The environmental audit process often feels like navigating through murky waters. India currently has 45 Common Hazardous Waste Treatment, Storage and Disposal Facilities (TSDFs) operating across 18 States/UTs. This makes proper wastewater management more important than ever.

Environmental audits go far beyond simple compliance checks. They work as diagnostic tools that evaluate a facility’s entire environmental management system.

The Clean Water Act maintains strict regulations on direct and indirect discharges. These controls target priority pollutants, conventional pollutants like biochemical oxygen demand, and non-conventional pollutants.

This piece will guide you through each step to conduct a successful environmental audit for wastewater treatment facilities. Our practical approach will help you become skilled at this crucial process, whether you’re an experienced environmental professional or new to compliance management.

Understanding the Purpose of Environmental Audits

Environmental audits help organizations track their environmental effects and management systems. These structured evaluations give a complete picture of environmental compliance and performance that goes way beyond regular inspections.

What is an environmental audit?

An environmental audit reviews and documents how well organizations meet their environmental responsibilities. The process helps identify gaps in compliance and management systems, then suggests fixes. These audits work like financial audits and give organizations a clear picture of their environmental obligations.

Two main types of environmental audits exist: compliance audits and management systems audits.

Environmental auditors look at water usage, wastewater treatment, air emissions, waste management, and chemical handling. They gather evidence and review documents to make sure systems meet current standards and regulations.

Why audits matter in wastewater treatment

Wastewater treatment facilities use environmental audits as vital tools to find ways to save money, work better, and improve capacity. These audits can spot equipment problems that might get pricey, cause downtime, or break regulations.

Environmental protection laws make it necessary to review water and wastewater treatment plants regularly. These reviews prove that treatment plants work efficiently—a vital part of following regulations.

There’s another reason wastewater management audits are important. They can spot small changes in pressure, unusual control patterns, or minor flow issues that might signal bigger problems. Finding these warning signs early helps prevent expensive shutdowns, damaged equipment, and regulatory violations.

Environmental audit objectives and scope

The main goals of environmental audits are to:

- Find environmental risks in an organization’s operations

- Make sure organizations follow environmental laws at all levels

- Help sustainability by reviewing resource use and waste creation

- Make environmental performance better

- Reduce environmental incidents by spotting risks early

Wastewater treatment audits look at infrastructure, current practices, and ways to follow regulations. They also find management gaps and suggest fixes. Many audit plans review facility design, layout, and location criteria.

These audits give a full picture by looking at treatment processes, maintenance timing, lab testing methods, and safety procedures. They don’t just check if rules are followed—they review the whole system’s sustainability and long-term success.

Preparing for the Audit: Key Roles and Tools

Environmental audit success depends on careful preparation before visiting the site. Good planning will give the audit team a quick way to check compliance and find ways to improve the wastewater treatment process.

Who conducts the audit?

People from different backgrounds and expertise conduct environmental audits. In India, State Pollution Control Boards (SPCBs) or Pollution Control Committees (PCCs) bring in qualified institutes, organizations, or firms to do these audits. External auditors provide unbiased evaluations that carry more weight than internal reviews.

A company’s environmental team handles internal audits. These self-checks help spot potential risks before regulatory inspections take place. Both methods serve different purposes. Internal audits get organizations ready for compliance. External audits check if standards are met.

The best audit teams have professionals who know environmental regulations and understand how the facility works. This mix of skills helps auditors spot areas that need regulatory attention and violations that could affect performance. The core team must understand regulatory requirements and operational contexts, whether they’re engineers, scientists, lawyers, or business operators.

Essential documents and flow diagrams

The audit team needs to collect and review several important documents:

- Site drawings and flow diagrams

- Previous energy and environmental audit reports

- Agreements with utility companies

- Climate data relevant to facility operations

- Pump and blower curves for equipment evaluation

- Copy of the State Pollution Elimination Discharge System (SPEDS) permit

- Process flow charts that illustrate the environmental audit procedure

Flow diagrams help everyone see the audit process clearly. These diagrams show each step from registration to certification, which helps auditors and facility staff understand what happens next.

Using the environmental audit checklist

A well-laid-out checklist looks at many parts of wastewater treatment operations. This includes drainage systems, water flow monitoring, plant design, operations and maintenance procedures, operator skills, and local regulation compliance. The checklist should cover facility conditions, air emissions, water discharge, waste management, chemical storage, emergency planning, and management policies.

Auditors must record their observations and data through physical inspection and verification while using these checklists. In fact, successful compliance auditing depends on good documentation of findings, which are the foundations for corrective action plans and future improvements.

Step-by-Step Inspection of Wastewater Treatment Units

A full picture of wastewater treatment units serves as the foundation of any environmental audit that works. When you analyze each treatment stage, you can see how well operations run and if they comply with regulations. This helps spot potential risks before they become bigger problems.

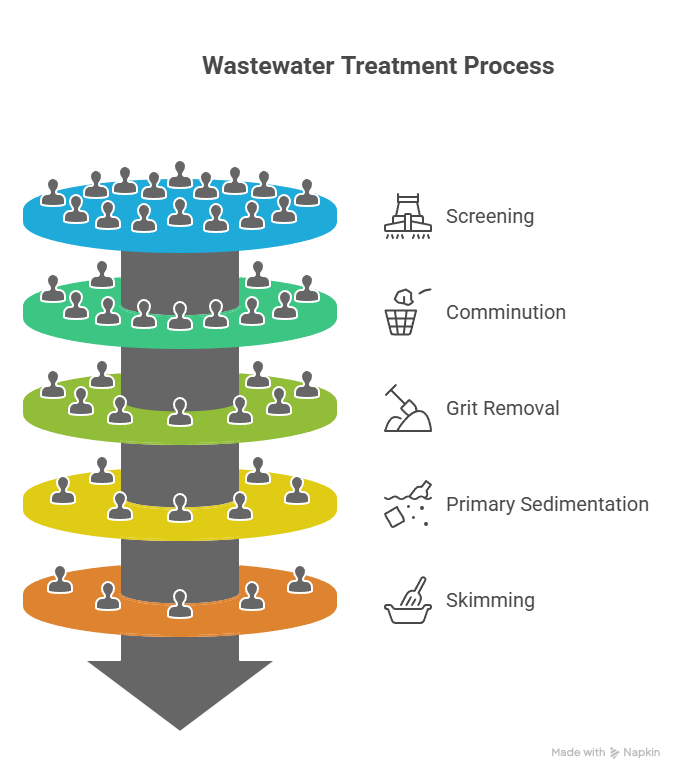

Preliminary treatment: screens and grit removal

The first step to audit a wastewater treatment facility starts with checking the preliminary treatment units. This phase has screening and grit removal among other methods like comminution. Auditors should watch for:

- Spacing of screening bars between 0.25 to 2.0 inches and excessive screen clogging

- Proper functioning of comminutors that grind solid waste into smaller pieces

- Velocity-controlled grit removal processes maintaining approximately 1 foot per second

- Operational status of air diffusers in aerated grit chambers

Your preliminary treatment audit should confirm that coarse screens (openings over 6mm) catch larger debris while micro screens (openings as small as 1mm) remove finer particles. You should then check if comminutors use rotating blades properly to prevent larger solids from blocking or damaging downstream equipment.

Primary treatment: sedimentation tanks

The review of primary sedimentation tanks focuses on removal efficiency and operational parameters. Key inspection points include:

- Checking for excessive gas bubbles, grease accumulation, or floating sludge

- Verifying hydraulic retention time (HRT), which typically ranges between 0.33 to 13 hours

- Looking at influent/effluent characteristics with typical SS removal rates between 50-70%

- Inspecting sludge collection and removal mechanisms

Temperature substantially affects sedimentation efficiency because warmer temperatures reduce water viscosity and enhance settling rates. Inspectors should record water temperature along with other parameters.

Secondary treatment: biological processes

Secondary treatment review concentrates on biological processes that remove dissolved organic matter. During this phase, check for:

Activated sludge tanks—look for adequate dissolved oxygen levels (>1.0 mg/l except in denitrification areas), proper mixed liquor color, and appropriate foam characteristics Trickling filters—check for ponding, uneven distribution, excessive sloughing, or odor issues Rotating biological contactors—look at biomass development, sloughing, and mechanical integrity

Tertiary treatment and disinfection

The tertiary treatment review covers advanced filtration and disinfection systems. Audit points include:

Filtration systems—check activated carbon, sand, or membrane filtration units for proper operation Chlorination—confirm adequate retention time (typically 30 minutes at peak flow) and proper chlorine feed systems UV disinfection—confirm all bulbs work and quartz sleeves are clean Alternative systems—review ozonation equipment if applicable

Sludge treatment and disposal

The final audit component looks at sludge management practices. The Smart Sludge Management Audit (SSMA) concept helps review the whole process from generation to final usage. Your inspection should verify:

Appropriate sludge wasting rates (typically 0.65-0.85 lbs of sludge per lb of BOD removed) Effective thickening, dewatering, and storage facilities Proper handling of treated sludge and compliance with disposal regulations Biogas utilization efficiency if anaerobic digestion is used

Many wastewater facilities find that proper treatment and disposal of sludge can get pricey and complex. This part of the audit just needs extra attention to ensure environmental compliance and operational efficiency.

Evaluating Safety, Maintenance, and Lab Practices

Proper upkeep, lab protocols, and safety practices are the key pillars that make environmental audits work. These operational elements go beyond just checking equipment. They determine how well a facility stays compliant and reliable over time.

Maintenance schedules and equipment checks

A well-laid-out maintenance schedule helps prevent breakdowns that can get pricey while making equipment last longer. A complete schedule has daily performance checks, weekly filter and screen cleaning, monthly sensor adjustments, quarterly gasket and seal inspections, and yearly assessment of all equipment. This preventive approach helps wastewater treatment facilities stay within regulations and avoid expensive emergency fixes.

Automatic samplers need specific checks before each field trip. The team must verify proper operation through forward, reverse, and automatic modes. They should check desiccant, batteries, and run at least one purge-pump-purge cycle to ensure everything works. The pumping volume needs verification at least twice with adjusted containers before sampling starts.

Equipment records are just as crucial. Each piece of equipment should have a log that tracks repairs. The log identifies samplers by manufacturer’s serial number, model number, and property control details. Equipment needs proper tagging after field use to show what cleaning it needs. Any mechanical problems should be clearly noted.

Lab testing and sampling protocols

Good sampling protocols are the foundations of accurate compliance checks. The team must verify that all sampling equipment is clean based on set procedures. Samples need proper custody seals during storage or shipping. Chain-of-custody papers must stay with samples until someone else takes over.

Temperature control makes a big difference in sample quality. Samples should stay at 4°C during collection and transport. The team should run analyzes within one day of sampling, so quick lab delivery is crucial.

Field books must record all sampling details, including photos, sampling location diagrams, and field data. Quality control is essential. Even facilities that run their own tests should send duplicate samples to environmental agency labs.

Personal protective equipment and safety signage

Safety comes first during wastewater sampling and treatment. Workers must use proper protective gear. This means gloves, eye shields when needed, and sometimes hearing protection and steel-toed boots in industrial settings. Clean latex gloves are a must when collecting volatile organic samples to avoid contamination.

Safety signs remind everyone about hazards and needed precautions. These signs work best at eye level, with nothing blocking them, and close to the hazard they warn about. Regular sign checks help spot any faded, damaged, or missing signs that need replacement right away.

Sign inspections should confirm that all signs meet required standards, stay visible, and clearly show hazards. These checks look at fire alarms, eyewash stations, exit signs, and emergency kits to make sure everything works and people can reach them easily.

Ensuring Compliance and Recordkeeping

A solid regulatory compliance framework serves as the foundation of every successful wastewater treatment facility. Good recordkeeping shows compliance with legal standards and helps improve the environmental audit process.

Legal requirements and permits

Wastewater facilities need proper permits to discharge treated effluent. The National Pollutant Discharge Elimination System (NPDES) under the Clean Water Act regulates direct discharges into navigable waters. The EPA has given 43 states the authority to run this program. Facilities must provide detailed analytical data about pollutants in their effluent during permit applications. India’s Water Pollution Control Act of 1977 takes a different approach by letting authorities charge for industrial or household water use.

The Environmental Protection Act (EPA) of 1986 gives state governments the power to enforce wastewater standards that vary by industry. If standards differ, facilities must follow the stricter requirements.

Monitoring and reporting procedures

Wastewater operators submit regular Discharge Monitoring Reports (DMRs) to show their treatment works. Most jurisdictions require electronic submission through systems like NetDMR. The documentation should cover maintenance records, lab analyzes, and incident reports.

Facilities should keep these records to verify compliance:

- Copies of all environmental permits

- Environmental inspection reports and checklists

- Chemical inventories and usage logs

- Employee training records

Common audit findings and how to fix them

Audits often find issues like missing permits, unmet permit requirements, and poor waste handling practices. Violations frequently stem from outdated environmental programs that don’t match current site conditions or regulatory standards.

The solution lies in implementing corrective actions that include quick fixes, root cause analysis, and checking if the changes work. High-risk findings demand immediate attention – operating after finding serious compliance issues could lead to bigger penalties if something goes wrong.

Conclusion

Wastewater treatment facilities use environmental audits as key tools to stay compliant with regulations and run efficiently. This piece explores the complete process of these essential evaluations. The focus stays on everything from early preparation to final documentation.

Becoming skilled at environmental audits needs a clear grasp of their purpose. They help identify risks, ensure compliance, and boost environmental performance. Good preparation separates basic inspections from meaningful assessments. The process runs smoothly when qualified audit teams come together and gather key documents beforehand.

A step-by-step inspection gives structure to explore each treatment phase. The audit covers preliminary screening through tertiary treatment and sludge management. This organized evaluation spots areas that need improvement. It also confirms the treatment system works properly.

Audits must focus equally on safety rules, maintenance plans, and lab practices. These core elements help facilities stay compliant and reliable over time. Auditors verify proper records of maintenance work, sampling methods, and safety steps.

Regulatory compliance creates the foundation for successful wastewater management. Detailed records show adherence to legal standards and support ongoing improvements. Quick fixes prevent small problems from growing into serious violations when audits reveal issues.

The whole process might look daunting at first. Breaking it into smaller steps makes this vital task both doable and worthwhile. You can develop a systematic way to evaluate wastewater operations by doing this. Regular audits become powerful tools that reduce risks, boost performance, and support environmentally responsible wastewater management.

Key Takeaways

Environmental audits are systematic diagnostic tools that go beyond simple compliance checking to evaluate entire wastewater management systems and identify improvement opportunities.

- Prepare thoroughly by assembling qualified audit teams, gathering essential documents like flow diagrams and permits, and using comprehensive checklists to guide the evaluation process.

- Follow a structured inspection approach examining each treatment stage from preliminary screening through tertiary treatment, focusing on operational efficiency and compliance status.

- Maintain rigorous safety protocols, documented maintenance schedules, and proper laboratory testing procedures to ensure long-term facility reliability and regulatory compliance.

- Address audit findings promptly through corrective action plans, comprehensive recordkeeping, and regular monitoring to prevent minor issues from escalating into serious violations.

- Implement regular audits as powerful tools for risk mitigation, performance enhancement, and sustainable wastewater management rather than one-time compliance exercises.

When conducted systematically, environmental audits transform from overwhelming regulatory requirements into valuable management tools that drive operational excellence and environmental protection in wastewater treatment facilities.

Frequently Asked Questions

Q1. What is the purpose of an environmental audit for wastewater treatment facilities?

Environmental audits for wastewater treatment facilities serve as diagnostic tools to evaluate compliance, identify risks, and improve overall environmental performance. They help facilities detect potential issues early, ensure regulatory compliance, and optimize operational efficiency.

Q2. Who typically conducts environmental audits?

Environmental audits can be conducted by both internal teams and external professionals. Internal audits are often performed by a company’s environmental team, while external audits may be carried out by qualified institutes, organizations, or firms engaged by regulatory bodies like State Pollution Control Boards.

Q3. What are the key components of a wastewater treatment facility inspection?

A thorough inspection includes examining preliminary treatment (screens and grit removal), primary treatment (sedimentation tanks), secondary treatment (biological processes), tertiary treatment and disinfection, and sludge treatment and disposal. Each stage is evaluated for efficiency and compliance with regulations.

Q4. How important is maintenance in the environmental audit process?

Maintenance is crucial in the audit process. A structured maintenance schedule helps prevent costly breakdowns, extends equipment lifespan, and ensures long-term compliance. Auditors check for regular equipment checks, cleaning protocols, and proper documentation of maintenance activities.

Q5. What should facilities do if audit findings reveal compliance issues?

When audits uncover compliance issues, facilities should implement corrective action processes. This includes making immediate short-term corrections, conducting root cause analysis, and verifying the effectiveness of implemented solutions. For high-risk findings, immediate action is necessary to avoid potential penalties.