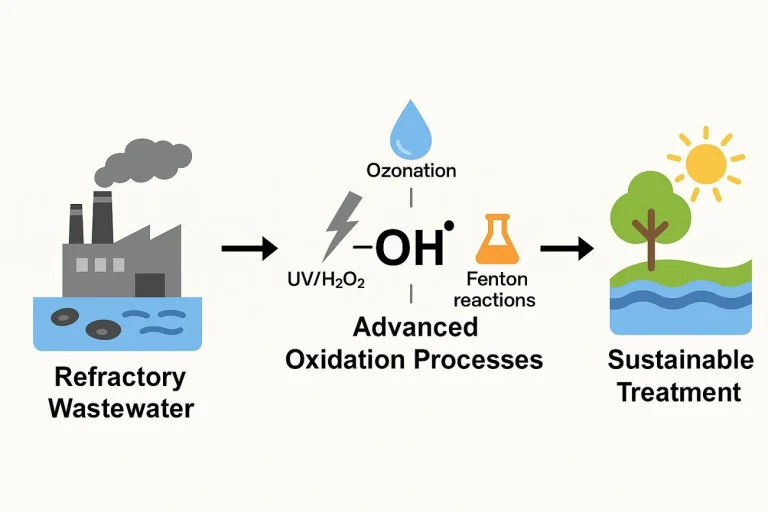

Advanced oxidation process represents an exciting frontier in environmental engineering that captures growing interest from researchers. Scientists first proposed these methods in the 1980s to treat drinking water. These powerful chemical processes have become accessible to more people who study various types of wastewater treatment. Research has spanned decades, yet many advanced oxidation processes (AOPs) developed in laboratories haven’t made their way to pilot- and full-scale operations.

The effectiveness of these processes stems from their unique chemistry. AOPs generate hydroxyl radicals (OH·) or sulfate radicals (SO4·−) in quantities sufficient to break down stubborn pollutants that conventional treatments can’t handle. The process also creates other reactive species like superoxide anions and hydrogen peroxide. These compounds work together to attack complex contaminants. Engineers can use AOPs in wastewater treatment for several purposes. The applications range from reducing organic content (COD) to destroying specific pollutants. They also help improve sludge treatment, boost bioavailability of recalcitrant organics, and reduce color and odor.

This piece will break down what advanced oxidation process is and get into the various types of AOPs available. We’ll explore their practical applications in wastewater treatment systems. The discussion will cover performance metrics, optimization parameters, and limitations that engineers should think over when implementing these powerful oxidation technologies.

What is Advanced Oxidation Process in Wastewater Treatment

Scientists first developed advanced oxidation process in the 1980s. We used it to treat drinking water. These processes create powerful reactive species that break down water contaminants. Scientists later expanded AOPs beyond drinking water. They started using it to clean different types of wastewater containing stubborn organic pollutants.

Definition and origin of AOPs

Advanced oxidation processes are technologies that employ highly reactive oxidizing agents. These agents, mainly hydroxyl radicals (•OH), clean water in sufficient quantities. The concept later grew to include processes that use sulfate radicals (SO4•−). AOPs don’t just separate contaminants from water like traditional methods. They completely destroy both organic and inorganic contaminants.

These processes create powerful radicals right where they’re needed. They usually combine oxidizing agents (like H2O2 and O3) with energy sources (ultraviolet light or ultrasound), and sometimes catalysts (such as Fe2+). This improves oxidation kinetics and breaks down contaminants into carbon dioxide or other harmless substances.

Role of hydroxyl and sulfate radicals in oxidation

Hydroxyl radicals are the life-blood of most AOPs. They pack an extraordinary oxidation potential between 2.8 V (at pH 0) and 1.95 V (at pH 14). Only fluorine beats them as a reactive oxidizing agent. These radicals don’t discriminate – they react faster with many substances at rates of 108–1010 M−1 s−1. They can break down almost any organic molecule in wastewater.

Hydroxyl radicals attack organic pollutants in four main ways:

- Radical addition to carbon-carbon double bonds

- Hydrogen abstraction from C-H bonds

- Electron transfer processes

- Radical combination reactions

Sulfate radical-based processes have grabbed scientists’ attention lately, even though hydroxyl radicals dominated AOPs for years. Sulfate radicals (SO4•−) pack a powerful 2.6 V oxidation potential. They last longer (30–40 μs versus hydroxyl radicals’ microsecond existence). They also work better across pH levels from 4-9 compared to hydroxyl radical processes.

These radical types work differently. Hydroxyl radicals usually add to C=C bonds or grab hydrogen from C-H bonds. Sulfate radicals prefer to steal electrons from organic molecules to create radical cations.

Comparison with conventional chemical oxidation in wastewater treatment

Traditional chemical oxidation uses oxidants like chlorine, potassium permanganate, or potassium dichromate. These methods might only partially oxidize organic compounds. AOPs offer better solutions:

AOPs create oxidizing agents with much higher oxidation potential. Traditional oxidants might handle simple compounds, but they don’t deal very well with complex, stubborn pollutants that AOPs easily destroy.

The environment benefits from AOPs. They don’t move pollutants between phases like chemical precipitation or adsorption do. They also don’t create large amounts of dangerous sludge. Complete AOP treatment usually produces harmless substances like CO2, H2O, and inorganic ions.

AOPs work on many types of pollutants. You’ll find them cleaning everything from landfill leachate to pharmaceutical waste, textile effluents, and industrial wastewaters of all types.

AOPs can work alone or help biological processes. They turn non-biodegradable compounds into substances that break down more easily. This improves how well biological treatment works afterward.

Types of Advanced Oxidation Processes and Their Mechanisms

Advanced oxidation processes use different mechanisms to create highly reactive radical species that break down stubborn pollutants. Each process uses unique reaction pathways and brings specific benefits to wastewater treatment.

UV/H2O2 and UV/O3 Photolytic Systems

UV/H2O2 systems work through hydrogen peroxide photolysis by ultraviolet radiation. This creates hydroxyl radicals through the reaction: H2O2 → 2 •OH. The process works better than ozone-based methods because H2O2 dissolves better than O3. This leads to more hydroxyl radical production with the same energy input.

Scientists first developed UV/O3 systems in the 1970s to treat high-concentration cyanide wastewater. These systems work by breaking down dissolved ozone into hydroxyl radicals. UV light at 254 nm breaks down ozone molecules to produce active oxygen radicals. These radicals then react with water to create hydrogen peroxide and hydroxyl radicals. The process follows these steps: O3 + hv → O2 + O•, then O• + H2O → H2O2, and finally H2O2 + hv → 2 •OH.

Both systems break down pharmaceutical compounds well. They remove more than 95% of various pharmaceuticals in pilot-scale tests.

Fenton and Photo-Fenton Reactions

The classic Fenton process uses a reaction between ferrous iron (Fe²⁺) and hydrogen peroxide to create hydroxyl radicals. The reaction works best at pH 2.8–3.0. Beyond this pH, iron starts to precipitate as Fe(OH)₃, which reduces efficiency. The standard Fenton process produces one hydroxyl radical for each hydrogen peroxide molecule.

Photo-Fenton makes this reaction better by adding UV or visible light. The light helps turn Fe³⁺ back into Fe²⁺ through photolysis: Fe(OH)²⁺ + hv → Fe²⁺ + •OH. This change doubles the radical production, creating two radicals per H₂O₂ molecule. Photo-Fenton works better than regular Fenton reactions under the right conditions. It can completely break down pharmaceuticals like sulfamethoxazole, carbamazepine, and ibuprofen in just 10 minutes.

Electro-Fenton and Electrochemical AOPs

Electro-Fenton (EF) combines electrochemistry with Fenton chemistry. The process makes hydrogen peroxide continuously at the cathode through oxygen reduction. This on-site H₂O₂ production works better than traditional Fenton systems.

Electrochemical advanced oxidation processes use electrons as clean reagents. They are environmentally friendly, versatile, and safe at room temperature. The cathode material plays a big role in how well the process works. Carbon-felt and O₂-diffusion cathodes are popular choices. The anode creates more hydroxyl radicals by oxidizing water on materials like boron-doped diamond, PbO₂, or Ti₄O₇. This makes the treatment more effective.

EF works best at acidic pH (around 3), which makes it hard to scale up. Recent improvements like chelate-EF, self-powered EF, and bio-EF have made this technology more practical.

Ozone-Based AOPs and Peroxone Systems

Ozone-based advanced oxidation processes make ozone’s oxidation potential better through various combinations. The O₃/H₂O₂ system (peroxone) starts when hydroperoxide anions (HO₂⁻) react with ozone to make hydroxyl radicals. This happens in steps: H₂O₂ ⟶ HO₂⁻ + H⁺, then HO₂⁻ + O₃ ⟶ HO₂• + O₃•⁻, which ends up creating •OH.

Electro-peroxone is a newer version that combines ozonation with electrochemically produced hydrogen peroxide. This combined approach works much better than regular ozonation at breaking down total organic carbon.

Sonolysis and Ultrasound-Driven AOPs

Sonolysis uses ultrasound waves (20-1000 kHz) to create acoustic cavitation – tiny bubbles that form, grow, and violently collapse. The collapse creates extremely hot spots (around 5000K) under high pressure (about 1000 atm). These conditions break water molecules into hydroxyl radicals.

Ultrasonic degradation happens in three places: inside cavitation bubbles (for compounds that evaporate easily), where bubbles meet liquid, and throughout the solution. Lower frequencies often work better – studies show faster breakdown rates at 544 kHz compared to 1081 kHz for some pharmaceuticals.

Sonochemical processes break down pharmaceutical compounds well but don’t completely mineralize them as effectively as other AOPs. Combining them with other oxidation methods like Fenton processes often creates better results.

Applications of AOPs in Treating Complex Wastewater Streams

Traditional treatment methods often fail to clean complex industrial wastewaters. Advanced oxidation processes are a great way to break down stubborn compounds in waste streams of all types.

Landfill leachate treatment using Fenton and UV/O3

Landfill leachate creates major treatment challenges. COD levels range from 100-8,000 mg/L with varying BOD5/COD ratios. The Fenton process removes 45-85% of leachate COD. Photo-Fenton systems work even better and can remove up to 83.2% of COD under the right conditions. This treatment also boosts biodegradability. BOD5/COD ratios rise from less than 0.10 to between 0.14-0.60.

Ozone-based AOPs show great results in leachate treatment. Ozonation makes landfill leachate 1.6-80 times more biodegradable, depending on the contaminants. The O3/UV combination works best as a tertiary treatment and removes up to 83% of COD.

Effluent organic matter (EfOM) removal in BTSE

Biologically treated sewage effluent (BTSE) contains several organic matter types: biopolymers (6%), humic substances (53%), low MW acids (20%), and low MW neutrals (21%). Boron-doped diamond electrodes help solve this problem through electro-oxidation. They cut transmembrane pressure by 36-67% in ultrafiltration systems by breaking down fouling compounds.

Pharmaceutical wastewater treatment with UV/H2O2

H2O2/UV treatment removes up to 87.6% of COD from pharmaceutical wastewater. This happens during 70 minutes of oxidation at pH 4 with 500 mg/L H2O2. The process breaks down pharmaceutical compounds when hydroxyl radicals form from H2O2 photolysis.

UV/H2O2 treatment removes about 90% of pharmaceutical and personal care products (PPCPs) from wastewater. This works even with concentrations from nanograms to milligrams per liter. The process excels at cleaning effluent with trace contaminants.

Color and odor removal in textile wastewater

Textile industry’s wastewater creates unique challenges because of its high color content and complex organic structures. AOPs tackle these problems through multiple ways. Ozonation (300 mg/dm3) removes 95-99% of color from textile effluent in 40-60 minutes.

Fenton treatment works well on foul odor compounds in industrial wastewater. The Fe2+/H2O2 system cuts odor concentration from 2980 ou e/m3 to just 100 ou e/m3—a 96.3% reduction. This system also stops hydrogen sulfide from forming over long periods, which prevents odors from coming back.

The Fenton process is affordable too. It uses the lowest median electrical energy (0.98 kWh m-3 order-1) among various AOPs, making it a cost-effective choice for treating textile effluent.

Performance Metrics and Optimization Parameters

Successful AOP performance needs careful control of parameters to break down pollutants while using fewer resources.

Effect of pH, temperature, and oxidant dose

pH plays a big role in how well AOPs work. Fenton reactions work best at pH 2.8-3.0, while persulfate systems perform better in neutral to slightly alkaline conditions. Acidic environments boost hydroxyl radical oxidation potential. However, too much acid reduces the reaction between Fe²⁺ and H₂O₂. The results are better in alkaline conditions (pH 7-9) for ozonation, with COD removal reaching 98% at pH 9.0.

Temperature makes a real difference in reaction speed. Higher temperatures speed up radical formation but might break down H₂O₂ into water and oxygen. The right oxidant dose is crucial – too much leads to radical scavenging, while too little reduces efficiency. Scientists can calculate the perfect H₂O₂ concentration using the formula Copt-theoretical=Ab·Sc/ε·k.

COD and TOC reduction standards

Fenton processes can remove 35-95% of COD. Photo-Fenton takes this even further, reaching 95.5% under the right conditions. UV/H₂O₂ systems can eliminate 89.8-100% of pharmaceuticals like ibuprofen. Ozone-based AOPs remove 32% TOC and 61% COD in 3 hours. H₂O₂/UV treatment can achieve 87.6% COD removal in 70 minutes at pH 4.

Energy consumption and reaction time trade-offs

Different methods need different amounts of energy. Photo-Fenton uses about 7.66 kWh/kg COD removed, while UV/H₂O₂ needs 30.39 kWh/kg. The Fenton process is more cost-effective with the lowest median electrical energy use (0.98 kWh m⁻³ order⁻¹) among AOPs. Most reactions work best between 30-90 minutes – any longer rarely gives better results worth the extra energy.

Sludge generation and handling in Fenton-based AOPs

Fenton processes create a lot of chemical sludge – about 150 mL for every 250 mL of treated wastewater when removing 60% of COD. The amount of sludge relates directly to Fe²⁺ concentration rather than the H₂O₂/COD ratio. Using Fe³⁺ instead of Fe²⁺ creates less sludge while maintaining COD removal efficiency. New techniques use neutralizers like lime or red mud to raise pH and create hard network structures that help with dewatering.

Limitations and Integration with Other Technologies

Lab tests show that advanced oxidation processes work well, but moving these technologies to industrial use comes with real challenges. Let’s get into these limitations and ways we can make them work together.

Challenges in scaling AOPs to full-scale plants

Taking advanced oxidation processes from labs to industry faces big hurdles. We found that making micro/mesoporous structures needed for radical delivery is complex and gets pricey. These structures might also be toxic to cells. The hydroxyl and sulfate radicals don’t last very long, which makes it hard to get them where they need to go. Right now, we can only move hydrogen peroxide, ozone, hypochlorous and hypobromous acids from where they’re made to where they’re used. We also can’t measure reactive oxygen species quickly enough on-site, which makes it harder to scale up.

Formation of toxic byproducts like bromate

Ozonation has a big problem – it creates bromate, a cancer-causing substance that drinking water standards limit to 10 μg/L. This happens through complex reactions with ozone and hydroxyl radicals. AOPs can also create nitro-derivatives that are more dangerous than the original pollutants. The treatment produces aldehydes and other small compounds that aren’t regulated but can harm health and help microbes grow.

Combining AOPs with biological treatment

Biological processes could help solve AOP limitations. Using chemical oxidation alone to break down everything is expensive, but mixing it with biological treatment cuts costs. These combined systems work really well – when we use chemical treatment followed by biological treatment, we can remove 85-93% of COD from tough industrial wastewater. AOPs turn non-biodegradable compounds into forms that bacteria can break down, which makes the biological treatment work better.

Cost-effectiveness and sustainability concerns

AOPs work well but need lots of money upfront for special equipment like UV reactors and ozone generators. These systems use lots of energy, especially UV-based and ozonation systems. Electro-Fenton is more economical with the lowest median electrical energy use (0.98 kWh m⁻³ order⁻¹) among AOPs. Life cycle studies show that chemical and electricity-driven advanced oxidation might harm the environment. Using fewer chemicals and dealing with less sludge can cut running costs by 20-30% over time.

Conclusion

Advanced oxidation processes have become powerful tools that tackle complex pollutants where conventional treatment methods fall short. Our research shows these processes create highly reactive radical species that break down stubborn contaminants in waste streams of all types.

Hydroxyl and sulfate radicals lead the charge in AOPs. These compounds possess remarkable oxidation potentials that turn persistent pollutants into harmless byproducts. They work through different reaction mechanisms and adapt well to various wastewater types.

Each AOP technology brings its own strengths to the table. Fenton processes provide economical solutions, while UV/H₂O₂ systems remove pharmaceuticals quickly. Ozone-based methods excel at eliminating color and odor from textile effluents. Environmental engineers can pick the right technology based on specific contaminant profiles.

The right parameters make a big difference in AOP efficiency. The treatment’s effectiveness depends on pH, temperature, oxidant dose, and reaction time. Engineers must balance energy use against pollutant removal rates – a challenge that demands careful evaluation of economic and environmental factors.

Lab results look promising, but scaling AOPs to full operations comes with real challenges. Toxic byproducts might form, energy needs run high, and capital costs add up substantially. All the same, pairing AOPs with biological treatment systems boosts overall performance while keeping costs in check.

The field will likely focus on creating energy-efficient processes, reducing harmful byproducts, and finding new ways to work with conventional methods. These improvements should tackle current limitations while keeping AOPs’ exceptional ability to remove contaminants.

AOPs will keep evolving as key parts of complete wastewater treatment strategies, especially as regulations get stricter and new complex pollutants emerge. These processes turn non-biodegradable compounds into biodegradable intermediates, making them great partners for biological treatments rather than standalone solutions. This combined approach offers the best path forward to tackle our toughest water pollution problems effectively and sustainably.

Key Takeaways

Advanced oxidation processes represent a breakthrough technology for treating complex wastewater pollutants that resist conventional methods. Here are the essential insights for water treatment professionals:

• AOPs generate powerful hydroxyl and sulfate radicals that break down persistent pollutants with oxidation potentials up to 2.8V, making them highly effective against pharmaceuticals, textile dyes, and industrial contaminants.

• Multiple AOP technologies offer specialized advantages: Fenton processes provide cost-effectiveness (0.98 kWh/m³), UV/H₂O₂ achieves 95%+ pharmaceutical removal, and ozonation excels at color/odor elimination.

• Optimal performance requires precise parameter control – pH 2.8-3.0 for Fenton, neutral-alkaline for persulfate systems, with careful oxidant dosing to prevent radical scavenging.

• Integration with biological treatment maximizes efficiency while reducing costs by 20-30%, transforming non-biodegradable compounds into biodegradable intermediates for subsequent biological processing.

• Scaling challenges include high energy consumption and toxic byproduct formation like bromate, requiring hybrid approaches and careful process design for successful industrial implementation.

The future of wastewater treatment lies in combining AOPs with conventional biological systems, leveraging their complementary strengths to achieve comprehensive pollutant removal while maintaining economic viability.

Frequently Asked Questions

Q1. What are the main advantages of advanced oxidation processes in wastewater treatment?

Advanced oxidation processes generate powerful oxidizing agents like hydroxyl radicals that can break down complex pollutants conventional treatments can’t handle. They’re effective at reducing organic content, destroying specific contaminants, improving sludge treatment, and removing color and odor from wastewater.

Q2. How do hydroxyl and sulfate radicals differ in their oxidation mechanisms?

Hydroxyl radicals typically add to carbon-carbon double bonds or abstract hydrogen from C-H bonds. Sulfate radicals, on the other hand, tend to remove electrons from organic molecules to form radical cations. Sulfate radicals also have a longer lifetime and work effectively across a wider pH range compared to hydroxyl radicals.

Q3. What are some common types of advanced oxidation processes?

Common types of AOPs include UV/H2O2 and UV/O3 photolytic systems, Fenton and photo-Fenton reactions, electro-Fenton and electrochemical AOPs, ozone-based processes, and sonolysis (ultrasound-driven AOPs). Each type has its own mechanisms and advantages for treating different kinds of wastewater.

Q4. How effective are AOPs in treating pharmaceutical wastewater?

AOPs are highly effective in treating pharmaceutical wastewater. For instance, UV/H2O2 treatment can remove up to 90% of various pharmaceutical and personal care products from wastewater, even at very low concentrations. Some studies have shown COD removal efficiencies of up to 87.6% for pharmaceutical wastewater using H2O2/UV treatment.

Q5. What are the main challenges in scaling up AOPs for industrial use?

Scaling up AOPs faces several challenges, including the complexity and cost of synthesizing micro/mesoporous structures for radical delivery, the extremely short half-lives of hydroxyl and sulfate radicals, and the lack of capability for rapid, in-situ measurement of reactive oxygen species. Additionally, the formation of toxic byproducts like bromate and high energy consumption are significant concerns for industrial implementation.