Sewage treatment plants serve a vital role to keep our water sources clean and safe. A diagram of sewage treatment plant operations reveals how these facilities change harmful wastewater into environmentally friendly water through 5 distinct stages. Clean water might seem like a given, but treatment facilities’ complex processes deserve our attention and understanding.

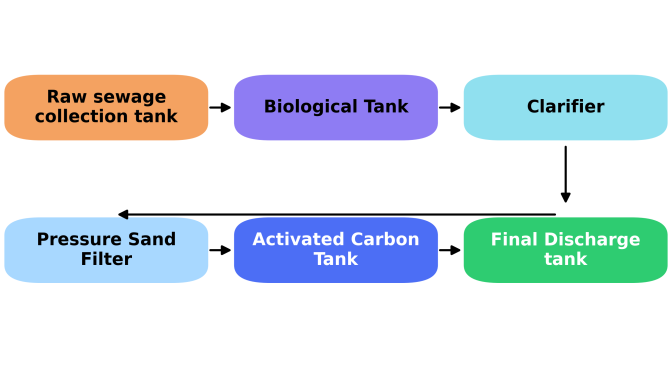

The wastewater treatment plant diagram shows how facilities receive waste from homes, businesses, and industries. These plants remove contaminants from sewage to produce treated effluent that safely returns to the environment or gets reused for different purposes. A sewage treatment plant process flow diagram demonstrates wastewater’s transformation – from original drainage into the facility to suspended solids separation. The two-step biological process results in remarkably clean water.

Let’s explore how a sewage treatment plant works through detailed diagrams that show each treatment stage. This visual guide offers a clear picture of these significant facilities, whether you want to learn about environmental engineering or understand your water’s journey after it leaves your home.

What is a Sewage Treatment Plant and Why It Matters

Sewage Treatment Plants (STPs) play a vital role in treating wastewater from multiple sources before releasing it back into the environment. These specialized facilities are the foundations of modern water management systems. They work quietly yet effectively to protect public health and natural ecosystems.

Definition of STP and its role in water safety

Engineers design sewage treatment plants to remove contaminants from wastewater, which makes it safe for discharge or reuse. These plants defend against water pollution by eliminating harmful substances that could contaminate our waterways. The United States processes approximately 34 billion gallons of wastewater daily through these facilities. STPs remove nitrogen and phosphorus through mechanical, biological, and chemical processes. These nutrients could lead to eutrophication and oxygen depletion in natural water bodies if left untreated.

Sources of wastewater: residential, commercial, industrial

Wastewater treatment facilities receive input from three main sources:

Domestic wastewater: Homes and apartments generate used water from toilets, showers, sinks, and laundry. This water contains putrescible organic materials, plant nutrients, and disease-causing microbes, though it’s more than 99.9% water.

Commercial wastewater: Restaurants, hotels, and office buildings produce waste that often contains food residue, grease, oils, and commercial chemicals.

Industrial wastewater: Manufacturing processes, chemical plants, food processing, mining operations, and other industrial activities create waste with specific chemicals and higher pollutant concentrations.

Storm sewage from precipitation might enter combined sewer systems. Modern facilities typically separate these flows.

Overview of the sewage treatment plant process flow diagram

The sewage treatment plant diagram shows five main stages of processing. Wastewater flows into the plant through underground pipes, sometimes with help from pumping stations. The preliminary treatment removes large debris such as diapers, sanitary items, and street grit using screens. Large sedimentation tanks in primary treatment allow solid particles to settle into sludge. Bacteria break down organic matter during secondary treatment through the “activated sludge method.” The final polishing happens in tertiary treatment using special tanks or reed beds before the clean water flows into receiving water bodies.

Visual Overview: Sewage Treatment Plant Diagram Explained

Visual diagrams help us understand complex processes in sewage treatment facilities. A complete diagram of sewage treatment plant operations shows how wastewater changes from raw sewage to clean effluent.

Step-by-step walkthrough of a typical STP plant diagram

The sewage treatment plant process flow diagram shows five sequential stages of wastewater treatment:

Wastewater Collection – Raw sewage flows into the facility through underground pipes. Pumping stations help move sewage from areas below the main sewer system.

Preliminary Treatment – Screening systems remove large objects like diapers, sanitary items, and plastic bags. Sand and gravel settle in grit chambers.

Primary Treatment – Large sedimentation tanks slow the flow dramatically. This allows suspended solids to settle at the bottom and form primary sludge.

Secondary Treatment – The diagram shows aeration tanks where bacteria consume organic matter. Secondary clarifiers let activated sludge settle next.

Tertiary Treatment – Filtration systems and disinfection chambers polish the water before releasing it into the environment.

Key components: screens, tanks, aerators, filters

The plant diagram’s critical components include:

Screening Systems – Bar screens with automated rake systems catch large debris

Grit Chambers – These slow water flow so dense materials settle

Primary Clarifiers – Large circular or rectangular tanks use mechanical scrapers

Aeration Tanks – Diffusers or mechanical aerators maintain oxygen levels

Secondary Clarifiers – These tanks separate biomass from clear water

Filtration Systems – Sand, activated carbon, or membrane filters remove fine particles

Disinfection Units – UV radiation or chemical treatment systems eliminate pathogens

How the sewage treatment diagram helps in understanding flow

The sewage treatment diagram works as a visual roadmap that shows relationships between treatment components. Engineers and operators use these diagrams to see how wastewater moves through various treatment units. Each component removes specific contaminants. The diagram shows water quality improvements at every stage. These visual tools are a great way to get training insights, fix operational issues, and plan facility upgrades.

Core Stages of the Sewage Treatment Process

Modern sewage treatment plants work in sequential stages. Each stage removes specific contaminants from wastewater. The treatment process has four core phases that clean water progressively until it becomes safe to release into the environment.

Preliminary Treatment: Screening and Grit Removal

The first stage focuses on removing coarse materials that could damage equipment. Large bar screens filter out objects like rags, sticks, plastic packets, and other debris from sewage streams. Large facilities use mechanically raked bar screens that remove these materials automatically. Smaller plants might use manually cleaned screens instead. The process then moves to grit chambers where the wastewater flow slows down. This allows heavy materials like sand, gravel, and rocks to settle. This essential step protects equipment from damage and reduces how often the tanks need cleaning.

Primary Treatment: Sedimentation and Sludge Formation

The wastewater moves to primary sedimentation tanks or clarifiers after preliminary processing. The flow slows down significantly here. This allows suspended solids to sink while lighter materials like grease and oil float up. The water stays in these tanks for 1.5 to 2.5 hours, and they remove:

50-70% of suspended solids

25-40% of biological oxygen demand (BOD)

Mechanical arms or scrapers move settled solids (primary sludge) to collection hoppers. Surface skimmers remove floating materials to ensure cleaner water moves to secondary treatment.

Secondary Treatment: Aeration and Biological Breakdown

Secondary treatment uses biological processes to digest remaining organic matter after primary clarification. The process can use either suspended-growth systems (like activated sludge) or biofilm processes (such as trickling filters). Activated sludge systems use aeration tanks that add oxygen to help bacteria grow. These bacteria eat organic pollutants and form biological flocs. This process takes about six hours. The bacteria convert dissolved organics into stable substances and cellular material during this time. The mixture then flows to secondary clarifiers where activated sludge settles. About 30% goes back into the system to keep biological activity going.

Tertiary Treatment: Filtration, Disinfection, and Nutrient Removal

The final stage involves tertiary treatment, also known as “advanced treatment” or “effluent polishing.” Sand beds or synthetic membranes filter out any remaining suspended particles. The process also removes phosphorus and nitrogen compounds that might cause eutrophication in receiving waters. Disinfection happens through chemical means (using chlorine or iodine) or physical methods (ultraviolet radiation) to kill remaining pathogens. This complete process will give a treated water output that meets specific standards. The water becomes safe for environmental discharge or reuse in irrigation and industrial applications.

Sludge Management and Treated Water Reuse

Sludge management plays a crucial role as the final step in sewage treatment by handling solids removed during earlier stages. A complete sewage treatment plant diagram shows these processes as key elements that help recover resources and minimize waste.

Sludge thickening and dewatering methods

The process of sludge thickening reduces water content to make handling easier by decreasing volume. Gravity thickening stands out as the simplest method where solids settle in specialized tanks to reach 4-6% concentration. The dissolved air flotation method uses air bubbles to lift solids and achieves 5-10% solids content. Mechanical processes take over after thickening to reduce volume further through dewatering. Belt filter presses can achieve 14-25% solids concentration with 85-95% capture. Centrifuges work even better with 15-30% solids concentration and 95-99% capture efficiency. Smaller facilities often use sludge-drying beds as a simple solution that spreads digested sludge on sand and removes water through evaporation and drainage.

Anaerobic digestion and biogas recovery

Anaerobic digestion reduces sludge volume and generates valuable biogas by breaking down organic materials without oxygen. This process converts about 50% of organic solids into liquids and gasses. The resulting biogas, which contains mostly methane and carbon dioxide, serves as renewable energy for heat, electricity generation, or upgraded biomethane. The process recovers about 0.27 kWh/m³ of electrical energy and offsets 50-60% of a treatment plant’s energy needs. Optimized digesters that use thermal hydrolysis pretreatment can convert 60-70% of solid matter into gasses.

Effluent discharge and reuse in irrigation or industry

India generates 72,368 MLD of sewage daily but treats only 28% of its urban wastewater. Treated wastewater serves as a valuable resource across multiple applications. Irrigation leads the global reuse market at 32%. Industrial applications make up 19%, especially in cooling systems for thermal power plants and pulp and paper industries. Properly treated wastewater can replace freshwater in construction (using 101.9 MLD nationally), landscape irrigation (20% of global market), and groundwater recharge (2% globally).

Conclusion

Sewage treatment plants are amazing engineering achievements that protect our water resources through complex, multi-stage processes. This piece explores how these facilities turn harmful wastewater into clean, reusable water through five different treatment stages. The water’s trip starts when it’s collected from homes, businesses, and industries. The first step removes large debris, and then primary treatment lets solids settle into sludge that needs proper handling.

The sort of thing I love is the secondary treatment stage, where bacteria constantly break down organic matter through biological processes. Tertiary treatment adds the final polish before water goes back to nature. The treatment cycle finishes with sludge management through thickening, dewatering, and anaerobic digestion. This process creates useful byproducts like biogas.

Visual diagrams help make these complex operations easier to understand. They show how each part – from screens and tanks to aerators and filters – has its own job in the treatment sequence. These systems are the foundations of our response to growing water shortages worldwide.

Treated water now serves many purposes – from irrigation to industrial use and even groundwater recharge. This shows how wastewater treatment has grown beyond just controlling pollution. Without doubt, these facilities now act as resource recovery centers that protect public health while supporting eco-friendly water management.

Sewage treatment plants work quietly behind the scenes, but they reshape the scene of modern life. Next time you use your tap or flush your toilet, you’ll know the remarkable trip your water takes before safely returning to nature. This hidden infrastructure needs our attention and support as it’s crucial to public health and environmental protection.

Frequently Asked Questions

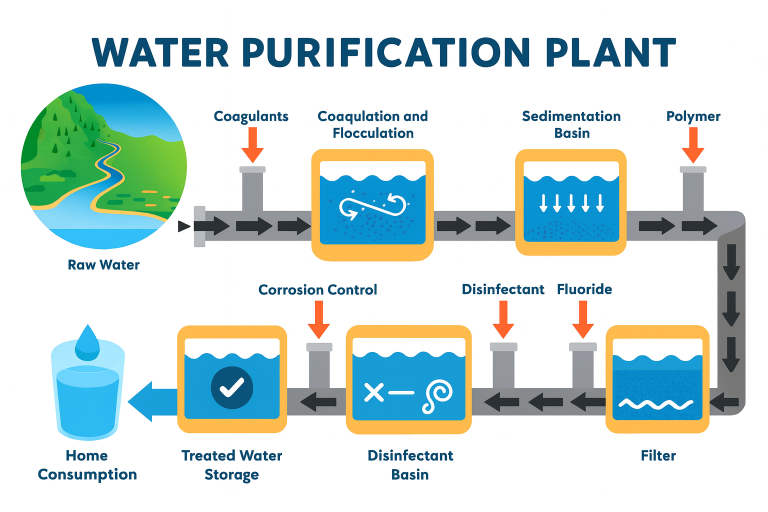

1. What is a water purification plant and how does it work?

A water purification plant is a facility that treats raw water to remove dirt, chemicals, and microorganisms through processes like coagulation, sedimentation, filtration, and disinfection, making it safe for use.

2. What are the main steps in the water purification process?

The process generally includes coagulation and flocculation, sedimentation, filtration, disinfection, and treated water storage before distribution.

3. Why are coagulants and polymers used in water treatment?

Coagulants and polymers help bind fine particles together, forming larger clumps (flocs) that can settle or be filtered out more easily, improving water clarity.

4. How does filtration improve water quality?

Filtration removes suspended particles, sediments, and some microorganisms from water by passing it through layers of sand, gravel, or other filter media.

5. Is the treated water from a purification plant safe for drinking?

Yes. Treated water that meets national and international drinking water standards is safe for consumption, provided the plant is well-maintained and regularly monitored.