Alarming failure rates plague industrial wastewater treatment systems around the world. Many facilities can’t meet their compliance standards. Industries produce such big quantities of wastewater that contains harmful pollutants, including chemicals, heavy metals, and organic waste. The environment, human health, and aquatic ecosystems face severe risks without proper treatment.

Most industries’ processes need specialized facilities to treat their wastewater. The treatment process becomes more complex because industrial wastewater’s composition varies among industries. A treatment plant’s design must adapt to changing water chemistry needs and handle process variations in contamination and flow while meeting strict water effluent requirements. Many systems simply can’t keep up with these challenges.

Untreated wastewater’s high BOD (Biological Oxygen Demand) levels point to elevated concentrations of biodegradable material. Food processing waste, cleaning chemicals, or fertilizer runoff often cause these elevated levels. On top of that, it becomes a bigger problem when treatment systems fail to remove nitrates and phosphates. These nutrients can trigger increased BOD and cause extensive algae and phytoplankton growth in local environments.

In this piece, we’ll get into the reasons behind industrial wastewater treatment systems frequent failures and explore practical solutions. We’ll give you practical insights about improving your facility’s wastewater management by looking at technical gaps and industry-specific treatment challenges.

Failure Patterns Across Industrial Wastewater Treatment Plants

Industrial wastewater treatment facilities show troubling patterns in their operations. Companies of all sizes face unique challenges that cause treatment failures. These failures lead to environmental violations and waste precious resources.

High Failure Rates in Food, Textile, and Pharma Sectors

The food industry creates wastewater with high levels of COD, BOD, TSS, TN, and TP from its processing activities. Meat processing uses the most water in this sector. Dairy products, fruits and vegetables, bakery products, and grain mill operations follow. Many facilities don’t have the specialized treatment processes these effluents need.

The textile industry faces even bigger challenges with wastewater treatment. A significant number of textile wastewater treatment plants in developing countries remain non-functional because industries resist change and focus on profits. Standard treatment systems in this sector fail because they just need too much – energy, time, infrastructure, materials, land, people, and money. Regular systems can’t handle textile effluents well because they mix dyes, surfactants, and salts in complex ways.

Pharmaceutical manufacturing creates the toughest wastewater to treat. The water has high levels of Active Pharmaceutical Ingredients (APIs), solvents, and organic contaminants that need special treatment methods. The wastewater also has antibiotics, anti-inflammatories, steroids, hormones, and spent solvents that don’t break down easily. Regular biological treatment processes often fail to handle these stubborn compounds.

Common Failure Metrics: BOD > 30 mg/L, TSS > 50 mg/L

You need to understand key measurements to spot treatment failures. Biochemical Oxygen Demand (BOD) has two parts: Carbonaceous BOD and Nitrogenous BOD, written as BOD5 = CBOD5 + NBOD5. Carbon oxidation creates carbonaceous BOD, while ammonia oxidation produces nitrogenous BOD.

Ammonia oxidation needs lots of oxygen – 4.6 mg O2 for each mg of NH4+ that turns into NO3-. This is a big deal as it means that it needs more oxygen than carbon conversion, which only uses 1.42 mg of oxygen per mg of organic biomass.

Treatment plants usually fail when their output goes beyond:

- BOD levels of 30 mg/L

- Total Suspended Solids (TSS) of 50 mg/L

- pH outside 5.5-9.0

High BOD can come from ammonia, algae blooms, or sludge problems. Each needs its own fix. High TSS might mean sludge particles are escaping, bacterial floc isn’t working right, or rotifers are blooming.

Case Study: 2023 Audit of 100 Indian Industrial STPs

An audit of India’s sewerage systems revealed some scary facts about treatment infrastructure. Only 598.34 MLD (50%) of the 1188.53 MLD sewage created got treated. The government spent Rs.323.96 crore on 158 incomplete Urban Sewerage Schemes by March 2013. All but one of these projects sat unfinished for three to eight years.

The audit found several specific problems:

Bawal town’s Sewage Treatment Plant cost Rs. 5.48 crore but didn’t work at all. The Kosli town project was abandoned after spending Rs. 9.15 crore. Ganaur town officials said they finished their STP in September 2010, but it ran without filter media – basically dumping untreated wastewater.

Faridabad could treat 160 MLD but only handled 94 MLD of its 200 MLD wastewater. The worst part? 229 out of 232 samples from 18 STPs built under the Yamuna Action Plan failed to meet standards. This shows that treatment infrastructure problems are systemic.

These findings show we urgently need better industrial wastewater treatment solutions. These solutions must tackle industry-specific challenges and reliably meet environmental standards.

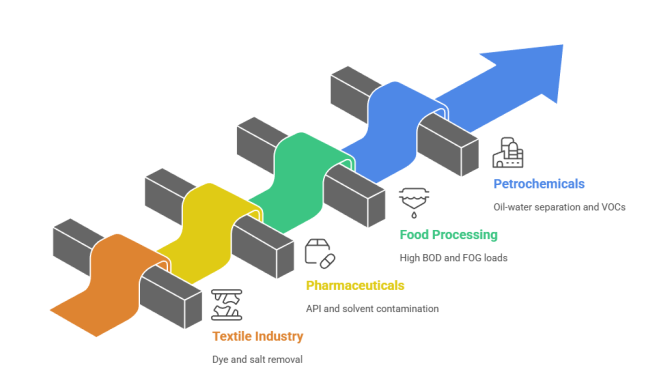

Industry-specific Challenges in Wastewater Treatment

Standard systems don’t deal very well with unique wastewater treatment challenges in industrial sectors. Each sector needs its own custom treatment approach to succeed.

Textile Industry: Dye and Salt Removal Complexity

Chemical composition makes textile wastewater treatment particularly challenging. The industry uses about 200 liters of water to process one kilogram of fabric daily. This creates wastewater full of dangerous dyes, pigments, acids, alkalis, and high salt levels. World Bank data shows textile dyeing and finishing creates 17-20% of global industrial wastewater.

The biggest problem lies in the wastewater’s high color, elevated BOD/COD ratio, and heavy salt (TDS) content. The BOD/COD ratio of 0.25 shows large amounts of non-biodegradable substances. Regular biological treatment methods fail because of this low biodegradability.

Pharmaceuticals: API and Solvent Contamination

Active pharmaceutical ingredients (APIs) make pharmaceutical wastewater exceptionally hard to treat as they survive regular treatment processes. Scientists have found these contaminants in treated wastewater, groundwater, and drinking water sources. API levels change by region and season. Winter sees higher antibiotic presence due to more people taking medicine for respiratory infections.

API manufacturing has changed locations dramatically over 25 years. India’s share grew from 19% to over 50%, while China’s jumped from 5% to about 32%. This change created contamination “hotspots” where API-rich wastewater can cause immediate ecological damage and help create antibiotic-resistant bacteria.

Food Processing: High BOD and FOG Loads

High levels of fats, oils, and grease (FOG) in food service wastewater create major treatment hurdles. Trinidad & Tobago alone releases about 231,304 kg/day of untreated FOG-containing wastewater into the environment.

FOG-laden wastewater causes serious operational issues. FOG hardens when cool and sticks to pipes, blocking sewers and causing overflows. These blockages create oxygen-free conditions that produce hydrogen sulfide and create fire risks. Regular treatment systems can’t remove FOG well because it forms stable emulsions.

Petrochemicals: Oil-Water Separation and VOCs

Petrochemical wastewater treatment faces two key challenges: separating oil from water and managing volatile organic compounds (VOCs). This wastewater contains various organic and inorganic components that need different treatment methods.

VOC emissions from open treatment basins pose a serious problem. These emissions contain dangerous compounds like benzene, toluene, xylene, and methane. These pollutants escape into the air during aeration, stirring, and open storage. Treatment systems must handle both water contaminants and air pollution at the same time.

Technical Gaps in Existing Treatment Systems

Technical shortcomings plague many industrial wastewater treatment systems beyond sector-specific challenges. Engineering and operational gaps create compliance failures that affect businesses of all types.

Lack of Pretreatment for Suspended Solids

Many industrial treatment systems overlook the crucial step of removing suspended solids effectively. Poor pretreatment affects downstream processes because suspended solids clog equipment and prevent biological treatment from working properly. Most facilities don’t screen particles larger than 3mm before starting the main treatment process. Heavy particles don’t settle properly when sedimentation time is too short, which damages equipment and reduces treatment effectiveness.

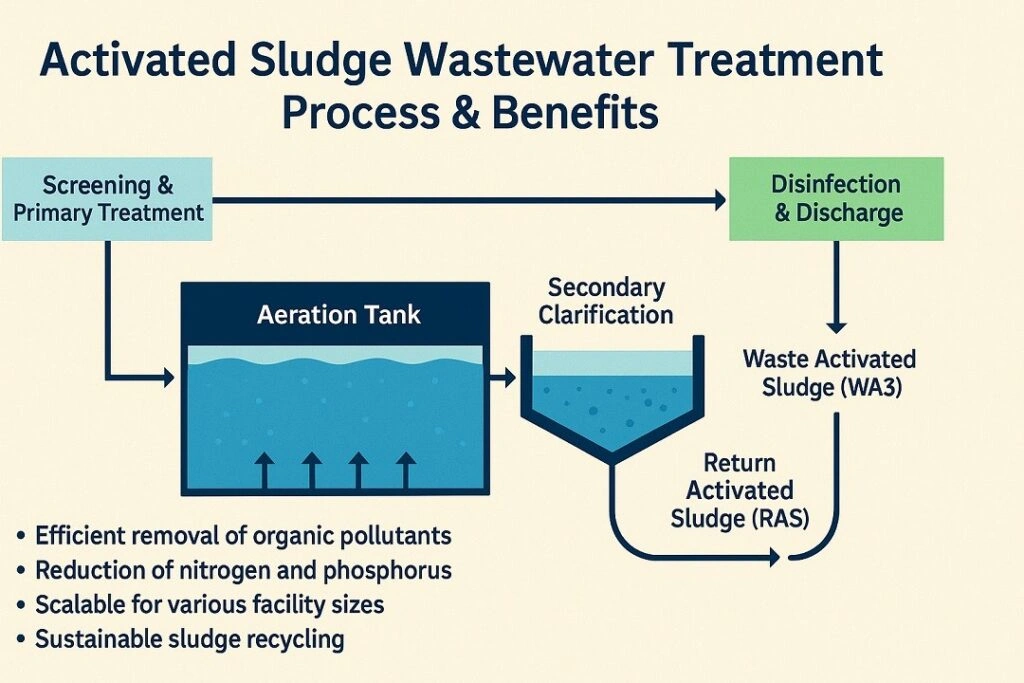

Inadequate Biological Load Handling

System failures often occur because biological treatment systems don’t match the incoming waste streams in size and design. The Food to Microorganism (F/M) ratio determines how well the treatment works by balancing organic matter with microbial population. High F/M ratios cause too much biomass growth and overload the system. The treatment becomes less effective when there’s not enough F/M ratio because microbes starve. Systems don’t handle changing hydraulic and organic loads well, especially in seasonal production industries.

Membrane Fouling Due to Poor Design

Membrane fouling creates major problems in advanced treatment systems and makes up half of the operating costs in membrane-based processes. Excess solutes build up on membrane surfaces or inside pores. Four main types of fouling reduce treatment effectiveness: biofouling from microorganisms, organic fouling from carbon-based materials, scaling from precipitated salts, and particulate/colloidal fouling. Membranes quickly lose their effectiveness without proper pretreatment and design, which drastically reduces water flux and system performance.

Sludge Management and Dewatering Bottlenecks

The biggest yet often ignored financial challenge comes from sludge management. Operating costs at wastewater treatment plants are more than 50% attributed to this aspect. Poor sludge dewatering creates problems throughout the treatment process. Dewatering technologies at many facilities don’t reduce sludge volume enough, which increases transportation and disposal costs. Common methods like centrifugation and filter presses don’t work well without proper upstream conditioning. Space-limited facilities face extra challenges in creating effective sludge management solutions.

Fixing the System: Engineering and Operational Solutions

Modern engineering brings groundbreaking solutions to fix recurring failures in industrial wastewater treatment systems. Companies can meet compliance standards and recover valuable resources when they combine cutting-edge technologies with better operational strategies.

Upgrading to MBR and SBR Technologies

Membrane Bioreactor (MBR) technology pairs biological processes with membrane filtration. This combination eliminates the need for sedimentation tanks and works with higher mixed liquor suspended solid concentrations. The global MBR market grows at 7% CAGR annually and experts project it will reach INR 354.40 billion by 2024. MBRs excel at treating high-BOD industrial wastewater because they keep slow-growing microorganisms that break down tough organic matter.

Sequencing Batch Reactor (SBR) technology stands out with its time-based treatment process, unlike conventional space-based methods. Research shows MBRs perform better than SBRs with higher removal rates: COD (93% vs. 78%), BOD5 (94% vs. 87%), TSS (99% vs. 93%), Total Nitrogen (91% vs. 60%), and Total Phosphorus (85% vs. 78%).

Advanced Oxidation Processes for Refractory Pollutants

Advanced Oxidation Processes (AOPs) create powerful hydroxyl radicals that break down stubborn contaminants. Ozonation removes carbamazepine in just 20 minutes with 95% mineralization efficiency. Fenton and photo-Fenton processes exploit iron catalysts to generate hydroxyl radicals and work best in acidic conditions.

These processes excel because they:

- Attack all pollutants at once

- Produce minimal harmful byproducts faster

- Make stubborn compounds more biodegradable

- Lower toxicity before biological treatment

Zero Liquid Discharge (ZLD) and Brine Management

Zero Liquid Discharge systems prevent liquid waste from leaving industrial facilities. This approach allows treated wastewater recirculation and safe solid waste processing. ZLD systems recover valuable materials like caustic soda and polyvinyl alcohol. Tirupur demonstrates this success with more than 18 Common Effluent Treatment Plants that process millions of liters daily using ZLD systems.

AI-based Monitoring and Predictive Maintenance

AI revolutionizes wastewater treatment through up-to-the-minute monitoring and prediction capabilities. Machine learning algorithms spot equipment failures before they happen by analyzing sensor data. This approach reduces downtime and extends equipment life. AI systems detect contaminants and anomalies by processing vast amounts of water quality sensor data, which leads to better monitoring accuracy and regulatory compliance.

IoT, cloud computing, and AI create reliable monitoring systems that give quick updates on key parameters like pH, COD, BOD, turbidity, and flow rates. These digital tools help make evidence-based decisions crucial for sustainability reporting and ESG disclosures.

SUSBIO ECOTREAT: A Proven Solution for Industrial Wastewater

SUSBIO ECOTREAT stands out as a detailed solution to industrial treatment challenges among wastewater solutions. This innovative system tackles the problems that conventional systems don’t deal very well with.

Integrated Biological and Chemical Treatment

SUSBIO ECOTREAT uses a unique dual-treatment process that blends anaerobic and aerobic methods to remove pollutants and contaminants. This integrated approach delivers better wastewater purification than single-method systems. The biological processes break down organic matter while chemical treatments target residual contaminants.

Compact Footprint with High Throughput

The system’s prefabricated, modular design needs minimal space but maintains high processing capacity. This space-efficient setup makes SUSBIO ECOTREAT perfect for facilities with limited installation area. The standardized design delivers consistent performance in different installations.

CIP-enabled Membrane Modules

SUSBIO ECOTREAT’s clean-in-place technology removes the need to disassemble equipment for maintenance. The system’s membrane life extends through regular automated cleaning cycles, which cuts operational costs and downtime.

Compliance-ready for CPCB and EPA Norms

The system meets and often surpasses environmental discharge standards. SUSBIO ECOTREAT’s advanced monitoring capabilities help industries establish credibility as environmentally responsible operators. The treated effluent meets strict environmental standards for safe discharge or reuse.

Conclusion

Industrial wastewater treatment failures create most important environmental and operational challenges in a variety of sectors. This piece explores how food processing, textile, pharmaceutical, and petrochemical industries face unique wastewater treatment obstacles. Poor pretreatment processes, insufficient biological load handling capabilities, membrane fouling issues, and problematic sludge management have led to an alarming failure rate of 83%.

Our research shows that industry-specific contaminants need specialized solutions instead of one-size-fits-all approaches. Textile wastewaters contain complex dyes with high salt concentrations. Pharmaceutical effluents carry persistent active ingredients that don’t work well with conventional treatment methods. Food processing facilities can’t handle overwhelming BOD and FOG loads through traditional systems.

Treatment systems face technical gaps that contribute to widespread non-compliance with environmental regulations. Many facilities lack proper suspended solids removal capabilities. They operate with improper food-to-microorganism ratios and experience membrane fouling due to poor system design. These shortcomings mean BOD levels exceed 30 mg/L and TSS exceeds 50 mg/L.

Several promising solutions can fix these ongoing problems. Advanced technologies like MBR and SBR systems work better than conventional treatment methods. Advanced Oxidation Processes effectively target refractory pollutants that resist biodegradation. Zero Liquid Discharge systems and AI-based monitoring improve treatment capabilities and provide great ways to recover resources.

SUSBIO ECOTREAT stands out as a complete answer to industrial wastewater treatment challenges. The system’s integrated biological and chemical treatment approach, compact footprint, CIP-enabled membrane modules, and compliance-ready design tackle the failure points we’ve found across industrial sectors.

Environmental regulations continue to get stricter worldwide, making effective wastewater treatment solutions more critical than ever. The economic and environmental costs of system failures are nowhere near the investment needed for proper treatment infrastructure. Companies that upgrade their wastewater treatment capabilities will gain competitive advantages through regulatory compliance, resource recovery, and better sustainability credentials.

Success requires thoughtful engineering solutions tailored to specific industrial needs rather than generic approaches that fall short. The evidence shows that complete solutions like SUSBIO ECOTREAT offer the best path toward fixing the ongoing failures in industrial wastewater treatment systems today.

Key Takeaways

Industrial wastewater treatment failures are widespread and costly, but understanding the root causes and implementing targeted solutions can dramatically improve compliance and operational efficiency.

• 83% of industrial treatment systems fail due to inadequate pretreatment, poor biological load handling, membrane fouling, and ineffective sludge management

• Textile, pharmaceutical, and food processing industries face unique challenges requiring specialized treatment approaches beyond conventional methods

• Upgrading to MBR technology delivers superior performance with 93% COD removal vs 78% for traditional SBR systems

• Advanced Oxidation Processes effectively eliminate persistent pollutants that resist biodegradation, achieving 95% mineralization in 20 minutes

• AI-based monitoring and predictive maintenance prevent equipment failures while ensuring real-time compliance with environmental regulations

The key to success lies in moving away from generic, one-size-fits-all solutions toward industry-specific treatment technologies that address the unique contaminant profiles and operational challenges of each sector. Companies investing in comprehensive solutions like integrated biological-chemical treatment systems position themselves for long-term regulatory compliance and competitive advantage.

Frequently Asked Questions

Q1. Why do industrial wastewater treatment systems often fail?

Industrial wastewater treatment systems frequently fail due to inadequate pretreatment, poor biological load handling, membrane fouling, and ineffective sludge management. These issues are compounded by the complex and varied nature of industrial effluents across different sectors.

Q2. What are the main challenges in treating industrial wastewater?

The main challenges include removing complex chemicals and pollutants specific to each industry, dealing with high levels of BOD and TSS, managing varying wastewater compositions, and meeting stringent regulatory standards. Industries like textiles, pharmaceuticals, and food processing face unique treatment obstacles.

Q3. How can advanced technologies improve industrial wastewater treatment?

Advanced technologies such as Membrane Bioreactors (MBR), Advanced Oxidation Processes (AOPs), and Zero Liquid Discharge (ZLD) systems can significantly improve treatment efficiency. These technologies offer superior pollutant removal, handle refractory contaminants, and enable water reuse and resource recovery.

Q4. What role does AI play in wastewater treatment?

AI enhances wastewater treatment through real-time monitoring, predictive maintenance, and data-driven decision-making. It helps detect anomalies, predict equipment failures, and ensure regulatory compliance by analyzing large volumes of sensor data.

Q5. How does SUSBIO ECOTREAT address common industrial wastewater treatment failures?

SUSBIO ECOTREAT addresses common failures through its integrated biological and chemical treatment approach, compact design, CIP-enabled membrane modules, and compliance-ready features. It offers a comprehensive solution that tackles industry-specific challenges while meeting environmental standards.