Screening is a vital first line of defense against harmful solids that can damage whole wastewater treatment systems. These solids need removal right at the start of the treatment process. They can make the system less efficient, damage costly equipment, or contaminate water. Fine screens remove 20 to 35 percent of suspended solids and BOD, which shows their major effect on water quality.

Bar screening in wastewater treatment plants does more than just filter. The process prevents clogging, cuts down on machinery wear and tear, and leads to better treatment efficiency. The screening process brings major benefits to wastewater treatment. It increases efficiency by reducing strain on sedimentation and filtration stages. Plants also save money through reduced equipment maintenance and repair costs. Screening systems face challenges that can affect how well they work, despite their importance. In this piece, we’ll look at common problems with bar screens in wastewater treatment and share expert solutions to keep your screening systems running at their best.

Common Screening Challenges in Wastewater Treatment

Wastewater treatment facilities struggle with many operational challenges that affect system performance. These problems need quick solutions to keep the treatment process running smoothly.

Clogging in bar screen in wastewater treatment systems

Debris builds up fast on bar screen surfaces and clogs them. The accumulated waste creates an extra filter that catches particles smaller than the screen’s design. During storms, “first-flush” loads wash through sewer systems and bring heavy debris loads to the bar screen in the first few hours. The flow speed becomes crucial – it needs to stay above 1.25 feet per second to keep solids moving, but shouldn’t exceed 3-4 feet per second or debris might force through the openings.

Inefficiencies in manual screening during peak flow

Staff must rake manual bar screens often to clear waste, which takes a lot of work. Water might surge or overflow while cleaning happens, putting operators at risk. Manual systems struggle to keep up during high flows, especially in older systems where groundwater seeps through cracks and leaky joints. Daily flow rates can jump 10-20 times higher during peak periods, and manual cleaning can’t keep pace.

Mechanical failure in chain-driven coarse screens

Chain-driven screens clean automatically but still face operational problems. The system’s overload protection stops working when blocked – this needs fixing. Parts underwater wear down faster, and chains rub against frames. This means regular checks and lubrication are essential. Rakes need proper design to move past heavy objects stuck between bars without jamming further.

Overloading of fine screens in high-solids environments

Heavy debris like stones and odd-shaped objects from stormwater can damage fine screens with 0.5mm to 6mm openings. This debris causes problems by collecting on aerators, building up scum in digesters, and blocking pumps in final clarifiers. Fine screens need constant cleaning to work, especially when solid loads are too high. Combined sewer systems face tough challenges during storms because both the amount and types of debris increase.

Types of Screens and Their Problem Areas

Screen technologies in wastewater treatment plants face unique operational challenges that limit how well they work. Each design comes with its own maintenance needs and performance limits that operators need to handle.

Bar screening in wastewater treatment: Maintenance and wear issues

Bar screens serve as the first defense against large debris, but they need constant maintenance to work properly. Corrosion remains one of the most important concerns, even with stainless steel construction. Protective coatings help limit the damage. Teams must regularly check for bent or broken rake teeth that show up during normal operation. Chain-driven bar screens show more wear on parts underwater. Their chains rub against frames and need regular lubrication. Clogging is the biggest problem, so periodic raking prevents flow restrictions.

Step screens: Debris accumulation and cleaning limitations

Step screens use fixed and movable lamellae in a stepped setup to catch fine solids. The filter grid can bend and break easily, so regular inspections are crucial. The original design included self-cleaning features where movable lamellae lift screenings up to the discharge point. All the same, this mechanism doesn’t deal very well with heavy debris loads, which can reduce how efficiently it works. Screened material moves toward the discharge area through relative motion between fixed and movable blocks. This needs careful adjustment to clean effectively.

Rotary drum screens: Flow rate mismatches and overflow risks

Rotary drum screens work much slower when dealing with higher solids loads if the slot size doesn’t match the influent characteristics. These screens handle flow rates from 128 m³/h to 165 m³/h based on their nominal capacity. Head loss becomes critical during operation, usually measuring 60-70 mm under normal conditions. The screens’ spray wash systems can clog up, which makes them less effective at cleaning. Drum screens must adapt to changing influent conditions while keeping their screening efficiency between 91-99%.

Static wedge wire screens: Manual cleaning and clogging concerns

Wedge wire screens use v-shaped profiles that create continuous slots, letting them handle higher flow rates than other filter designs. These screens have a reliable structure but come with their own challenges. Manual cleaning requirements in large treatment plants top the list. The wedge design creates just two contact points between retained particles and slots. This reduces clogging but doesn’t eliminate it completely. Even with self-cleaning features, operators must keep the backwash mechanisms working well to prevent buildup on screen surfaces.

Expert Solutions to Screening Process Failures

Modern engineering solutions tackle critical failures in screening systems. These solutions help wastewater treatment plants work at their best even in tough conditions.

Upgrading to self-cleaning continuous belt screens

Self-cleaning continuous belt screens mark a big step forward in screening technology. These systems use unique filter elements woven together on stainless steel shafts that form an endless moving belt to collect and remove solids. The two-stage screening method filters particles smaller than the actual screen opening. It does this through coarse filtration on the leading edge and fine screening on the recessed face. Screen openings range from 1mm to 30mm, making these adaptable systems work with three cleaning modes: self-cleaning elements, rotating brushes, and optional water sprays.

Integrating dual-stage screening for coarse and fine solids

Dual-stage screening guards fine screening systems against high coarse material loads. This setup puts a coarse screen before a fine screen, either combined or as separate machines. The system prevents membrane fouling at membrane bioreactor facilities. This protection stops suspended solids from damaging membranes and raising life-cycle costs. The first screen catches larger debris that could harm the fine screens, letting them do their job properly.

Using flow sensors to optimize screen operation cycles

Flow sensors boost screening system performance by stopping damage and downtime from mechanical wear. These electronic devices track different liquid types and give exact digital flow rate measurements. Most new sensors come with IO-Link technology that delivers more process data and makes trend analysis possible over time. Screens can now adjust their operation cycles based on real flow conditions instead of fixed timers.

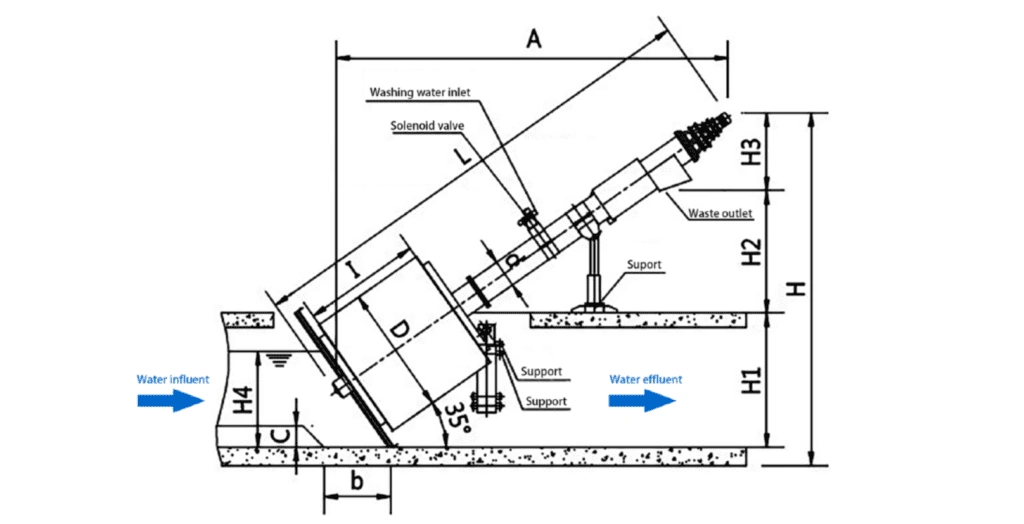

Retrofitting bar screens with automated rakes

Multi-rake bar screen systems make screening much more efficient through mechanized cleaning. These systems have multiple rakes fixed between two chains. The chains move upward to carry debris from inclined bars to discharge points. This non-stop cleaning process prevents clogs even during high flows. Advanced designs like the HUBER Multi-Rake Bar Screen include smart detection systems that spot potentially dangerous contaminants before damage occurs. The system’s design removes submerged sprockets and cuts down friction between chain and frame parts.

Best Practices for Screening in Wastewater Treatment Plants

Wastewater screening works best when facilities implement proven practices that maximize efficiency and reduce operational disruptions.

Choosing screen type based on influent characteristics

The right screen selection depends on wastewater composition and treatment goals. You must think about material properties like particle size distribution, shape, and moisture content among other throughput capacity factors. Systems with combined sewers that carry larger objects need coarse screening before fine screening. Large objects can damage perforated plate fine screens more easily, while multiple rake screens and stair screens work properly without upstream coarse screening.

Designing for peak flow and redundancy

The wastewater systems should handle peak flows even when the largest unit stops working. Research shows peaking factors range from 4 to 15 times the average flow. Gravity-fed facilities need mechanical screens with backup manual bypass bar screens. This backup prevents untreated effluent from discharging when equipment fails.

Routine inspection schedules for mechanical screens

Equipment lasts longer with regular maintenance. The staff should check if all mechanical equipment works properly each day. Bar screen maintenance requires regular cleaning and inspection of rake teeth to avoid breakage. The filter grid needs special attention during step screen inspections because it bends easily. The spray wash systems should spray evenly without clogs.

Training operators on emergency bypass protocols

Facilities with only one unit must keep a manual bar rake ready for emergency bypass. Operators need detailed training to handle equipment and screened materials safely. The team should review emergency protocols regularly to respond quickly in critical situations.

Conclusion

Proper screening is the life-blood of successful wastewater treatment operations. Many facilities still face challenges with outdated or poorly managed systems. This piece explores common problems that affect screening processes – from clogging and mechanical failures to inefficiencies during peak flows. We also get into specific issues affecting different screen types like bar screens, step screens, rotary drums, and static wedge wire setups.

Most facilities can substantially improve their screening operations by putting these expert solutions to work. Self-cleaning continuous belt screens work better than traditional systems, and dual-stage screening gives vital protection to sensitive downstream processes. Flow sensors help optimize operational cycles that reduce unnecessary wear and make equipment last longer. Plants that use manual cleaning can benefit greatly from automated rake systems.

Screen selection based on influent characteristics is fundamental to system success. A design that accounts for peak flow capacity and redundancy will give uninterrupted operation even in extreme conditions. Regular checks stop small issues from becoming expensive system failures. Well-trained operators play a vital role in keeping these critical systems running smoothly.

Wastewater screening may look simple compared to biological or chemical treatment processes. The original treatment stage ended up determining how well all later operations work. Plants that choose the right screening technology, create solid maintenance protocols, and train their staff well will experience fewer disruptions. These facilities also see lower repair costs and better treatment results. Your screening system needs this attention since it protects your entire treatment process.

Key Takeaways

Wastewater treatment screening faces critical challenges that can compromise entire system performance, but expert solutions can dramatically improve operational efficiency and reduce costly failures.

• Clogging and mechanical failures plague screening systems during peak flows, requiring immediate attention to prevent system-wide disruptions and equipment damage.

• Self-cleaning continuous belt screens and dual-stage screening configurations eliminate manual cleaning requirements while providing superior debris removal efficiency.

• Flow sensors and automated rakes optimize operation cycles based on real-time conditions, reducing mechanical wear and extending equipment lifespan significantly.

• Proper screen selection based on influent characteristics and designing for peak flow redundancy prevents operational failures during extreme conditions.

• Regular maintenance schedules and comprehensive operator training on emergency protocols are essential for preventing minor issues from escalating into costly system failures.

Investing in modern screening technology and establishing robust maintenance protocols protects downstream treatment processes while delivering substantial cost savings through reduced equipment repairs and improved overall treatment outcomes.

Frequently Asked Questions

Q1. What are the main challenges in wastewater treatment screening?

Common challenges include clogging of bar screens, inefficiencies during peak flow, mechanical failures in chain-driven screens, and overloading of fine screens in high-solids environments.

Q2. Why is screening crucial in wastewater treatment processes?

Screening is essential as it removes harmful solids that can damage equipment, reduce system efficiency, and contaminate water. It also enhances overall treatment effectiveness by reducing the load on subsequent treatment stages.

Q3. How can wastewater treatment plants improve their screening operations?

Plants can upgrade to self-cleaning continuous belt screens, integrate dual-stage screening, use flow sensors to optimize operation cycles, and retrofit bar screens with automated rakes to significantly improve screening efficiency.

Q4. What factors should be considered when selecting a screen type for a wastewater treatment plant?

Key factors include influent characteristics (such as particle size and shape), desired throughput capacity, and treatment goals. For combined sewer systems, coarse screening before fine screening is often essential.

Q5. How important is maintenance in wastewater screening systems?

Regular maintenance is crucial for extending equipment lifespan and preventing system failures. This includes daily inspections of mechanical equipment, cleaning of rake teeth, and ensuring spray wash systems are functioning properly.