Hospitals use massive amounts of water and produce huge quantities of wastewater every day because of modern medical advances. Healthcare facilities face a growing challenge with sewage treatment as they continue to expand their services.

A closer look at hospital sewage reveals dangerous components like microbial pathogens, hazardous chemicals, heavy metals, pharmaceuticals, drug residues, and radioactive isotopes. The sewage treatment process needs special attention to handle these specific challenges. The wastewater shows high levels of BOD, COD, TDS, TSS, TS, TOC, TN, nitrites, nitrates, and TP. On top of that, it contains concentrated amounts of infectious microbes, multi-drug resistant microbes, and drug resistance genes. A well-designed STP sewage treatment plant plays a crucial role to keep these contaminants from contaminating our water systems.

The Pollution Control Board requires every hospital to run and maintain their own sewage treatment plant. This rule exists because hospital wastewater can seriously threaten public health and lead to disease outbreaks. SUSBIO ECOTREAT has emerged as India’s most advanced packaged STP that provides a future-ready approach to hospital waste management.

This piece will help you understand the essential safety standards for hospital STPs, the key steps in sewage treatment, and solutions that work for facilities of all sizes.

Understanding Hospital Sewage and Its Hazards

Hospital wastewater creates unique challenges compared to domestic sewage. The toxicity levels in hospital sewage can be 5–15 times higher than urban effluent. This situation demands specialized sewage treatment plants for hospitals.

Sources of hospital sewage: ICUs, labs, canteens, and wards

Healthcare facilities generate sewage from several departments. The main sources are emergency rooms, operating theaters, intensive care units (ICUs), laboratories, radiology departments, and patient wards. Support services like canteens, laundries, and administrative areas also contribute substantial volumes. A single hospital bed produces 200-1000 liters of sewage daily. Hospitals in developed countries generate 400–1200 L per bed each day while those in developing countries produce 200–400 L.

Common contaminants: pathogens, pharmaceuticals, and heavy metals

The sewage composition varies based on its source department and has these common elements:

- Biological hazards: Pathogenic bacteria (E. coli, Salmonella, Pseudomonas), viruses (Hepatitis B/C, Norovirus, Coronavirus), fungi, protozoa, and parasitic worms

- Pharmaceutical compounds: Over 300 pharmaceutically active compounds including antibiotics, analgesics, psychiatric drugs, and chemotherapy agents

- Chemical substances: Disinfectants, laboratory reagents, contrast media, solvents, and detergents

- Heavy metals: Mercury, lead, cadmium, and platinum from broken equipment and laboratory reagents

Many pharmaceutical compounds remain active in the environment because they dissolve in water but resist biodegradation.

Impact on groundwater and public health

Untreated hospital effluent threatens environmental and public health. These contaminants can seep into groundwater when discharged into water bodies, making it unsafe to drink. This pollution leads to waterborne disease outbreaks, especially in areas that don’t have adequate sewage treatment plants.

The most worrying aspect is hospital sewage’s role in antimicrobial resistance. Antibiotics in wastewater help create drug-resistant microorganisms. Many experts call this situation a “silent pandemic.”

SUSBIO ECOTREAT, India’s most advanced packaged STP, provides advanced technology that handles complex hospital waste effectively. This solution ensures compliance with strict safety standards and protects public health.

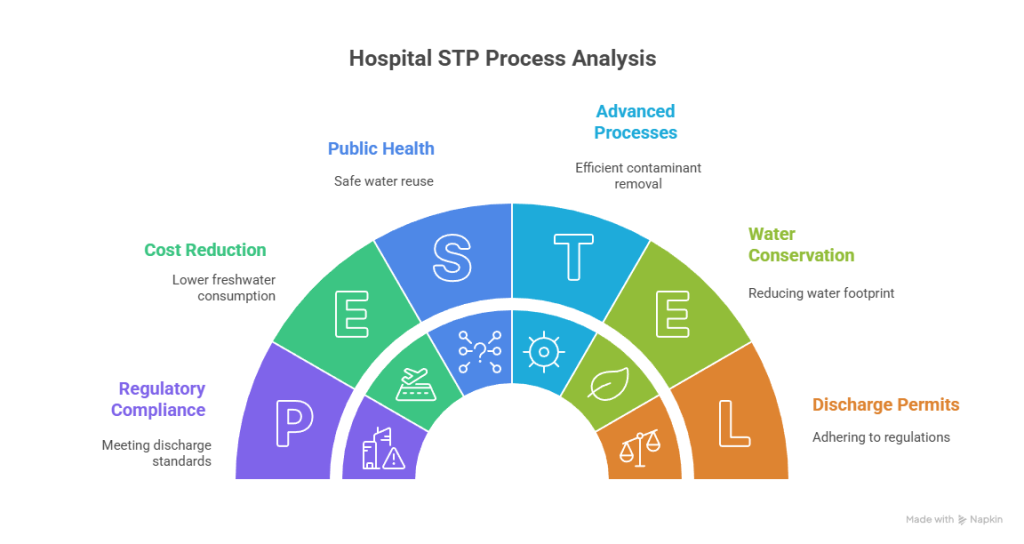

Step-by-Step Hospital STP Process Explained

A multi-stage hospital sewage treatment plant (STP) changes hazardous wastewater into safe, reusable water through a series of advanced processes. Each stage targets specific contaminants to ensure complete purification of hospital effluent.

Pre-treatment: Bar screens and grit chambers

The wastewater flows through bar screens with spacing from 6mm to 75mm to filter out large debris like rags, plastics, and other substantial materials. These screens protect downstream equipment from damage. The grit chambers slow down sewage flow and let heavier inorganic particles like sand and gravel settle while keeping organic matter suspended. This essential first stage removes about 40-60% of the biological oxygen demand (BOD).

Primary treatment: Clarifiers and sludge separation

Physical separation happens when wastewater enters sedimentation tanks or clarifiers. Solid particles settle at the bottom as primary sludge and contain about 60-70% of total solids. Oils and greases float to the surface where they get skimmed off. The wastewater becomes ready for biological treatment after suspended particles are removed.

Secondary treatment: Aeration tanks and activated sludge

Secondary treatment forms the core of the process where biological processes remove dissolved organic matter. Bacteria break down contaminants in aeration tanks while oxygen supports microbial activity. The activated sludge process reduces organic pollutants by up to 90%. The mixture then flows to secondary clarifiers where solids settle as secondary sludge. Some of this sludge gets recycled to maintain bacterial populations.

Tertiary treatment: UV, ozone, and chlorine disinfection

Advanced tertiary treatment kills remaining pathogens through disinfection. Ultraviolet light at 254 nm disrupts microbial DNA in 20-30 seconds. Ozone treatment works 3,000 times better than chlorine and needs 10-30 minutes of contact time. Chlorine disinfection adds 15-25 mg/L to secondarily treated wastewater. SUSBIO ECOTREAT, India’s most advanced packaged STP, uses triple-layer disinfection that combines UV, ozone, and optional chlorination to control hospital-grade pathogens.

Final discharge or reuse: Treated water applications

The purified water meets regulatory standards before discharge or reuse. People can use treated effluent for gardening, landscaping, toilet flushing, floor washing, and cooling systems. This reduces freshwater consumption by up to 80%.

Critical Safety Standards for Hospital STPs

Proper sewage management in hospitals is the foundation of environmental protection across India. Healthcare facilities must follow strict standards that prevent contamination and safeguard public health.

CPCB and WHO compliance requirements

The Central Pollution Control Board (CPCB) created a detailed framework for hospital STPs under the Water (Prevention and Control of Pollution) Act, 1974, and the Environment Protection Act, 1986. WHO’s “Safe Management of Wastes from Health-Care Activities” bans hospitals from releasing hazardous substances like photo-chemicals, aldehydes, and pharmaceuticals directly into sewer systems. The National Green Tribunal makes sure hospitals follow these rules through heavy penalties. Hospitals that break these rules face substantial fines, closure orders, and might lose their accreditation.

Effluent quality parameters: BOD, COD, TSS, TN

Hospitals must ensure their effluents meet these quality standards before discharge:

- pH: 6.5–8.5

- BOD (Biochemical Oxygen Demand): <10 mg/L

- COD (Chemical Oxygen Demand): <50 mg/L

- TSS (Total Suspended Solids): <10 mg/L

- Total Nitrogen (TN): <5 mg/L

- Fecal Coliform: <100 MPN/100mL

These parameters help verify that treated water is safe for release into water bodies or reuse systems. The BOD/COD ratio shows biodegradability levels, and hospital wastewater typically has a lower ratio than municipal sewage.

Disinfection protocols for pathogen removal

Proper disinfection plays a vital role since hospital effluent contains many pathogens. Standard disinfection methods include:

- Chlorination: Needs 15-25 mg/L dosage for secondary treated wastewater

- Ultraviolet (UV) irradiation: Works best at 254 nm wavelength

- Ozonation: Requires 10-15 minutes contact time with 15-20 mg/L concentration

SUSBIO ECOTREAT leads India’s packaged STP market with its triple-layer disinfection system that combines these technologies to eliminate pathogens effectively.

STP plant full form and regulatory documentation

STP stands for Sewage Treatment Plant. Required regulatory documents include:

- Online monitoring systems that track BOD, COD, TSS, flow, and pH

- “Danger” signs placed around STPs for safety

- Warning labels that read “water not appropriate for drinking” on reused water outlets

Regulations specify that sensor systems should use communication protocols like RS 485 with Modbus to ensure accurate monitoring and reporting.

Choosing the Right STP for Your Hospital

Hospitals need to think about many factors when choosing a sewage treatment plant. This helps them meet regulations and get the best performance.

Sewage treatment plant for small hospitals vs large facilities

The size of a hospital plays a big role in picking the right STP. Small hospitals with up to 50 beds create 1,000-5,000 liters of wastewater each day. They need compact, budget-friendly systems. Large facilities with more than 50 beds produce 5,000-50,000 liters daily. These need more complex treatment systems with multiple stages. To cite an instance, a 100-bed hospital creates about 40,000-50,000 liters daily (40-50 KLD). These differences in volume help decide the capacity needs, technology choice, and space requirements.

Packaged STP vs custom-built systems

Healthcare facilities get many benefits from packaged STPs. This is especially true when space is tight. These pre-made units come ready to install and cut setup time from months to days. They take up very little space and work great in hospital basements or utility yards. But facilities with complex wastewater makeup or changing volumes still do better with custom-built systems.

Maintenance and monitoring best practices

STPs work best with careful maintenance that includes:

- Regular checks of pH, BOD, COD, and microbial counts

- Removing sludge every month or quarter

- Checking blowers, pumps, and sensors often

- Keeping detailed records for audits

Annual Maintenance Contracts (AMCs) are a great way to get help when hospitals don’t have technical experts on staff.

SUSBIO ECOTREAT: India’s most advanced packaged STP

SUSBIO ECOTREAT stands out with its innovative dual treatment process. It uses both anaerobic and aerobic methods. The system’s prefab, modular design makes installation quick and needs less space. Users save up to 90% on energy costs compared to regular STPs. The system runs quietly without any smell, which makes it perfect for hospitals. Its FRP construction lasts long and meets or beats all discharge standards.

Conclusion

Hospital sewage treatment plays a vital role in healthcare infrastructure beyond meeting regulations. This piece explores the real importance of proper wastewater management in hospitals. Medical facility wastewater contains everything from pharmaceutical residues to biological hazards, which makes specialized treatment necessary to protect both the environment and public health.

The multi-stage treatment process will give a complete solution that works well. Each stage targets specific contaminants in hospital wastewater, starting from preliminary screening and moving through tertiary disinfection. This methodical process removes harmful substances before water returns to the environment or gets reused within the hospital premises.

CPCB and WHO’s standards are 15 years old, and with good reason too. BOD, COD, TSS and pathogen levels must stay within strict limits to stop water contamination and disease spread. Healthcare facilities that fail to meet these standards harm the environment and risk heavy penalties along with reputation damage.

A hospital’s size affects its STP needs, so proper planning becomes crucial. Small hospitals need compact, quick systems while larger facilities require sophisticated treatment setups to handle bigger volumes. Space-constrained settings benefit from packaged STPs, though custom-built systems work better in certain cases.

SUSBIO ECOTREAT leads India’s packaged STP market with its advanced technology. Its dual-treatment technology, energy efficiency, and small footprint make it an ideal choice especially when you have modern healthcare facilities looking for environmentally responsible waste management options.

Regular monitoring and strict safety protocols help maintain long-term STP performance. Proper sewage treatment substantially pays off through environmental protection, regulatory compliance, and potential water reuse benefits. Modern healthcare facilities keep expanding their services, and their responsibility to manage wastewater safely grows too – a challenge that modern STP solutions like SUSBIO ECOTREAT handle effectively.

Key Takeaways

Hospital sewage treatment is a critical safety requirement that protects both public health and the environment from hazardous medical waste contamination.

- Hospital wastewater contains dangerous pathogens, pharmaceuticals, and heavy metals—making it 5-15 times more toxic than regular sewage

- Multi-stage STP processes (pre-treatment, primary, secondary, tertiary) systematically remove contaminants and achieve 90% pollutant reduction

- CPCB compliance requires strict effluent parameters: BOD <10 mg/L, COD <50 mg/L, TSS <10 mg/L with mandatory disinfection protocols

- Hospital size determines STP needs: small facilities (50 beds) need 1,000-5,000L capacity while larger hospitals require 5,000-50,000L systems

- Advanced packaged STPs like SUSBIO ECOTREAT offer 90% energy savings, rapid installation, and triple-layer disinfection for superior performance

Proper hospital STP implementation not only ensures regulatory compliance but also enables water reuse for non-potable applications, reducing freshwater consumption by up to 80% while safeguarding community health from antimicrobial resistance and waterborne diseases.

Frequently Asked Questions

Q1. What is the primary purpose of a Sewage Treatment Plant (STP) in hospitals?

An STP in hospitals serves to treat wastewater, reducing water pollution and enabling the reuse of treated water for non-potable applications. It also demonstrates the hospital’s commitment to environmental responsibility and helps protect water resources.

Q2. How does hospital sewage differ from regular domestic sewage?

Hospital sewage is significantly more hazardous, containing a complex mixture of pathogens, pharmaceuticals, and heavy metals. It can be 5-15 times more toxic than regular domestic sewage, requiring specialized treatment processes.

Q3. What are the key stages in a hospital sewage treatment process?

The hospital sewage treatment process typically involves four main stages: pre-treatment (screening and grit removal), primary treatment (sedimentation), secondary treatment (biological processes), and tertiary treatment (advanced disinfection).

Q4. What are the critical effluent quality parameters that hospital STPs must meet?

Hospital STPs must ensure their treated effluent meets strict quality parameters set by regulatory bodies. These include BOD <10 mg/L, COD <50 mg/L, TSS <10 mg/L, and proper disinfection to remove pathogens.

Q5. How do STP requirements differ for small versus large hospitals?

STP requirements vary based on hospital size. Small hospitals (up to 50 beds) typically need systems capable of treating 1,000-5,000 liters daily, while larger facilities may require systems handling 5,000-50,000 liters or more per day.