Sewage Treatment Plants (STPs) are at the core of sustainable wastewater management, offering vital solutions for protecting the environment, conserving water resources, and ensuring public health. With rapid urbanization and increasingly stringent environmental regulations, the demand for efficient, eco-friendly, and technologically advanced sewage treatment solutions is at an all-time high.

In this blog, we explore what STPs are, how they work, their key benefits, advanced technologies involved, and future trends shaping the industry.

What is a Sewage Treatment Plant (STP)?

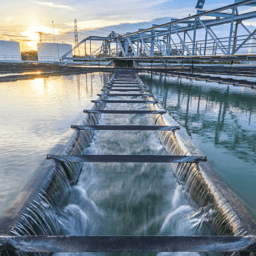

A sewage treatment plant is a facility that treats wastewater from residential, commercial, and industrial sources. It removes contaminants like organic matter, solids, nutrients, and pathogens, producing treated water that can be safely discharged into natural water bodies or reused for non-potable applications like irrigation, landscaping, or industrial processes.

Key Benefits of Sewage Treatment Plants

- Environmental Protection: By treating wastewater before discharge, STPs prevent pollution of rivers, lakes, and oceans.

- Water Reuse: Treated water can be repurposed for non-potable uses like agriculture or industrial cooling.

- Public Health Safety: Proper treatment eliminates harmful pathogens, reducing the risk of waterborne diseases.

- Regulatory Compliance: Industries and municipalities can meet environmental standards and avoid penalties by using STPs.

- Energy Recovery: Modern STPs can generate energy through processes like anaerobic digestion of sludge.

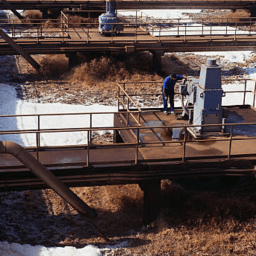

How Do Sewage Treatment Plants Work?

STPs operate through a series of processes designed to treat wastewater in stages:

- Preliminary Treatment:

- Removes large debris like plastics and stones using screens and grit chambers.

- Primary Treatment:

- Sedimentation tanks separate suspended solids from wastewater.

- Secondary Treatment:

- Biological processes break down organic matter using microorganisms in systems like activated sludge or trickling filters.

- Tertiary Treatment:

- Advanced methods such as filtration, disinfection (UV or chlorine), and nutrient removal ensure high-quality effluent.

- Sludge Management:

- Sludge generated during treatment is processed for safe disposal or converted into biogas for energy recovery.

Top Sewage Treatment Technologies

- Activated Sludge Process (ASP)

- A widely used biological treatment method that uses aeration tanks to promote microbial activity.

- Suitable for municipal wastewater treatment.

- Membrane Bioreactor (MBR)

- Combines biological treatment with membrane filtration for superior effluent quality.

- Ideal for areas with stringent discharge standards.

- Sequencing Batch Reactor (SBR)

- A batch-based process offering flexibility in nutrient removal.

- Compact design makes it suitable for small to medium-scale applications.

- Moving Bed Biofilm Reactor (MBBR)

- Uses biofilm carriers to enhance biological treatment efficiency.

- Low maintenance and energy-efficient.

- Anaerobic Digestion

- Converts organic waste into biogas while reducing sludge volume.

- A sustainable solution for energy recovery.

Optimizing Efficiency in Sewage Treatment Plants

To maximize the performance of STPs while minimizing costs and environmental impact, consider these strategies:

- Energy Optimization:

- Upgrade to energy-efficient equipment like variable frequency drives (VFDs) for pumps and blowers.

- Integrate renewable energy sources such as solar panels or biogas systems.

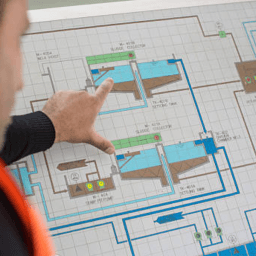

- Automation & Monitoring:

- Use advanced control systems to monitor parameters like flow rate, pH levels, and nutrient concentrations in real time.

- Regular Maintenance:

- Conduct routine inspections to prevent breakdowns and ensure optimal performance.

- Sludge Management:

- Implement efficient dewatering processes or explore options like composting or anaerobic digestion for sludge reuse.

- Staff Training:

- Equip operators with the knowledge to handle advanced technologies and respond effectively to operational challenges.

Future Trends in Sewage Treatment

The future of sewage treatment lies in sustainability and innovation:

- Decentralized Systems:

- Compact STPs designed for small communities or remote areas reduce infrastructure costs and improve accessibility.

- AI & IoT Integration:

- Artificial intelligence and Internet of Things (IoT) technologies enable predictive maintenance and process optimization.

- Resource Recovery:

- Advanced systems recover valuable resources like phosphorus from wastewater for use as fertilizers.

- Carbon Neutrality Goals:

- Many facilities are adopting renewable energy solutions to reduce their carbon footprint.

Conclusion

Sewage treatment plants are indispensable for managing wastewater responsibly in today’s world. By adopting advanced technologies like MBRs or SBRs and focusing on energy efficiency, industries and municipalities can not only meet regulatory requirements but also contribute to a sustainable future.

Investing in modern sewage treatment solutions is an investment in environmental protection, resource conservation, and public health. Whether you’re planning a new installation or upgrading an existing system, choosing the right technology tailored to your needs is key to long-term success.

For more insights into wastewater management solutions or expert guidance on optimizing your sewage treatment plant, stay connected with our blog!