Membrane bioreactor technology has transformed the wastewater treatment industry. The market grew at 22.4% and reached US$838.2 million in 2011. This growth shows how this technology helps solve modern water challenges. The world faces a growing lack of water, so we need the quickest ways to treat water that deliver high-quality effluent with minimal environmental effects.

MBR systems stand out because they combine biological treatment with membrane filtration, which makes them better than conventional activated sludge technologies. These systems need up to 50% less space than traditional ones since they don’t require large clarifiers. The effluent from membrane bioreactor systems comes out free of suspended solids and has lower bacterial and viral content that needs minimal disinfection. This matters even more now as effluent quality regulations get stricter.

This piece takes you through the foundations of membrane bioreactor technology. You’ll learn about different configurations and see how they work in both municipal and industrial settings. The content covers everything from operational benefits to common challenges. Whether you’re just starting with bioreactors or want to boost your knowledge, you’ll understand why MBR systems have become a proven process option for modern wastewater treatment.

Core Components of a Membrane Bioreactor System

A membrane bioreactor system works best when its core components work together smoothly. These components play a crucial role in treatment efficiency, energy consumption, and overall system performance.

Suspended vs Attached Growth Bioreactors

Bioreactors are specialized chambers that support biologically active environments where bacteria and protozoa consume substances in wastewater. You’ll find three basic types of bioreactors: suspended growth, attached growth, and hybrid systems.

Suspended growth bioreactors let biomass grow in flocs that float throughout the liquid medium. These are the most common setup in membrane bioreactor applications because they’re simple to operate. The activated sludge moves freely in the reactor and interacts with contaminants throughout the tank.

On the flip side, attached growth (biofilm) bioreactors use carriers that give surfaces for biomass to stick to. You can use different media like polyurethane cubes, polystyrene beads, Kaldnes carriers, and activated carbon. Sponge carriers work really well because they act as mobile carriers for active biomass. They improve organic and nutrient removal and help reduce membrane fouling. Lab studies show that attached growth membrane bioreactors (AG-MBR) can boost critical flux up to 48 L m−2 h−1 and lower total resistance to 5.69 × 1011 m−1.

Hybrid bioreactors mix both approaches and offer better treatment capabilities with proper design. These systems often remove more COD, nitrate, nitrite, and ammonia than pure suspended growth setups.

Microfiltration vs Ultrafiltration Membranes

Membrane bioreactor systems can use both microfiltration (MF) and ultrafiltration (UF) membranes, but each has its own way of separating materials.

MF membranes have pore sizes from 0.1 to 0.5 microns. They effectively remove suspended solids, bacteria, and some larger viruses. These membranes act as physical barriers that catch particles too small for regular filters but too big for nanofiltration systems.

UF membranes, with their smaller pores (0.01 to 0.1 microns), can remove bacteria, suspended solids, viruses, and high-molecular-weight organic compounds. They also show better separation qualities and don’t get fouled as easily because their pores are less likely to clog.

While both types work in MBR applications, UF membranes are usually the top choice. They’re better at removing colloids and viruses, and they resist fouling more effectively.

Membrane Geometries: Hollow Fiber, Flat Sheet, Tubular

The shape of a membrane affects how well it performs, how you clean it, and how much energy it uses. Three main designs lead the MBR market:

Hollow Fiber (HF): Looks like thousands of spaghetti-like hollow fibers packed tightly together. These setups usually run at higher fluxes but lower mixed liquor suspended solids (MLSS) concentrations. HF systems need more frequent physical and chemical cleaning and stricter pre-treatment. All the same, they’re the top choice for bigger installations because they use less aeration energy and have more surface area.

Flat Sheet (FS): Uses membrane sheets placed on plate-like structures. These can handle higher MLSS concentrations and are easier to install, operate, and maintain than hollow fiber systems. Their design makes them perfect for decentralized and packaged applications.

Tubular: Contains several tube-like membranes inside a pipe/shell. This design creates better fluid dynamics without needing spacers. The setup reduces fouling potential and makes cleaning easier.

Spiral-wound designs, while common in other membrane applications, don’t work well in MBR systems because they’re too sensitive to suspended solids content.

Your choice among these designs will depend on what you need for your specific application, your wastewater characteristics, and your operational limits.

Submerged vs Sidestream MBR Configurations

Membrane bioreactors work in two distinct configurations. Each setup offers unique advantages for different applications. The choice between these configurations affects energy usage, maintenance needs, and how well the system runs.

Vacuum-Driven Submerged MBRs for Municipal Use

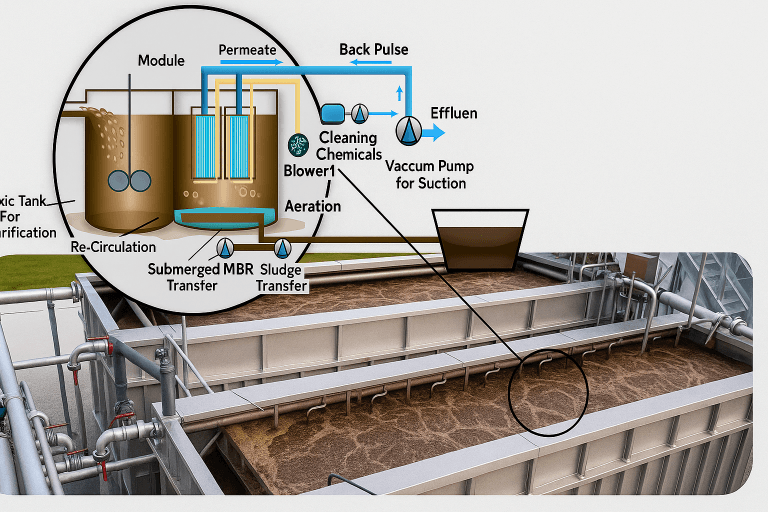

Submerged membrane bioreactor setups place membrane modules directly in the biological reactor or a separate chamber with activated sludge. These systems use hollow fiber or flat sheet membranes that work through vacuum-driven permeation. Clean water passes through the membrane while biomass stays in the tank during filtration.

Submerged MBRs use coarse bubble aeration to give oxygen to microorganisms and create turbulence that cleans membrane surfaces to reduce fouling. Research shows that air-induced cross flow effectively removes or reduces the fouling layer on membrane surfaces. The system works best when aeration rates (UG) stay between 0.07–0.11 m/s.

Municipal applications favor the submerged configuration because it’s simple to operate and needs less power. These systems can process large volumes efficiently, making them perfect for municipal facilities that need large-scale treatment.

Pressure-Driven Sidestream MBRs for Industrial Wastewater

In stark comparison to this, sidestream configurations place membrane modules outside the bioreactor. Mixed liquor pumps from the bioreactor through membrane modules, and concentrated biomass returns to the biological process.

Sidestream MBRs run at higher cross-flow velocities (CFV) between 0.25–0.55 m/s. This creates enough shear forces to control membrane fouling. These systems commonly use tubular membrane modules that handle higher pressures and are easier to clean.

Industrial applications benefit from sidestream configurations in several ways. They need less membrane area due to higher flux operation. The systems offer complete flexibility for cleaning cycles, lower maintenance costs, less plant downtime, and can handle higher solids concentrations. Small flows of hard-to-treat industrial effluents work better with sidestream configuration. The setup is easier to operate, takes up less space, and needs simpler servicing.

Energy Consumption Comparison Between Configurations

Energy usage sets these configurations apart. MBR energy consumption varies by a lot, ranging from 1,170 to 20,300 kWh/MG across different systems.

Sidestream MBRs use more energy than submerged systems because they need pumps to maintain high cross-flow velocities. Submerged MBRs need 10–25 times less energy for filtration compared to external MBR. But sidestream systems make up for this energy disadvantage. They operate at nearly four times higher flux than submerged configurations.

Large-scale municipal applications almost always choose submerged configurations with hollow fiber membranes because they cost less to run. Small industrial applications often find pressure-driven sidestream MBRs more economical when treatment challenges matter more than energy costs.

New technology has helped cut energy needs in both setups. Companies have created innovative strategies. GE/Zenon developed the 10/10 or 10/30 aeration approach. Enviroquip/Kubota introduced flux-based air scouring, and Siemens/Memcor created the Mempulse strategy. These advances have cut unit energy consumption by a lot, making MBR technology a strong match for conventional treatment methods.

Advantages of Membrane Bioreactor Technology

MBR systems have several clear advantages that make them popular choices for modern wastewater treatment applications. These benefits go beyond conventional treatment methods and deliver better performance in many areas.

High-Quality Effluent with Pathogen Removal

The membrane filtration in MBR technology delivers exceptional pathogen removal capabilities. Studies show that well-designed MBR systems consistently remove suspended solids, protozoa, and coliform bacteria. These systems can remove various viruses and phages under the right conditions. Microfiltration membranes with pore sizes of 0.1-0.4 microns will give a clean treated water free from pathogens and bacteria.

A 10-year study of the Porlock MBR showed average log reduction values (LRVs) for fecal coliforms exceeded 5, while male-specific coliphage reduction was greater than 4. The system achieved an LRV above 3.0 for protozoa, and Giardia specifically showed greater than 3.5 LRV. As a result, MBR-treated effluent meets strict requirements for reuse applications without extra disinfection steps.

Reduced Footprint and Higher Biomass Concentration

One major advantage of membrane bioreactors is their compact design. MBR systems need much less space than conventional treatment methods by combining filtration and biological treatment processes. The system’s capacity to maintain higher mixed liquor suspended solids (MLSS) concentrations means smaller space requirements.

The higher biomass concentration lets the system operate at extended solids retention times (SRTs) under lower food-to-microorganism (F/M) ratios, which reduces excess sludge production. This space efficiency makes MBR technology valuable in urban settings or when treatment capacity needs expansion without buying more land.

Automation and Remote Monitoring Capabilities

Modern MBR systems come with sophisticated automation and monitoring technologies to streamline operations. Many systems use programmable logic controller (PLC) based automation that enables remote monitoring. Advanced systems blend IoT technology with user-friendly mobile applications for immediate performance tracking.

Operators can see data, get alerts, and manage systems from anywhere. The automation controls dissolved oxygen, blower pressure, and air flow precisely—factors that improve energy efficiency throughout the treatment process. Automation and remote monitoring reduce labor needs, help troubleshoot issues faster, and maintain consistent treatment performance whatever the influent variations.

Challenges in MBR Operation and Fouling Control

Membrane bioreactors offer many advantages but face operational challenges. Membrane fouling remains the biggest obstacle that prevents wider adoption. The energy consumption from fouling ranges between 30-70% in MBR systems and leads to much higher operational costs.

Types of Membrane Fouling: Biofouling, Scaling, Organic

The characteristics of foulants help categorize membrane fouling into several distinct types:

Biofouling: This happens when microorganisms stick to membrane surfaces and create biofilms. It makes up over 45% of all membrane fouling and remains the hardest type to remove. Microbial cells and their byproducts like soluble microbial products (SMP) and extracellular polymeric substances (EPS) are the main causes.

Organic fouling: The membrane surface or pores get clogged when proteins, polysaccharides, humic acids, and other organic compounds build up.

Inorganic fouling/scaling: This occurs when salts like calcium carbonate, barium sulfate, and silica reach supersaturation and start depositing.

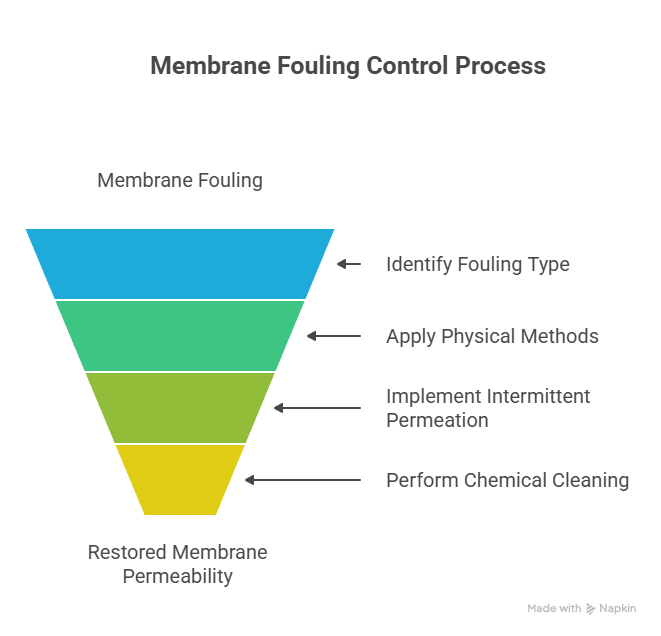

The fouling starts with blocked pores. A cake layer then forms on the membrane surface. These issues increase the transmembrane pressure (TMP) and reduce flux.

Air Scouring and Intermittent Permeation Techniques

Air scouring stands out as the main physical method to control membrane fouling. This process takes up 35-50% of MBR operational costs. The technique creates turbulence and uses hydraulic shear forces to clean foulant from membrane surfaces.

Research shows that intermittent permeation strategies work well. A study revealed that cyclic filtration worked best with 9 minutes permeation, followed by 0.5 minutes relaxation and 1 minute backwashing. The stable flux improved by 240% when intermittent filtration was combined with controlled shear stress.

Chemical Cleaning Protocols: NaOCl and Citric Acid

Chemical cleaning becomes essential when physical methods fail to restore membrane permeability or TMP goes beyond 40-50 kPa. The industry relies on two main cleaning agents:

Sodium hypochlorite (NaOCl): Concentrations between 500-6000 mg/L remove organic fouling and biofouling. Lower concentrations (1000-2000 mg/L) work better for preventive maintenance.

Citric acid: Doses of 2-30 g/L (preventive: 2-5 g/L) help remove inorganic fouling and scaling.

Regular cleanings with lower chemical concentrations work better than occasional cleanings with stronger solutions. Standard cleaning needs 1-3 hours of membrane soaking in the cleaning solution. Intensive cleaning might take 12-24 hours based on how severe the fouling is.

Applications of MBR in Wastewater Treatment

MBR technology serves three main wastewater treatment sectors. Each sector has its unique features and treatment challenges. The adaptability of MBR systems helps them process different wastewater streams through specialized setups and integration with other technologies.

Municipal Wastewater Reuse and Urban Irrigation

Municipal applications remain the oldest and most common use of membrane bioreactor technology. These systems deliver impressive results by removing 93.5% of COD and 98.6% of NH4+-N. The treatment reduces turbidity by 99.8% and removes TSS above 99.8%. This makes it perfect for water reuse projects in urban areas.

MBR effluent becomes even better through strategic blending. Studies show that mixing equal parts of MBR effluent and nanofiltration permeate creates water with 730 μS cm−1 conductivity and 1.67 SAR value. These numbers fall within WHO and FAO guidelines’ “none” restriction category. This makes MBR-treated wastewater a dependable source for agricultural irrigation where water is scarce.

Industrial Wastewater with High Organic Load

Industrial waste streams create unique challenges because they contain high organic loads and tough-to-break-down compounds. MBR systems work well with wastewater from food processing, petrochemicals, and electronics manufacturing. The semiconductor and TFT-LCD industries use MBR with reverse osmosis to recover more than 88% of wastewater.

MBR systems keep all biomass, which allows for more diverse bacteria and protozoa populations. This rich microbial mix helps break down stubborn substances like herbicides and pesticides. Industrial MBR installations have shown impressive durability. Ultrafiltration membranes last more than seven years, while reverse osmosis components work well for over four years.

Landfill Leachate Treatment with RO Integration

Landfill leachate contains high levels of organic and inorganic compounds, making it hard to treat. Old leachate becomes less biodegradable. Leachates older than 10 years show BOD/COD ratios below 0.1. Metals and inorganic substances keep leaching from landfills for many years.

MBR systems treat leachate well by improving biotreatment with shorter hydraulic retention times than conventional processes. The effluent has low silt density index, making it ready for RO/NF treatment without extra processing. Treatment systems that combine MBR with nanofiltration and reverse osmosis handle both organic matter and inorganic contaminants, including heavy metals. Biological performance reaches its peak in spring months, likely because of ideal microbial conditions.

Conclusion

Membrane bioreactor technology offers a state-of-the-art solution to our growing global water treatment challenges. This piece shows how MBR systems combine biological treatment with membrane filtration to deliver superior wastewater treatment performance. The remarkable growth rate of 22.4% shows how businesses of all sizes are adopting this technology.

MBR systems’ biggest advantage comes from producing exceptionally high-quality effluent while taking up substantially less space than conventional treatment methods. These systems excel through different configurations – vacuum-driven submerged systems work best for municipal applications, while pressure-driven sidestream arrangements handle complex industrial wastewaters.

Without doubt, MBR technology’s strength lies in removing pathogens effectively. Studies show impressive log reduction values for various contaminants. This makes MBR-treated water perfect for reuse with minimal additional treatment.

Membrane fouling remains the biggest problem and drives much of the operational costs. All the same, better fouling control strategies have emerged. Optimized air scouring techniques and effective chemical cleaning protocols help improve system performance and cut energy use.

MBR technology serves multiple sectors well. From municipal wastewater treatment that enables urban irrigation to handling high-organic-load industrial effluents and complex landfill leachate – this adaptability shows why membrane bioreactors are a 15-year old process option in modern wastewater treatment.

Water shortage concerns grow stronger worldwide, and MBR technology plays a vital role in water management strategies. State-of-the-art membrane materials, system configurations, and automation capabilities point toward more budget-friendly solutions ahead. MBR systems represent both a current treatment option and an environmentally responsible approach to one of our most pressing environmental challenges.

Frequently Asked Questions

Q1. What is membrane bioreactor (MBR) technology and how does it work?

MBR technology combines conventional biological wastewater treatment with advanced membrane filtration (microfiltration or ultrafiltration). The biological stage breaks down organic matter, while the membranes act as a physical barrier to suspended solids, bacteria, and viruses—delivering high-quality effluent suitable for reuse.

Q2. What are the main advantages of MBR systems compared to traditional wastewater treatment plants?

MBRs produce pathogen-free, crystal-clear effluent with minimal need for disinfection, require up to 50% less land area, allow higher biomass concentration, reduce sludge generation, and support automation and remote monitoring for easier operation.

Q3. Where is MBR technology most commonly applied?

MBRs are used in municipal wastewater treatment plants for urban water reuse and irrigation, in industries with high-organic-load effluents such as food processing, petrochemicals, and electronics, and for treating challenging landfill leachate when combined with reverse osmosis (RO).

Q4. What are the main challenges in operating an MBR system?

The biggest challenge is membrane fouling—caused by biofilms, organic matter, and scaling deposits. Fouling increases operational costs and energy consumption. Control strategies include optimized aeration (air scouring), intermittent permeation, and periodic chemical cleaning with sodium hypochlorite or citric acid.

Q5. Is MBR technology cost-effective in the long run?

Although MBR systems have higher initial capital and operational costs (especially due to fouling control and energy demand), they provide significant long-term savings by reducing land requirements, producing reusable water, minimizing sludge handling costs, and complying with increasingly strict effluent regulations.