Did you know that a wastewater treatment plant (WWTP) serves as the heart of a community’s water management system? These facilities collect, treat, and either discharge or reuse wastewater from the entire community.

Your treatment facility’s proper operation isn’t just vital—the work to be done protects both the environment and public health. Plant operators must watch and control multiple processes to keep treatment systems running smoothly. Poor management can lead to serious problems. Equipment failures can halt the treatment process and create compliance issues with regulations.

This piece walks you through everything about the WWTP process. You’ll learn about treatment stages and create maintenance schedules that work. The text also shows how industrial wastewater management is different from regular operations, especially when you have industrial wastewaters mixed with domestic wastewater.

Your plant’s success depends on monitoring flow rates, adjusting pH levels, and analyzing data—the foundation of effective wastewater treatment. This guide gives you the skills to run your plant with precision. Let’s take a closer look at wastewater treatment and help you achieve excellence!

Understanding the WWTP Process

Wastewater treatment plants (WWTPs) clean contaminated water through a series of well-designed processes to produce environmentally safe effluent. Let me walk you through how these systems work and give you the basics you’ll need as a new operator.

Overview of wastewater treatment stages

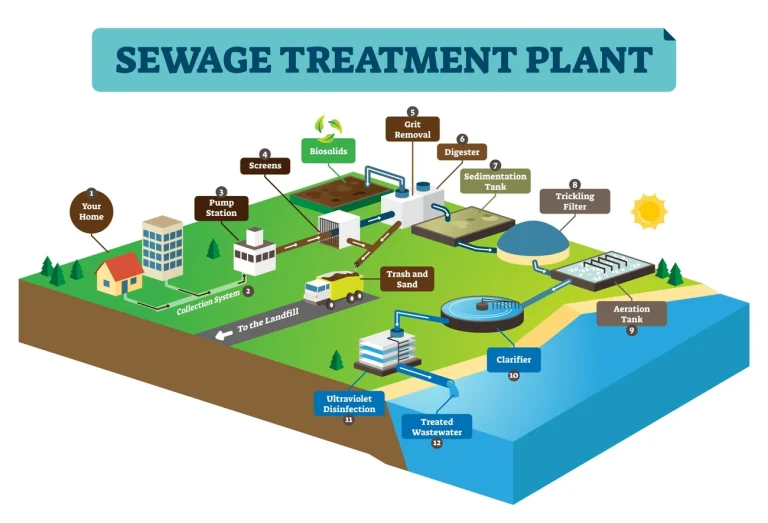

The treatment process follows a logical sequence. Preliminary treatment starts by removing large debris with screens and grit chambers. This step protects downstream equipment and gets the water ready for additional processing.

The process moves through primary, secondary, and sometimes tertiary stages. Each phase builds on previous results and steadily improves water quality. Primary treatment eliminates 50-70% of suspended solids and 25-40% of biological oxygen demand (BOD). Secondary treatment reduces organic matter further, while tertiary treatment refines the water to meet specific quality standards.

Reading a wastewater treatment plant WWTP diagram

WWTP diagrams show water’s journey through the facility. The best way to understand these diagrams is to trace the path from influent (incoming wastewater) to effluent (treated water).

Raw wastewater flows through intake pipes to the headworks building for preliminary treatment. The water then moves to primary settling tanks and biological treatment units like trickling filters or aeration tanks. Secondary settling tanks come next. The plant’s design determines if water needs extra filtration and disinfection before discharge.

Types of treatment: primary, secondary, tertiary

Primary treatment uses physical processes in large sedimentation tanks. Gravity pulls heavier solids (sludge) to the bottom, while oils and grease rise to the top for removal. This stage focuses on separation rather than purification.

Secondary treatment uses biological processes to break down organic matter. Activated sludge systems let bacteria consume organic waste under different oxygen conditions. Most facilities end with this stage since it removes most contaminants effectively.

Tertiary treatment provides final cleanup by removing lingering bacteria, nutrients, or harmful chemicals. Sand or carbon filters, UV disinfection, or chemical treatment make the water clean enough for environmental release or reuse in some cases.

Daily Operations and Monitoring

Running a wastewater treatment plant (WWTP) needs constant watchfulness and careful monitoring. The daily supervision of key parameters will give a smooth treatment performance that meets regulations.

Checking flow rates and pH levels

Flow rate monitoring forms the heart of WWTP operations. Check influent volumes regularly to adjust treatment parameters. Live flow data helps in respond quickly to changes. Some facilities use ultrasonic clamp-on flowmeters to verify inline flowmeter readings and monitor pump performance. The flow rates usually range between 270-350 m³/h.

The pH measurement is just as significant as flow monitoring. Biological activity in wastewater treatment works best between pH 7-8. This slightly alkaline environment creates perfect conditions for treatment bacteria. The right pH levels also ensure enough alkalinity to neutralize acids from biological treatment, especially during nitrification.

Using sensors and manual sampling

Today’s WWTPs use both continuous monitoring systems and manual sampling methods. Continuous or quasi-continuous measurement offers the best way to track wastewater dynamics. Online sensors track key parameters like dissolved oxygen, reduction-oxidation potential, pH, temperature, ammonium, phosphate, turbidity, and total suspended solids.

These samples mix different quasi-instantaneous sub-samples collected through the day and give a detailed picture of average wastewater composition. Plants serving fewer than 50,000 equivalent inhabitants need 12 daily average measurements throughout the year.

Adjusting processes based on test results

The monitoring data helps in making needed adjustments to improve treatment. These adjustments include:

- Modifying activated sludge extraction rates

- Adjusting recirculation flow rates

- Controlling oxygen supply to biological reactors

Regular pH monitoring helps in adjusting chemical dosages precisely. This prevents underfeeding that causes incomplete treatment or overfeeding that wastes money. The flow measurement data also helps verify pump efficiency for operational adjustments. These precise controls ensure consistent treatment quality, meet regulations, and create budget-friendly operations.

Routine Maintenance and Equipment Care

Proper maintenance serves as the foundation of any successful wastewater treatment plant (WWTP) operation. The most sophisticated systems will break down faster without regular care. This can lead to expensive repairs and potential environmental risks.

Creating a preventive maintenance schedule

A complete maintenance schedule helps spot problems early. Daily checks should cover flow rates, pressure, and chemical levels. The team needs to clean filters and screens weekly. Equipment health checks, backup system tests, and sensor calibration should happen monthly. The core team must examine gaskets, seals, and system piping every quarter to check for wear.

Cleaning and inspecting pumps and blowers

Pumps and blowers are the heart of your WWTP. Staff should listen for strange noises or vibrations that signal problems. Moving parts need regular lubrication. Debris removal helps maintain system efficiency. For Roots blowers, pressure differences must stay within specs to protect the motor from overload.

Handling common issues in sewage treatment plant maintenance

Equipment failures, sensor malfunctions, and sludge buildup are typical maintenance challenges. Keeping spare pumps and motors ready will ensure operations continue during breakdowns. On top of that, proper staff training helps identify and fix issues quickly. Regular pipeline checks and backflushing prevent flow restrictions.

Safety, Training, and Team Readiness

Safety is the foundation that drives successful wastewater treatment plant (WWTP) operations. Treatment facility operators face hazards of all types that need proper protocols and training to handle safely.

Basic safety protocols for new operators

Good hygiene practices are the life-blood of wastewater safety. Operators must wash their hands with soap right after handling waste, before meals, and after restroom visits. On top of that, it helps prevent infections when cuts stay covered with clean bandages.

Emergency planning plays a vital role in safety. Every WWTP should have protocols ready for potential hazards like backup power sources and hazardous material inventory. Teams that practice emergency drills regularly understand their crisis responsibilities better.

Using PPE and handling chemicals safely

Personal protective equipment (PPE) remains non-negotiable for wastewater work. The minimum PPE requirements has:

- Goggles or splash-proof face shields

- Waterproof gloves

- Rubber boots

- Liquid-repellent coveralls

Research shows that 80% of wastewater workers use PPE during every shift. Safe chemical management matters just as much since most WWTPs use potentially hazardous substances. Before handling any chemicals, operators must check their PPE’s compatibility with specific substances. To name just one example, concentrated sulfuric acid (>70%) needs butyl rubber or polyethylene gloves.

Training and certification requirements

Certification will give operators the knowledge they need to run and maintain treatment plants properly. States require certification through written exams, plus ongoing education for renewal. Simple-level operators typically need 18 hours of continuing education over three years, while advanced operators need 24 hours.

Complete training covers hazard communication, PPE usage, and emergency response procedures. The Environmental Finance Center Network provides webinars about common hazards, confined space entry, and equipment lockout procedures.

Conclusion

Operating a wastewater treatment plant demands dedication, technical knowledge, and attention to detail. This piece explores everything in WWTP operations, from treatment stages to resilient maintenance protocols.

A solid grasp of treatment fundamentals creates a foundation for daily decisions. Primary, secondary, and tertiary treatment stages each play a vital role to transform raw wastewater into environmentally safe effluent.

Effective monitoring is the backbone of successful plant operations. Regular checks of flow rates, pH levels, and other key parameters help you adjust and maintain optimal treatment efficiency. Automated sensors and manual sampling work together to give a complete picture of your system’s performance.

Preventive maintenance saves time and resources while extending equipment life. Your plant’s pumps, blowers, and other critical components need regular care to work properly. A well-laid-out maintenance schedule helps you prevent problems instead of just reacting to emergencies.

Safety should be your top priority. PPE usage, chemical handling protocols, and emergency preparedness protect you and your team from workplace hazards. Regular training and certification improve your skills to run the plant safely and effectively.

Your role as a wastewater treatment plant operator is crucial for public health and environmental protection. The skills you gain through hands-on experience and continuous learning help you tackle challenges with confidence while meeting all regulatory requirements.

Be proud of your work – you’re not just running a facility; you protect water resources for your entire community. The knowledge from this piece and your growing experience will help you become skilled at this essential profession.

Key Takeaways

Master these essential principles to successfully operate a wastewater treatment plant and protect your community’s water resources:

• Understand the three-stage treatment process: Primary removes 50-70% of solids, secondary uses biological processes to break down organics, and tertiary provides final polishing for environmental discharge.

• Monitor critical parameters daily: Check flow rates (270-350 m³/h typical) and maintain pH between 7-8 for optimal biological activity, using both automated sensors and 24-hour composite samples.

• Implement preventive maintenance schedules: Perform daily equipment inspections, weekly filter cleaning, monthly system analysis, and quarterly seal/gasket checks to prevent costly breakdowns.

• Prioritize safety through proper PPE and training: Always wear goggles, waterproof gloves, rubber boots, and coveralls; maintain certification through continuing education (18-24 hours per 3-year period).

• Make data-driven operational adjustments: Use monitoring results to modify sludge extraction rates, recirculation flows, and oxygen supply to maintain treatment efficiency and regulatory compliance.

Successful WWTP operation combines technical knowledge, consistent monitoring, proactive maintenance, and unwavering commitment to safety protocols. Your role directly impacts public health and environmental protection for your entire community.

Frequently Asked Questions

Q1. What are the main stages of wastewater treatment?

Wastewater treatment typically involves three main stages: primary treatment (removing 50-70% of solids), secondary treatment (using biological processes to break down organic matter), and tertiary treatment (final polishing for environmental discharge or reuse).

Q2. How often should wastewater treatment plant equipment be maintained?

Regular maintenance is crucial. Daily inspections of flow rates and equipment, weekly cleaning of filters and screens, monthly in-depth analysis of equipment health, and quarterly inspections of gaskets, seals, and system piping are recommended.

Q3. What are the essential safety measures for wastewater treatment plant operators?

Essential safety measures include wearing proper PPE (goggles, waterproof gloves, rubber boots, and coveralls), following chemical handling protocols, and participating in regular safety training and emergency drills.

Q4. How do operators monitor and adjust wastewater treatment processes?

Operators use both automated sensors and manual sampling to monitor key parameters like flow rates, pH levels, and dissolved oxygen. Based on these results, they adjust processes such as sludge extraction rates, recirculation flows, and oxygen supply to maintain treatment efficiency.

Q5. What qualifications are needed to become a wastewater treatment plant operator?

Most entry-level positions require a high school diploma, but an associate degree in a related field can be beneficial. Operators must also obtain certification through written examinations and complete continuing education (typically 18-24 hours over a three-year period) to maintain their licenses.