Here’s a shocking fact – only 52% of sewage worldwide gets proper treatment. Sewage treatment plants play a vital role in protecting our environment and public safety, though their implementation varies drastically across the globe.

The numbers tell an interesting story. High-income countries treat about 74% of their sewage. However, developing nations manage just 4.2% on average. Sewage treatment plants serve an essential purpose by collecting, treating and discharging wastewater. Our natural water sources and delicate ecosystems would face contamination from harmful pollutants without proper treatment. Modern STP plants now run mostly on automation, which has improved their performance and cut down the risk of human errors. The treatment process works in stages. Primary treatment removes about 60% of solids and 35% of BOD. Secondary treatment follows and eliminates roughly 85% of BOD and solids. Advanced wastewater treatment takes things further – it can remove over 95% of BOD, solids, nitrogen, and phosphorus.

This piece will walk you through the basic processes of sewage treatment plants, their core components, and their role in protecting public health and environmental balance.

Understanding Sewage and the Need for Treatment

What is sewage and where does it come from?

Human activity creates wastewater we call sewage. This wastewater contains 99.9% water, and the remaining 0.1% consists of dissolved and suspended solids. These solids break down into proteins (40%), carbohydrates (25-50%), oils and grease (10%), and various chemicals.

Sewage comes from three main sources. Domestic sewage flows from our homes, including waste from toilets, kitchens, and bathrooms. Businesses and service establishments generate commercial sewage that serves communities. Manufacturing processes and production facilities create industrial wastewater.

Why sewage treatment is essential for public health

Raw sewage contains dangerous pathogens that can make people seriously ill. Bacteria like Salmonella and E. coli, viruses such as hepatitis A and rotavirus, protozoa including Giardia and Cryptosporidium, and helminths (intestinal worms) thrive in untreated sewage. These pathogens spread infectious diseases rapidly through contaminated water.

Waterborne diseases kill around 829,000 people each year. Developing countries bear 90% of these deaths, and children make up almost half of the victims. Sewage treatment plants protect our communities by removing these deadly pathogens before they reach our water sources.

Environmental risks of untreated wastewater

Raw sewage devastates natural water bodies. The high organic content uses up oxygen in water, creating “dead zones” where fish and other aquatic life cannot survive. Nitrogen and phosphorus overload leads to eutrophication, which triggers harmful algal blooms that choke aquatic ecosystems.

Raw sewage also dumps toxic chemicals into our water systems. Heavy metals, pharmaceuticals, microplastics, and industrial pollutants poison aquatic life. Today, people release more than 80% of global wastewater into the environment without proper treatment. This pollution damages sensitive ecosystems like coral reefs and seagrass beds, putting biodiversity at risk.

SUSBIO ECOTREAT, India’s most advanced packaged STP, helps solve these challenges by cleaning sewage thoroughly before it enters the environment. A well-designed sewage treatment process protects both public health and our natural ecosystems.

Core Stages of the Sewage Treatment Process

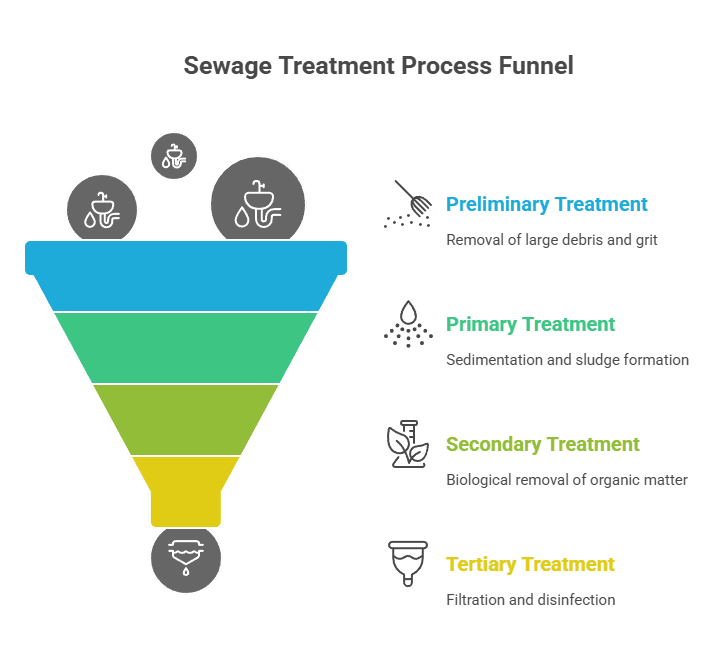

The sewage treatment process works through four sequential stages that clean wastewater step by step. Each stage targets specific contaminants and removes them through mechanical, biological, and chemical processes.

Preliminary treatment: Bar screens and grit chambers

Raw sewage flows into the preliminary treatment phase to remove large objects. Bar screens with 15-25mm spaces catch materials like rags, plastics, and sticks. Workers can clean these screens manually, or the system might use automated raking. The wastewater then moves to grit chambers where sand, gravel, and heavy particles settle naturally. This vital step shields downstream equipment from damage and cuts down maintenance needs. The grit chamber’s design could be horizontal flow, aerated, or vortex type. Each design maintains specific flow speeds to separate grit from organic matter.

Primary treatment: Sedimentation and sludge removal

The sewage then reaches primary sedimentation tanks (clarifiers) and stays there for 1.5 to 2.5 hours. Gravity pulls heavier solids down as primary sludge, while oils and grease float up for skimming. This stage removes 50-70% of suspended solids and 25-40% of biological oxygen demand (BOD). The system’s mechanical scrapers constantly push settled sludge toward collection hoppers.

Secondary treatment: Activated sludge and biofilters

The activated sludge process stands at the heart of secondary treatment. Microorganisms in aeration tanks consume organic matter when oxygen is added. This creates biological flocs that break down pollutants and cut BOD by more than 90%. Some plants use trickling filters instead, where bacteria grow on stone or plastic media beds and break down waste as water flows through.

Tertiary treatment: Disinfection and nutrient removal

The last stage tackles stubborn contaminants through advanced methods. Sand beds or membranes filter out remaining suspended solids. Chlorine, UV radiation, or ozone destroys harmful pathogens. The process removes nutrients like nitrogen and phosphorus through specialized biological processes. Nitrification turns ammonia into nitrates in oxygen-rich conditions, followed by denitrification in oxygen-poor environments. SUSBIO ECOTREAT, India’s most advanced packaged STP, brings all these stages together in a compact, efficient system ready for future needs.

Key Components of a Sewage Treatment Plant

Modern sewage treatment plants use specialized equipment that works in sequence to convert raw sewage into clean water. These components are the foundations of modern wastewater treatment systems.

Bar screens and comminutors

Bar screens act as the first physical barrier that catches large objects like rags and plastics. The spacing between these screens typically ranges from 15-50mm. Workers can clean them manually, or automated rakes can handle the task. Comminutors work like industrial grinders and shred larger solids into smaller pieces instead of removing them. Plant operators install them before pumping stations to protect pumps from damage, though this means solids stay in the system.

Grit chambers and pre-aeration tanks

Grit chambers remove sand, gravel, and other heavy inorganic materials that have a specific gravity around 2.65. The system uses three main types—horizontal flow, aerated, and vortex—that maintain velocities of 0.8-1.3 ft/s to separate grit from organic matter. Pre-aeration tanks help stabilize incoming wastewater and improve settling performance in primary clarifiers.

Aeration tanks and clarifiers

Aeration tanks supply oxygen to aerobic microorganisms that break down organic pollutants. Both diffused and mechanical aeration systems help maintain dissolved oxygen levels for effective biological treatment. Clarifiers use sedimentation to separate treated water from biological solids. The clear effluent flows over at the top while sludge collects at the bottom.

Sludge handling units and digesters

Sludge handling combines thickening to reduce volume and dewatering to increase solids content. Anaerobic digesters process organic solids without oxygen and produce biogas with high methane content that serves as renewable energy. This process cuts sludge volume by 40-50%. SUSBIO ECOTREAT, India’s most advanced packaged STP, blends these components into a compact, future-ready system.

Applications, Benefits, and Reuse of Treated Water

Treated wastewater serves as a valuable resource instead of waste. Modern sewage treatment plant processes create opportunities for environmentally responsible water management and environmental protection.

Reuse in irrigation and industrial cooling

Using treated sewage water substantially reduces the strain on freshwater sources for irrigation. Israel stands as a global leader by using 90% of its reclaimed water for agriculture. Industrial applications benefit too – treated wastewater in cooling towers saves large amounts of water. A pilot study showed a 27% reduction in water consumption and annual savings of 16,501 m³ for a 1,200-ton AC plant. SUSBIO ECOTREAT, India’s most advanced packaged STP, produces high-quality effluent that works perfectly for these applications.

Fertilizer and biogas from sludge

Sewage sludge becomes valuable through anaerobic digestion. This process creates biogas with high methane content that powers treatment facilities. The treated sludge also produces nutrient-rich fertilizer containing nitrogen, phosphorus, and essential micronutrients. Research shows that sludge-based fertilizers result in lower nitrate leaching compared to standard options.

Reducing pollution in rivers and lakes

Clean treated wastewater keeps our environment safe and protects aquatic ecosystems. STPs maintain oxygen levels in water bodies by removing pollutants. These treatment plants act as vital barriers between human waste and natural environments, which helps preserve biodiversity and ecosystem balance.

Conclusion

This piece explores how sewage treatment plants protect our public health and keep environmental balance. The numbers tell a stark story – developed nations treat 74% of their sewage while developing countries manage just 4.2%. This gap emphasizes our urgent need for better treatment facilities worldwide.

Clean water comes from a four-stage treatment process that works as one system. The preliminary, primary, secondary, and tertiary stages each target specific contaminants. These stages use more advanced methods as they progress and end up producing water that’s safe to discharge or reuse.

Bar screens, grit chambers, aeration tanks, and clarifiers create the foundation of good sewage treatment plants. A well-designed system that’s properly managed can remove up to 95% of pollutants. This reduces waste’s effect on our environment by a lot.

The lack of water makes treated wastewater valuable, especially for agricultural irrigation and industrial cooling. These are just two ways to use treated sewage instead of fresh water. The process also creates useful byproducts like biogas and nutrient-rich fertilizer, which help both the economy and environment.

“SUSBIO ECOTREAT” leads India’s packaged STP market with its state-of-the-art solution. It combines all treatment stages into one compact, quick system. This shows how modern technology can tackle wastewater challenges while recovering resources.

Our growing population and expanding cities make proper sewage treatment crucial. We must keep investing in treatment facilities – it’s not just good for the environment, it’s essential for sustainable human development. Clean water remains our most precious resource, and we need proper sewage management to protect it.

Key Takeaways

Understanding sewage treatment fundamentals is essential for protecting public health and environmental sustainability. Here are the critical insights every professional should know:

- Only 52% of global sewage receives proper treatment, with developing nations treating just 4.2% compared to 74% in high-income countries

- The four-stage treatment process (preliminary, primary, secondary, tertiary) progressively removes contaminants, achieving up to 95% pollutant removal

- Untreated sewage causes 829,000 annual deaths from waterborne diseases, with 90% occurring in developing countries

- Treated wastewater becomes a valuable resource for irrigation, industrial cooling, biogas production, and nutrient-rich fertilizer

- Modern sewage treatment plants protect aquatic ecosystems by preventing oxygen depletion and toxic contamination in water bodies

The gap between treatment needs and current infrastructure represents both a critical challenge and significant opportunity for sustainable development. Proper sewage treatment transforms waste into resources while safeguarding communities and ecosystems for future generations.

Frequently Asked Questions

Q1. What are the main stages of sewage treatment?

The main stages of sewage treatment are preliminary treatment (using bar screens and grit chambers), primary treatment (sedimentation and sludge removal), secondary treatment (activated sludge and biofilters), and tertiary treatment (disinfection and nutrient removal).

Q2. Why is sewage treatment important for public health?

Sewage treatment is crucial for public health because it eliminates harmful pathogens that can cause waterborne diseases like cholera, typhoid, and dysentery. Proper treatment prevents the spread of these illnesses, which claim approximately 829,000 lives annually, mostly in developing countries.

Q3. How does untreated sewage affect the environment?

Untreated sewage severely impacts the environment by depleting oxygen levels in water bodies, causing eutrophication, introducing toxic chemicals and microplastics, and damaging fragile ecosystems like coral reefs. It threatens biodiversity and creates “dead zones” where aquatic life cannot survive.

Q4. What are some applications for treated wastewater?

Treated wastewater has various applications, including irrigation for agriculture, industrial cooling processes, and groundwater recharge. It significantly reduces the demand on freshwater sources and provides a sustainable alternative in water-scarce regions.

Q5. What valuable byproducts can be obtained from sewage treatment?

Sewage treatment produces valuable byproducts such as biogas and nutrient-rich fertilizer. Biogas, generated through anaerobic digestion, can be used as a renewable energy source. The treated sludge creates fertilizer containing essential nutrients like nitrogen and phosphorus, which can be used in agriculture.