Sewage Treatment Plants (STPs) are essential for modern urban and industrial infrastructure, ensuring that wastewater is treated safely and efficiently before being released or reused. From understanding the basics to installation, operation, and disinfection, this guide covers everything you need to know about STPs—including why SUSBIO is India’s trusted STP plant manufacturer.

What Are STPs? Understanding the Basics

A Sewage Treatment Plant (STP) is a facility designed to remove contaminants from wastewater, making it safe for discharge into the environment or for reuse. STPs play a crucial role in protecting public health, preserving water bodies, and ensuring compliance with environmental regulations.

Sewage Treatment Plant (STP): Process, Working & Installation

Process and Working:

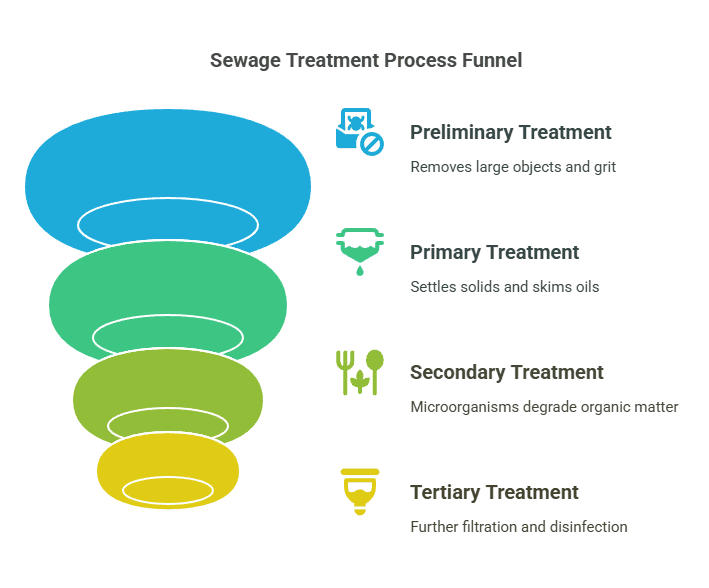

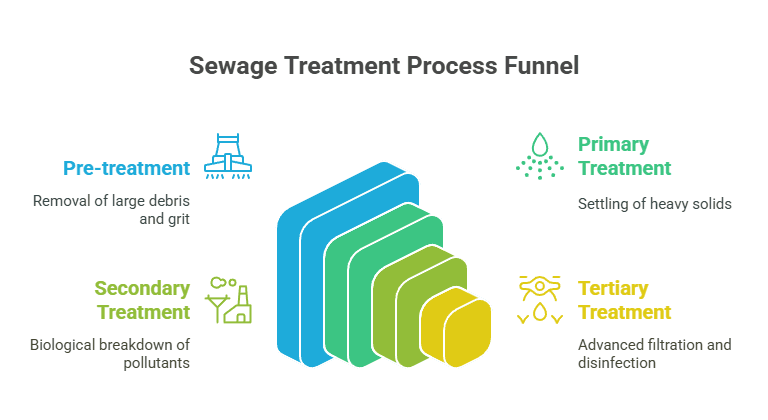

- Preliminary Treatment:

- Screening removes large objects like rags, plastics, and debris to prevent equipment damage and blockages.

- Grit chambers separate sand, gravel, and small stones, protecting pumps and pipes from abrasion and wear.

- Skimming tanks remove oils and grease that float on the surface, while heavier solids settle at the bottom.

- Primary Treatment:

- Wastewater enters sedimentation or primary clarifier tanks where flow velocity is reduced.

- Heavier suspended solids settle as sludge, and lighter materials like grease and oils float and are skimmed off.

- This stage removes about 30% of the organic matter and significantly reduces the load on subsequent biological treatment units.

- Secondary Treatment (Biological Treatment):

- Effluent from primary treatment is directed to biological reactors (such as aeration tanks, trickling filters, or biofilm reactors).

- Microorganisms (mainly bacteria) degrade dissolved and colloidal organic matter under aerobic or anaerobic conditions.

- Aeration supplies oxygen for aerobic bacteria, converting organic pollutants into carbon dioxide, water, and more biomass.

- The treated water then flows to secondary clarifiers, where microbial biomass (activated sludge) settles out. Some sludge is recycled to maintain bacterial populations; excess is removed for further treatment.

- Tertiary Treatment (Advanced Treatment):

- Further filtration and chemical or physical processes (such as sand filtration, activated carbon, reverse osmosis, or disinfection) are used to polish the effluent.

- Disinfection (chlorination or UV) ensures removal of pathogens, making the water safe for discharge or reuse.

Installation Steps:

- Conduct a comprehensive site assessment, considering soil, space, proximity to water sources, and legal requirements.

- Determine the required STP capacity based on projected wastewater flow.

- Design and engineer the STP layout to meet regulatory and environmental standards.

- Obtain necessary permits and approvals from authorities.

- Procure high-quality equipment and materials, including tanks, pumps, aerators, and control systems.

- Assemble and install all STP components according to design specifications.

- Complete plumbing and electrical works for smooth integration.

- Commission the plant, test all systems, and train operators for optimal performance.

Challenges and Drawbacks of Sewage Treatment Plants

- High Installation Costs: Significant capital is required for construction, equipment, and setup, especially for large-capacity plants.

- Operational and Maintenance Expenses: Continuous power supply is essential, leading to high energy costs. Annual maintenance, including parts replacement and skilled labor, adds to operational expenses.

- Odor and Noise Issues: Decomposition of organic matter can produce foul odors (hydrogen sulfide, ammonia) affecting workers and nearby communities. Equipment like blowers and pumps may generate noise pollution.

- Bacterial Imbalance: Fluctuations in bacterial populations can disrupt treatment efficiency, slow down processes, or lead to the proliferation of resistant strains.

- Sludge Management: Handling, treatment, and disposal of sludge byproducts require additional infrastructure and compliance with environmental standards.

- Environmental Footprint: Residues and greenhouse gas emissions (CO2, N2O) from treatment processes contribute to the plant’s carbon footprint. Improperly managed sludge or effluent can cause secondary pollution.

- Land Requirements: Large land areas are needed for construction, which can be challenging in densely populated urban areas.

- Infrastructure and Regulatory Challenges: Outdated equipment and infrastructure may struggle to meet modern wastewater volumes and stricter regulations. Obtaining and maintaining compliance with evolving environmental standards can be complex.

- Peak Flow and Capacity Issues: Plants may face difficulties managing peak inflows, risking overflow and untreated discharges.

- Skilled Workforce Shortages: Efficient operation requires trained personnel, which may be scarce, especially in remote locations.

Types of Sewage Treatment Plants

- Conventional Activated Sludge Process (ASP): Uses aeration and sedimentation to treat municipal sewage.

- Sequential Batch Reactors (SBR): Operate in timed cycles, ideal for variable flow rates and loads.

- Moving Bed Biofilm Reactor (MBBR): Employs suspended biofilm carriers for efficient treatment in compact spaces.

- Membrane Bioreactor (MBR): Combines biological treatment with membrane filtration for high-quality effluent.

- Extended Aeration: Simplified system with longer aeration, suitable for smaller communities.

- Package STPs: Pre-engineered, modular units for rapid deployment and easy installation.

Components of a Sewage Treatment Plant

- Inlet Chamber: Entry point for raw sewage, equipped with screens and grit chambers to remove large debris, plastics, sand, and gravel.

- Screening Unit: Removes coarse solids and floating materials that could damage downstream equipment.

- Grit Chamber: Allows sand, gravel, and small stones to settle, protecting mechanical parts from abrasion.

- Comminutors (if present): Chop up remaining solids to facilitate further treatment.

- Pre-aeration Tank: Adds oxygen to the wastewater, reducing odors and aiding subsequent biological treatment.

- Primary Sedimentation Tank: Slows down water flow, allowing heavy solids to settle as sludge and lighter materials to float for removal.

- Skimmers: Remove floating grease and scum from the surface of tanks.

- Aeration Tank (Secondary Treatment): Provides oxygen to support aerobic bacteria that break down organic pollutants.

- Biological Filters (if present): Media beds where microorganisms further degrade organic matter.

- Secondary Clarifier: Separates treated water from biological sludge, which settles at the bottom.

- Tertiary Treatment Units: Advanced filtration (sand filters, activated carbon, reverse osmosis) and disinfection (chlorine, UV) for final polishing.

- Disinfection Unit: Ensures pathogenic microorganisms are destroyed before discharge or reuse.

- Sludge Handling Units: Thickening units concentrate sludge; digesters reduce its volume and stabilize organic content; dewatering systems remove excess water for easier disposal or reuse.

- Control Panel: Automates and monitors plant operations, ensuring safety and efficiency.

Advantages of STPs in Urban and Residential Settings

STPs are crucial for cities and housing developments, as they prevent untreated sewage from contaminating rivers and groundwater. They help reduce the spread of waterborne diseases and enable the reuse of treated water for landscaping, flushing, or industrial purposes. Modern STPs are designed to minimize odor and noise, ensuring they are neighborhood-friendly. Additionally, they support compliance with environmental regulations and can even recover resources like biogas or nutrients from sludge.

Chlorination in Sewage Treatment

Chlorination is a widely adopted disinfection method in STPs, ensuring that treated wastewater is free from harmful bacteria, viruses, and other pathogens. The process involves adding chlorine compounds to the final effluent, which rapidly destroys microorganisms and provides a residual effect to prevent recontamination during storage or transport.

Types of Chlorine Used in STP Disinfection

- Chlorine Gas: Highly effective and economical for large-scale plants but requires careful handling due to its hazardous nature.

- Sodium Hypochlorite: A liquid form of chlorine, easy to store and dose, commonly used in small to medium-sized STPs.

- Calcium Hypochlorite: Available as granules or tablets, stable and suitable for remote or decentralized installations.

Why Wastewater is Treated with Chlorine

Chlorine is used in wastewater treatment because it is a powerful and fast-acting disinfectant. It not only eliminates disease-causing organisms but also helps control odors and ensures that the treated water meets regulatory standards for safe discharge or reuse. The use of chlorine is particularly important in applications where the treated water may come into contact with humans or be used for irrigation.

Choosing the Right STP Solution

Selecting the right STP begins with a thorough assessment of your wastewater volume, quality, and site constraints. Consider the available space, budget, and operational requirements. Evaluate the pros and cons of different technologies—such as ASP, SBR, MBBR, or MBR—and opt for a system that offers automation, energy efficiency, and ease of maintenance. Reliable after-sales support and compliance with local regulations are also critical factors in making the right choice.

Why SUSBIO is the Trusted STP Plant Manufacturer in India

SUSBIO has established itself as a leader in India’s STP market by delivering innovative, energy-efficient, and robust sewage treatment solutions. Their plants are designed for Indian conditions, offering durability, low maintenance, and superior performance. SUSBIO provides turnkey services, from design and installation to commissioning and maintenance, ensuring a hassle-free experience for clients. With a commitment to quality, regulatory compliance, and customer satisfaction, SUSBIO is the preferred partner for residential, commercial, and industrial sewage treatment projects across the country.

Frequently Asked Questions (FAQs)

Q1: How long does it take to install an STP?

Most packaged STPs can be installed and commissioned within a few weeks, depending on site conditions and plant size.

Q2: Is treated sewage water safe for reuse?

Yes, when properly treated and disinfected, the water is safe for uses like gardening, flushing, and landscaping.

Q3: What are the main maintenance tasks for an STP?

Regular cleaning of screens, monitoring aeration systems, checking pumps, and periodic sludge removal are essential.

Q4: Can an STP treat industrial wastewater?

Some STPs can be customized for industrial effluent, but the process must be tailored to the specific contaminants present.

Q5: How is sludge managed in an STP?

Sludge is typically dewatered and can be composted, used as fertilizer, or disposed of according to environmental guidelines.

Conclusion

A well-planned and expertly installed Sewage Treatment Plant is a smart investment for urban and residential developments. STPs protect the environment, enable water reuse, and ensure compliance with health and safety standards. By choosing the right technology and a trusted manufacturer like SUSBIO, you can enjoy efficient, sustainable, and worry-free sewage treatment from installation to daily operation.

Ready to transform your wastewater management? Partner with SUSBIO for reliable, future-ready STP solutions tailored to your needs.