Clean water resources are becoming increasingly scarce, making wastewater treatment a critical necessity today.

Wastewater treatment serves as a cornerstone to protect public health, preserve ecosystems, and manage water sustainably. Traditional sewage treatment plants often use complex and expensive processes. Many businesses and communities now seek practical alternatives. SUSBIO ECOTREAT offers a perfect solution that combines state-of-the-art technology with sustainability. These systems treat sewage at the source and provide affordable, energy-efficient solutions with minimal environmental impact.

Let me walk you through the sewage and wastewater treatment world in this piece. You’ll learn about the wastewater treatment plant process and discover why SUSBIO ECOTREAT could be your ideal affordable solution. This piece will help if you need a reliable treatment system that fits your budget.

What Is Wastewater and Why It Needs Treatment

Water becomes wastewater when human activities contaminate it so much that you can’t reuse it right away without treating it first. The way we define wastewater helps us see why we need good treatment methods.

Types of Wastewater: Domestic, Industrial, Stormwater

Three main types of wastewater exist based on where it comes from and what’s in it. Domestic wastewater (also called sanitary sewage) flows from our homes, offices, and shops. This water comes from toilets, showers, washing machines, and kitchen sinks. It usually has organic materials, nutrients, and harmful germs in it.

Manufacturing processes create industrial wastewater, and its makeup changes a lot depending on what the factory makes. You’ll find chemicals, heavy metals, oils, and solvents that need special cleaning methods. Textile factories, for example, release water with dyes and tiny plastic bits, while food processing plants produce waste full of organic solids and fats.

Rain or melting snow creates stormwater runoff as it flows over roads, roofs, and other surfaces. This water picks up oil, pesticides, trash, and other pollutants before it reaches drainage systems. Unlike other types of wastewater, stormwater often flows into natural water bodies without any treatment, which creates big environmental problems.

Health and Environmental Risks of Untreated Sewage

Letting untreated wastewater flow into nature causes problems way beyond what you might expect. The World Health Organization reports that only 57% of people worldwide have access to safe sanitation services. This lack of proper treatment puts many lives at risk.

Raw sewage carries many disease-causing germs that lead to:

- Campylobacteriosis (most common diarrheal illness in the United States)

- Cryptosporidiosis (“Crypto”)

- E. coli infections (causing kidney failure in 2-7% of cases with O157:H7 strain)

- Salmonellosis

- Leptospirosis

People exposed to wastewater can get skin diseases, parasitic infections, and health problems that last years. A scary fact is that farmers in developing countries use untreated wastewater to water crops on about 30 million hectares of land. This practice puts 885 million city dwellers at serious health risk.

Untreated wastewater destroys ecosystems too. Sewage in water bodies makes microorganisms use up oxygen as they break down waste, leaving little for fish and other aquatic life. The extra nutrients in sewage also cause algae to grow like crazy, which speeds up how fast lakes and waterways age unnaturally.

What Is Wastewater Treatment and Its Importance

Wastewater treatment covers all the steps needed to clean contaminated water so it’s safe to release back into nature or reuse. These steps work like nature’s own water cleaning process, just faster and in a controlled setting.

Clean water means more than just protecting health and nature right now. Studies show that good wastewater management helps achieve 11 out of 17 Sustainable Development Goals (SDGs). This includes having more water for farming, better public health, new ways to make money, turning waste into energy, and helping the environment.

Good wastewater treatment saves money by preventing damage to nature and health crises. Research shows that poor wastewater treatment costs us big time, hurting both today’s people and future generations through lasting health issues and damaged ecosystems.

Clean water gets harder to find every day worldwide, so treating wastewater becomes more crucial for saving and reusing water. Cleaned wastewater works great for watering plants, running factories, and other uses that don’t need drinking-quality water. This helps save fresh water in places where it’s scarce.

Stages of the Wastewater Treatment Plant Process

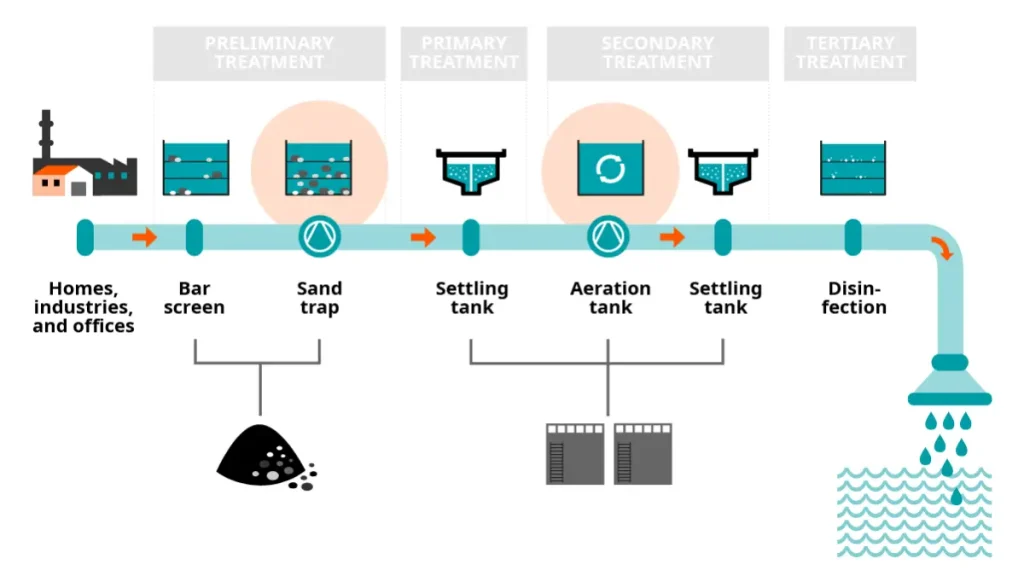

Wastewater treatment works through a step-by-step process that cleans sewage before releasing it back into the environment. Each step builds on the previous one and targets specific pollutants with more advanced methods.

Primary Treatment: Sedimentation and Oil Separation

The first step uses physical processes to remove solid materials from wastewater. Large debris gets filtered out through preliminary screening. The water then flows into large settling tanks called primary clarifiers where gravity does most of the work. Heavy solids (sludge) sink to the bottom while oils, grease, and lighter materials float up. Mechanical scrapers push settled sludge to collection hoppers at the tank base, and pumps move it to separate treatment facilities.

Special devices skim the floating materials from the surface. These materials contain fats, oils, and grease (FOG) and make up about 25-35% of total chemical oxygen demand in raw wastewater. Water stays in these primary sedimentation tanks for about 1.5 to 2.5 hours. This process removes 50-70% of suspended solids and 25-40% of biological oxygen demand (BOD). However, dissolved pollutants and harmful microorganisms still remain.

Secondary Treatment: Aerobic and Anaerobic Methods

The second step uses biological processes to break down dissolved organic matter and nutrients like nitrogen or phosphorus. Microorganisms eat organic waste through their natural metabolic processes.

Most facilities use the activated sludge system. Wastewater enters aeration tanks full of bacteria that thrive with oxygen. Diffusers at the tank bottom pump compressed air to provide oxygen and mix the contents. Bacteria multiply and form biological flocs that consume harmful organic matter. This process turns organic contaminants into carbon dioxide, water, and more microorganisms.

Some facilities use anaerobic treatment without oxygen, often in covered digestion lagoons. This method has several benefits:

- It uses less energy since it doesn’t pump oxygen

- It creates valuable biogas (methane) that becomes energy

- It works well for strong industrial wastewaters

Some plants use anoxic treatment—a middle ground where microbes work without free molecular oxygen but can use oxygen from compounds like nitrates. The water then moves to another settling tank where remaining solids sink down, removing over 90% of suspended solids.

Tertiary Treatment: Filtration and Disinfection

The final cleanup stage removes any leftover contaminants through advanced processes. This step becomes vital when water must meet strict quality standards for environmental release or reuse.

Filtration plays a key role by catching fine particles that slipped through earlier treatments. Common filtration methods include:

- Sand beds or media filters catch leftover suspended particles

- Carbon filters absorb remaining organic compounds

- Advanced membrane filtration systems deliver higher purity

The last step kills harmful microorganisms through different methods. North American facilities often use chlorination because it’s affordable and works well, though they must remove the chlorine before release to protect aquatic life. UV light offers a chemical-free option that damages microorganisms’ genetic structures. Ozone treatment uses reactive O₃ gas to destroy remaining pathogens.

These three treatment stages turn sewage into clean water that meets regulatory standards. After tertiary treatment, total suspended solids typically drop below 10 mg/L.

Benefits of Using a Packaged Sewage Treatment Plant

Packaged sewage treatment plants have revolutionized wastewater management technology. These compact, self-contained units work better than conventional systems and solve many common treatment challenges.

Space-Saving and Modular Design

These plants save space and fit perfectly in locations with tight constraints. The systems need 10 times less space than conventional Activated Sludge Process systems. Urban developers and sites with limited land can benefit from this design. The prefabricated, modular structure needs minimal digging and doesn’t require large civil structures. You can install them in compact spaces like rooftops and basements. The units can even be moved when needed.

Low Energy Consumption

Modern packaged sewage treatment plants excel at saving energy. The systems use 30% less power than traditional facilities through better aeration and control systems. Advanced models like SUSBIO ECOTREAT use power-saving technologies that cut electricity use by 90% compared to standard systems. Lower power consumption reduces both operating costs and the carbon footprint of wastewater operations.

Quick Deployment and Minimal Supervision

Traditional plants take months or years to build. These packaged STPs are ready within days or weeks. The quick setup happens because manufacturers deliver pre-engineered and factory-assembled systems that need simple connections to existing infrastructure. The units run with little human oversight thanks to automated controls and monitoring. Smart automation adjusts treatment processes immediately and ensures peak performance whatever the wastewater volume.

Cost-Effective for Long-Term Use

These plants save money throughout their lifecycle. The upfront costs are lower than conventional systems because they need less construction and installation work. Other benefits include:

- Systems can run maintenance-free for over 5 years

- Power-efficient technologies cut operating costs

- Water reuse options for landscaping, flushing, and industrial cooling reduce water bills

Packaged sewage treatment plants clean wastewater well while saving space, energy, time, and money. They’ve become the top choice for residential, commercial, and industrial users.

Inside SUSBIO ECOTREAT: Features That Stand Out

SUSBIO ECOTREAT stands out in the wastewater treatment market with its smart engineering and practical design. This advanced sewage treatment solution merges new technology with intuitive features to solve common wastewater management problems.

Prefabricated and Scalable Units

SUSBIO ECOTREAT comes as a ready-to-install, prefabricated module made from durable fiber-reinforced plastic (FRP) that gives it exceptional strength and fights corrosion. You won’t need extensive construction on-site, and installation takes weeks instead of months. The system offers two configurations to match different capacity needs:

- Capsule Type: Handles 1-20 KLD, perfect for villas, small hotels, and offices

- Cylinder Type: Manages 20-500 KLD, ideal for apartments, factories, and commercial complexes

This modular design adapts to specific project requirements, from single buildings to large industrial facilities. The system’s compact footprint needs 50% less space than traditional systems, making it a great fit for space-limited urban areas.

Advanced MBBR and SBR Technology

The heart of SUSBIO ECOTREAT is its sophisticated dual-treatment process that uses both anaerobic and aerobic methods. The system combines Moving Bed Biofilm Reactor (MBBR) and Sequencing Batch Reactor (SBR) technologies to clean wastewater better. Here’s how the treatment flows:

- Oil and grease separation

- Sedimentation for solid matter removal

- Anaerobic contact media processing

- Moving bed media treatment

- Secondary sedimentation

- Disinfection

This integrated approach removes pollutants and contaminants effectively. MBBR technology delivers high treatment efficiency for BOD, COD, and ammonia removal, and performs well even when loads change.

Real-Time Monitoring and Automation

SUSBIO ECOTREAT runs automatically without needing an on-site operator. Advanced automation systems manage the plant’s operations and monitor the treatment process. Smart sensors track key water quality parameters and adjust treatment as needed. The automation brings several benefits:

- Lower labor costs

- Consistent treatment quality

- Easy operation and maintenance

- Quick problem detection

The system uses 90% less electricity than regular sewage treatment plants and runs quietly to minimize environmental impact.

Regulatory Compliance and Safety Standards

SUSBIO ECOTREAT’s manufacturing follows strict quality standards to meet environmental regulations. Every component goes through quality checks during production. The treated water meets or exceeds discharge standards for BOD, COD, pH, TSS, and pathogens. These standards matter because sewage treatment must follow strict federal, state, and local quality requirements. The plant’s design includes clear warning signs and safety features throughout.

Who Should Choose SUSBIO ECOTREAT?

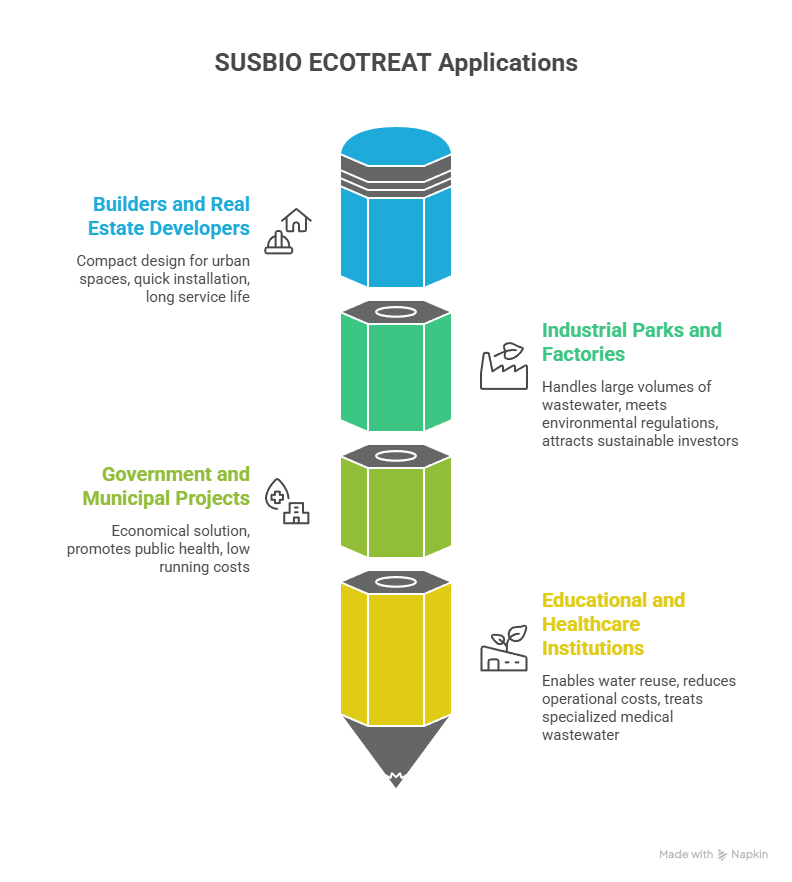

SUSBIO ECOTREAT helps businesses in a variety of sectors with its advanced wastewater treatment capabilities. This packaged STP system adapts to each industry’s unique sewage treatment needs.

Builders and Real Estate Developers

Real estate developers love SUSBIO ECOTREAT’s compact design that needs minimal space—perfect for urban developments with space constraints. The system installs quickly and saves developers time and money. Its fiber-reinforced plastic construction will give a long service life, with tank warranties extending up to 25 years. The system works great in high-density developments and fits anywhere—podiums, basements, or rooftops.

Industrial Parks and Factories

Industrial zones create large amounts of wastewater that need special treatment. SUSBIO ECOTREAT’s centralized wastewater management meets strict environmental regulations. The system’s dual treatment process handles different industrial effluents effectively and removes harmful pollutants through detailed purification. Industrial parks using this system attract investors and global partners who care about sustainability.

Government and Municipal Projects

Municipal authorities looking for economical wastewater solutions find great value in SUSBIO ECOTREAT. The system promotes public health by removing pollutants effectively. Running costs stay low thanks to its energy-efficient operation. The prefabricated designs cut installation costs, helping authorities make the most of their budgets while protecting the environment and meeting regulations.

Educational and Healthcare Institutions

Educational campuses produce large volumes of wastewater daily from hostels, cafeterias, laboratories, and administrative buildings. SUSBIO ECOTREAT makes water reuse possible for gardening, flushing, and cooling systems, which cuts operational costs and reduces water dependency. Healthcare facilities benefit because the system treats specialized medical wastewater effectively. These institutions show their steadfast dedication to environmental care through proper sewage treatment and create learning opportunities about sustainability.

Conclusion

Wastewater treatment technology has definitely advanced significantly, and packaged sewage treatment plants like SUSBIO ECOTREAT are leading this development. Traditional wastewater management doesn’t deal very well with space, cost, and efficiency challenges. SUSBIO ECOTREAT tackles these issues head-on. The system’s combination of MBBR and SBR technologies delivers superior treatment results while using 90% less electricity than conventional systems.

The system’s prefabricated, modular design is a game-changer for many organizations. Real estate developers love its space-saving features. Industrial facilities value the system’s capability to handle specialized effluents. On top of that, quick deployment and minimal supervision requirements make this solution attractive to organizations of all types, from healthcare facilities to educational institutions.

SUSBIO ECOTREAT’s dual-treatment process will give a thorough elimination of pollutants. Users find compliance straightforward as the system meets all regulatory standards. The system’s reliability comes from rigorous factory testing and quality control measures.

Global water shortages increase yearly. This makes efficient wastewater treatment more vital than ever. SUSBIO ECOTREAT offers a direct solution by enabling water reuse in landscaping, flushing, and industrial applications. Organizations can reduce their dependence on fresh water sources and cut operational costs through water recycling.

Packaged STPs might become the new standard for wastewater treatment. The advantages are clear – from space efficiency to cost-effectiveness – this change seems inevitable. SUSBIO ECOTREAT offers an affordable, practical solution that combines technological advancement with environmental responsibility. Organizations that want to solve wastewater challenges while meeting sustainability goals should think over this packaged STP system.

Key Takeaways

SUSBIO ECOTREAT offers a revolutionary approach to wastewater treatment that addresses the critical challenges of space, cost, and efficiency in modern sewage management.

• Space-efficient design: Requires 50% less space than traditional systems with modular units handling 1-500 KLD capacity for diverse applications.

• Energy savings: Consumes 90% less electricity than conventional plants through advanced MBBR and SBR technology integration.

• Rapid deployment: Prefabricated units install in weeks versus months, eliminating extensive construction and reducing upfront costs significantly.

• Automated operation: Fully automated system requires no on-site operator while ensuring regulatory compliance and consistent treatment quality.

• Water reuse capability: Enables treated water recycling for landscaping, flushing, and industrial cooling, reducing freshwater dependency and operational costs.

This packaged STP solution represents the future of sustainable wastewater management, making advanced treatment technology accessible and affordable for builders, industries, municipalities, and institutions seeking reliable, eco-friendly sewage treatment solutions.

Frequently Asked Questions

Q1. What are the main advantages of using SUSBIO ECOTREAT for wastewater treatment?

SUSBIO ECOTREAT offers several key benefits, including a space-saving modular design, low energy consumption (up to 90% less than conventional systems), quick deployment, and cost-effectiveness for long-term use. Its advanced technology ensures efficient treatment while requiring minimal supervision.

Q2. How does SUSBIO ECOTREAT handle different types of wastewater?

SUSBIO ECOTREAT uses a dual-treatment process combining Moving Bed Biofilm Reactor (MBBR) and Sequencing Batch Reactor (SBR) technologies. This comprehensive approach effectively treats various types of wastewater, including domestic, industrial, and specialized effluents, ensuring thorough elimination of pollutants and contaminants.

Q3. Is SUSBIO ECOTREAT suitable for both small and large-scale applications?

Yes, SUSBIO ECOTREAT is designed to be scalable. It offers two configurations: Capsule Type for 1-20 KLD capacity (suitable for villas, small hotels, and offices) and Cylinder Type for 20-500 KLD capacity (ideal for apartments, factories, and commercial complexes). This flexibility makes it suitable for a wide range of applications.

Q4. How does SUSBIO ECOTREAT contribute to water conservation efforts?

SUSBIO ECOTREAT enables water reuse for various purposes such as landscaping, flushing, and industrial cooling. This capability significantly reduces dependency on freshwater sources, helping to conserve water and lower operational costs for users.

Q5. What makes SUSBIO ECOTREAT a good choice for urban environments?

SUSBIO ECOTREAT is particularly well-suited for urban settings due to its compact design, which requires up to 50% less space than traditional systems. Its prefabricated, modular units can be installed in tight areas, including rooftops and basements, making it ideal for locations with space constraints.