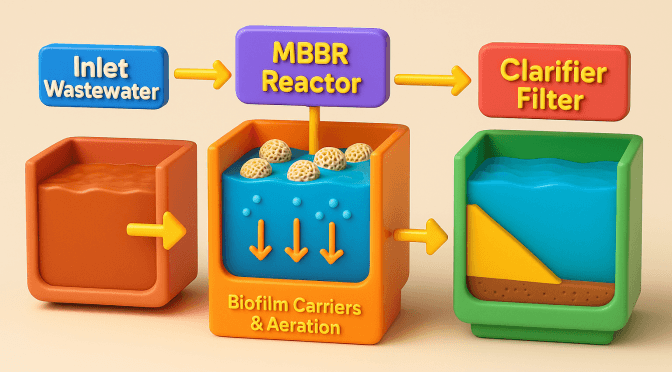

Moving Bed Biofilm Reactor (MBBR) technology is a highly efficient biological process used to treat both municipal and industrial wastewater. Developed in the 1980s, MBBR utilizes thousands of specially designed plastic carriers, known as biofilm media, which float freely within an aeration tank. These carriers provide a large surface area for beneficial bacteria to grow and form biofilms. As wastewater flows through the tank, these microorganisms break down organic pollutants, nitrogen, and phosphorus. The constant movement of the carriers, maintained by aeration, ensures optimal contact between the biofilm, wastewater, and oxygen—resulting in effective, reliable treatment.

How MBBR Stands Apart from Other Wastewater Treatment Technologies

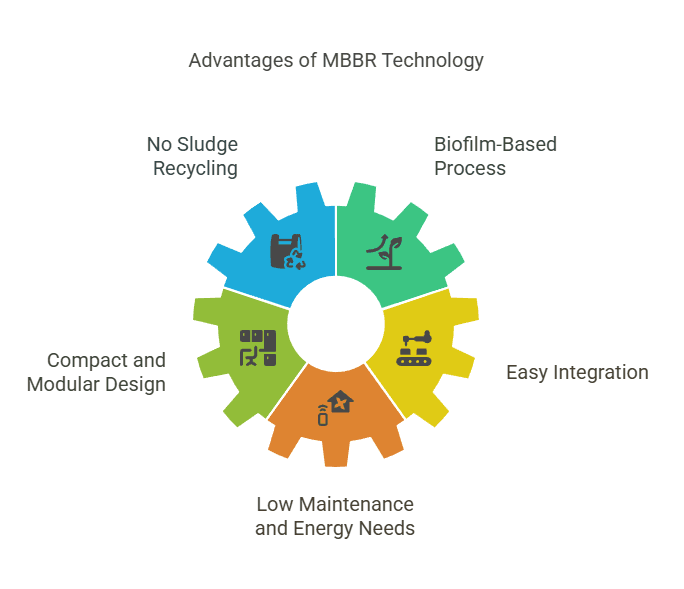

MBBR technology offers several unique advantages over traditional wastewater treatment methods:

No Sludge Recycling: Unlike conventional activated sludge systems, MBBR does not require the recycling of sludge, making operation simpler and more robust.

Biofilm-Based Process: The use of attached-growth biofilms on carriers makes MBBR more resilient to fluctuations in load and shock events compared to suspended growth systems.

Compact and Modular Design: MBBR systems require significantly less space than traditional activated sludge or trickling filter systems, making them ideal for urban installations and retrofits.

Easy Integration: MBBR can be retrofitted into existing plants to increase capacity and performance without major construction or downtime.

Low Maintenance and Energy Needs: With no membranes to clean and self-cleaning carriers, MBBR systems offer lower energy consumption and minimal maintenance requirements.

The Role of MBBR in Modern Wastewater Treatment

MBBR technology is widely adopted for various applications, including:

Municipal Sewage Treatment: Effectively removes organic matter and nutrients to help cities meet stringent discharge standards.

Industrial Wastewater Treatment: Handles complex and variable loads from industries such as textiles, food processing, chemicals, and pharmaceuticals.

Retrofitting Aging Plants: Enhances the performance and capacity of older treatment facilities without the need for extensive civil works.

Decentralized and Residential STPs: Provides compact, reliable solutions for residential complexes, hospitals, hotels, and commercial buildings.

Top 5 Advantages of Using MBBR in Wastewater Treatment

1. Superior Treatment Efficiency and Reliability

MBBR systems deliver high removal rates for BOD, COD, nitrogen, and phosphorus due to the large surface area provided by the biofilm carriers. The attached biofilms remain active even during fluctuations in wastewater load, ensuring consistent compliance with regulatory standards.

2. Space-Saving and Compact Footprint

MBBR systems can achieve the same or better treatment results as traditional plants but require up to 70% less space. This makes them ideal for urban areas or sites with limited land availability.

3. Low Sludge Production and Simple Handling

The efficient breakdown of organic matter by biofilms leads to significantly less sludge production compared to conventional systems. This reduces the costs and environmental impact associated with sludge handling, transport, and disposal.

4. Flexible and Scalable Operation

MBBR systems are highly adaptable to changing influent loads and can be easily expanded by adding more carriers or tanks. This modularity is especially beneficial for growing cities or industries with variable production volumes.

5. Cost-Effective and Low Maintenance

With no need for sludge recycling, minimal moving parts, and energy-efficient aeration, MBBR systems offer reduced operational and maintenance costs. The self-cleaning nature of the carriers further decreases the risk of clogging and system downtime.

SUSBIO ECOTREAT: The Leading MBBR Technology STP

SUSBIO ECOTREAT represents a new generation of MBBR-based sewage treatment plants, setting benchmarks for efficiency, durability, and sustainability. Here’s what makes SUSBIO ECOTREAT stand out:

Dual-Stage Biological Treatment: SUSBIO ECOTREAT combines both anaerobic and aerobic biological processes in a single, compact unit. This dual-stage approach ensures comprehensive removal of organic pollutants, nitrogen, and phosphorus, resulting in high-quality treated water.

Prefabricated, Modular Design: The system is delivered as a ready-to-install, prefabricated unit made from high-strength FRP (Fiber Reinforced Plastic). This allows for quick installation, easy relocation, and seamless expansion as demand grows.

Robust and Durable: With a 10-year warranty on the FRP structure, SUSBIO ECOTREAT is built to withstand harsh environmental conditions and deliver reliable performance for years.

Energy Efficient: The system is engineered for low power consumption, utilizing efficient aeration and process controls to minimize operational costs.

Handles High Loads: SUSBIO ECOTREAT is designed to treat wastewater with high COD and BOD concentrations, making it suitable for both domestic and challenging industrial applications.

Eco-Friendly and Regulatory Compliant: The treated water consistently meets or exceeds CPCB and local pollution control board standards, supporting sustainability and environmental compliance.

Low Maintenance: The self-cleaning carriers and automated controls ensure minimal manual intervention, reducing the need for skilled labor and lowering overall maintenance costs.

Smart Monitoring: Advanced versions of SUSBIO ECOTREAT can be equipped with IoT-based remote monitoring, enabling real-time performance tracking and proactive maintenance.

SUSBIO ECOTREAT is widely used in residential societies, commercial complexes, hotels, hospitals, and industrial estates across India and abroad. Its plug-and-play design, reliability, and eco-friendly operation make it a preferred choice for developers and facility managers seeking hassle-free sewage treatment solutions.

Real-World Example: SUSBIO ECOTREAT in Action

A large residential township in a metro city was struggling with space constraints and fluctuating wastewater volumes. By installing SUSBIO ECOTREAT, the township achieved:

Consistent compliance with stringent discharge norms, even during festivals and peak occupancy.

A 45% reduction in sludge disposal costs, thanks to efficient biofilm-based treatment.

Rapid installation and commissioning due to the prefabricated, modular design.

Trouble-free operation with minimal maintenance, allowing facility staff to focus on other priorities.

Real-time monitoring and reporting, ensuring transparency and accountability to residents and regulators.

Similar success stories are found in industries such as food processing, textiles, and chemicals, where SUSBIO ECOTREAT has enabled efficient, reliable, and sustainable wastewater management.

Frequently Asked Questions about MBBR Technology

What is the main difference between MBBR and other biological treatment methods?

MBBR uses free-floating plastic media for biofilm growth, eliminating the need for sludge recycling and providing greater resilience to load fluctuations compared to suspended-growth or membrane-based systems.

Is MBBR suitable for retrofitting existing treatment plants?

Yes, MBBR can be easily integrated into older plants to increase capacity and improve treatment performance without major civil works.

How much space does an MBBR system require?

MBBR systems can operate in tanks up to 70% smaller than those required for conventional systems, making them ideal for urban and retrofit projects.

What kind of maintenance does MBBR need?

Maintenance is minimal, mainly routine checks of aeration and carrier integrity. There’s no need for membrane cleaning or sludge recycling.

Can MBBR handle industrial wastewater?

Absolutely. MBBR is proven in treating effluents from textiles, chemicals, food processing, and more, thanks to its robust and adaptable design.

Conclusion: MBBR and SUSBIO ECOTREAT—The Future of Efficient Wastewater Treatment

MBBR technology is setting new standards for wastewater treatment, offering unmatched efficiency, compactness, and operational simplicity. Its ability to deliver high-quality effluent, adapt to changing loads, and minimize sludge makes it the preferred choice for municipalities, industries, and residential complexes.

SUSBIO ECOTREAT takes these benefits even further, combining advanced dual-stage treatment, prefabricated modular construction, and smart monitoring in a durable, eco-friendly package. Whether you’re upgrading an old plant, building a new facility, or looking for a sustainable solution for your community, SUSBIO ECOTREAT offers a proven, hassle-free path to cleaner water and a greener future.

Ready to transform your wastewater treatment experience? Discover how SUSBIO ECOTREAT and MBBR technology can help you achieve compliance, save costs, and support environmental sustainability—today and for years to come.