The cost of an STP treatment plant varies substantially based on its capacity and use. A small residential STP with 5-10 KLD capacity costs between ₹1.75-3 lakhs, while industrial-scale systems can cost more than ₹2 crore. These numbers show why you need careful planning before investing in wastewater treatment infrastructure.

Industrial Wastewater Treatment has become a requirement, not a choice, as cities grow and environmental rules get stricter. Industrial areas, from automotive to pharmaceuticals and food processing, create large amounts of wastewater that needs proper treatment. Without treatment, this waste creates serious environmental and health risks like water pollution and soil contamination. The sewage plant treatment happens in three stages: Primary Treatment removes solid waste, Secondary Treatment eliminates organic matter, and Tertiary Treatment handles advanced purification.

This piece will get into the complete sewage treatment plant cost breakdown and what affects pricing. You’ll learn the quickest way to pick the right STP sewage treatment plant that fits your industry’s needs. It also looks at advanced technologies that will change the Wastewater Treatment Plant world in 2026. This knowledge will help you balance compliance, efficiency, and long-term operational costs.

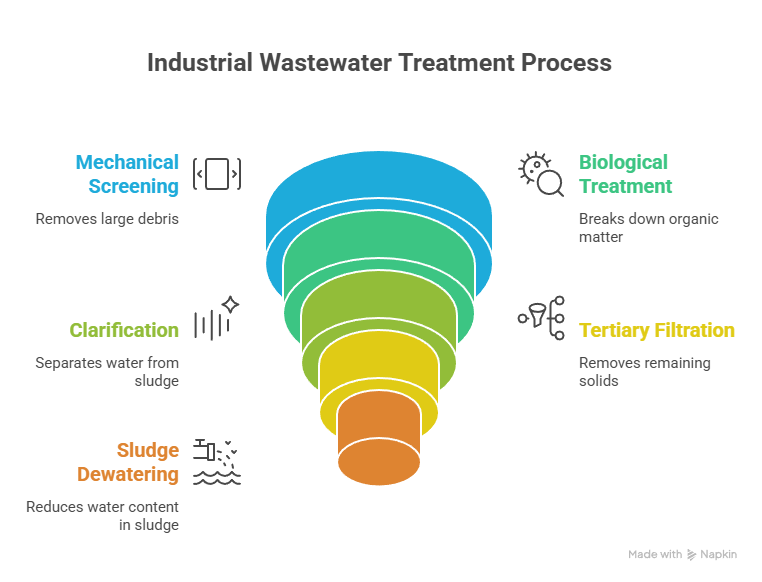

Step-by-Step Breakdown of Industrial Wastewater Treatment Process

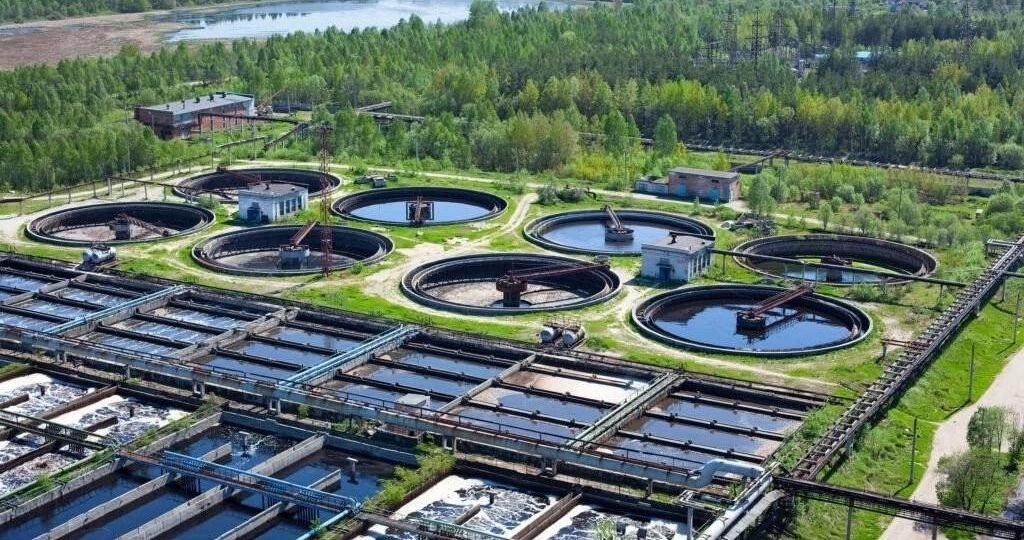

Industrial wastewater treatment uses specialized processes that remove contaminants from effluent before safe discharge or reuse. You need to understand each treatment stage to create effective solutions in 2026 and beyond.

Stage 1: Mechanical Screening and Grit Removal

The first step at any industrial wastewater treatment plant removes large physical contaminants. The treatment starts as wastewater flows through screens with openings typically ranging from 6 to 38 mm (0.25 to 1.5 inches) that catch rags, paper, plastics, and large debris. The water then moves to grit chambers where heavier particles like sand, gravel, and small stones settle at the bottom through gravity.

The original screening protects downstream equipment from physical damage and stops pipes and mechanical components from clogging. Industry standards show that proper grit removal can extract approximately 60 liters of grit trap material per 1,000 m³ of processed wastewater.

Stage 2: Biological Treatment via Aeration or Biofilm

The wastewater goes through biological treatment after physical screening to break down organic matter and remove nutrients like nitrogen and phosphorus. This stage employs bacteria and microorganisms to degrade organic contaminants.

Two main approaches work for this stage:

Activated Sludge Systems – Wastewater stays in tanks under varying oxygen conditions (aerobic, anoxic, anaerobic) where bacteria consume organic matter. This process creates a biological floc containing oxidized materials.

Biofilm Media Technologies – These systems use fixed media where microorganisms attach and grow, creating a biofilm that treats water as it flows past. Fixed rope media technology showed removal rates of 0.23±0.15 to 0.38±0.26 gNH₃-N/m²·d for ammonia and 1.35±0.95 to 3.05±1.21 gCOD/m²·d for COD.

Biofilm-mediated systems have become popular because of their economic benefits and environmental friendliness.

Stage 3: Clarification and Sludge Separation

Clarification separates treated water from biomass as it settles by gravity in specialized tanks. These clarifiers serve three main functions: they produce clarified effluent (with suspended solids below 20-30 mg/L), concentrate sludge for recirculation, and store extra sludge during hydraulic overloads.

Primary clarifiers remove about 60% of suspended solids and 30-40% of Biological Oxygen Demand. Secondary clarifiers, which sit after biological treatment, separate microbial biomass from treated water and return activated sludge to maintain proper concentrations in bioreactors.

The clarifier’s performance depends on the tank’s surface area, sidewater depth, and sludge recirculation rate.

Stage 4: Tertiary Filtration and Disinfection

Tertiary treatment improves water quality through advanced filtration and disinfection. This stage removes remaining suspended solids (usually to 5-10 mg/L), residual phosphorus and nitrogen components, and reduces microbial load.

Common tertiary filtration methods include:

- Surface filtration – Using two-dimensional filter media like micro-net cloth filters

- Depth filtration – Using granular material beds such as sand filters

- Membrane filtration – Using pressure-driven systems with hollow fibers or composite sheets

Facilities use chlorine, UV radiation, or ozonation to destroy pathogens before final discharge.

Stage 5: Sludge Dewatering and Disposal

The last stage deals with sludge byproducts. Raw sewage sludge contains only 1-5% solids while water makes up 95-99% of its volume. Dewatering cuts this water content, which reduces transportation costs and makes disposal or reuse easier.

Several dewatering options exist:

- Mechanical presses (filter presses, belt presses)

- Centrifuge systems

- Sludge dewatering bags

- Drying beds

Proper dewatering cuts disposal costs and helps recover resources through agricultural applications or energy production from treated biosolids.

Advanced Equipment and Technologies in 2026

Industrial facilities have transformed their treatment options thanks to major technological breakthroughs in wastewater management since the 1990s. The specialized equipment solutions of 2026 show remarkable results in industrial applications.

Submersible Mixers for Homogeneous Treatment

Modern industrial wastewater treatment systems rely heavily on stainless steel submersible mixers. These units create powerful axial flow that keeps solids suspended and distributes oxygen throughout treatment tanks while preventing sedimentation. The latest models with IE3/IE4 motors can substantially cut energy use without compromising performance. These mixers work great for various tasks like agitating, blending, and dissolving solids in both municipal and industrial settings.

New mixer designs come with propeller sizes from 181mm to 600mm and power capacities between 0.75kW to 14kW. This range makes them perfect for multiple treatment stages, particularly in biological processes where consistent mixing matters most.

Membrane Bioreactors (MBR) for Space-Constrained Sites

MBR technology has revolutionized treatment options for industrial facilities with space limitations. These systems combine biological treatment with membrane filtration and need 30-40% less space than traditional methods. MBRs excel at treatment efficiency and come in two main setups:

- Submerged membrane bioreactors where membranes sit directly in the biological reactor

- Side-stream configurations with membranes outside the bioreactor

Today’s MBR systems handle heavy metals and complex industrial wastewaters with ease, producing high-quality effluent you can reuse. Urban developments and facility updates benefit from their compact design when space is tight.

Ultrafiltration and Reverse Osmosis for Tertiary Treatment

Ultrafiltration (UF) has proven itself as a budget-friendly option for tertiary treatment over the years. These systems remove particles as small as 0.01 microns to ensure excellent water quality. Research shows UF systems maintain steady filtration performance whatever the temperature changes or feed water quality variations.

Reverse osmosis (RO) works alongside UF systems by filtering out dissolved substances through a semipermeable membrane with tiny 0.0001-micron pores. A typical RO system has:

- Pretreatment components (sand filtration, carbon filtration)

- High-pressure pumps

- Membrane assembly units

- Post-treatment systems for pH adjustment and remineralization

Smart Sensors and IoT for Real-Time Monitoring

Industrial facilities now use IoT-based monitoring systems to track key parameters like pH, dissolved oxygen, electrical conductivity, total dissolved solids, turbidity, and temperature continuously. These systems use layered architectures with sensing, edge, and application layers to process data comprehensively.

By 2026, facilities will depend on cloud-based performance dashboards and remote system access that send automated alerts when problems arise. This technology spots potential issues like pump wear and fouling risks before they cause failures.

Pre-Treatment and Filtration Optimization Strategies

Pre-treatment is the foundation of any successful industrial wastewater treatment system. These original processes protect downstream equipment from damage and help the system last longer.

Coarse Filtration to Prevent Membrane Fouling

Membrane fouling happens when deposits build up on membrane surfaces and remains a constant challenge in wastewater treatment. Coarse filtration removes larger particles that would clog membrane pores. This vital step protects sensitive downstream components, especially in systems that use Nanofiltration (NF) and Reverse Osmosis (RO) membranes which have much smaller pores than Microfiltration (MF) or Ultrafiltration (UF) systems.

Modern stp treatment plants use several strategies for coarse filtration like screening, sedimentation, and media filtration. These processes catch larger particles before they reach membrane surfaces and maintain steady flow rates throughout the system.

Chemical Conditioning with Coagulants and Flocculants

Chemical conditioning is another vital pre-treatment strategy. Coagulation neutralizes suspended particles’ charges to destabilize them, while flocculation helps particles bind into larger, settleable flocs. These processes together can reduce suspended solids and organic loads by up to 90%.

Coagulants fall into two categories:

- Organic coagulants (PolyAMINEs, PolyDADMACs): Need lower dosages, create less sludge, and don’t affect pH

- Inorganic coagulants (aluminum sulfate, ferric chloride): Usually more affordable and work well with low-turbidity water

You need to pick the right type based on wastewater characteristics, and jar testing helps determine the best types and concentrations.

Cartridge Filters: Melt-Blown vs Pleated

Cartridge filters provide vital final-stage filtration in industrial wastewater systems. Melt-blown and pleated cartridges each have their advantages depending on what you need them for.

Pleated filters have a design that maximizes surface area, so they can trap more particles before clogging. These filters work better than alternatives with micron ratings from 0.5 to 75. A 40″ high-flow pleated filter can handle 30m³/h compared to just 2m³/h for similar melt-blown options.

Melt-blown cartridges are great at catching particles of different shapes and sizes because of their depth-filtration properties. They cost less upfront, but pleated filters often save more money in the long run because they last longer.

Impact of Pre-Treatment on Membrane Lifespan

Good pre-treatment helps membranes last longer. This means fewer replacements, less waste, and big operational savings.

Good pre-treatment systems keep membranes from fouling by removing suspended solids, reducing hardness, and getting rid of performance-impairing contaminants. Industries can save more water and improve their water recovery rates by using detailed pre-treatment strategies.

SUSBIO ECOTREAT: Industry-Leading Modular STP System

SUSBIO ECOTREAT emerges as a complete solution for industrial wastewater management in 2026. The advanced modular STP treatment plant sets itself apart by combining innovative design with innovative technology to deliver exceptional performance in a variety of industrial applications.

Compact Design with 30–40% Smaller Footprint

SUSBIO ECOTREAT’s modular design reduces spatial requirements significantly and occupies 30-40% less space than traditional sewage treatment plants. Space efficiency is a great way to get value for urban industrial facilities where land availability costs more. The system’s high-quality fiber-reinforced plastic (FRP) construction provides exceptional durability while staying lightweight and corrosion-resistant. Teams can install pre-engineered units faster and commission them with flexible options—including rooftops, basements, or existing structures—based on specific infrastructure needs.

Self-Regulating Biofilm Media for Load Fluctuations

The stp sewage treatment plant’s self-regulating biofilm media technology adapts automatically to varying conditions. The innovative system maintains optimal biological activity between 10-45°C and handles flow fluctuations of 30-150% without performance degradation. The adaptive control system adjusts treatment parameters continuously to ensure consistent output quality whatever the input variations. Self-controlling biomass removes the need to monitor F/M ratio, MLSS, and SVI continuously.

Carbon Filtration for Odor Control

Odor control is vital for industrial facilities. SUSBIO ECOTREAT uses specialized activated carbon filtration systems that neutralize unpleasant odors from sewage gasses effectively. The activated carbon removes hydrogen sulfide by oxidizing it to sulfur within the carbon pores and eliminates organic sulfur components like mercaptans and other offensive organic hydrocarbons. Better workplace conditions and fewer complaints from neighboring areas result from this integrated odor control technology.

Remote Monitoring and Cloud-Based Alerts

IoT-based monitoring capabilities track critical parameters including pH levels, pollutant concentrations, and flow rates continuously. Smart automation provides live data access through secure dashboards that operators can access from anywhere. Operators get immediate notifications of abnormal conditions, which allows swift intervention before problems escalate. Remote capabilities add particular value for unmanned or remote locations where consistent performance matters most.

Implementation Timeline and Compliance Checklist

A successful industrial wastewater treatment system needs careful planning and execution in several phases. The right timeline will ensure critical elements meet regulatory requirements properly.

Pre-Installation: Site Assessment and Design Finalization

Qualified consultants must conduct a detailed site assessment before construction begins. Their evaluation should document surface constraints like drainage networks, vegetation, slopes, and existing structures. Soil profiles need to extend at least one meter deep at proposed effluent management areas. The documentation should cover texture, structure, and dispersibility details. The design phase ends when the designer’s Design Producer Statement warrants specifications and creates a detailed System Design document for the installer.

Installation Phase: Civil, Mechanical, and Electrical Work

The installation timeline usually takes 5-6 months based on plant complexity. This phase combines:

- Civil work – Construction of tanks, foundations, and access structures

- Mechanical installation – Placement of pumps, blowers, valves, and filtration equipment

- Electrical instrumentation – Installation of control systems, sensors, and monitoring equipment

Each component needs verification against specifications. The inspection results must be documented thoroughly before moving to commissioning.

Commissioning: Seeding, Testing, and Operator Training

A structured approach helps transition the plant from construction to operation during commissioning. The biological seeding and acclimatization typically follows this schedule:

- Week 3: Initial seeding at 25% of recommended dosage

- Week 4: Increase to 50% dosage with 20% reduction in chemical coagulant

- Week 5: Full biological dosage with 40% chemical reduction

- Week 6: System stabilization with consistent COD/BOD monitoring

Performance testing can last 2-12 weeks depending on plant complexity. Operators learn system operation, maintenance procedures, and troubleshooting techniques during this time.

Regulatory Approvals: PCB, NOC, and Environmental Clearance

Two main permissions are needed for regulatory clearance:

- Consent to Establish (CTE) – Required before starting operations

- Consent to Operate (CTO) – Needed after plant establishment

Application documents should include project reports, site plans, manufacturing process details, and pollution control measures. Most approvals stay valid for 5-10 years based on industry category. Regular site inspections verify compliance with pollution control measures. Recognized laboratories analyze the samples.

Conclusion

Industrial wastewater treatment plays a vital role in protecting the environment, meeting regulations, and managing water sustainably. This piece explores modern wastewater treatment systems that will shape industrial practices in 2026 and beyond.

A five-stage treatment process is the foundation of any effective system. The stages start from mechanical screening and end with sludge dewatering. Each stage has its purpose and works together to turn harmful industrial effluent into safe, reusable water. Of course, the technologies used at each stage keep getting better and more eco-friendly.

Modern equipment like submersible mixers, membrane bioreactors, and ultrafiltration systems have without doubt changed treatment capabilities. These technologies solve specific challenges like space limits, tough contaminants, and energy use. The systems also use IoT-based monitoring to give better control through live data analysis and predictive maintenance.

Pre-treatment optimization is maybe even the most budget-friendly strategy for industrial facilities. Using coarse filtration, chemical conditioning, and the right cartridge filters substantially extends membrane life while cutting operating costs. Smart investments in proper pre-treatment often lead to big long-term savings.

The SUSBIO ECOTREAT system shows where industrial wastewater treatment is headed – it’s compact, flexible, smart, and easy to use. Its self-regulating biofilm media handles changing loads well, and remote monitoring ensures it runs at its best with minimal oversight.

Setting up a wastewater treatment system needs careful planning from pre-installation through commissioning. Meeting regulations just needs detailed documentation and testing throughout. So, following proven timelines and checklists becomes crucial to success.

The future looks bright as wastewater treatment technologies get better, smaller, and more automated. Smart industrial facilities will benefit from investing in these advanced systems now instead of facing pricey updates later. Clean wastewater treatment protects our environment and helps businesses stay sustainable by using less water and meeting regulations.

Key Takeaways

Industrial wastewater treatment in 2026 combines proven processes with cutting-edge technology to deliver efficient, compliant solutions for diverse industrial applications.

• Five-stage treatment process ensures comprehensive contaminant removal: mechanical screening, biological treatment, clarification, tertiary filtration, and sludge dewatering for optimal results.

• Advanced MBR technology reduces facility footprint by 30-40% while maintaining superior treatment quality, making it ideal for space-constrained industrial sites.

• Proper pre-treatment optimization significantly extends membrane lifespan and reduces operational costs through coarse filtration, chemical conditioning, and appropriate cartridge filter selection.

• IoT-enabled monitoring systems provide real-time parameter tracking, predictive maintenance alerts, and remote system control for enhanced operational efficiency and reduced downtime.

• Implementation requires 5-6 months with structured phases including site assessment, installation, biological commissioning, and regulatory approvals (CTE/CTO) for legal compliance.

The integration of smart technologies with proven treatment methods creates sustainable, cost-effective solutions that meet both environmental regulations and operational efficiency goals for industrial facilities.

Frequently Asked Questions

Q1. What are the main stages of industrial wastewater treatment?

Industrial wastewater treatment typically involves five main stages: mechanical screening and grit removal, biological treatment, clarification and sludge separation, tertiary filtration and disinfection, and sludge dewatering and disposal.

Q2. How can advanced technologies improve wastewater treatment efficiency?

Advanced technologies like membrane bioreactors (MBRs), ultrafiltration, reverse osmosis, and IoT-based monitoring systems can significantly improve treatment efficiency by reducing plant footprint, enhancing contaminant removal, and enabling real-time process optimization.

Q3. Why is pre-treatment important in industrial wastewater management?

Pre-treatment is crucial as it protects downstream equipment, extends membrane lifespan, and improves overall system efficiency. Effective pre-treatment strategies include coarse filtration, chemical conditioning, and proper selection of cartridge filters.

Q4. What are the benefits of modular STP systems like SUSBIO ECOTREAT?

Modular STP systems like SUSBIO ECOTREAT offer benefits such as a compact design with a smaller footprint, self-regulating biofilm media for handling load fluctuations, integrated odor control, and remote monitoring capabilities for easier management.

Q5. How long does it typically take to implement an industrial wastewater treatment system?

The implementation of an industrial wastewater treatment system typically takes about 5-6 months, including phases for site assessment, installation of civil, mechanical, and electrical components, commissioning, and obtaining necessary regulatory approvals.