Wastewater treatment is no longer just about removing visible impurities — it’s about ensuring complete pathogen destruction before water is discharged or reused. Disinfection is the final and most crucial step that makes treated water safe for the environment and human health.

Untreated wastewater is a breeding ground for harmful bacteria, viruses, and parasites such as E. coli, Salmonella, Cryptosporidium, and Giardia. Left unchecked, these pathogens cause life-threatening diseases like cholera, typhoid, hepatitis, and gastroenteritis. That’s why every sewage treatment plant (STP) must adopt reliable disinfection methods as its last line of defense.

This expert guide covers everything you need to know about modern disinfection technologies in sewage treatment (2025), from traditional chlorine dosing to advanced hybrid systems like SUSBIO ECOTREAT.

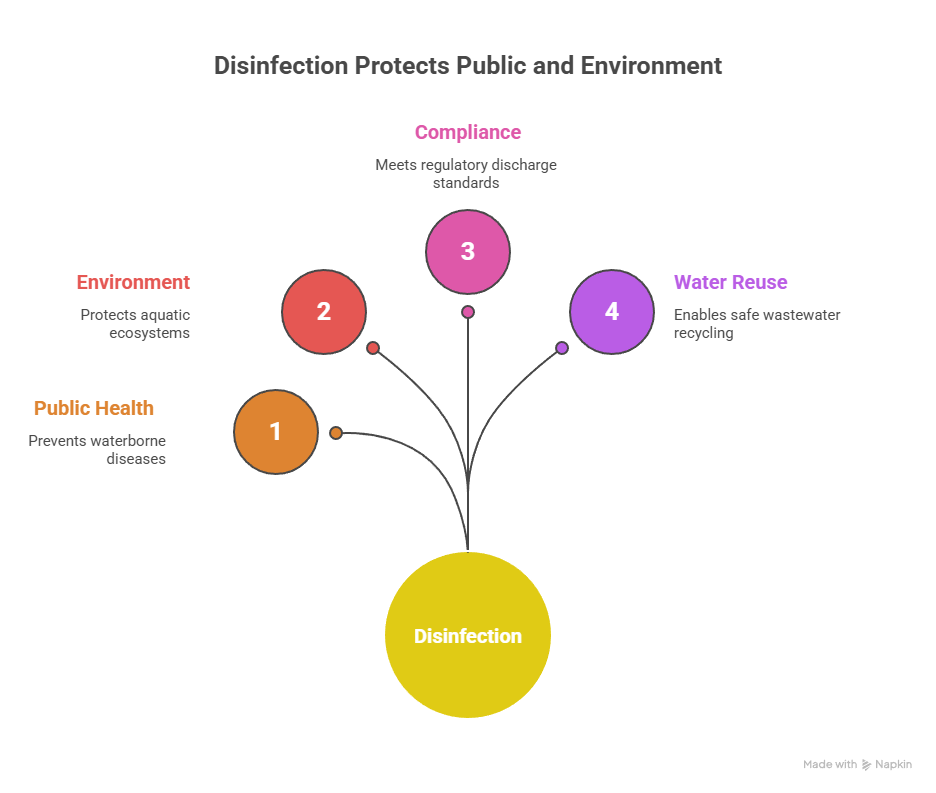

Why Disinfection is Critical in Sewage Treatment

1. Safeguarding Public Health

Communities depend on safe water for drinking, bathing, and sanitation. Disinfection neutralizes disease-causing organisms before they can spread through rivers, lakes, or groundwater.

2. Environmental Protection

Even small amounts of untreated wastewater can damage aquatic ecosystems. Pathogens infect fish, plants, and wildlife, creating ripple effects across the food chain.

3. Regulatory Compliance

Authorities like the Central Pollution Control Board (CPCB) in India and international bodies like the WHO mandate strict discharge standards. Without proper disinfection, STPs fail compliance and risk penalties.

4. Water Reuse & Sustainability

Modern urban planning encourages wastewater recycling. But reuse (for landscaping, flushing, or industrial processes) is only possible if the treated water is disinfected to a safe level.

Core Disinfection Methods in Wastewater Treatment

1. Chlorination: Affordable but with Byproducts

Chlorination has been the world’s most widely used method for decades. It involves adding chlorine gas or sodium hypochlorite to wastewater.

How it works: Chlorine forms hypochlorous acid (HOCl) and hypochlorite ions (OCl⁻) that break down cellular processes in microorganisms.

Dosage range:

Sodium hypochlorite: 0.2–2 mg/L

Chlorine gas: 1–16 mg/L

Pros:

Cost-effective

Provides residual protection in pipelines

Cons:

Produces disinfection byproducts (DBPs) such as trihalomethanes (THMs) and haloacetic acids (HAAs).

DBPs are linked to cancer and long-term health risks.

2. UV Disinfection: Light that Destroys DNA

Ultraviolet (UV) light at 254 nm penetrates microorganisms and disrupts their DNA by forming thymine dimers, preventing them from replicating.

Time required: 20–30 seconds (much faster than chlorine).

Effectiveness: 3-log (99.9%) reduction in total coliforms at 164.1 mWs/cm².

Pros:

No harmful chemicals

Highly effective against chlorine-resistant organisms like Cryptosporidium and Giardia

Cons:

No residual protection

Some microbes recover via photoreactivation or dark repair

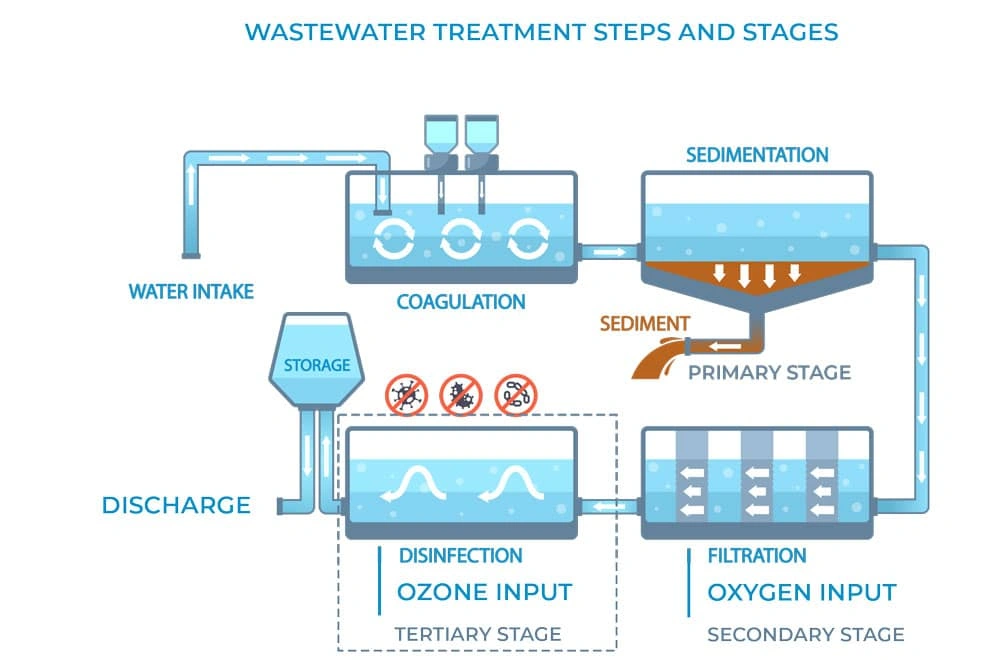

3. Ozonation: Nature’s Most Powerful Oxidizer

Ozone (O₃) is generated onsite using corona discharge in oxygen or dry air. It’s one of the strongest disinfectants known.

Strength: 3,000 times more effective than chlorine.

Contact time: 10–30 minutes.

Pros:

Destroys bacteria, viruses, and protozoa

Works well against chlorine-resistant organisms

Cons:

Higher energy demand

Complex equipment (generators, contact chambers, air dryers)

4. Chlorine Dioxide: A Cleaner Alternative

ClO₂ disinfects by oxidizing organic molecules through one-electron transfer reactions.

Dosage range: 0.07–2.0 mg/L

Pros:

Produces fewer DBPs than chlorine

Works better in highly polluted water

Cons:

Must be produced onsite

Sensitive to storage and handling conditions

5. Membrane Filtration: Physical Barrier

Microfiltration (MF) and ultrafiltration (UF) remove microorganisms physically based on pore size.

MF pores: 0.1–10 μm (blocks bacteria and turbidity)

UF pores: 0.001–0.1 μm (blocks viruses and macromolecules)

Pros:

High pathogen removal efficiency

No chemicals involved

Cons:

Expensive membranes

Susceptible to fouling

Factors That Influence Disinfection Efficiency

Water treatment operators must optimize several key factors to achieve maximum pathogen elimination through different types of disinfection. A proper understanding of these variables will give a better wastewater treatment in a variety of conditions.

Contact Time and Flow Rate Optimization

Pathogens need enough contact time with disinfectants to be eliminated effectively. Most low-level disinfectants take 30–60 seconds to eliminate vegetative bacteria, yeasts, mycobacteria, and viruses. Notwithstanding that, each disinfectant needs different exposure times—ozone works faster than chlorine. The CT value (concentration × time) remains the main measurement to check disinfection effectiveness, especially with the T10 method (time for 10% of concentration to pass through a contact basin). High flow rates reduce treatment time, so contact time calculations must factor in peak flows.

Turbidity and Organic Load Effect on UV and Chlorine

Water quality substantially affects how well disinfection works. Total Suspended Solids (TSS) can hurt disinfection even at levels under 20 mg/L. Particles in UV systems protect microorganisms from light exposure. The efficiency drops at UV doses of 7.5 mJ/cm² once TSS hits 50 mg/L. Organic matter reacts with chlorine and reduces available germicide. This shows up as a strong negative link between turbidity and disinfection efficiency (r = -0.96 to -0.98).

Residual Disinfectant Monitoring in Distribution Systems

Distribution networks need proper disinfectant residuals to serve three vital purposes: they kill microorganisms, show system problems, and control biofilm growth. Pipe volume, water characteristics, disinfectant type, and contamination events all affect residual maintenance. Regular checks of residual levels help catch sudden changes that might point to contamination.

System Design: Baffling, Mixing, and Dosing Accuracy

System setup plays a big role in how well disinfection works. Tank baffles cut down free space and create even velocity distribution. This minimizes short circuits and recirculation zones. The baffling factor affects chlorine contact time directly—numbers closer to 1.0 mean better-distributed flow and contact between water and disinfectants. On top of that, good mixing helps disinfectants reach all water parts and prevents problematic air pockets.

Advanced & Emerging Disinfection Technologies

Advanced Oxidation Processes (AOPs)

Generate hydroxyl radicals (•OH) that break down pharmaceutical residues and micropollutants.

Examples: UV/H₂O₂, Fenton’s method.

Electrochemical Disinfection

Electrodes generate oxidants directly from water.

Perfect for decentralized STPs in remote locations.

Can run on solar energy for sustainable operation.

Hybrid Systems

Combine UV + ozone + membranes for multi-barrier protection.

Designed to tackle chlorine-resistant pathogens and micropollutants.

SUSBIO ECOTREAT: Next-Gen Disinfection in Packaged STPs

Traditional disinfection methods work — but modern challenges like emerging pathogens, energy efficiency, and sustainability goals demand something better. This is where SUSBIO ECOTREAT, India’s leading packaged STP technology, makes the difference.

What is SUSBIO ECOTREAT?

SUSBIO ECOTREAT is a prefabricated, FRP-based packaged sewage treatment plant designed for plug-and-play installation with minimal civil work. Unlike conventional STPs, it integrates biological, physical, and chemical treatment with advanced disinfection technologies to ensure water is reusable, safe, and CPCB-compliant.

Disinfection Approach in SUSBIO ECOTREAT

Triple-Layer Disinfection

UV systems for chlorine-resistant pathogens.

Ozone dosing for strong oxidation and odor control.

Optional chlorination for residual protection in distribution.

Bio-Enzymatic Cleaning

Uses natural enzymes to prevent biofilm growth inside tanks and pipelines.

Reduces chemical dependency for maintenance.

Hospital-Grade Pathogen Control

Designed to meet stringent standards for schools, hospitals, apartments, and commercial campuses.

Advantages of SUSBIO ECOTREAT

Plug & Play: Installation in 2–5 days (vs. months for traditional STPs).

Energy Efficient: Up to 90% lower energy use compared to conventional aeration systems.

Reuse Ready: Treated water can be used for landscaping, flushing, and cooling towers.

IoT Monitoring: Real-time data on flow, performance, and disinfection levels.

Durability: FRP tanks with 10+ year warranty.

Compact Design: Requires 50% less space than RCC plants.

Why SUSBIO ECOTREAT is Different

Most STPs focus on either cost or efficiency. SUSBIO ECOTREAT strikes the right balance by:

Reducing OPEX through enzyme cleaning and optimized dosing.

Offering multi-barrier disinfection (UV + ozone + chlorine).

Being future-ready for stricter environmental norms.

How to Choose the Right Disinfection Method for Your STP

When planning or upgrading your STP, consider:

Cost vs. Long-Term Value: UV may cost more upfront but saves more in O&M.

Environmental Concerns: Avoid DBPs from chlorine if your project is near sensitive ecosystems.

Pathogen Profile: UV + ozone recommended if chlorine-resistant organisms are a risk.

Space Availability: Membrane filtration and UV are compact solutions.

Integration with Existing Systems: Hybrid retrofits like SUSBIO ECOTREAT can be easily added to old setups.

Conclusion

Disinfection is the final and most crucial safeguard in modern sewage treatment systems. It stands as the last barrier between potentially harmful wastewater and our environment, ensuring pathogens are eliminated effectively. While each disinfection method has its own advantages, their suitability depends on specific applications and conditions.

Chlorination remains widely used for its cost-effectiveness, but growing concerns about harmful byproducts make it less attractive for long-term sustainability.

UV disinfection excels at neutralizing chlorine-resistant organisms by disrupting DNA, though it lacks residual protection.

Ozonation offers powerful oxidation with minimal residue, while chlorine dioxide strikes a middle ground between effectiveness and byproduct control.

Membrane filtration provides a strong physical barrier against microorganisms of varying sizes.

The effectiveness of any disinfection system depends on contact time, turbidity levels, residual monitoring, and smart system design. When these factors are optimized, treatment plants achieve more reliable and consistent pathogen removal.

Looking forward, advanced oxidation processes, electrochemical disinfection units, and bio-enzymatic technologies are redefining wastewater treatment. These innovations are especially promising for decentralized and smaller-scale STPs, where flexibility and cost-efficiency are vital.

Decision-makers must carefully weigh capital investment, operational expenses, environmental impact, and pathogen resistance when selecting the right technology. No single solution works everywhere — the future of sewage treatment lies in integrated, multi-barrier approaches that combine methods for maximum safety and sustainability.

This is exactly where SUSBIO ECOTREAT sets a benchmark. By blending UV, ozone dosing, optional chlorination, and bio-enzymatic cleaning within a compact, plug-and-play packaged system, SUSBIO ECOTREAT delivers robust disinfection, lower operational costs, and water that is safe for reuse. With its IoT-enabled monitoring, energy efficiency, and CPCB-compliance, it represents the kind of all-encompassing, future-ready solution that modern wastewater management demands.

As regulations tighten and public awareness of water quality grows, solutions like SUSBIO ECOTREAT are not just an option but a necessity — offering communities, industries, and institutions a smarter way to protect health, preserve the environment, and secure a sustainable water future.

Frequently Asked Questions

Q1. What are the main disinfection methods in wastewater treatment?

Chlorination, UV disinfection, ozonation, chlorine dioxide, and membrane filtration are the primary disinfection technologies used in modern sewage treatment plants.

Q2. Why is UV disinfection better than chlorination?

UV kills chlorine-resistant pathogens, doesn’t create harmful byproducts, and saves up to 63% in operating costs compared to chlorine systems.

Q3. What makes SUSBIO ECOTREAT different from other STPs?

SUSBIO ECOTREAT combines UV, ozone, and optional chlorination with bio-enzymatic cleaning and IoT monitoring, making it the most advanced packaged STP in India.

Q4. Can treated wastewater be reused safely?

Yes. With multi-barrier disinfection, treated water can be reused for landscaping, flushing, and industrial applications.

Q5. What’s the future of disinfection in STPs?

The future lies in integrated hybrid systems (UV + ozone + membranes) and smart packaged plants like SUSBIO ECOTREAT that balance efficiency, cost, and sustainability.