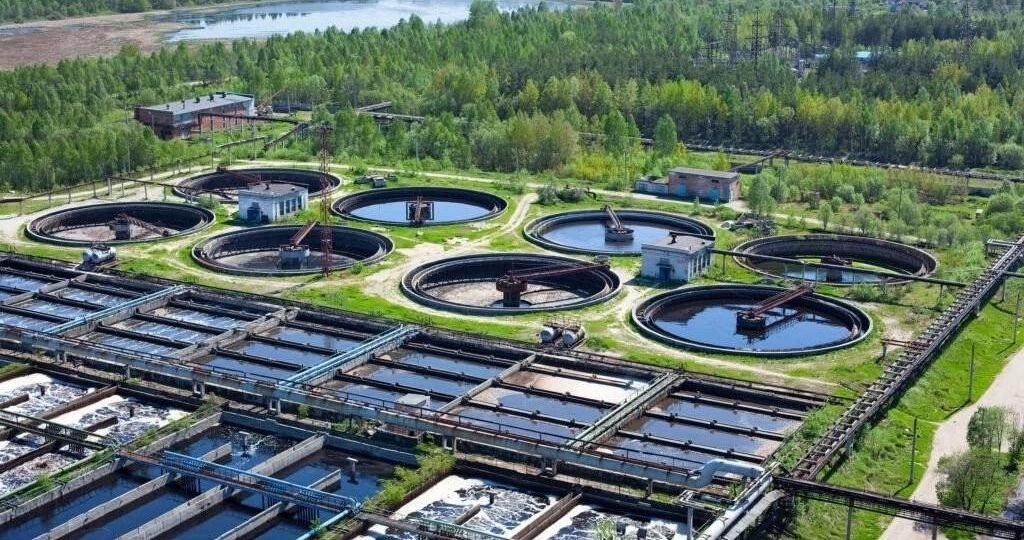

Modular sewage treatment plants take up 10 times less space than conventional Activated Sludge Process systems. These plants cut capital costs by a lot while delivering the same performance. Companies of all sizes worldwide now choose these compact and efficient solutions to tackle their growing infrastructure and space limitations. The pre-engineered and factory-assembled design helps these plants cut down installation time compared to traditional systems.

These innovative treatment systems come in standard modules that handle anywhere from 5 m³/day to 500 m³/day in container-like structures. The plants’ appeal comes from their durable build, lightweight design, and excellent resistance to corrosion. On top of that, they need less power and cost less to operate and maintain. The treated sewage becomes useful for flushing, irrigation, and construction projects. In this piece, you’ll learn about different sewage treatment systems and SUSBIO ECOTREAT – India’s most advanced modular STP. This future-ready solution tackles sewage treatment plant problems while keeping service costs in check.

How Modular STPs Work in 2025

Modern modular sewage treatment plants transform wastewater into reusable water through multiple stages. These systems in 2025 deliver exceptional performance from a smaller footprint by combining advanced technology with compact design.

Screening and Grit Removal Process

The treatment starts when large debris gets filtered out to protect downstream equipment. Current 2025 systems feature two screening phases: coarse screens (6mm or larger openings) catch bulky materials like rags and plastics, while fine screens (1.5-6mm openings) capture smaller particles that could affect later treatment stages. Wastewater then moves to grit chambers where the flow slows down. Heavy materials like sand, gravel, and coffee grounds settle at the bottom. This crucial step helps prevent equipment wear and abrasion. Mechanical screening paired with grit removal gives pumps and downstream components the protection they need.

Biological Treatment Using MBBR Technology

Most modular STPs in 2025 use Moving Bed Biofilm Reactor (MBBR) technology at their core. This innovative method combines activated sludge and biofilm processes to achieve superior results. MBBR systems use special plastic carriers with density close to water (0.9g/cm³) that float freely in the aeration tank. These carriers create an extensive surface area where microbes can grow and break down organic pollutants efficiently. Fine bubble aeration systems feed oxygen to the biofilm and support aerobic microbial activity. The continuous movement stops biomass from building up and spreads microorganisms evenly, which streamlines processes. MBBR systems are nowhere near as space-hungry as conventional ones, needing 30-40% less room – perfect for modular applications with limited space.

Tertiary Treatment: UV and Membrane Filtration

The water goes through additional purification after biological treatment:

- UV Disinfection: Low-pressure UV systems work at wavelengths between 250-270 nm to damage microbial DNA and stop reproduction. A dose of 164 mWs/cm² reduces Total Coliform Count by 3 logs while completely eliminating Fecal Coliform, Pseudomonas, and Staphylococcus.

- Membrane Filtration: Microfiltration (MF) with 0.1-10 μm pores removes bacteria and turbidity. Ultrafiltration (UF) with smaller 0.001-0.1 μm pores catches viruses, endotoxins, and proteins. These advanced filtration technologies ensure water quality meets strict standards.

Effluent Reuse for Irrigation and Flushing

Modular STPs produce high-quality treated water that becomes a valuable resource. The 2025 treated wastewater supports many reuse applications – mainly irrigation, toilet flushing, cooling towers, and construction activities. Real estate sector just needed 101.9 MLD of water in 2019, which treated effluent could largely supply. Ready-mix concrete plants used 6,740 million liters of water for estimated concrete production of 22,46,262 cum/month—another way to use treated wastewater. SUSBIO ECOTREAT, India’s most advanced modular STP in 2025, makes this circular approach possible with its zero-sludge generation system and advanced water quality standards, which ended up reducing dependence on freshwater sources.

Smart Design Features That Define Modern Modular STPs

Modern modular STPs showcase remarkable design innovations that solve traditional sewage treatment challenges. Smart features have revolutionized wastewater management approaches in 2025.

Plug-and-Play Setup with Containerized Units

Pre-engineered and factory-assembled modular STPs cut installation time compared to conventional systems. Quick and straightforward on-site assembly needs only simple connections and a flat foundation for these pre-fabricated modules. Containerized STPs work perfectly for emergency situations, construction sites, and remote locations. Modular units become operational within weeks after delivery – a huge advantage for businesses that face urgent wastewater management challenges.

Wireless Monitoring and Remote Access Panels

Smart monitoring systems in modern STPs have changed maintenance protocols:

- Live monitoring of parameters like flow rate, pH levels, and pollutant concentrations

- Microprocessor-based controllers with HMI, PLC, and VFD capabilities

- Remote access via SCADA systems for off-site oversight

- AI algorithms detect system faults and generate timely alerts

Operators can access live data and control system parameters from anywhere through wireless integration. This enables centralized management without constant on-site presence.

Low Power Consumption and Auto-Controlled Systems

Systems use up to 30% less power than traditional STPs, making energy efficiency one of their best features. SUSBIO ECOTREAT, India’s most advanced modular STP, uses 90% less electricity than conventional systems. Optimized aeration systems and smart automation adjust operational parameters based on incoming sewage characteristics. Energy conservation happens through automatic standby modes during low-demand periods without affecting treatment effectiveness.

Compact Footprint for Urban and Remote Installations

Space-efficient design needs 40-60% less area than conventional systems. These units fit perfectly in constrained locations like urban environments or industrial facilities. Easy transportation and placement within existing infrastructure happens through containerized or skid-mounted configurations without major land clearance.

Advanced Microfiltration and Disinfection Units

State-of-the-art filtration technologies, including membrane filtration and UV disinfection, raise water quality standards. Chemical-free treatment options reduce environmental impact and operational costs. Integration with predictive maintenance stops 90% of potential failures. This ensures consistent performance throughout the system’s lifespan.

Comparing STP Plant Types and Modular Configurations

The right sewage treatment solution depends on knowing the differences between available setups. Each type comes with its own advantages that match specific project needs.

Containerized vs Skid-Mounted Modular STPs

Standard shipping containers house treatment equipment in containerized units, which makes transportation and installation easier on simple foundations. These self-contained systems work best for smaller projects and temporary setups where mobility matters. Skid-mounted modules rest on frames that forklifts or cranes can move, which makes them perfect for sites that just need periodic upgrades or changes. Teams can switch individual modules to add treatment steps while operations continue. SUSBIO ECOTREAT provides both options with features that are a big deal as it means that standard modular capabilities.

Modular Type STP vs Traditional ASP Systems

Traditional Activated Sludge Process (ASP) systems are common but take 8-12 hours for treatment, while MBBR-based modular systems only take 4-6 hours. ASP plants use more energy and create more sludge. MBBR systems handle shock loads better because of their stable biofilm formation. It also manages variable effluent conditions more effectively, which makes it perfect for decentralized applications. Yes, it is these modular treatment systems that deal with centralized facilities’ limitations through eco-friendly, decentralized methods.

Scalability and Upgrade Paths in Modular Designs

You can expand modular designs without major redesign work. Projects can start with minimal modules and add units as they just need more capacity. Communities can adapt to changing requirements this way without wasting resources. Modules work in other projects during relocation, which extends their investment value. This flexibility creates custom solutions that match specific capacity needs, space limits, and discharge requirements.

Cost of New Sewage Treatment Plant vs Retrofit Options

Modernizing existing infrastructure saves money significantly. A case study shows modernizing a 20-inch water main cost INR 84.38 million compared to INR 210.95 million for new construction. Notwithstanding that, modernization involves complex permits and operational challenges. Aging facilities with limited space or budget constraints can improve efficiency and compliance without complete replacement. SUSBIO ECOTREAT offers budget-friendly modular solutions that balance original investment with long-term operational savings through energy efficiency and minimal maintenance needs.

SUSBIO ECOTREAT: India’s Most Advanced Modular STP

SUSBIO ECOTREAT leads India’s state-of-the-art sewage treatment systems with advanced technical capabilities that surpass standard modular systems. This future-ready solution tackles complex treatment challenges through specialized engineering.

Integrated Pre-Anoxic Tank for Better Denitrification

The pre-anoxic tank creates an oxygen-free environment before the main treatment stage. Specialized bacteria convert nitrates into nitrogen gas. This process reduces total nitrogen content by up to 80% and meets strict discharge regulations without extra chemicals.

Live Monitoring with AI-Based Predictive Maintenance

SUSBIO combines smoothly with IoT sensors that measure critical parameters like dissolved oxygen, MLSS concentration, and nutrient levels. The AI-driven analytics platform spots potential problems early. This system cuts maintenance needs by 60% and extends equipment life.

Zero-Sludge Generation and Low Sewage Treatment Plant Service Cost

The company’s biodigestion process eliminates excess sludge production. A 100 KLD plant saves ₹45,000-60,000 monthly in handling costs. This zero-sludge approach reduces annual maintenance expenses by nearly 40% compared to standard modular systems.

Designed for Harsh Climates and Variable Load Conditions

SUSBIO ECOTREAT uses corrosion-resistant materials and thermal insulation to maintain optimal biological activity between 10-45°C. The adaptive control system adjusts treatment parameters during flow fluctuations of 30-150%. This ensures consistent output quality whatever the input variations.

Conclusion

Modern wastewater management has changed dramatically thanks to modular sewage treatment plants with their smart design and efficiency. These compact systems work much better than conventional treatment methods. They need less space and cost less to install. Modern STPs blend advanced biological processes with intelligent monitoring systems to deliver better performance.

The multi-stage treatment process works quickly and effectively, especially when you have MBBR technology. These plants need minimal space and energy to process wastewater. On top of that, UV disinfection and membrane filtration ensure high-quality output you can reuse in many ways.

Smart features make modern modular STPs stand out. They’re easy to set up, monitor wirelessly, run efficiently, and fit in tight spaces – perfect for both city and remote locations. So organizations save money while getting excellent treatment results.

Modular systems perform better than traditional ASP setups in every way – faster treatment, lower energy use, and better adaptability. They’re also flexible enough to grow as your treatment needs change.

SUSBIO ECOTREAT leads India’s modular STP market with features that go beyond standard systems. This future-ready solution tackles complex problems with its integrated pre-anoxic tank, AI-based predictive maintenance, zero-sludge output, and tough operating capability. Businesses looking for environmentally responsible wastewater management will find great value in SUSBIO ECOTREAT’s lower service costs and environmental benefits.

Water shortages are becoming a global concern. These groundbreaking modular sewage treatment plants are a vital part of sustainable water management. Knowing how to turn wastewater into a valuable resource shows substantial progress in environmental protection and resource conservation.

Key Takeaways

Modern modular sewage treatment plants represent a revolutionary approach to wastewater management, offering smart design features that dramatically improve efficiency while reducing costs and environmental impact.

- Compact Efficiency: Modular STPs reduce system footprint by 10x compared to conventional systems while cutting installation time through pre-engineered, plug-and-play designs.

- Smart Technology Integration: Advanced wireless monitoring, AI-based predictive maintenance, and automated controls reduce operational interventions by 60% and maintenance costs by 40%.

- Superior Treatment Performance: MBBR technology processes wastewater 50% faster than traditional ASP systems while using 30% less energy and producing high-quality reusable water.

- Scalable Investment: Modular designs enable capacity expansion without major redesign, allowing organizations to start small and grow incrementally based on demand.

- Zero-Waste Innovation: Advanced systems like SUSBIO ECOTREAT eliminate sludge generation entirely, saving ₹45,000-60,000 monthly in handling costs for 100 KLD plants.

These intelligent treatment systems transform wastewater from a disposal problem into a valuable resource for irrigation, flushing, and industrial applications, making them essential for sustainable water management in 2025 and beyond.

FAQs

Q1. What are the key components of a modular sewage treatment plant?

A modular sewage treatment plant typically includes screening units, grit chambers, biological reactors using MBBR technology, clarifiers, and advanced disinfection systems like UV and membrane filtration. These components are designed for efficient wastewater treatment in a compact, pre-engineered package.

Q2. How do modular STPs differ from traditional sewage treatment systems?

Modular STPs are more compact, energy-efficient, and faster to install compared to traditional systems. They use advanced technologies like MBBR, which processes wastewater 50% faster than conventional activated sludge processes while consuming 30% less energy. Modular systems also offer greater flexibility for expansion and relocation.

Q3. What are the smart features of modern modular sewage treatment plants?

Modern modular STPs incorporate features such as wireless monitoring, AI-based predictive maintenance, automated control systems, and compact designs suitable for urban and remote installations. These smart features enable real-time data access, reduce operational interventions, and optimize energy consumption.

Q4. How do modular STPs contribute to water conservation?

Modular STPs produce high-quality treated water suitable for reuse in applications like irrigation, toilet flushing, and industrial processes. This approach helps conserve freshwater resources by providing an alternative water source for non-potable uses, addressing growing water scarcity concerns.

Q5. What makes SUSBIO ECOTREAT stand out among modular STPs?

SUSBIO ECOTREAT is distinguished by its integrated pre-anoxic tank for enhanced denitrification, AI-driven predictive maintenance, zero-sludge generation, and ability to handle harsh climates and variable load conditions. These features result in lower operational costs, reduced environmental impact, and consistent performance under challenging conditions.