Challenge 1 - Inadequate Infrastructure and Maintenance

Sewage treatment plants often face issues related to outdated or insufficient infrastructure. Many plants operate with older equipment that struggles to meet the demands of modern wastewater volumes and regulatory standards.

Solution: Upgrade and Regularly Maintain Infrastructure

Implementing regular maintenance and upgrading equipment is essential for improving plant efficiency. Modernizing infrastructure with advanced filtration systems, automated monitoring, and control systems can enhance performance and reduce downtime.

Challenge 2 - High Operating Costs

Operating costs for sewage treatment plants can be substantial, especially with high energy consumption, labor costs, and chemical usage.

Solution: Adopt Energy-Efficient Technologies

Energy-efficient technologies, such as anaerobic digesters and advanced aeration systems, can significantly reduce operational expenses. Additionally, renewable energy sources, like solar or biogas generated onsite, can lower electricity costs, making operations more sustainable.

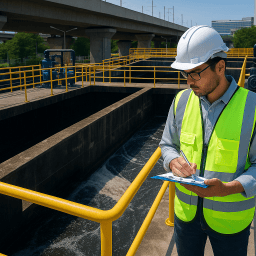

Challenge 3 - Meeting Regulatory Standards

Stricter environmental regulations demand higher treatment quality and more robust safety practices, making compliance a challenge for many facilities.

Solution: Implement Compliance Monitoring and Reporting Systems

Primary wastewater treatment involves automated monitoring systems can ensure that treatment processes meet regulatory requirements in real time. Regular training and audits also help maintain compliance, avoiding penalties and supporting environmental protection.

Challenge 4 - Odor and Noise Issues

Odor and noise pollution are common complaints near sewage treatment plants, impacting surrounding communities and presenting public relations challenges.

Solution: Introduce Odor Control and Noise Reduction Measures

Investing in odor control solutions, such as activated carbon filters or biofilters, can effectively minimize unpleasant smells. Installing noise barriers or selecting quieter machinery can reduce sound pollution, fostering a better relationship with the community.

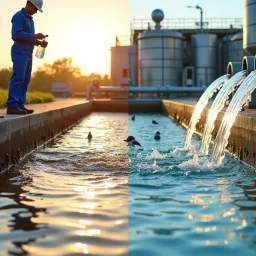

Challenge 5 - Limited Capacity for Peak Flow Management

Many plants face difficulties handling peak flows, which can lead to overflow, contamination, and equipment strain.

Solution: Enhance Storage and Flow Management Systems

Building additional storage tanks and using real-time flow monitoring systems can help manage peak loads effectively. These measures ensure consistent treatment even during high-demand periods, preventing overflows and maintaining treatment quality.

Challenge 6 - Sludge Management and Disposal

Sludge byproducts require careful handling and disposal, and inadequate sludge management can lead to environmental and health hazards.

Solution: Invest in Advanced Sludge Treatment and Disposal Options

Adopting advanced sludge treatment methods, like dewatering, digestion, and composting, can reduce sludge volume and create byproducts suitable for agricultural use or energy generation, minimizing disposal issues.

Challenge 7 - Skilled Workforce Shortages

Operating an efficient sewage treatment plant requires skilled personnel. However, finding and retaining skilled workers can be a challenge, especially in remote locations.

Solution: Implement Training Programs and Consider Automation

Providing continuous training and certification programs helps develop a skilled workforce. Where possible, automation can supplement human resources, allowing fewer staff to oversee operations efficiently.

Conclusion

Sewage treatment plants play an essential role in protecting our environment, public health, and water resources. However, these facilities face numerous challenges, from infrastructure limitations and rising operational costs to stringent regulatory requirements and community concerns about odor and noise. By tackling these issues head-on, wastewater facilities can improve both their efficiency and their environmental footprint. Effective liquid waste treatment is crucial in overcoming these challenges, ensuring that wastewater is treated to the highest standards while minimizing its impact on the surrounding environment and communities.

Overcoming these obstacles requires a strategic approach that incorporates modern technology, efficient resource management, and ongoing workforce development. For instance, upgrading infrastructure and adopting energy-efficient technologies can significantly cut costs and enhance operational reliability including tertiary wastewater treatment. Regular maintenance and targeted investments in odor control and noise reduction systems foster positive relationships with the surrounding community, supporting both social and environmental goals. Advanced monitoring systems also play a crucial role, as they ensure plants meet regulatory standards and can respond swiftly to real-time changes, helping to prevent costly compliance issues.

Furthermore, as treatment plants adapt to rising peak flow demands and tackle sludge management challenges, they contribute to sustainable practices by recycling resources, reducing waste, and even generating renewable energy through secondary wastewater treatment. Workforce challenges, although daunting, can be addressed by investing in ongoing training and incorporating automation, which not only eases staffing pressures but also builds a more knowledgeable and capable team. These advancements play a crucial role in optimizing processes, especially in the field of industrial water treatment, where efficiency and sustainability are paramount.

In addressing these challenges proactively, sewage treatment plants can significantly enhance their effectiveness and resilience, paving the way for a cleaner, healthier future. With innovative solutions, efficient practices, and a commitment to sustainability, the industry can continue to evolve, meeting both current and future demands with confidence and responsibility including through the implementation of effective chemical wastewater treatment.