Wastewater treatment facilities filter billions of gallons of contaminated water daily before releasing it back to our ecosystems. This vital process protects our environment. Facilities that don’t meet pollutant standards can face penalties from thousands to millions of dollars, based on how serious the violation is.

The technology behind wastewater treatment has made huge strides, especially when you have tertiary treatment stages where advanced filtration delivers better precision and streamlines processes. These advanced systems produce high-quality treated water that contains minimal suspended solids. The treated water usually meets the strict EU standards of 10 mg/L total suspended solids at discharge. Clean filtration plays a key role in providing safe drinking water and protecting ecosystems. It helps reduce climate change impact by lowering greenhouse gas emissions.

This piece covers the different types of filtration used in modern wastewater treatment systems. We’ll get into everything from rapid filtration that serves as the final clarifying step in municipal plants to state-of-the-art membrane technologies like Reverse Osmosis that filter out salts and heavy metals. The information here will help facility managers and anyone interested in understanding how these systems protect our water resources. You’ll learn the quickest ways to use modern filtration methods effectively.

Where Filtration Fits in the Wastewater Treatment Process

Wastewater treatment uses multiple stages to purify contaminated water. The process combines physical, chemical, and biological methods. Each stage of this complete treatment pathway needs different types of filtration.

Role of Filtration in Primary, Secondary, and Tertiary Stages

Physical processes like screening and sedimentation define primary treatment filtration. The filters at this stage catch large debris and protect downstream equipment from damage.

Biological processes take center stage in secondary treatment to eliminate organic contaminants and nutrients. The filtration system uses finer filters like sand or membrane filters that capture tiny particles at the micron level. These filters work together with biological treatment methods.

The final polishing happens during tertiary treatment where filtration plays a vital part. Advanced filtration brings suspended solid levels down to 5-10 mg/L. This stage also tackles remaining phosphorus, nitrogen components, and microbial contamination.

Tertiary Treatment of Sewage: Why It Matters

Primary and secondary stages don’t deal very well with all pollutants, making tertiary treatment a necessity. This advanced stage matters because it:

- Makes disinfection work better by making water clearer

- Gets rid of leftover contaminants that could harm the environment

- Helps meet strict rules about water discharge

- Lets us reuse water for non-drinking purposes like farming and industrial work

Filtration Process in Water Treatment Explained

Tertiary treatment filtration falls into three main types:

- Surface Filtration: A two-dimensional staining process catches suspended substances using filter media like micro-net cloth filters.

- Depth/Volume Filtration: This three-dimensional process lets contaminants pass through granular material or compressible material. Sand filters and free-fiber cloth filters work better than surface filtration.

- Membrane Filtration: This method pushes wastewater through thin membranes made of hollow fibers or composite material sheets. The process removes even the tiniest contaminants.

Filtration protects downstream processes and ensures water quality before discharge or reuse. Water composition, treatment goals, and regulations determine the choice of filtration technology.

Types of Filtration Used in Modern Systems

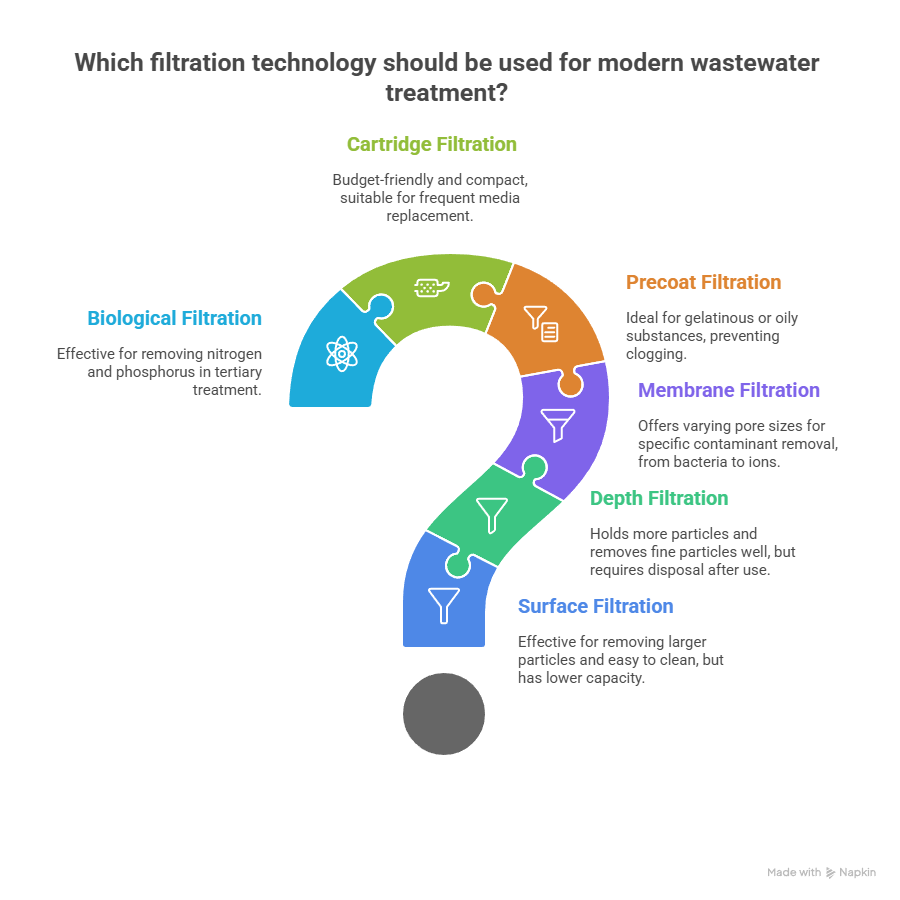

Modern wastewater treatment facilities use many filtration technologies. Each technology tackles specific contaminant removal challenges. Understanding these filtration mechanisms will help you select systems that work best.

Surface Filtration vs Depth Filtration

Surface and depth filtration are two basic approaches to mechanical solid-liquid separation. Surface filtration keeps particles on the filter medium’s surface. These particles create a growing filter cake without going inside. The process works like a sieve where pore sizes are smaller than particle sizes. Surface filters are great at removing larger particles and are easy to clean because collected particles stay available on the filter surface. The biggest problem is their lower capacity since filter cakes gradually reduce filtrate flow.

Depth filtration works differently by catching particles inside the filter medium. Thick filter layers made of grains or fibers let liquid flow through them. Particles much smaller than the pores go into the filter medium and stick to its inner surfaces. These filters can hold more particles and remove fine particles well, but you’ll need to throw them away after use.

Membrane Filtration: Micro, Ultra, Nano

Membrane filtration technologies vary mainly by pore size, which determines what they can filter out:

- Microfiltration uses membranes with pore sizes around 0.1 microns that remove bacteria and suspended solids effectively

- Ultrafiltration has smaller pores (about 0.01 microns) that can also catch viruses

- Nanofiltration, with tiny pores (about 0.001 microns), removes 50-90% of monovalent ions like chlorides and sodium

Precoat and Cartridge Filtration in Industrial Settings

Precoat filtration puts filter aids like diatomaceous earth, perlite, or cellulose onto filter elements. These layers catch particles as small as half a micron. This technology is great for filtering gelatinous or oily substances that might clog regular filters. Cartridge filters come in both surface and depth types. They are budget-friendly solutions in compact packages, perfect for industrial applications where you need to replace media often.

Biological Filtration in MBBR and BIDA® Systems

Moving Bed Biofilm Reactor (MBBR) systems use floating plastic carriers with high surface area (>5500 m²/m³) where microorganisms attach and grow. These carriers move constantly through aeration to create optimal conditions for biological treatment. The attached biofilm eats organic material while the movement ensures excellent oxygen transfer. MBBR systems work especially well for removing nitrogen and phosphorus in tertiary treatment.

Design, Operation, and Efficiency Considerations

The right design parameters for filtration systems need to balance performance requirements and operational efficiency. These choices will affect treatment effectiveness and costs over time.

Filter Media Selection: Sand, Cloth, Membranes

The right filter media depends on contaminant type, flow rate, and desired water quality. Sand media should have good hydraulic characteristics, durability, and it shouldn’t dissolve in water. The key parameters include effective size (the sieve opening that lets water pass through while collecting impurities) and uniform coefficient (the ratio between different sizes of media in the filter bed). Membranes provide precise particle removal based on pore size. Activated carbon works best at removing organic pollutants and chlorine.

Backwash Methods: Air Scour and Surface Wash

Good backwashing stops filter failure and makes media last longer. The process starts when water drains to a level above the filter bed. Compressed air then moves upward through the media to break up the compacted bed. Clean water flows up next to carry suspended particles into backwash troughs. Surface wash systems break up heavily clogged surface layers with water jets. These systems are either buried in the filter media or suspended above it.

Filtration Rate and Head Loss Parameters

Water loses pressure through friction as it moves through filter beds. We call this head loss. Head loss follows Darcy’s equation at low velocities, where loss matches filtration rate, water viscosity, and layer depth. Ergun’s formula works better for higher velocities because it accounts for kinetic energy loss. Head loss goes up with flow rate and sand content, but drops as filter screen aperture size increases.

Dual-Media Filters: Sand and Anthracite Layers

Dual-media filters use two different materials to work better – usually anthracite coal sits on top of sand. Anthracite catches larger contaminants first because it has larger particle size and lower density. The finer sand below then traps smaller particles. This setup prevents quick clogging and needs less frequent backwashing. Dual-media filters work better than single-media systems because they use the whole filter bed effectively.

Applications and Innovations in Tertiary Treatment

Modern tertiary treatment technologies now go well beyond basic filtration. They provide innovative solutions to today’s water resource management challenges.

Water Reuse in Agriculture and Industry

Agricultural water reuse creates reliable, environmentally responsible water supplies while reducing the need for fresh water. Israel now guides the world in water reuse. The country recycles 90% of its wastewater and uses 85% of it in agriculture. This approach prevents nutrients from polluting sensitive water bodies and provides nutrient-rich irrigation for crops. Industrial reuse applications are a great way to get cost and energy savings. Companies use recycled water in manufacturing processes and data center cooling because this water doesn’t need extensive treatment.

PFAS Destruction Using SCWO and PRD

Supercritical water oxidation (SCWO) technology destroys per- and polyfluoroalkyl substances (PFAS) in contaminated water. The PFAS Annihilator® showed remarkable results – 99.7% destruction of target PFAS in concentrated influent and 98.8% destruction of total organofluorine. Tests of all sizes with three SCWO providers showed >99% reduction of total identified PFAS. This makes it a viable alternative to incineration for permanent PFAS destruction.

Real-Time Monitoring with IoT and AI Sensors

IoT-based monitoring systems track multiple parameters at once – pH, turbidity, temperature, conductivity, and dissolved oxygen. These systems send data to cloud platforms for analysis. This allows quick intervention when pollution exceeds limits. AI algorithms make use of information to predict equipment failures, automate maintenance, and optimize treatment processes.

Energy-Efficient Systems for Decentralized Treatment

Decentralized wastewater treatment systems (DEWATS) are affordable compared to centralized facilities. These modular systems allow expansion as populations grow. Revolutionary technologies like membrane aerated biofilm reactors cut energy use by up to 90% compared to traditional methods.

Conclusion

Modern wastewater treatment relies heavily on advanced filtration technologies that protect our environment and meet tough regulatory standards. This piece shows how filtration works through primary, secondary, and tertiary treatment stages. Each stage plays a key role in cleaning contaminated water.

The rise from simple sand filters to sophisticated membrane systems shows how far treatment capabilities have come. Surface filtration catches contaminants on the outside of the media. Depth filtration catches particles inside the filter matrix. Membrane technologies like microfiltration, ultrafiltration, and nanofiltration remove contaminants with amazing precision based on their size.

System performance depends on several design factors. Filter media choice, backwash methods, filtration rates, and dual-media setups help improve operations. These elements determine how well the treatment works, what maintenance it needs, and its running costs.

New breakthroughs have taken filtration beyond just treating wastewater. Farmers and industries now use recycled water as a sustainable option instead of fresh water. Technologies like Supercritical Water Oxidation destroy stubborn PFAS compounds. Live monitoring and system optimization happen through IoT sensors and AI algorithms.

Wastewater treatment’s future looks bright as smaller, energy-saving systems become common. These advanced filtration methods protect our water and support sustainable practices worldwide. Modern filtration technologies offer adaptable solutions for industrial waste and municipal sewage. They protect public health and keep our environment clean for future generations.

Key Takeaways

Modern wastewater treatment relies on sophisticated filtration systems that progressively remove contaminants through multiple stages, with tertiary treatment being crucial for meeting strict regulatory standards and enabling water reuse applications.

- Tertiary filtration achieves 5-10 mg/L suspended solids, enabling water reuse for agriculture and industry while meeting stringent discharge requirements.

- Membrane technologies (micro, ultra, nano) provide precise contaminant removal based on pore size, with nanofiltration removing 50-90% of monovalent ions.

- Dual-media filters using anthracite and sand layers maximize efficiency by preventing rapid clogging and extending service cycles compared to single-media systems.

- Advanced innovations like SCWO technology destroy 99.7% of PFAS compounds, while IoT sensors enable real-time monitoring and AI-driven process optimization.

- Decentralized treatment systems reduce construction costs and energy consumption by up to 90% while offering modular expansion capabilities for growing communities.These filtration advances represent a paradigm shift from basic treatment to comprehensive water resource management, supporting both environmental protection and sustainable water reuse practices across agricultural and industrial applications.

FAQs

Q1. What are the main types of advanced filtration used in modern wastewater treatment?

Advanced filtration methods include membrane technologies like microfiltration, ultrafiltration, and nanofiltration. These processes use different pore sizes to remove contaminants ranging from bacteria and suspended solids to dissolved ions and heavy metals.

Q2. Why is tertiary treatment important in wastewater management?

Tertiary treatment is crucial for meeting strict regulatory standards, improving water clarity for effective disinfection, removing residual contaminants that pose environmental risks, and enabling water reuse for applications like agricultural irrigation and industrial processes.

Q3. How do dual-media filters improve filtration efficiency?

Dual-media filters, typically using anthracite coal atop sand, maximize efficiency by trapping larger contaminants in the upper layer and smaller particles in the lower layer. This configuration prevents rapid clogging, ensures longer service cycles, and requires less frequent backwashing compared to single-media systems.

Q4. What role does IoT and AI play in modern wastewater treatment?

IoT sensors enable real-time monitoring of multiple water quality parameters, while AI algorithms analyze this data to predict equipment failures, automate maintenance, and optimize treatment processes. This technology allows for swift intervention when pollution exceeds thresholds and improves overall system efficiency.

Q5. How are decentralized wastewater treatment systems beneficial?

Decentralized systems offer advantages such as lower construction and operational costs, modular installation allowing for expansion with population growth, and reduced energy consumption. Some innovative technologies in these systems can reduce energy use by up to 90% compared to traditional centralized facilities.