Industrial waste is often seen as an inevitable byproduct of progress. But what if we could transform this waste into value, fueling a new era of sustainability and innovation? Welcome to the world of smart solutions, where industrial waste isn’t just managed—it’s reinvented. In this blog, we’ll explore how industries are turning waste into resources, the technologies powering this shift, and how a circular economy is within reach.

Understanding Industrial Waste: The Foundation of Change

Industrial waste encompasses all the unwanted materials generated during manufacturing and industrial processes. These wastes can take many forms, each with its own management challenges and environmental impacts:

1. Solid Waste

Examples: Scraps of metal, plastics, packaging materials, and production debris.

Impact: If not properly managed, solid waste can contribute to landfill overflow and environmental pollution.

2. Liquid Waste

Examples: Wastewater from cleaning, chemical residues, oils, and coolants.

Impact: Liquid waste can contaminate water sources if released untreated, posing risks to ecosystems and human health.

3. Hazardous Byproducts

Examples: Toxic chemicals, heavy metals, solvents, and flammable or corrosive substances.

Impact: These require specialized handling and disposal due to their potential to cause significant harm to the environment and public health.

Industrial Waste vs. Hazardous Waste: What’s the Difference?

Understanding the distinction between industrial and hazardous waste is crucial for effective waste management and regulatory compliance.

Industrial Waste

Definition: A broad category that includes all waste generated from industrial activities, such as packaging, organic matter, and non-toxic byproducts.

Examples: Cardboard boxes, food processing waste, wood shavings.

Hazardous Waste

Definition: A specific subset of industrial waste that contains substances known to pose significant risks to health or the environment.

Examples: Lead-acid batteries, chemical solvents, radioactive materials.

Key Point: While all hazardous waste originates from industrial activities, not all industrial waste is hazardous. Proper identification and segregation are essential for safe handling and disposal.

Industrial Wastewater Treatment: Turning Wastewater into Opportunity

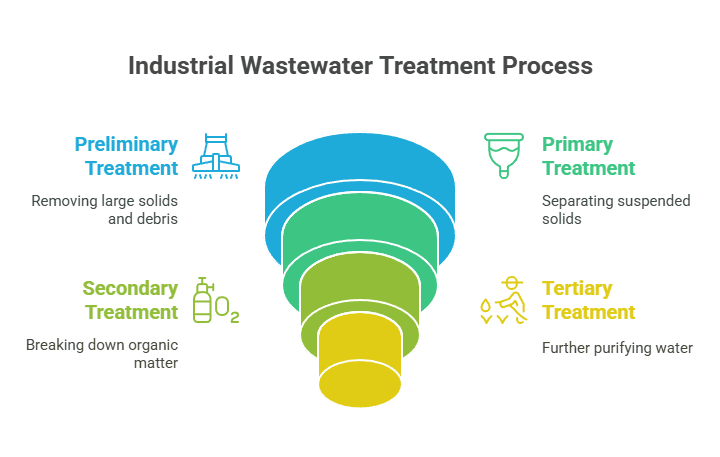

Industrial wastewater is a major byproduct of manufacturing, but with advanced treatment, it can be transformed from a liability into a valuable resource. Here’s a detailed look at how the treatment process works:

1. Preliminary Treatment

Purpose: Remove large solids and debris that could damage equipment or hinder further treatment.

Process: Wastewater passes through screens and grit chambers to filter out plastics, rags, sand, and gravel.

Outcome: Protects downstream processes and improves overall treatment efficiency.

2. Primary Treatment

Purpose: Separate suspended solids from the liquid waste.

Process: Wastewater enters large settling tanks where gravity causes heavier particles to sink to the bottom, forming sludge, while lighter materials float to the top and are skimmed off.

Outcome: Reduces the load on secondary treatment and removes up to 60% of suspended solids.

3. Secondary Treatment

Purpose: Break down dissolved and suspended organic matter.

Process: Utilizes biological methods, such as activated sludge systems or biofilters, where bacteria and other microorganisms consume organic pollutants.

Outcome: Removes up to 90% of organic matter, significantly improving water quality.

4. Tertiary Treatment

Purpose: Further purify water to meet stringent discharge or reuse standards.

Process: Advanced filtration (such as sand filters, membrane filtration) and chemical treatments (like nutrient removal and disinfection) eliminate remaining contaminants, including nutrients, pathogens, and trace chemicals.

Outcome: Produces water that is safe for discharge into the environment or for reuse in industrial processes, irrigation, or even potable applications.

Chemical Treatment of Wastewater: Methods and Uses

Chemical treatments are often essential for targeting specific pollutants that biological processes can’t remove. Here’s a closer look at the most common methods:

1. Coagulation and Flocculation

Purpose: Aggregate fine particles and colloids into larger clumps (flocs) that can be easily removed.

How it Works: Chemicals called coagulants (e.g., alum, ferric chloride) are added to destabilize particles. Flocculants are then introduced to bind these particles together, forming flocs that settle out during sedimentation.

Benefits: Highly effective for removing suspended solids, color, and some types of organic matter.

2. Neutralization of Acids and Alkalis

Purpose: Adjust the pH of wastewater to neutral levels, preventing corrosion of infrastructure and harm to aquatic life.

How it Works: Acidic waste streams are treated with alkaline substances (like lime or sodium hydroxide), while alkaline wastes are neutralized with acids (like sulfuric acid).

Benefits: Ensures compliance with discharge regulations and protects downstream biological treatment processes.

3. Oxidation/Reduction Reactions

Purpose: Transform toxic or hazardous substances into less harmful compounds.

How it Works: Oxidizing agents (such as ozone, chlorine, or hydrogen peroxide) break down contaminants like cyanides, phenols, or sulfides. Reduction agents can be used to treat substances like chromium(VI) by converting them to less toxic forms.

Benefits: Essential for treating persistent organic pollutants and certain heavy metals.

4. Disinfection Using Chlorine or Ozone

Purpose: Destroy pathogenic microorganisms to ensure water safety.

How it Works: Chlorine or ozone is introduced at the final treatment stage, killing bacteria, viruses, and other pathogens.

Benefits: Protects public health and meets regulatory standards for water reuse or discharge.

5. Heavy Metal Removal Using Precipitation

Purpose: Remove dangerous metals such as lead, mercury, cadmium, and arsenic.

How it Works: Chemical agents are added to convert dissolved metals into insoluble compounds (precipitates), which are then separated from the water by filtration or sedimentation.

Benefits: Prevents toxic metals from entering water bodies and accumulating in the food chain.

How Industries Can Help Prevent Water Pollution

Industries play a vital role in safeguarding water resources. Here’s how they can make a difference:

Adopt closed-loop processes to recycle water within the facility.

Implement real-time monitoring to detect and address leaks or spills.

Switch to eco-friendly chemicals that break down safely in the environment.

Train employees on best practices for waste handling and spill prevention.

Collaborate with local authorities to ensure compliance and innovation.

Types of Industrial Waste Collection: Smarter, Safer, Greener

Modern waste collection methods are designed for efficiency and safety:

On-site segregation: Separating waste at the source for easier recycling.

Automated collection systems: Using smart bins and sensors to optimize pickup schedules.

Specialized containers: For hazardous or sensitive materials, ensuring safe transport and disposal.

Reverse logistics: Returning used materials to manufacturers for reuse or recycling.

The Role of Technology in Modern Waste Collection & Management

Technology is revolutionizing how we handle industrial waste:

IoT sensors provide real-time data on waste levels and composition.

AI-driven analytics optimize collection routes and recycling processes.

Robotics automate sorting and handling of complex waste streams.

Blockchain ensures transparency and traceability in waste management.

These innovations not only reduce costs but also help industries achieve their sustainability goals.

Challenges and Opportunities in Industrial Waste Circularity

Key Challenges

Complex waste streams: Mixed materials are harder to recycle.

Regulatory hurdles: Compliance can be costly and complex.

Initial investment: Upgrading systems requires upfront capital.

Exciting Opportunities

Resource recovery: Extracting valuable materials from waste streams.

New business models: Offering waste-as-a-service or circular supply chains.

Brand reputation: Leading in sustainability attracts customers and investors.

Frequently Asked Questions (FAQs) About Industrial Waste

1. What is industrial waste?

Industrial waste is any non-hazardous or hazardous waste generated by industrial processes, including manufacturing, construction, and maintenance. It can be solid, liquid, or gaseous and includes everything from packaging and scraps to chemical residue.

2. Why does industrial waste management matter?

Proper industrial waste management protects the environment and human health. Responsible practices, such as recycling and zero waste initiatives, can also reduce regulatory and business expenses

3. What types of sites require industrial waste management services?

Sites such as manufacturing plants, food processing facilities, automotive shops, warehouses, and distribution centers typically require industrial waste management

4. How can I reduce my facility’s need for industrial waste management?

Upgrade to newer, less wasteful technology

Train employees on best practices

Maintain equipment to prevent leaks and spills

Implement recycling programs

Partner with waste management services to track and reduce waste generation

5. What is a zero waste initiative?

A zero waste initiative is a sustainability plan aiming to eliminate waste by redesigning processes, encouraging recycling, and reusing materials. Benefits include lower costs, less waste, and a greener company image

6. How is industrial wastewater treated?

Treatment involves physical (filtration, sedimentation), chemical (coagulation, neutralization, oxidation), and biological (aerobic/anaerobic digestion) processes, as well as advanced methods like membrane filtration and activated carbon adsorption for complex contaminant.

7. Are there regulations or permits required for industrial waste disposal?

Yes, many regions require permits and appointments for industrial waste disposal at designated facilities. For example, in Calgary, certain types of industrial waste require permits and must be disposed of at specific landfill facilities during set hours

8. Is there a weight or quantity limit for industrial waste disposal?

Generally, there is no weight limit, but charges are based on the type and weight of materials. Some items, like tires or hazardous waste, may have quantity restrictions

Conclusion: Reinventing Industrial Waste for a Circular Economy

Understanding and managing industrial waste is the first step toward building a more sustainable and responsible industrial sector. By leveraging advanced sewage treatment technologies and smart chemical processes, industries can significantly reduce their environmental impact while also recovering valuable resources. Embracing a circular economy approach not only helps companies comply with regulations but also unlocks new opportunities for cost savings, innovation, and improved brand reputation. When waste is seen as a potential resource rather than just a problem, industries can lead the way in creating a cleaner, more resilient future for everyone. The shift starts with knowledge and is powered by action—let’s turn industrial waste into a catalyst for positive change.