Smart sewage treatment systems are transforming the wastewater management industry with impressive efficiency gains. Industries and water utilities worldwide spend about USD 76 billion each year to run treatment plants. These high costs make it vital to optimize these systems for sustainable operations.

Traditional wastewater treatment processes have limitations, particularly in monitoring key parameters. Conventional methods don’t provide quick results and plant operators can’t make timely adjustments. AI applications offer promising solutions to these challenges. These technologies achieve impressive prediction accuracy (R² value) between 0.64 and 1.00 for pollutant removal, which proves their effectiveness in waste water treatment.

AI-powered solutions lead the way as the best sewage treatment systems for modern facilities. Many countries and municipalities now run pilot projects to test these smart sewage treatment plants. AI’s capability to mimic human intelligence through learning, reasoning, and decision-making helps streamline operations. AI paradigms such as ANN, LSTM, and SVM perform exceptionally well, while Random Forest and Decision Tree provide better interpretability.

This piece uses ground data to show how intelligent process optimization in wastewater treatment creates a chance to automate control processes and provide immediate decision support for plant operators. The specific technologies, methods, and results enable these systems to reduce operating costs by up to 40%.

Dataset and Infrastructure Setup for Real-Time Monitoring

Smart sewage treatment systems rely on effective monitoring. Instant data collection helps optimize operations better than old methods ever could. Treatment facilities can cut operational costs and still meet discharge regulations by setting up strong monitoring systems.

Sensor Network for COD, BOD, TSS, TN, TP

Today’s wastewater treatment facilities use advanced sensor networks to track key water quality markers. These systems monitor Chemical Oxygen Demand (COD), Biological Oxygen Demand (BOD), Total Suspended Solids (TSS), Total Nitrogen (TN), and Total Phosphorous (TP) – the six main factors that discharge limits focus on.

Lab testing of these markers can take anywhere from minutes to days. But sensors give instant readings, so staff can act quickly when something goes wrong. To cite an instance, see how COD sensors track organic pollution in water, BOD sensors measure how much oxygen microbes use, and TSS sensors check suspended solids levels. Other sensors keep an eye on ammonia nitrogen, total phosphorus, and total nitrogen to stay within legal limits.

These measurements are now much more accurate. Studies show correlation coefficients (R²) of 80-85% for COD, BOD5, and TSS models, and 66-74% for TN and TP models. Research also shows that green spectrum wavelengths (497-570 nm) work best for all monitored parameters.

Data Collection from SCADA and IoT Devices

SCADA systems and IoT technology working together have changed how we collect data. This setup gathers continuous information from:

- Water quality sensors and flow meters

- Past operational data (usually 12-36 months)

- Up-to-the-minute operational data from SCADA systems

- Lab results, energy use measurements, and weather forecasts

SCADA systems gather live data from treatment plants about flow rates, chemical dosing, pump status, and storage tanks. The system works through three main parts: process control units watch and adjust control loops, interface units show data visually, and quality assessment units check processes.

The system alerts operators right away about sensor problems, chemical imbalances, or unexpected flow changes. Staff can also monitor and adjust systems from far away, which helps manage large wastewater operations better.

Environmental and Operational Variables Captured

Smart sewage treatment systems track more than just basic quality markers. A study of 78 pollutants (including 7 common pollutants, 19 heavy metals, and 52 micropollutants) showed how this data helps evaluate treatment plant discharge effects on nearby water bodies in both dry and wet weather.

Key operational factors tracked include:

- Flow rates and mixed liquor suspended solids

- Dissolved oxygen levels

- pH and temperature values

- Electrical conductivity

- Energy use patterns

Some measurements can stand in for more complex ones, saving money. Research shows total suspended solids and electrical conductivity might work as substitutes for tracking micropollutants. This approach could cut monitoring costs while staying effective.

The rich data collected helps with more than just following rules and running things better. Machine learning uses this information to predict treatment needs, optimize chemical use, and achieve the 40% cost savings this analysis highlights.

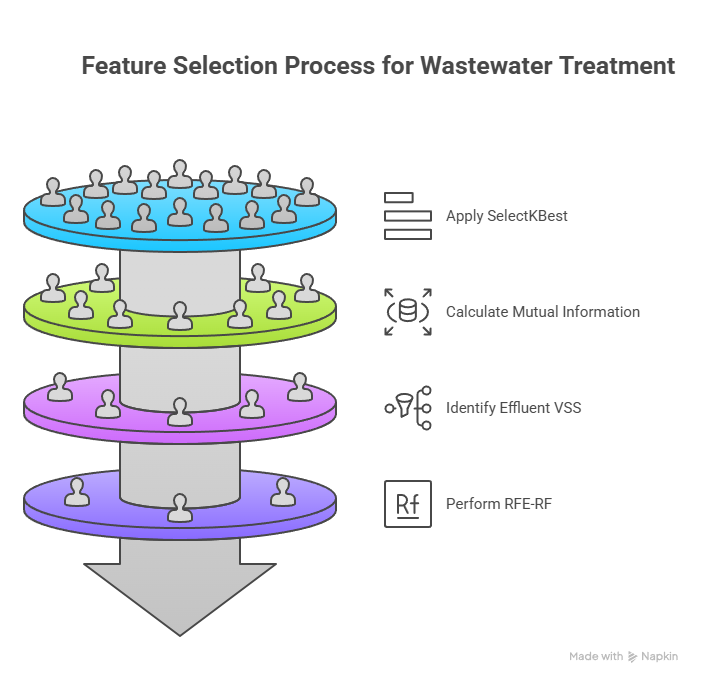

Feature Selection Techniques for Cost-Effective Modeling

Feature selection plays a vital role in building economical models for smart sewage treatment systems. Wastewater datasets contain many parameters. Picking only the most influential variables cuts down computational complexity and keeps the predictive power intact.

SelectKBest and Mutual Information for Top Predictors

SelectKBest is a basic approach to feature selection that picks the most relevant parameters from complex datasets. This technique scores each input variable against target outcomes to prioritize features in wastewater treatment modeling. A detailed study showed that SelectKBest cut down the number of features from 65 to just 10.

Mutual Information (MI) calculation is a reliable way to capture both linear and non-linear relationships between variables. MI spots complex connections in wastewater parameters better than correlation-based methods. This makes it valuable for sewage treatment modeling where relationships rarely follow simple patterns. The approach measures how much each input feature tells us about the target variable like effluent quality and prioritizes the most informative ones.

Effluent VSS as the Most Influential Feature

Effluent Volatile Suspended Solids (VSS) stands out as the top predictor of wastewater treatment performance across different feature selection methods. VSS measures undissolved organic matter in water samples and serves as a key parameter in wastewater analysis. Scientists get this measurement by igniting total suspended solids at temperatures between 550°C and 600°C.

VSS’s importance becomes clear in feature importance scores. One analysis gave Effluent VSS a score of 168.89. This is a big deal as it means that VSS scored much higher than the second-ranked feature, Effluent Dissolved COD. This huge gap shows VSS’s crucial role in predicting treatment outcomes and controlling operational costs.

Recursive Feature Elimination with Random Forest

RFE-RF boosts model performance by removing less important features step by step. The algorithm starts with all features and removes those that barely help classification accuracy. This gives wastewater treatment applications a systematic way to cut down features while keeping their predictive power.

The process follows these steps:

- Random Forest algorithms rank features by importance

- The system removes parameters that contribute less than 10%

- The model trains again with remaining features

- This cycle continues until all features contribute more than the threshold

RFE-RF has found that Effluent Nitrate Nitrogen, Iron Usage, and Methanol Usage are crucial predictors in wastewater treatment. This approach offers great benefits. It makes models simpler, removes redundant features, and needs fewer sensors for monitoring.

These smart feature selection techniques help sewage treatment plants focus on truly important parameters. Plants can cut instrument costs while keeping their predictive accuracy high—a key factor in achieving the 40% operational cost reduction this analysis explains.

Model Performance Comparison for Cost Reduction

Machine learning algorithms are the foundations of smart sewage treatment systems. Their performance directly affects how much money these systems can save. The right model choice becomes crucial to achieve operational savings after selecting the best features.

XGBoost vs LightGBM vs Gradient Boosting

Ensemble learning methods work better than traditional approaches in wastewater treatment applications. XGBoost and LightGBM stand out because they scale well, deliver accurate results, and process data quickly. XGBoost reaches an R² value of 0.8730, which beats LightGBM’s 0.8162. XGBoost’s edge comes from its regularization techniques that prevent overfitting while keeping its predictive power strong.

Different algorithms show varying strengths with specific treatment parameters. Gradient Boosting predicts BOD removal with an R² value of 0.92. XGBoost shows better results for COD prediction with an R² of 83.41%. Smart sewage treatment plants often use multiple models because each one excels at different parameters.

MAE and R2 Scores for COD, BOD, TSS, TN, TP

The predictive accuracy varies a lot between wastewater parameters. XGBoost delivers the lowest MSE (119.24) for COD prediction. Random Forest achieves an R² of 0.91, which shows how reliable it is. Gradient Boosting leads TSS prediction with an R² of 97.04% and the lowest MAE (3.73).

Gradient Boosting shows its strength in Total Nitrogen prediction with an R² of 64.15%. It also has the lowest MAE (0.67) and MSE (1.12). Total Phosphorus proves hard to predict, but LightGBM gets the best results with an R² of 28.68%.

CatBoost models reach amazing accuracy levels with Particle Swarm Optimization. They achieve R² values of 0.9998, MAE of 0.6298, and RMSE of 0.7758. These results help control treatment processes better and save costs.

Decision Tree Underperformance and Overfitting Issues

Decision Trees perform worse than ensemble methods for all wastewater parameters. Their weakness shows up clearly in Total Nitrogen prediction where they get negative R² scores (-84.08%). These scores mean you’d get better results by just using the mean value.

Decision Trees struggle because they tend to overfit. They grow too perfectly around training data and lose their ability to work with new data. Small changes in data can also change their whole structure.

These trees also struggle with similar samples. Take the 2530-4550 interval case where multiple true values matched similar predictions. Ensemble methods like Random Forest and XGBoost fix these problems through bagging or boosting techniques. Their better accuracy makes smart sewage treatment systems cost-effective.

Operational Insights from Real Data Analysis

Analysis of real-life systems shows smart sewage treatment can cut costs by targeting essential operational parameters. Live data analysis helps operators identify the most important cost factors and optimize their strategies.

Effluent VSS and SCOD as Key Cost Drivers

Effluent Volatile Suspended Solids (VSS) and Soluble Chemical Oxygen Demand (SCOD) stand out as the most influential factors in wastewater treatment costs. Live monitoring of these parameters gives vital insights to optimize processes. Studies show VSS scored 168.89 in importance—far higher than other parameters. This stark difference explains why VSS control leads to major cost savings. SCOD monitoring also enables exact carbon source dosing during denitrification and prevents both overdosing and underdosing problems.

Energy Optimization via Aeration Control

Aeration costs dominate wastewater treatment expenses, using 50-70% of total plant energy. Biological treatment in China’s urban wastewater plants consumes 50-70% of their total energy. Smart aeration control can reduce energy use by up to 22%.

Effective strategies include:

- DO-based feedback control systems adjust blower speeds based on live oxygen needs

- Model Predictive Control (MPC) approaches work better than traditional PID controllers

- Time-based optimization cuts aeration during low-demand periods

Chemical Usage Reduction through Predictive Dosing

Chemical expenses make up 3-15% of total operational costs in treatment facilities. Chemical production and transportation generate 19-28% of total plant emissions. Traditional “fixed dosing” wastes 15-40% of reagents, offering a big chance to cut costs.

Predictive dosing systems use live water quality data to adjust chemical addition rates. Continuous monitoring replaces manual sampling and responds quickly to changing wastewater characteristics. Machine learning combined with sensor technology enables precise control that cuts chemical use while maintaining treatment quality.

Limitations and Future Enhancements in Smart STPs

Smart sewage treatment systems face several operational challenges despite their impressive capabilities. The industry needs to address these limitations to tap into their full potential for reducing costs and improving efficiency.

Seasonal Variability and Data Gaps

Wastewater quality and quantity show major changes with seasons, which creates uncertainty in plant operations. Research teams have analyzed 332 sets of hourly data that cover yearly maximum and minimum influent temperatures, highest and lowest flowrates, and both rainy and dry seasons to understand these patterns.

Data collection remains problematic in many facilities. Missing values create a fundamental challenge in developing machine learning models. The forecasting accuracy drops as missing values increase. Research shows that data imputation methods work well with missing data only up to 45% – results become unreliable beyond this threshold.

Privacy protection, legal restrictions, organizational challenges, and the shortage of precise, durable, and affordable sensors lead to a persistent lack of data in wastewater treatment plant modeling.

Need for Hybrid Feature Selection + Expert Input

Feature selection approaches today don’t transfer well between different treatment plant configurations. Models trained on one facility’s data might not work well for another because many plants operate under unique conditions.

Hybrid feature selection methods that blend evidence-based approaches with domain expertise offer a solution. These systems use both machine learning algorithms and expert knowledge to find truly influential parameters across different operational contexts.

Smart Statistical Process Controls (SSPC) mark an improvement over traditional methods by combining innovative technologies with conventional frameworks. This approach enables live monitoring and gives systems predictive capabilities and adaptive control.

Integration with Real-Time Control Systems

Two main factors limit Model Predictive Control (MPC) use in wastewater treatment: the lack of effective process models and too few online process sensors for parameters like influent soluble COD.

Live control centers have made this task easier over the last several years, but implementation challenges continue. Expert systems running in live environments don’t deal very well with integration. SCADA systems and external processes use proprietary protocols for communication, which makes standardization difficult.

A promising approach involves creating early warning systems that can predict fluctuations several hours ahead. This gives operators enough time to adjust system operations before problems occur. These systems must overcome data collection issues through strategic sensor placement and better imputation methods to handle inevitable data gaps.

Conclusion

Smart sewage treatment systems have revolutionized wastewater management. Our analysis shows how combining advanced sensor networks, feature selection techniques, and machine learning algorithms cuts operating costs by 40% through several ways.

The numbers prove these systems work well. XGBoost models reach impressive R² values of 0.87 for overall system performance. Custom algorithms optimize specific parameters and help operators focus on vital cost drivers like Effluent VSS and SCOD.

Smart aeration control reduces energy costs by up to 22%. Predictive chemical dosing eliminates 15-40% of reagent waste compared to fixed dosing methods. These upgrades need less investment than traditional plant improvements.

Smart sewage treatment plants face some hurdles. They don’t deal very well with seasonal changes, gaps in data, and fitting into existing control systems. Better hybrid feature selection approaches and improved up-to-the-minute control systems will solve these problems.

Smart sewage treatment systems now deliver real financial benefits beyond theory. Plants that welcome these technologies save money while meeting environmental standards and becoming more resilient. This analytical approach to wastewater management benefits both the economy and environment, showing the industry’s future direction.

Key Takeaways

Smart sewage treatment systems leverage AI and real-time monitoring to achieve remarkable cost reductions while maintaining environmental compliance. Here are the essential insights from analyzing real operational data:

- Effluent VSS emerges as the most critical parameter – monitoring this single factor (importance score 168.89) enables targeted optimization that drives significant cost savings

- Energy costs drop 22% through intelligent aeration control – since aeration consumes 50-70% of plant energy, smart DO-based feedback systems deliver substantial savings

- Predictive chemical dosing eliminates 15-40% reagent waste – replacing fixed dosing with real-time adjustments based on water quality data dramatically reduces chemical costs

- XGBoost models achieve 87% accuracy (R² = 0.87) – this precision enables operators to make data-driven decisions that optimize treatment processes in real-time

- Feature selection reduces monitoring complexity by 85% – focusing on 10 key parameters instead of 65 maintains predictive power while cutting instrumentation costs

The combination of advanced sensors, machine learning algorithms, and predictive control systems transforms traditional wastewater treatment from reactive to proactive management, delivering both economic and environmental benefits that make smart sewage treatment systems essential for modern facilities.

Frequently Asked Questions

Q1. How do smart sewage treatment systems reduce operational costs?

Smart sewage treatment systems can cut operating costs by up to 40% through real-time monitoring, predictive modeling, and intelligent control of key parameters like effluent VSS and SCOD. They optimize energy usage in aeration and reduce chemical consumption through precise dosing.

Q2. What are the main advantages of using AI in wastewater treatment?

AI in wastewater treatment enables more accurate predictions of pollutant removal, with accuracy rates between 0.64 and 1.00. It allows for real-time decision support, automates control processes, and helps optimize operations, leading to significant cost savings and improved efficiency.

Q3. How does feature selection improve the efficiency of smart sewage treatment systems?

Feature selection techniques like SelectKBest and Recursive Feature Elimination with Random Forest help identify the most influential parameters in wastewater treatment. This reduces monitoring complexity by up to 85%, focusing on key factors like Effluent VSS, which significantly impacts cost and performance.

Q4. Which machine learning models perform best for wastewater treatment prediction?

Ensemble methods like XGBoost and Gradient Boosting consistently outperform traditional approaches in wastewater treatment applications. XGBoost achieves an impressive R² value of 0.8730 for overall system performance, while specific algorithms excel at predicting individual parameters like COD, BOD, and TSS.

Q5. What challenges do smart sewage treatment systems face?

Smart sewage treatment systems face challenges such as seasonal variability in wastewater quality and quantity, data gaps in monitoring, and integration difficulties with existing control systems. Overcoming these limitations requires developing hybrid feature selection methods, improving data collection techniques, and enhancing real-time control capabilities.