treatment, energy efficiency, and easy maintenance, making them a leader in the industry.

The lifespan of an advanced sewage treatment plant can vary depending on the design, materials used, and maintenance practices. However, a well-maintained STP can last anywhere from 20 to 50 years or more.