A modern waste water treatment plant combines physical, chemical, and biological processes to purify contaminated water. These facilities serve as the backbone of urban sanitation systems, processing millions of liters of sewage and industrial effluent daily before safely returning clean water to the environment. With growing urbanization and increasing water scarcity, the importance of efficient waste water treatment plants has never been more critical. This article explores the essential components, processes, and technologies that make up modern waste water treatment plants, with a focus on innovative solutions like SUSBIO ECOTREAT that are changing the industry landscape.

Essential Waste Water Treatment Plant Components

Every waste water treatment plant consists of several key components working together to transform contaminated water into environmentally safe effluent. Understanding these components is crucial for anyone involved in water management or environmental engineering.

Primary Treatment Units

The initial stage of treatment occurs in primary treatment units, which include:

- Screening chambers: Remove large debris like plastic, paper, and other solid materials

- Grit chambers: Separate heavy inorganic materials like sand and gravel

- Primary clarifiers: Allow suspended solids to settle through gravity

These components form the first line of defense in the waste water treatment plant, removing approximately 50-60% of suspended solids and 30-40% of biochemical oxygen demand (BOD).

Secondary Treatment Systems

The heart of any waste water treatment plant lies in its secondary treatment systems, which typically include:

- Aeration tanks: Provide oxygen to support aerobic bacterial growth

- Biological reactors: Host microorganisms that break down dissolved organic matter

- Secondary clarifiers: Separate biological solids from treated water

The secondary treatment process can remove up to 90% of organic matter through biological processes, representing a critical phase in water purification.

Tertiary Treatment Units

For advanced purification, waste water treatment plants incorporate tertiary treatment units such as:

- Filtration systems: Remove remaining suspended particles

- Disinfection units: Eliminate pathogenic organisms

- Nutrient removal systems: Target nitrogen and phosphorus compounds

These components ensure that the final effluent meets stringent quality standards before discharge.

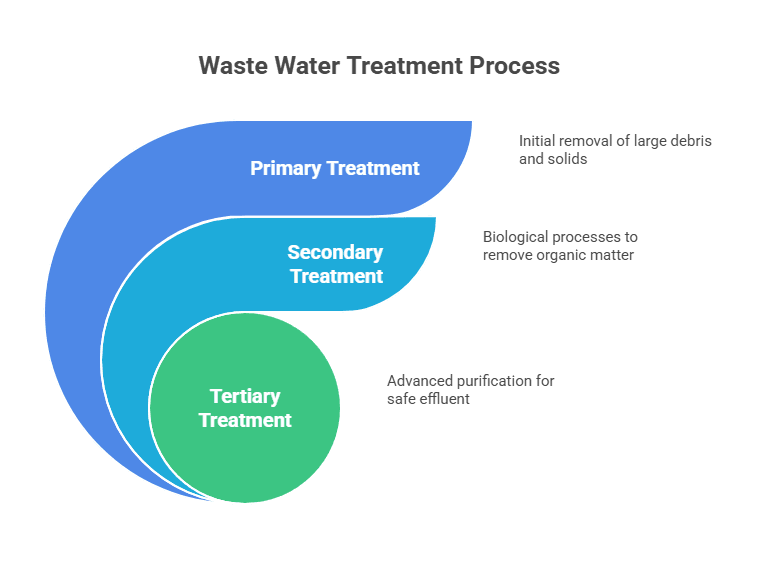

Analyzing a Waste Water Treatment Plant Diagram: A Visual Guide

A waste water treatment plant diagram provides valuable insights into the flow and treatment processes. Examining such diagrams reveals the sequential nature of water treatment and the interconnection between various components.

In a typical waste water treatment plant diagram, you’ll notice:

- Influent entry point: Where raw sewage enters the facility

- Preliminary treatment area: Housing screens and grit removal systems

- Primary treatment zone: Featuring sedimentation tanks

- Secondary treatment section: Including biological reactors and clarifiers

- Tertiary treatment region: With advanced filtration and disinfection systems

- Sludge handling facilities: For processing solid waste byproducts

- Effluent discharge point: Where treated water exits the system

Understanding this flow helps operators optimize performance and troubleshoot issues within the waste water treatment plant.

The Complete Waste Water Treatment Process in Modern Plants

The waste water treatment process typically involves multiple stages including preliminary treatment, primary treatment, secondary treatment, and tertiary treatment. Each stage plays a vital role in progressively purifying water to meet environmental standards.

Preliminary Treatment

The initial phase removes large debris through:

- Screening to capture large objects

- Grit removal to separate heavy inorganic materials

- Flow equalization to manage variable input volumes

This stage prepares water for more refined treatment processes downstream.

Primary Treatment

During primary treatment, physical processes dominate:

- Sedimentation allows suspended solids to settle

- Flotation helps remove oils and greases

- Primary clarification separates approximately 60% of suspended solids

Understanding each step in the waste water treatment process helps operators optimize system performance for maximum efficiency.

Secondary Treatment

The biological heart of the waste water treatment process occurs here:

- Aerobic digestion breaks down dissolved organic matter

- Microbial communities convert contaminants into biomass

- Secondary clarification separates biological solids from treated water

This phase typically removes 85-95% of organic pollutants through natural biological processes.

Tertiary Treatment

The final polishing stage includes:

- Advanced filtration through sand, anthracite, or membrane systems

- Disinfection using UV light, chlorination, or ozonation

- Nutrient removal targeting nitrogen and phosphorus compounds

After completing the entire waste water treatment process, the water is typically safe for environmental discharge or potential reuse applications.

Effective Waste Water Treatment Methods Used in Modern Plants

Different waste water treatment methods are employed depending on the specific contaminants present in the water. Modern facilities utilize a combination of physical, chemical, and biological approaches to achieve optimal results.

Physical Treatment Methods

Physical processes rely on mechanical forces:

- Sedimentation: Utilizes gravity to separate solids

- Filtration: Employs various media to capture particles

- Membrane separation: Uses semi-permeable barriers to remove contaminants

These methods form the foundation of most treatment strategies.

Chemical Treatment Methods

Chemical interventions alter contaminant properties:

- Coagulation and flocculation: Uses chemicals to aggregate particles

- Precipitation: Converts dissolved substances into settleable solids

- Oxidation: Breaks down organic compounds through chemical reactions

Chemical waste water treatment methods are particularly effective for specific industrial contaminants.

Biological Treatment Methods

Biological waste water treatment methods leverage natural processes to break down organic contaminants:

- Activated sludge process: Uses microorganisms to consume organic matter

- Trickling filters: Allow biofilms to develop on media surfaces

- Anaerobic digestion: Processes waste in oxygen-free environments

Advanced technologies like Susbio ecotreat have revolutionized biological treatment by combining anaerobic and aerobic processes in a single, efficient system.

Innovative Technologies in Waste Water Treatment Plants

The waste water treatment industry continues to evolve with new technologies enhancing efficiency and sustainability.

Susbio Ecotreat: A Revolutionary Approach

SUSBIO ECOTREAT represents a significant advancement in waste water treatment plant technology with its innovative packaged sewage treatment plant design. Key features include:

- Dual treatment process: Combines anaerobic and aerobic treatment for superior pollutant removal

- Fiber Reinforced Plastic (FRP) construction: Ensures durability and longevity

- Fully automated operation: Requires minimal human intervention

- Energy efficiency: Consumes up to 90% less electricity than conventional systems

- Compact design: Ideal for urban settings with space constraints

This technology has transformed the approach to waste water treatment plant design, offering a prefabricated, plug-and-play solution that can be rapidly deployed.

Other Emerging Technologies

Beyond SUSBIO ECOTREAT, other innovations include:

- Membrane bioreactors (MBRs): Combine biological treatment with membrane filtration

- Advanced oxidation processes: Use powerful oxidants to destroy contaminants

- Resource recovery systems: Extract valuable materials like phosphorus and energy

These technologies represent the future direction of waste water treatment plants worldwide.

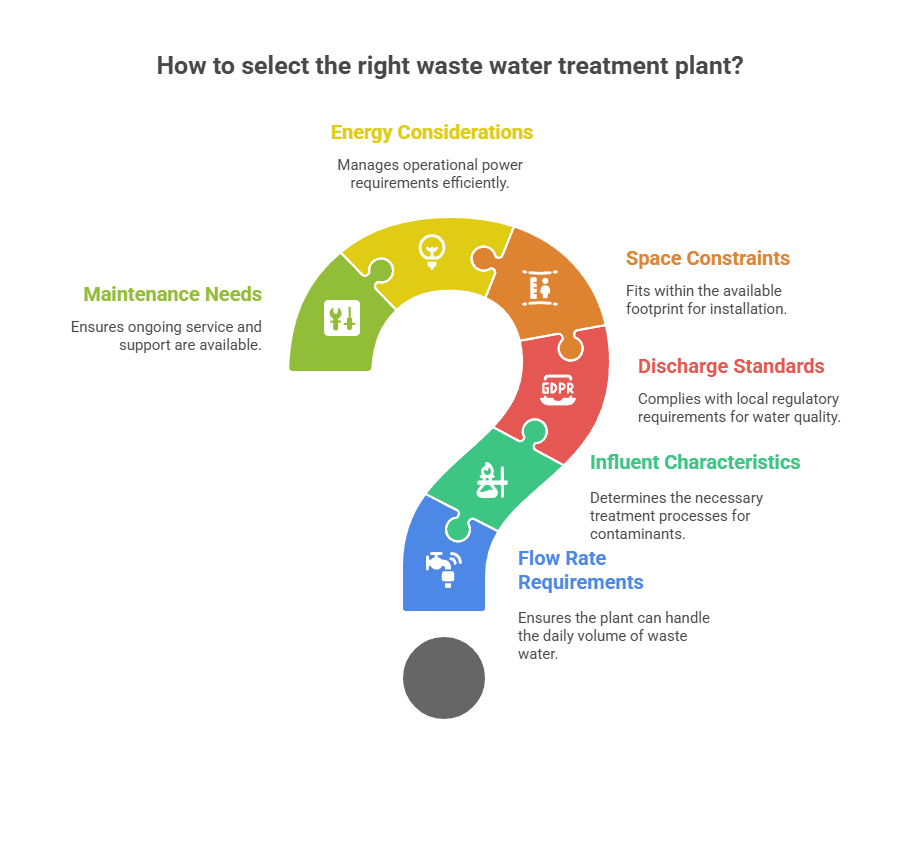

Selecting the Right Waste Water Treatment Plant

Selecting the right waste water treatment plant depends on factors like capacity requirements, space availability, and treatment goals. Decision-makers should consider:

- Flow rate requirements: Daily volume of waste water to be processed

- Influent characteristics: Types and concentrations of contaminants

- Discharge standards: Local regulatory requirements

- Space constraints: Available footprint for installation

- Energy considerations: Operational power requirements

- Maintenance needs: Ongoing service and support requirements

For many applications, packaged solutions like SUSBIO ECOTREAT offer an ideal balance of performance, efficiency, and ease of implementation.

Conclusion

A well-designed waste water treatment plant plays a crucial role in protecting public health and environmental quality. From preliminary screening to advanced tertiary treatment, each component and process contributes to the transformation of contaminated water into safe effluent. As technologies continue to evolve, solutions like Susbio ecotreat are setting new standards for efficiency, sustainability, and performance.

Regular maintenance ensures that your waste water treatment plant operates at peak efficiency throughout its lifecycle. By understanding the components, processes, and methods involved in modern treatment facilities, stakeholders can make informed decisions about system selection, operation, and optimization. As water scarcity and environmental regulations become increasingly stringent, investing in advanced waste water treatment plant technology represents not just a regulatory compliance measure, but a commitment to environmental stewardship and sustainable water management.