Sewage treatment plants aboard ships protect our oceans by preventing untreated waste contamination. Space limitations on vessels mean sewage can’t be stored long and must be discharged into the sea. Maritime regulations strictly control this process – ships must release treated sewage at least 4 nautical miles from land, while untreated waste requires a minimum distance of 12 nautical miles.

Ships need proper equipment and must follow global standards to manage sewage effectively. The system’s working principle relies on aerobic bacteria that break down raw sewage. This biological treatment has become the preferred method for most vessels. The system acts as an environmental safeguard that cleans wastewater before ocean release and protects sailors from maritime diseases. This piece details the sewage treatment plant’s components, including its four main chambers – Primary, Aeration, Settling, and Chlorination. The text also covers maintenance needs and regulatory frameworks like IMO MARPOL Annex IV that govern these vital systems.

What is a Sewage Treatment Plant on Ship?

Ships need Sewage Treatment Plants (STPs) to clean wastewater before releasing it back into the ocean. These systems work within tight space limits on vessels but must still meet strict international standards for water quality and discharge.

Definition and purpose of STP

Marine Sewage Treatment Plants clean contaminated water from toilets, showers, and other sources aboard ships. These systems reduce pollutants, kill harmful organisms, and make sure the discharge meets maritime regulations.

MARPOL Annex IV gives ships three options: an approved sewage treatment plant, a sewage grinding and disinfecting system, or a sewage holding tank. Most vessels choose treatment plants because they work better than holding tanks that need frequent emptying.

Marine STPs speed up how nature cleans water. These well-designed systems protect ocean ecosystems from harmful substances. Without them, pathogens, nutrients, detergents, pesticides, and heavy metals would create big risks to the environment and health.

Difference between blackwater and greywater handling

The difference between wastewater types plays a crucial role in proper treatment:

Blackwater comes from toilets and urinals, containing fecal matter, urine, and other biological contaminants. This waste poses serious risks due to its pathogen content. Maritime law prohibits untreated discharge within 12 nautical miles from land.

Greywater comes from showers, sinks, washing machines, galleys, and laundry facilities. Though cleaner than blackwater, it still contains chemicals, soaps, fats, and food particles that can harm marine life if released untreated.

Each type needs its own treatment approach. Blackwater needs more processing because it contains infectious materials and environmental hazards. Greywater often takes a different path to dedicated holding tanks or, where allowed, direct discharge.

Why biological treatment is preferred onboard

Ships choose biological treatment as their main method to handle sewage for several good reasons:

These systems use natural microorganisms to break down sewage contaminants. The process works like natural decomposition but happens much faster in a controlled space.

Aerobic bacterial treatment needs oxygen and produces much less harmful byproducts than anaerobic methods. While anaerobic bacteria can break down sewage, they create dangerous gasses like hydrogen sulfide and methane that pose safety and environmental risks.

Biological systems work well with extended aeration activated sludge processes. Sewage stays in aeration chambers for 18-24 hours, which creates conditions where bacteria outnumber their food supply. This setup reduces sludge buildup – a huge benefit in tight ship spaces.

Today’s biological STPs work in three stages: they remove large solids first, then use microorganisms to digest organic matter, and finally clarify and disinfect the water for safe discharge. This detailed process meets international standards without heavy chemical use, making it the best choice for ships.

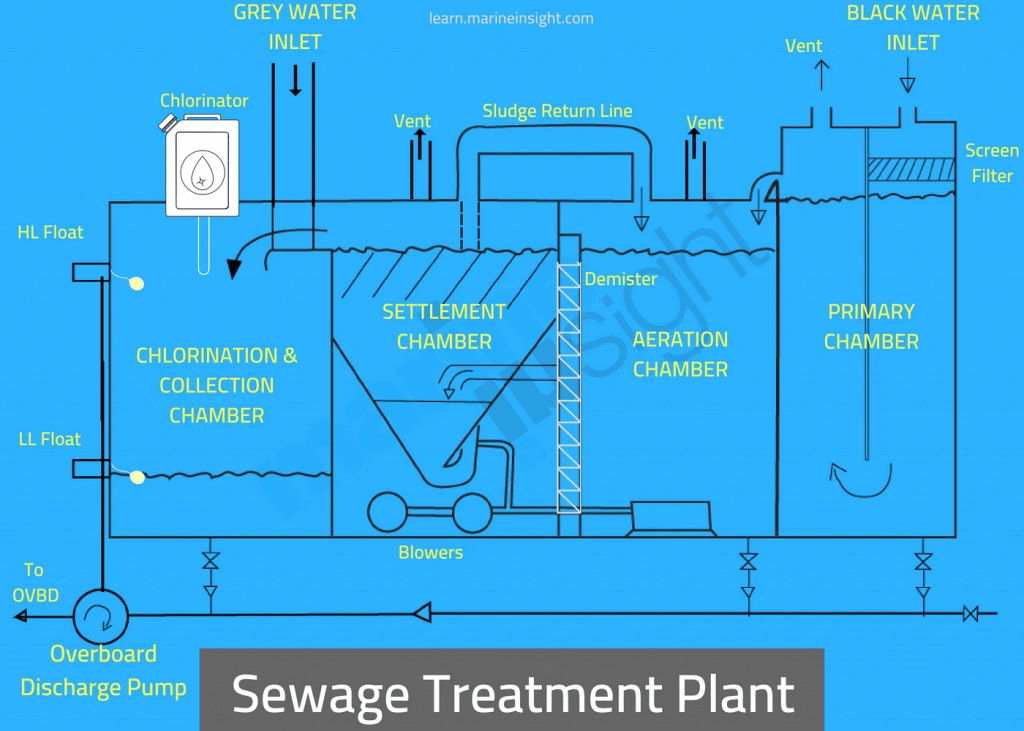

Core Components of Marine STP Systems

Marine sewage treatment plants have several integrated components that work together to turn raw waste into environmentally safe effluent. Each element has a specific role in the treatment chain. The system meets international discharge standards through a detailed process.

Collection System and Inlet Piping

The collection system works as the original component that moves sewage from sources to the treatment plant. Modern vessels use vacuum systems to move waste through the network. This system gives several advantages:

- The vacuum exists only in the piping network while collection points stay at atmospheric pressure until activated

- Each toilet connects to vacuum piping through valves that open only during flushing

- Specialized jet pumps connected to a central manifold create suction that pulls waste through the system

- These systems work great for marine applications because they use very little water

The system’s efficiency depends on proper inlet piping design. The gray water inlet pipe must stay below the water level inside the treatment plant to keep foam from forming. The inlet pipes also need proper slopes to stop clogging and condensation.

Treatment Tanks and Biofilters

The sewage moves into multiple treatment chambers where the actual cleaning happens. The biofilter reactor leads this phase and sits at the core of the biological treatment process.

Biofilters contain media where colonies of aerobic bacteria grow and break down organic matter. Blowers supply fine air bubbles that spread contaminants and help bacterial action. The sewage stays in extended aeration for 18-24 hours. This is a big deal as it means that bacterial populations grow larger than their available food supply, which reduces sludge buildup.

Treatment tanks have:

- Screening chamber with mesh filters to remove non-sewage materials

- Aeration chamber containing the biofilter reactor

- Sedimentation tank for settling solids

- Activated carbon chamber for removing Chemical Oxygen Demand

Activated carbon is vital in treating both Biological Oxygen Demand and suspended solids through filtration and absorption.

Disinfection Units: Chlorine and UV

The final treatment phase kills remaining pathogens through disinfection. Marine STPs usually use either chlorination or ultraviolet radiation.

Chlorination systems come in two main types. Tablet-based chlorinators let clean water touch chlorine tablets directly to form a disinfection solution. Chemical injection systems use diaphragm-type reciprocating pumps to add measured amounts of sodium hypochlorite to the sterilization tank.

UV disinfection offers a chemical-free option that avoids handling dangerous substances and removes concerns about leftover chlorine in discharged effluent. All the same, these systems need more complex equipment and use more power.

Float Switches and Discharge Pumps

Automated control systems ensure smooth operation throughout the treatment process. Float switches monitor liquid levels and trigger responses when needed.

Most installations use three float switches in the chlorination chamber: high level, low level, and high alarm level. These electromechanical devices move with liquid levels and control pump operation automatically to prevent overflow.

The discharge system uses duplex centrifugal pumps mounted on the final compartment. These non-clog pumps work mainly in automatic mode, controlled by level switches. The discharge pipe has a non-return valve and sits 200-300mm below the light water line to stop backflow.

A working float switch system helps in many ways. It makes pumps last longer by preventing dry runs and reduces the need for manual monitoring.

Sewage Treatment Plant Working Principle Explained

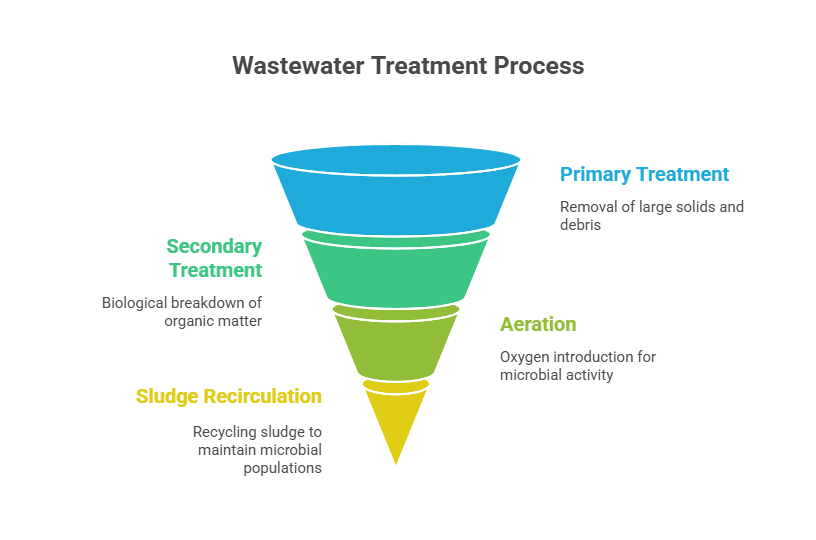

Ships use a three-stage process to clean sewage water until it’s safe to discharge. The system works through progressive purification stages that meet environmental standards. Let’s look at how these processes work together to keep our oceans clean.

Primary Treatment: Screening and sedimentation

Raw sewage first passes through coarse mesh filters that catch large solids and debris. This first step is crucial because it stops equipment from clogging and helps process wastewater smoothly. The system uses bar screens spaced 15-25 millimeters apart to catch items like rags, plastic, and other unwanted objects.

The wastewater moves to a comminutor that grinds and shreds any remaining debris. Breaking down sewage into smaller pieces creates more surface area for bacteria to work on. This stage manages to keep about 60% of total suspended solids and 35% of biochemical oxygen demand.

Next, the water sits in sedimentation tanks or primary clarifiers for about two hours. During this time, gravity pulls solids down while lighter materials float up where skimmers can remove them.

Secondary Treatment: Aerobic bacterial digestion

The biological degradation phase is where the real cleaning happens, usually through an activated sludge system. Aerobic bacteria that just need oxygen break down organic matter in the wastewater. This happens in an aerated chamber where blowers push air through diffusers. The fine bubbles that form help transfer more oxygen.

The system needs air pressure between 0.3-0.4 bars to mix everything properly and help decomposition through bubble movement. Sewage stays in this extended aeration process for 18-24 hours. This is a big deal as it means that bacterial populations grow larger than their food supply. So some bacteria die and become food for others, which helps reduce sludge buildup.

The mixture flows into settling tanks where clean water separates from the activated sludge. Clear water rises while heavier solids sink. The settled sludge contains helpful bacteria that return to the aeration chamber through an air lift. This seeds new sewage with active microorganisms.

Final Treatment: Chlorination and effluent discharge

The last cleaning stage kills any remaining harmful organisms like E. coli bacteria. Clear liquid from settling tanks goes through a chlorination chamber. It stays there for at least 60 minutes to ensure proper treatment.

Some ships use ultraviolet radiation instead of chemical chlorination. The cleaned water can then safely discharge according to maritime rules. Float switches turn discharge pumps on automatically when water levels get too high.

This natural biological process turns raw sewage into clean water that won’t harm marine life. Ships can operate efficiently without storing large amounts of waste while protecting our oceans.

SUSBIO ECOTREAT – Advanced MBBR Marine Sewage Treatment Plant

SUSBIO ECOTREAT is a next-generation MBBR-based marine sewage treatment plant designed to meet the demanding wastewater treatment needs of ships, offshore platforms, cruise liners, and marine vessels. Engineered with modular FRP construction and an advanced dual-stage biological treatment process, SUSBIO ECOTREAT delivers high-quality treated effluent, low operating cost, and full compliance with MARPOL Annex IV regulations.

Built for harsh marine environments, SUSBIO ECOTREAT provides a corrosion-resistant, vibration-tolerant, and long-life solution that outperforms conventional shipboard sewage treatment systems.

Modular & Plug-and-Play Design for Ships and Offshore Installations

SUSBIO ECOTREAT is supplied as a prefabricated, modular marine STP, making it ideal for both new vessel construction and retrofit projects. The lightweight fiber-reinforced plastic (FRP) tanks allow easy installation in limited onboard spaces such as engine rooms, technical decks, and service compartments.

Unlike RCC or steel-fabricated sewage plants, SUSBIO ECOTREAT requires no heavy civil work, welding, or structural modification, enabling fast dry-dock installation, minimal downtime, and lower installation cost. The system can be easily expanded by adding modules when vessel capacity increases.

Advanced MBBR Technology for Marine Wastewater Treatment

SUSBIO ECOTREAT is based on Moving Bed Biofilm Reactor (MBBR) technology, one of the most reliable biological treatment processes used in modern marine and decentralized wastewater systems.

The treatment process includes:

Anaerobic treatment to reduce high organic load

Aerobic MBBR reactors filled with high-surface-area bio media

Active biofilm growth that breaks down organic pollutants efficiently

Final clarification and filtration for clean effluent

The moving bio media inside the reactor creates a stable and shock-resistant biological system, allowing the plant to perform consistently even when passenger loads fluctuate — a common challenge on ships and offshore vessels.

High-Quality Treated Water Without Membrane Complexity

SUSBIO ECOTREAT delivers very low BOD, COD, and TSS levels through its advanced MBBR and polishing stages, producing clear, odor-free treated water suitable for MARPOL-compliant overboard discharge or non-potable reuse onboard.

Unlike membrane-based MBR systems, SUSBIO ECOTREAT:

Has no membrane fouling risk

Requires no membrane replacement

Has lower operating and maintenance cost

Is more reliable for marine conditions

This makes it an ideal solution for ship owners seeking high effluent quality with long-term operational stability.

Low-Maintenance, Fully Automatic Operation

SUSBIO ECOTREAT is designed for hands-off operation, making it ideal for marine crews. The system features:

Automated aeration and biological process control

No routine chemical dosing for biological treatment

Self-sustaining biofilm activity

Simple monitoring and alarm systems

This reduces manpower dependency, crew workload, and operational risk, ensuring smooth and reliable wastewater treatment throughout voyages.

Designed for MARPOL Annex IV Compliance

SUSBIO ECOTREAT is engineered to meet MARPOL Annex IV and IMO sewage discharge standards, allowing ships equipped with the system to safely discharge treated sewage in international waters, ports, and coastal areas, subject to regulatory limits.

The system helps ship owners remain compliant while protecting marine ecosystems from pollution, making it ideal for commercial vessels, cruise ships, offshore rigs, and luxury yachts.

Why SUSBIO ECOTREAT is the Best Marine STP

SUSBIO ECOTREAT stands out as one of the best sewage treatment plants for marine applications because it combines:

Proven MBBR biological technology

Compact and modular shipboard design

Low energy and maintenance cost

No membranes or chemical dependency

Fast installation and easy retrofitting

Marine-grade FRP construction

MARPOL and IMO compliance

For ship owners, operators, and designers looking for a reliable, future-ready, and cost-effective marine sewage treatment plant, SUSBIO ECOTREAT delivers unmatched performance and long-term value.

Regulations, Capacity, and Maintenance Considerations

Ships with sewage systems must comply with international maritime laws. These laws create a structure to manage wastewater at sea. This protects marine environments and helps ships run efficiently.

MARPOL Annex IV and IMO guidelines

MARPOL Annex IV governs international maritime sewage regulations. The rules apply to ships of 400 GT and above or vessels that carry more than 15 people. Ships have three legal options to discharge sewage. They can use an approved treatment plant, discharge processed sewage beyond 3 nautical miles from land, or release untreated sewage at least 12 nautical miles offshore. The Baltic Sea has special status and needs stricter standards. Passenger vessels there must meet higher requirements to remove nitrogen and phosphorus.

Sewage treatment plant capacity calculation for ships

The right size of marine sewage systems matters a lot. Passenger ships on trips longer than 24 hours need specific flow rates. Traditional systems use 70 liters per person daily, while vacuum systems need 25 liters. Systems handling both sewage and gray water require more capacity. They need 230 liters and 185 liters per person daily. Authorities can adjust these numbers for shorter trips or when ships use systems that need less water.

Routine maintenance and crew training

Daily checks of pressure levels are essential. The team should monitor sludge content weekly and verify proper air lift return. Adding bio-pac with aerobic bacteria weekly helps the system work better. The internal coatings need regular inspection for damage. High and low-level limit switches that control discharge pumps need verification too. IMO Resolution MEPC.227(64) states that “ship staff training should include familiarization in the operation and maintenance of the sewage treatment plant”.

Record-keeping for port inspections

Port State Control inspections need detailed documentation. Ships must track all discharge operations, including location and volume. They also need maintenance records, effluent testing results, and system malfunction reports. The International Sewage Pollution Prevention Certificate (ISPP) shows compliance with global standards. Ships must keep waste delivery receipts from ports for at least two years. New MARPOL Annex IV guidelines will soon require all ships to have a Sewage Management Plan (SMP). Surveyors will check this during inspections.

Conclusion

Marine sewage treatment plays a vital role in protecting the environment during maritime operations. This piece explores how marine STPs work as key systems that keep untreated waste from harming our oceans and help ships follow international rules. The four-chamber design gives us a complete approach to handle wastewater within limited vessel space. These chambers – Primary, Aeration, Settling, and Chlorination – work together seamlessly.

SUSBIO ECOTREAT stands out as an innovative solution for marine sewage treatment. The system uses advanced Membrane Bioreactor technology that combines anaerobic and aerobic treatment methods. Waste goes through an automatic screen press and moves to the bioreactor where active biomass breaks down organic materials. The membrane modules then filter the treated water until it’s crystal clear before discharge. This process creates superior quality effluent without chemicals and uses way less power than regular systems.

Ships today benefit from SUSBIO ECOTREAT’s modular, lightweight FRP construction. You can easily install it in both new builds and when you modernize older vessels. It also runs automatically, so you don’t need dedicated operators. This cuts down on crew training and maintenance needs. The system works without chemical dosing, which keeps marine ecosystems safe from harmful by-products like trihalomethanes.

Every vessel with sewage systems must comply with MARPOL Annex IV, especially when operating in Special Areas like the Baltic Sea. System selection depends on careful sizing calculations based on voyage length and passenger count. Your crew’s training, regular maintenance, and detailed record-keeping are great ways to get through port inspections and keep operations running smoothly.

Biological sewage treatment goes beyond just following rules – it’s an eco-friendly approach that copies nature’s own processes to protect our oceans. Aerobic bacterial digestion produces fewer dangerous byproducts than anaerobic methods, making these systems safer for crews and marine life. Space might be tight on ships, but sewage treatment plants work better than simple holding tanks that you need to empty often.

Ship-based sewage treatment will keep evolving as rules get stricter and environmental awareness grows. Chemical-free technologies like SUSBIO ECOTREAT show us how maritime operations can stay efficient while reducing their effect on the environment. Protecting our oceans takes both advanced technology and people’s steadfast dedication to running and maintaining these crucial systems properly.

Key Takeaways

Marine sewage treatment plants are critical environmental protection systems that transform raw waste into safe effluent while ensuring regulatory compliance and operational efficiency aboard vessels.

• Marine STPs use biological treatment with aerobic bacteria to break down sewage in four chambers: Primary, Aeration, Settling, and Chlorination for comprehensive waste processing.

• MARPOL Annex IV requires vessels over 400 GT to have approved treatment plants, allowing treated sewage discharge 4+ nautical miles from land versus 12+ miles for untreated waste.

• Modern systems like SUSBIO ECOTREAT eliminate chemical dosing, reduce power consumption by 90%, and use MBR technology for superior effluent quality without environmental hazards.

• Proper capacity calculation uses 70L/person daily for conventional systems or 25L for vacuum systems, with regular maintenance and crew training essential for compliance.

• Biological treatment is preferred over chemical methods as it produces fewer hazardous byproducts, mimics natural processes, and provides safer operation for both crews and marine ecosystems.

The shift toward chemical-free, automated sewage treatment systems represents the future of maritime waste management, balancing operational efficiency with environmental responsibility while meeting increasingly strict international regulations.

Frequently Asked Questions

Q1. What is the purpose of a sewage treatment plant on a ship?

A sewage treatment plant on a ship processes and cleans wastewater before it’s discharged into the marine environment. It reduces pollutants, eliminates pathogens, and ensures safe discharge that complies with maritime regulations, protecting marine ecosystems from harmful substances.

Q2. How does a marine sewage treatment plant work?

Marine sewage treatment plants typically use a three-stage process: primary treatment (screening and sedimentation), secondary treatment (aerobic bacterial digestion), and final treatment (disinfection). This process transforms raw sewage into environmentally acceptable effluent through natural biological processes accelerated in a controlled environment.

Q3. What are the key components of a marine sewage treatment system?

The core components include a collection system and inlet piping, treatment tanks with biofilters, disinfection units (using chlorine or UV radiation), and float switches and discharge pumps. These elements work together to collect, process, and safely discharge treated wastewater.

Q4. How does MARPOL Annex IV regulate sewage discharge from ships?

MARPOL Annex IV applies to ships of 400 GT and above or vessels certified to carry more than 15 persons. It allows three options for sewage discharge: using an approved treatment plant, discharging comminuted and disinfected sewage beyond 3 nautical miles from land, or releasing untreated sewage at least 12 nautical miles offshore.

Q5. What are the advantages of modern sewage treatment systems like SUSBIO ECOTREAT?

Modern systems like SUSBIO ECOTREAT offer several benefits, including chemical-free operation, reduced power consumption, superior effluent quality through advanced MBR technology, and compliance with strict international regulations. They also feature modular designs for easy installation in both new builds and retrofits, and require less maintenance and crew training.