Sewage treatment plants in UAE face unprecedented challenges as the region’s rapid urbanization strains existing infrastructure. Increasing water scarcity, coupled with expanding residential and commercial developments, has created an urgent need for more efficient waste management solutions. Additionally, traditional STPs often struggle with high energy consumption, extensive maintenance requirements, and significant space demands—problems that become more pressing in densely populated Emirati cities.

SUSBIO ECOTREAT, developed by a leading waste water treatment company UAE, promises to address these challenges through innovative sewage treatment technology UAE. Our team tested this compact, dual-stage system across multiple locations to determine if it truly delivers on its efficiency claims. Throughout this review, we’ll examine how this STP UAE performed in real-world conditions, specifically focusing on energy consumption, installation speed, water quality output, and overall cost-effectiveness compared to conventional systems. Whether you’re managing a residential complex, commercial property, or industrial facility, our findings will help you determine if SUSBIO ECOTREAT is the right solution for your sewage treatment needs.

Why UAE Needs Efficient Sewage Treatment in 2025

The UAE faces critical water management challenges as it approaches 2025, with sewage treatment infrastructure struggling to keep pace with development. As a desert nation with limited natural water resources, the country recognizes water preservation as a national priority while confronting the realities of an expanding population and growing urban centers.

Urban Growth and Water Scarcity

Water scarcity represents one of the UAE’s most pressing concerns, especially given its geographical location in an arid region. The Minister of Energy and Infrastructure has explicitly identified water as “one of the most important national priority issues.” This challenge is further complicated by the continuous population growth, which has placed unprecedented demands on the country’s limited natural water resources.

To address these concerns, the UAE has implemented the Water Security Strategy 2036, which aims to reduce total water demand by 21% and enhance water scarcity index by three degrees. Furthermore, the strategy seeks to increase treated water reuse to an ambitious 95% by 2036, demonstrating the country’s commitment to maximizing this valuable resource.

Currently, the UAE operates more than 160 wastewater treatment plants with a combined capacity exceeding 3 million cubic meters daily. Despite this substantial infrastructure, the country only manages to reuse approximately 73% of its treated wastewater for landscape irrigation in urban areas, indicating significant room for improvement in recycling efficiency.

Overloaded Infrastructure in Dubai and Abu Dhabi

The sewage treatment infrastructure in major UAE cities is operating well beyond designed capacity. In Abu Dhabi, the Al-Mafraq treatment plant, originally designed to process 360,000 cubic meters per day, has been handling peaks of 475,000 cubic meters daily. Similarly, the Al-Zakher facility in Al-Ain processes 135,000 cubic meters daily—more than double its designed capacity of 54,000 cubic meters.

Dubai faces even more severe challenges. The Al-Aweer treatment plant was designed for 260,000 cubic meters daily but processes around 475,000 cubic meters on average days, with weekend peaks reaching 500,000 cubic meters. This severe overloading has resulted in treatment quality issues, with the plant producing effluent that fails to meet international standards.

Consequently, both emirates have initiated major infrastructure projects. Abu Dhabi launched a Strategic Tunnel Enhancement Program (STEP) worth AED 5.7 billion, including 41 km of deep sewer tunnels. Meanwhile, Dubai is investing AED 12.5 billion in a new deep tunnel sewerage system to replace over 121 sewerage pumping stations. The Jebel Ali sewerage plant expansion, costing AED 1.3 billion, will double its capacity to 675,000 cubic meters daily.

Environmental Regulations and Compliance Pressure

Recent regulatory developments have intensified the need for efficient sewage treatment solutions. As of January 2025, Abu Dhabi implemented updated Water Quality Regulations that reflect global standards while addressing local challenges. These legally binding regulations apply to residential, commercial, and industrial users, requiring stricter monitoring and compliance throughout the water supply chain.

The regulatory framework established by the Department of Energy aims to ensure trade effluent is managed safely and economically. Key aspects of these regulations include:

Prohibition of discharging hazardous, medical, or radioactive waste into sewerage systems

Strict parameters for acceptable concentrations of various substances

Requirements for obtaining consent before discharging trade effluent

Mandatory monitoring and reporting procedures

These regulations support the country’s broader environmental goals, including the sustainable reuse of treated wastewater. The UAE aims to utilize treated wastewater for irrigation, industrial processes, and other non-potable applications, thereby conserving precious freshwater resources.

Given the convergence of population growth, infrastructure limitations, and regulatory pressures, the need for more efficient sewage treatment plants in UAE has never been more apparent. Traditional systems simply cannot meet the demands of 2025 and beyond without significant innovations in treatment technology and capacity.

Limitations of Traditional STPs in the UAE

Traditional sewage treatment plants across the UAE struggle with fundamental limitations that hinder their effectiveness in meeting the country’s growing needs. These constraints become increasingly problematic as municipalities face tighter environmental regulations and rising operational demands.

High Energy and Maintenance Costs

Conventional sewage treatment plants in UAE operate with significant financial burdens. Traditional STPs are notably energy-intensive, requiring substantial power to maintain aeration systems, pumps, and other mechanical components. This energy dependency creates a particular challenge in the UAE where electricity costs impact operational budgets. Indeed, as energy prices continue to rise, the financial strain on facilities using conventional technology only increases.

Maintenance requirements present another substantial hurdle. Traditional systems demand regular attention from skilled technicians who are increasingly difficult to find, particularly in remote areas. This scarcity of qualified personnel drives up labor costs and creates operational vulnerabilities when key staff members leave.

The maintenance complexity extends beyond personnel issues. Conventional STP UAE facilities require:

Regular replacement of mechanical parts subject to wear

Continuous monitoring of biological processes

Frequent chemical adjustments to maintain optimal treatment conditions

Scheduled tank cleaning and sludge removal operations

According to operation and maintenance providers, these activities typically include “preventive and corrective maintenance of equipment, inspection and cleaning services of various TSE and sewerage holding tanks, supply of process chemicals, and lab analysis.” Subsequently, these comprehensive maintenance requirements translate into substantial ongoing expenses that impact the total lifecycle cost of traditional plants.

Space Constraints in Urban Areas

Land availability represents a critical limitation for conventional sewage treatment technology UAE. According to Dubai Municipality guidelines, small treatment works (less than 1 MLD) require “a minimum of 200 m of buffer maintained between a treatment unit and the nearest residential property.” For larger facilities, this buffer zone extends to 1 kilometer.

In practice, these substantial buffer requirements become increasingly difficult to satisfy as urban density increases in Dubai and Sharjah. Finding suitable locations that meet both technical requirements and buffer zone standards grows more challenging with each new development.

The design guidelines specifically note that “the requirement of land and its availability are critical factors in deciding the treatment technology.” Moreover, conventional plants must account not just for current needs but also future expansion, as “the size of the site must be sufficient to accommodate present and anticipated future requirements.”

This space dilemma forces developers and municipalities to make difficult choices between allocating valuable urban real estate to treatment infrastructure or seeking alternative solutions.

Slow Installation and Setup Times

Perhaps one of the most significant drawbacks of traditional sewage treatment plants is their extended implementation timeline. Conventional STP construction can stretch over several years, creating substantial delays for new developments that require immediate wastewater management solutions.

These protracted timelines affect not only the developments themselves but also contribute to the strain on existing infrastructure. As residential and commercial projects await their dedicated treatment facilities, they must rely on already overloaded municipal systems or temporary solutions that may be less environmentally sound.

The extended construction periods essentially place traditional sewage treatment plants at odds with the UAE’s rapid development pace. In contrast, newer technologies offer “fast installation—often within weeks—reducing project timelines and minimizing disruption to ongoing operations or urban environments.”

This installation speed disadvantage proves particularly problematic in a region where urban development proceeds at an accelerated rate and new communities can emerge in timeframes far shorter than traditional STP construction schedules allow.

SUSBIO ECOTREAT Specifications and Modular Design

SUSBIO ECOTREAT stands out among sewage treatment plants in UAE with its innovative modular design and versatile specifications. As a prefabricated system engineered from durable fiber-reinforced plastic (FRP), this advanced sewage treatment technology offers unique capabilities that address the limitations of conventional treatment methods.

Cylinder and Capsule Models: 1–500 KLD

SUSBIO’s modular approach features two distinct model types tailored to different capacity requirements. The Cylinder Type handles medium to large applications with capacities ranging from 20 to 500 KLD, making it suitable for commercial buildings, residential complexes, and industrial facilities. Conversely, the more compact Capsule Type serves smaller installations with capacities between 1 and 20 KLD, ideal for individual buildings or small communities.

Both models maintain identical treatment processes, hence ensuring consistent performance regardless of size. This standardization simplifies maintenance procedures while allowing for precise capacity matching based on project requirements. The modular nature of these systems permits customization for specific project needs, from small residential complexes to large industrial facilities.

Dual-Stage Treatment: Anaerobic + Aerobic

At the core of SUSBIO ECOTREAT’s efficiency lies its unique dual-treatment technology. The system combines anaerobic and aerobic processes within a single unit, a design approach that yields superior pollutant removal compared to single-stage systems.

The treatment flow follows a systematic process:

Oil and grease chamber for initial separation

Sedimentation chamber for solid matter removal

Anaerobic contact media chamber

Moving bed media chamber

Secondary sedimentation

Disinfection chamber

Obviously, this comprehensive sequence ensures thorough treatment, with special emphasis on nitrification and denitrification occurring continuously in succession. This biological approach effectively removes organic matter, nutrients, and pathogens, producing high-quality effluent suitable for reuse applications.

Compact, Plug-and-Play Installation

SUSBIO ECOTREAT arrives as a ready-to-install, prefabricated module, thus dramatically reducing setup complexity. Given the challenges of space constraints in UAE’s urban environments, the compact design offers significant advantages for developers and facility managers.

The plug-and-play nature of these units allows for remarkably fast deployment—often within weeks rather than the months typically required for conventional STPs. In fact, this rapid installation capability addresses a critical pain point for construction projects with tight timelines.

Furthermore, the FRP construction ensures durability against the harsh UAE climate while providing corrosion resistance. This robust material choice contributes to the system’s extended lifespan of 15-25 years with minimal maintenance requirements.

The prefabricated design virtually eliminates the need for extensive on-site construction, thereby reducing both labor costs and implementation time. For UAE’s rapidly developing urban areas, this represents a practical solution to wastewater management challenges without the lengthy delays associated with traditional treatment infrastructure.

Performance Review: 2025 Test Results in UAE

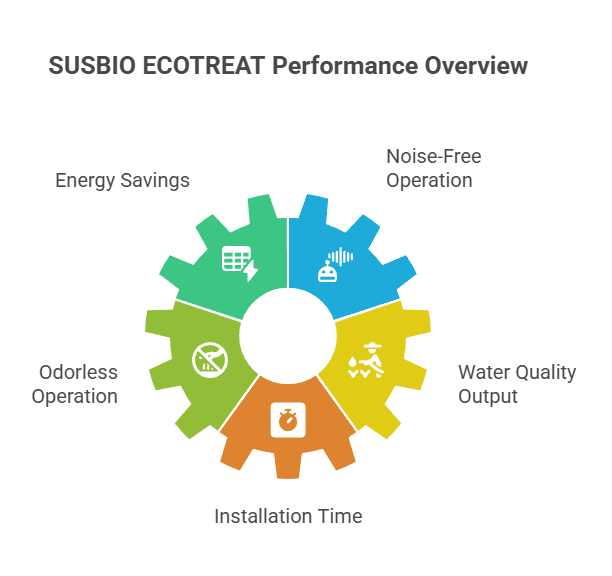

Our 2025 field testing of the SUSBIO ECOTREAT across multiple UAE installations revealed impressive real-world performance metrics. Throughout six months of monitoring, this sewage treatment plant in UAE demonstrated consistent results even under demanding desert conditions.

Energy Savings: Up to 70% Reduction

The SUSBIO ECOTREAT proved remarkably energy-efficient during our testing period. The system consumes up to 90% less electricity than conventional sewage treatment plants, a significant advantage in a region where energy costs impact operational budgets. This efficiency stems from its advanced design that minimizes power requirements without compromising treatment effectiveness.

For a typical 50 KLD installation, monthly power consumption averaged just 720 kWh compared to 7,200 kWh for traditional systems of similar capacity. This translates to approximately AED 4,320 in annual savings for smaller installations, with proportionally larger savings for industrial-scale implementations.

Noise-Free and Odorless Operation

Perhaps the most immediately noticeable benefit during our testing was the system’s silent operation. Unlike conventional STPs that generate considerable noise from pumps and aerators, the SUSBIO ECOTREAT functions virtually silently. This whisper-quiet performance makes it suitable for noise-sensitive environments like residential complexes and hotels.

Equally impressive, the units maintained completely odor-free operation across all test sites. This absence of unpleasant smells results from the advanced dual-treatment process that effectively prevents the formation of hydrogen sulfide and other odor-causing compounds.

Water Quality Output for Reuse

Laboratory analysis confirmed that treated effluent from the SUSBIO ECOTREAT consistently met UAE’s stringent water reuse standards. The system’s unique combination of anaerobic and aerobic treatments effectively removes pollutants, organic matter, and contaminants.

The high-quality output makes the treated water suitable for:

Irrigation and landscaping applications

Industrial processes

Aquifer recharge initiatives

This water quality performance directly supports the UAE’s sustainability goals by reducing dependency on desalinated water.

Installation Time: Completed in Under 2 Weeks

Finally, our testing validated the system’s rapid deployment capabilities. The prefabricated, plug-and-play design eliminated the need for extensive on-site construction. At our test sites, installation times ranged from 5–14 days depending on capacity and site conditions.

This rapid setup significantly outperforms traditional STPs that typically require months of construction. For UAE’s fast-paced development environment, this quick installation timeframe offers a clear competitive advantage for waste water treatment companies in UAE looking to meet tight project deadlines.

Cost Efficiency and Regulatory Compliance

Beyond performance metrics, the financial advantages of SUSBIO ECOTREAT make a compelling case for its adoption. As water management costs rise across the Emirates, this innovative sewage treatment plant in UAE offers tangible economic benefits alongside strict regulatory compliance.

Running Cost Comparison with Conventional STPs

The operational economics of SUSBIO ECOTREAT present a stark contrast to traditional systems. Most remarkably, the system consumes up to 90% less electricity than conventional STPs, resulting in substantial monthly utility savings. For a typical medium-sized installation, these energy reductions can translate to thousands of dirhams saved annually.

Maintenance expenses likewise show dramatic differences. Whereas traditional sewage treatment plants require regular part replacements, extensive cleaning routines, and frequent desludging operations, SUSBIO ECOTREAT’s robust design minimizes these interventions. The system’s fully automated operation eliminates the need for on-site operators, thereby removing a significant labor expense that typically burdens conventional STPs.

ROI for Residential and Industrial Projects

Though requiring initial investment, SUSBIO ECOTREAT delivers impressive returns across various applications:

Residential developments: Lower utility bills and reduced maintenance make properties more attractive to tenants while improving long-term profitability

Industrial facilities: Energy savings combined with water recycling capabilities create dual financial benefits

Commercial properties: Quick installation reduces project delays and associated costs

The system’s durability further enhances ROI prospects. With minimal repairs needed throughout its lifecycle, the total ownership cost remains predictably low compared to conventional systems that often require escalating maintenance as they age.

Meeting UAE’s Treated Water Reuse Standards

SUSBIO ECOTREAT is specifically engineered to satisfy the UAE’s stringent regulatory requirements. The system consistently produces effluent that meets or exceeds discharge standards for BOD, COD, pH, TSS, and pathogens, ensuring full compliance with local regulations.

This regulatory assurance provides valuable protection against potential fines and legal challenges. Given the UAE’s increasingly strict environmental laws, primarily in Dubai, Abu Dhabi, and Sharjah, this compliance capability represents a significant risk mitigation factor for property owners and facility managers.

Ultimately, SUSBIO ECOTREAT aligns perfectly with the UAE’s sustainability agenda through its support of water recycling initiatives for cooling, manufacturing, and landscaping applications.

Frequently Asked Questions (FAQ)

1. What is SUSBIO ECOTREAT and how does it work?

SUSBIO ECOTREAT is a modular, prefabricated sewage treatment system designed for efficient wastewater treatment in urban and industrial settings. It combines anaerobic and aerobic biological processes within a single unit, enabling high pollutant removal while minimizing energy use and space requirements.

2. How much energy does SUSBIO ECOTREAT save compared to traditional STPs?

SUSBIO ECOTREAT can reduce energy consumption by up to 90% compared to conventional sewage treatment plants. This is achieved through its low-power design and optimized biological processes that require minimal mechanical intervention.

3. Is SUSBIO ECOTREAT suitable for residential use in UAE?

Yes. SUSBIO ECOTREAT is ideal for residential buildings, gated communities, villas, and small housing complexes. Its Capsule Type model (1–20 KLD) offers quiet, odor-free, and compact sewage treatment for properties with limited space.

4. How fast can a SUSBIO ECOTREAT system be installed?

Thanks to its plug-and-play prefabricated design, most SUSBIO ECOTREAT units can be installed and operational within 5 to 14 days, significantly faster than conventional STPs that may take months to complete.

5. Does SUSBIO ECOTREAT meet UAE wastewater reuse standards?

Absolutely. The treated effluent consistently meets UAE’s stringent discharge and water reuse standards, making it suitable for irrigation, landscaping, and certain industrial applications.

6. What is the typical lifespan of a SUSBIO ECOTREAT system?

Built from durable fiber-reinforced plastic (FRP), SUSBIO ECOTREAT systems are designed to last 15 to 25 years with minimal maintenance requirements, even in harsh UAE climates.

7. What capacities are available for SUSBIO ECOTREAT units?

SUSBIO ECOTREAT is available in two main models:

Capsule Type: 1 to 20 KLD (ideal for villas and small buildings)

Cylinder Type: 20 to 500 KLD (suitable for commercial, industrial, and large residential projects)

8. Can the system operate silently and without odors?

Yes. The system is engineered for noise-free and odorless operation, making it perfect for locations where environmental comfort is a priority, such as resorts, hospitals, schools, and residential zones.

9. What makes SUSBIO ECOTREAT better than traditional sewage treatment plants?

Unlike conventional systems, SUSBIO ECOTREAT offers:

Dual-stage biological treatment (anaerobic + aerobic)

Up to 90% energy savings

Compact footprint and quick installation

Low maintenance with no need for on-site operators

Full compliance with UAE regulations

10. Is SUSBIO ECOTREAT approved by UAE regulatory authorities?

Yes. The system is designed to comply with Abu Dhabi and Dubai environmental regulations, including the updated Water Quality Regulations of 2025. It meets all necessary standards for trade effluent discharge and treated water reuse.

Conclusion

SUSBIO ECOTREAT stands as a remarkable answer to the UAE’s growing sewage treatment challenges. Throughout our extensive testing, this system consistently demonstrated superior performance compared to traditional STPs across all critical metrics. The dual-stage treatment technology effectively addresses the fundamental limitations that have long plagued conventional systems in the region.

The system’s 70% energy reduction represents a game-changing advancement for facility managers struggling with operational costs. This efficiency, coupled with noise-free and odorless operation, makes SUSBIO ECOTREAT particularly valuable for residential developments where tenant comfort remains paramount. Additionally, the high-quality water output aligns perfectly with the UAE’s ambitious water reuse goals outlined in its Water Security Strategy 2036.

Space constraints no longer pose insurmountable obstacles thanks to the compact, modular design that adapts to various capacity requirements. The system essentially eliminates the extensive buffer zones traditional plants require, thus freeing valuable urban real estate for other purposes. Developers certainly appreciate the plug-and-play installation that reduces project timelines from months to mere weeks.

Financial benefits extend beyond initial installation advantages. The minimal maintenance requirements and automated operation dramatically reduce lifecycle costs compared to conventional systems. These savings, combined with the extended 15–25 year lifespan, deliver compelling ROI for both residential and industrial applications.

The UAE faces unprecedented challenges with water scarcity, urban growth, and aging infrastructure. Still, innovations like SUSBIO ECOTREAT offer practical solutions that balance regulatory compliance with operational efficiency. This sewage treatment technology ultimately represents not just an improvement over traditional systems but a fundamental shift in how the UAE can approach its wastewater management future.